You will definitely need temporary housing, that is, a place where people involved in construction will live.

And it is quite important that the construction of this temporary premises does not take much time. The consumable building materials used should be readily available and have a minimum cost.

Frame change house standard type performed without using internal partitions, in this cabin there should be a small amount of and.

With this budget option this cabin will cost you about twice as much as a frame-panel cabin, but its quality will be much higher and more reliable, because frame cabin it turns out much stronger due to durable timber, and other building materials used in work.

Necessary building materials and tools for installing a cabin

A do-it-yourself change house is carried out only using the building materials necessary for the work, as well as tools.

Below is a list of required materials:

- To build a temporary foundation, cinder blocks are needed;

- Sand and geotextiles;

- or bitumen mastic;

- Wooden and logs;

- Sand-lime brick;

- Various fittings, corners, screws;

- For roof covering;

- Mineral wool and;

- Lining, wooden boards, bars of different sizes.

You also need to prepare the tools that you will definitely need when building a shed: a shovel, a hammer, a drill and others.

Do-it-yourself frame change house step by step instructions

If the shed is temporary, for easy disassembly in the future, the foundation is made of cinder blocks, which are easily disassembled and have a low cost.

Temporary cinder block foundation

Temporary cinder block foundation To install cinder blocks, you need to remove them from the ground, then compact the soil and cover it with special geotextiles, then cover everything with sand and compact it well again.

Cinder blocks are laid on the made base.

They must be placed in each corner and with intervals between them of 1.5 meters.

Cinder blocks must be waterproofed with roofing felt or mastic and secured with a special wooden one.

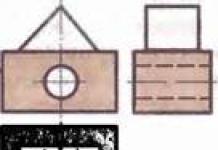

Drawings, materials

The third stage is the construction of the wall frame and installation of the roof.

Construction of walls and roof

Construction of walls and roof To begin with, build a base, using it around the perimeter of the entire structure. The logs are laid across and lengthwise.

Every owner land plot strives to arrange it in accordance with his preferences. During the construction period, a change house will serve as a comfortable accommodation for a family or a team of workers. A special type of temporary housing may be a mini-house with comfortable conditions. This article will talk about how to do country house with your own hands.

Purpose of country cabins

A simple-looking structure carries great functionality. Its presence on the site is determined by many factors:

- insulated change house is perfect as the main housing in summer cottage. If it is also equipped with communications, then it is quite possible to live year-round;

Change house, summer cottage vest

- while construction is underway, the change house can be equipped for short-term accommodation;

- it is often used as a utility room, storage gardening tools, a mini-warehouse for very “necessary” things;

- the building can be equipped for summer kitchen, breeding barn poultry, workshop or bathhouse.

Change houses country houses

- Available on the market huge selection ready-made cabins. Manufacturers offer to additionally equip them to meet the client’s current and future needs. They can be delivered to the site either assembled or disassembled.

- The standard width of wooden summer cottages is 2.3 m, height - 2.5 m, as for the length, it can be 5, 6, 7 m. The maximum dimensions of a non-permanent structure are 3x12 m.

- Strength metal buildings, as well as the environmental friendliness of wood leaves no doubt, so the choice of material remains only with the consumer. To the advantages of metal should be added the possibility of manufacturing 2- and even 3-story buildings.

- By individual orders Country houses are produced with verandas, equipped with a heating system, air conditioning or other equipment. It is proposed to install related elements: sockets, plumbing fixtures with the ability to connect to various communications. The interior space is planned with partitions that are located in standard version or according to the customer's request. You can often find two-story country houses on sale.

Building a shed with your own hands

Construction of non-permanent housing is quite feasible on our own. The work can take from a week to a month, this time period depends on the material used, the complexity of the project and, of course, skill.

- If you plan to operate the cabin on short term, then this fact will allow you to significantly save on interior design premises. You can abandon internal partitions, install a minimum of sockets, use cheaper materials for cladding, etc. If the building is planned to be used for a long time, then it is recommended to choose a country house project with a shower and toilet.

Layout of a summer cottage photo

- There is a lot to think about before construction important points, even with the condition of temporary residence.

- A foundation is necessary in any case. Typically, a base of pillars is used, which are placed in the corners and long sides of the building. The distance between them should not exceed 2.5 m.

- The gravel bed, arranged before laying the pillars, will serve as an obstacle to emerging trees and plants.

- The site for construction is selected on a hill, which will prevent flooding by melt and rainwater. If this condition is not met for a number of reasons, then mandatory storm drains are being installed.

- Window and door openings are placed on one side or on adjacent walls with access to the south or east.

- If you install a change house near a power line, you can significantly reduce the cost of laying overhead electrical wiring.

Material for making a summer cottage

Materials for a mobile structure are selected depending on the area of application of the structure and financial capabilities.

- Foundation. During construction, preference is given to columnar or pile foundation. The farther the pillars (piles) are from each other, the more reliable the grillage should be. It makes no sense to carry out labor-intensive and expensive work on arranging a capital foundation.

- Frame. The basis of any structure is a frame made of metal or wood. From channels and metal corners, cabins are produced that are completely ready for use. A wooden frame implies both prefabricated and stationary structures.

- Exterior finishing. Sheathing is done using profile sheets, siding, clapboard, block house, etc.

- Insulation. Thermal insulation is given special attention. To insulate a country house, foam plastic and glass wool are used, and the seams are sealed with foam. Floors are also laid with thermal and waterproofing materials.

- Interior decoration. The room is sheathed with hardboard, clapboard, MDF or PVC panels. During temporary use, the walls are covered with edged boards.

- Doors. Iron and plastic are installed on doorways wooden products. When arranging openings, special attention is paid to strengthening them. Due to soil movements and the lack of solidity of the mini-house, horizontal and vertical beams may become skewed and make it difficult to open/close the door leaf.

- Windows. There are only two materials for making frames - wood and plastic. To protect windows from intruders and vandals, you can install metal shutters. IN lately Roller shutters are popular among developers.

- Roof. Often the roof for a given building has one slope, less often it is equipped gable roof. The slope should not be less than 20°, this will prevent snow and rainwater from accumulating on the surface. A profiled sheet or slate is chosen as a covering.

- Layout. A country house can be two-room or not contain any partitions. Change houses come with attached veranda, shower, toilet, etc. The layout and availability of various amenities depends on the desire and financial capabilities of the developer.

Stages of building a summer cottage with your own hands

Based on general information regarding the choice of material, an approximate cost estimate is drawn up. A more accurate calculation is carried out using a plan-drawing of the future building.

Frame base

- The area under the foundation is cleared of debris, plant roots, etc. The soil is excavated to a depth of 15-20 cm, slightly larger than the perimeter of the building. Sand is poured into the bottom in a layer of 10 cm, moistened and thoroughly compacted.

- Brick pillars cement mortar laid out 20-30 cm high. Perfect for these purposes concrete blocks. They are placed in the corners of the cabin; pillars installed in the middle of the long side of the building will help to further strengthen the base.

- The area around the pillars is covered with coarse crushed stone. Adding lime to the gravel will help protect the subfloor space from nesting of rodents or other living creatures.

- If the site on which construction is being carried out has a slope, then the height of the columns must be varied, that is, installed at different heights.

Bottom harness

- The channel acts as a grillage. Its fixation can be done by anchor bolts in advance drilled holes in metal and supports.

- If wooden beams, the thickness of which must be at least 100x50 mm, are laid on pillars (piles), then the heads are covered with 2 layers of roofing felt or coated bitumen mastic. The wood is treated with impregnations that protect against rotting and damage by insects.

Frame assembly

- At the corners are placed vertical bars cross section 40x40 mm or 50x50 mm. The beams forming the wall with the entrance door should be 15-20 cm higher than the rear ones, depending on the planned roof slope.

- The top trim is made from above. Fastening of wooden parts is done with nails, self-tapping screws or using metal corners.

- The distance between the verticals, as a rule, is 60 cm. The count should be from the corner of the building to the windows, from the windows to doorways. Horizontal lintels are immediately installed, which will serve as supports for the double-glazed windows and the door frame.

- Transverse bars, which serve to strengthen the frame, are placed in the middle of the length of the wall. If you plan to install drywall, then the crossbars are installed to match the dimensions of the sheet.

- Along the short wall, logs are placed on the bottom trim; here you can use lumber with a cross-section of 100x50 mm. To do this, grooves are cut in the lower beams along the width of the logs with a depth of 25 mm, and grooves are selected from the ends of the supports in the same way.

- Logs can also be installed in the form of spacers between the beams of the lower frame. In this case, fixation is made metal corners and self-tapping screws. On top of them they are nailed tightly to each other edged boards, you can lay and sheet material - chipboards or fiberboard.

- Then logs are installed again, which can be placed both along and across the walls. The step between the floor supports is selected according to the floor covering, but it should not be less than 50 cm. A layer is laid between them waterproofing material and a layer of insulation.

- Next, it is laid flooring. If linoleum is used, then it is fixed to the logs wood slab or plasterboard sheets.

Roof, ceiling

- Set up on the top harness rafter system, the pitch of which is 600-800 mm. Cross bars are mounted at a distance of 500 mm. This sheathing design is suitable for coverings made of profiled sheets and slate.

- WITH inside Waterproofing and insulation are placed in the resulting cells. The pie is covered with sheets of plywood, fiberboard, chipboard, you can also use drywall.

Walls

- WITH outside surfaces are sheathed with clapboard, siding, corrugated sheets, and glass-magnesium sheets.

- Sheathing can be done with horizontal boards. Their installation begins from the lowest point, the next row is placed with a slight offset on the previous board. This method will increase the consumption of lumber, but at the same time provide protection from the penetration of wind and raindrops.

- It would be useful to recall that all wooden components of the structure are pre-treated with impregnating agents. The preparations will protect surfaces from exposure aggressive environments, which will significantly extend their service life.

- The inside of the walls can be sheathed with the same materials that were used for exterior work. Between external and internal walls if necessary, insulation boards are laid.

- If the country house is equipped with a toilet or shower, then it is advisable to cover the walls with plastic panels.

- Wiring is carried out in metal or plastic sleeves;

- the location of electrical appliances (lamps, sockets, switches, air conditioning, etc.), as well as showers and other plumbing fixtures, is calculated in advance;

- in places where heavy objects are attached to the wall, it is necessary to install an additional crossbar, on which, in principle, they will be fixed;

- For the arrangement of the bathroom area, only moisture-resistant materials are used. Great option portable dry toilets will serve;

- You can install a tank on the roof from which water will flow to the shower, taps, etc. To operate the cabin in winter period boiler is installed;

- used as insulation: bulk materials, mineral wool, polystyrene foam sheets, glass wool.

- To heat the room, stoves and heaters are used that run on solid and liquid fuels, gas, as well as electrical appliances. It should be remembered that heating efficiency is achieved in conjunction with competently and efficiently insulated structural elements(floor, walls, roof).

Country cabins of increased comfort

- The cabins, which have 2 floors, are characterized by increased living comfort. This, of course, is due to the increased area. The space allows you to place a bathroom and shower, a kitchen area, and allocate a place for relaxation.

- Access to the 2nd floor is carried out using ladder, due to the mobility of the structure, the arrangement of stairs inside the change house is not provided.

- When choosing such a structure, a stronger foundation is selected. Here a strip type of foundation is formed; a pile-rammed foundation is also perfect.

In any case, do you want to buy a ready-made country house or build one? with my own hands The main thing is to choose the right material and make a layout depending on its purpose.

A change house is small house, which is easy to transport on a trailer truck. The change house is used as temporary housing for builders, or a garden (dacha) house during the construction of a full-fledged dacha. Advantage homemade cabin The point is that it is inexpensive and provides at least a minimum level of comfort, so it is well suited for temporary living. There are wooden and metal cabins, read about the latter on this site. The cost of cabins that can be bought on the construction market or in stores starts from 30 thousand rubles (size 2x3 meters), so many people prefer to make a cabin themselves. This will not only save at least a third of the amount, but also make the change house more convenient for yourself. In this article we will talk about building a cabin with your own hands from the most available materials.

How the change house works

Any change house consists of the following elements:

- frame;

- roof;

- exterior decoration;

- insulation;

- interior decoration;

- windows;

- doors.

Frame

The frame is the basis of any shed; it is what determines its size and shape. The strength of the cabin, its ability to withstand wind and any other loads depends on it. To make the frame they use different materials- from debarked logs to galvanized steel profiles, but the most popular material remains sawn dry board 25 mm thick and 100 mm wide. To create a frame 6 meters long and 3 meters wide, 60–100 meters of board are required, which is 0.15–0.25 meters³.

At average cost such a board costs 10 thousand rubles; 2.5 thousand rubles are enough for boards for the frame. Metal profile And wooden beam are much more expensive. And the cost of ready-made cabins of this size starts from 40 thousand rubles.

Roof

The roof is made of dry boards 25x100 mm. To create a gable roof 1 meter high for a cabin 6 meters long and 3 meters wide, 100 meters of boards are enough, which will cost 2.5 thousand rubles. This board is used to make triangles that form the ceiling joists and roof rafters. For a change house 6 meters long, 7–8 such triangles are enough. From above, the triangles are connected by one board - a ridge. After this, the resulting roof frame is sheathed with the same board or OSB sheets (oriented particle board). The board is stronger, but more expensive.

If a gable roof is perceived as an unnecessary luxury, then they do pitched roof, the cost of creating which is a quarter less. Such a roof consists of triangles formed by the ceiling joists, the gable wall and the roof rafters. Then the roof frame is also sheathed with OSB sheets or boards. After completing these works, the roof is covered with a roofing, which uses the following materials:

- roofing felt;

- slate;

- roofing iron;

- galvanized iron;

- metal profile.

Exterior decoration

For exterior finishing use the most various materials. The most popular are:

- roofing iron;

- plastic and metal siding;

- moisture-resistant plywood or OSB;

- clapboard board.

Each material has advantages and disadvantages. Roofing iron is very cheap, but on a wooden frame under strong wind starts to rattle. Plastic or metal siding is durable and beautiful, but is much more expensive than any other materials. Moisture-resistant plywood or OSB are inexpensive, but they must be treated with water-repellent compounds at least once every two years. The lining board creates a beautiful and stylish appearance, but is expensive and requires treatment with hydrophobic compounds at least once every 2–3 years.

Insulation

To insulate a cabin, use:

- foam;

- foamed cellophane;

- mineral wool;

- polyurethane;

- ecowool;

- wood concrete;

- fiberboard

Interior decoration

- For interior decoration most often used:

- Fiberboard (fibreboard);

- drywall;

- carriage board.

The finishing material is chosen based on the desired interior of the cabin and the cost of materials.

Windows and doors

In most cases, either new or dismantled ones are used for cabins, but completely working windows and doors. Such windows and doors can be purchased inexpensively at some hardware stores that accept them on consignment. It is advisable to clean a new window or used door from old paint and repaint. There is no need to paint new windows and doors.

How to make a change house - step-by-step guide and drawing

Below we will tell you how to make a change house with dimensions of 2.2x3x2.2 meters (width, length, height), one window and one door. Here are the materials you will need for this:

- sawn board 25x100 mm – 0.5 m³;

- Moisture-resistant OSB with a thickness of 9–15 mm and a size of 2.44x1.22 meters - 20 sheets;

- plywood 5–7 mm thick or fiberboard of the same thickness – 7–8 m²;

- roofing material 7–10 m²;

- fine wave slate (used in good condition) 7 waves – 5 sheets;

- used wooden window and door, completely ready for installation;

- foam insulation 10 cm thick or any other area of 32 m²;

- floor and ceiling plinth 22–25 meters;

- galvanized ridge - 8 meters;

- hydrophobic impregnation with an antiseptic (for example, Senezh OgneBio);

- brush or roller;

- self-tapping screws of various lengths;

- nails of various lengths;

- reinforcing corners made of galvanized sheet metal 0.4–0.9 mm thick.

Required Tools

You will also need the following tools:

- electric circular saw;

- drill with a set of drills for wood and metal;

- screwdriver;

- jigsaw;

- grinder with a disc for stone;

- extension;

- electric generator (if it is not possible to connect to a 220 volt network);

- tape measure 5 meters long;

- hammer;

- axe;

- chisels;

- stapler;

- sharp knife;

- wood hacksaw;

- pliers;

- level;

- square;

- protractor;

- pencil;

- construction tape.

Step by step instructions

- Cut the following elements from a 25x100 mm board:

- vertical posts 230 cm long – 12 pcs;

- floor joists 220 cm long - 7 pieces;

- ceiling and roof logs 260 cm long – 7 pcs;

- roof rafters 3 meters long - 7 pieces;

- roof supports 120 cm long - 7 pieces;

- vertical roof posts 20 cm long – 7 pcs;

- cross boards 305 mm long - 7–8 pcs;

- cross boards 220 cm long – 15–20 pcs.

- Treat all cut elements with hydrophobic materials. Perform the same operation with other wooden parts, which you will cut from boards, plywood, fiberboard or OSB.

- Place two vertical posts on the ground parallel to each other at a distance of 220 cm from each other (measure the distance from the far sides). Place the ceiling joist along one edge so that it protrudes the same distance in both directions.

- Using a square, align the boards relative to each other so that all angles are equal to 90 degrees.

- Nail the ceiling joists to each board using nails 70–90 mm long. The nails must go right through.

- Step back 15 cm from the bottom edge of the vertical posts and lay the floor joist.

- Align all corners with a square and nail the joist to both vertical posts nails 70–90 mm long.

- Attach a vertical roof post to the front edge of the ceiling joist at an angle of 90 degrees and nail it with two nails 70–90 mm long.

- Connect the top of the vertical roof pillar and back ceiling joists using rafters so that the upper edge of the rafter runs along top corner ceiling joist and the outer corner of the upright, then nail in place.

- Install a support from the corner between the ceiling joist and the vertical roof post and rafter, then nail it in place.

- Turn the structure over and use pliers to bend the ends of the protruding nails into an “L” shape.

- Have a helper hold the head of each nail with an ax so you can drive the bent nails into the boards. Do not try to simply bend the nails with a hammer, this type of connection is very fragile, be sure to bend their ends in an “L” shape first.

- If necessary, cut off the protruding piece of the lid support.

- You need to make 5 such structures. Then make two more structures, but without the front vertical post; you will place them where you will install windows and doors.

- Determine the most convenient place installation of cross boards. We recommend placing the bottom board under the door so that the door rests on it, placing the top board directly above the door, and the middle one approximately between them. Another option is also possible, for example, placing the bottom one directly above the floor joists, the top one directly under the ceiling joists, and the middle one between them.

- Mark the locations for them on each structure and select a groove for their installation. To do this, use a jigsaw to cut 25 mm deep cuts at the end of the vertical board, the distance between the cuts is 100 mm, then carefully chop the wood with a chisel. If for some reason it is impossible to make such grooves, then double the number of transverse boards and nail them directly to the ends of the vertical posts, with the exception of the boards passing through the window and door.

- Place each structure vertically (as it should stand in the frame of the house), level it and nail a cross board to it.

- Nail the side cross boards to the vertical posts at a distance of 30–40 cm from each other.

- Nail vertical boards at 50 cm intervals to the side transverse boards; they will create a frame for interior decoration and insulation.

- From inside the change house, nail braces to the transverse boards, installing them at an angle of no less than 30 and no more than 60 degrees, which will increase the rigidity of the structure. It is advisable to install at least 2 braces on each wall. The optimal length of the braces is 80–120 cm. Use nails 70 mm long to fix the braces and bend them as described above.

- Place the change house on its side and hem the floor joists from below with plywood or OSB with a thickness of at least 6 mm. This is necessary for laying the insulation, then install the change house normally again.

- To insert a window and door, nail horizontal spacers to the vertical posts (they must be installed level), the distance between which is 2–5 mm greater than the height of the window and door frames.

- Insert windows and doors, support their frames with wood chips and make sure that the panel and sash open and close normally. After this, secure with self-tapping screws. To do this, drill holes in the horizontal boards of the box according to the diameter of the self-tapping screws, and in the spacers, drill holes with a diameter 2 times smaller than the diameter of the self-tapping screw. Then tighten the screws and make sure that the door leaf and window frame open and close normally.

- From the inside of the cabin, line the ceiling with OSB sheets, then tightly lay insulation on these sheets from the roof side.

- Lay a 25x100 mm board decking on the roof joists. We recommend using solid flooring when there are no gaps between the boards. It is more expensive, but it provides better warmth and sound insulation.

- Lay sheets of roofing felt over the flooring and secure them with a stapler.

- Lay slate on the roof.

- Cover the gable with a 25x100 mm board, laying the boards without gaps. Drill 6–8 holes with a diameter of 20 mm in the lower gable boards; they will ensure sufficient air movement for ventilation.

- At the front and sides, cover the joints between the pediment and the slate with a galvanized ridge.

- Sheathe the outside of the change house with OSB sheets, trying not to allow gaps larger than 0.5 mm. If cracks appear, they will need to be sealed with putty made from PVA glue and sawdust.

- Cut the foam to size and insert it from inside the cabin into the space between the vertical boards and secure it with construction tape. Then line the space between the floor joists with foam. Sew the floor with a 25x100 mm board. If it is possible to cover the floor with a thicker board, take advantage. Lay OSB over the floorboard.

- Sheathe the inside of the walls with OSB.

- Install the sex and ceiling plinth. If necessary, you can install plinths in the corners to hide the cracks.

- Treat the inside and outside of the cabin with hydrophobic agents and fire bioprotection.

Conclusion

Now you know what tools and materials are needed to build a shed, so with minimal construction and carpentry skills, you can build a shed yourself. Our step by step guide on how to build a shed yourself will help you avoid many mistakes and severe waste of material.

A change house is a small auxiliary building made of wood, metal or any other building material and equipped with everything necessary for temporary living in it. In addition, in buildings similar type As a rule, a special compartment is provided, like a pantry, used to store working tools and equipment. Before you make a change house with your own hands , you should clearly determine for what purposes it is needed. In the article we will look at options for cabins (carriages) that you can make yourself, give detailed step-by-step instructions, and also demonstrate drawings, photographs and videos.

Purpose of the building

In this case, two options are possible, determining the choice of design of the structure itself, as well as the material used in construction.

Firstly, a trailer cabin can serve as a long-term residence for workers hired to build the main house on the site allocated to you. In this case, it must provide a full range of amenities necessary for relaxation and eating, as well as for protection from bad weather and heating in winter time year. In addition, it is often necessary to store building materials and equipment in such a house, for which a special place must be allocated.

Secondly, the change house can simply be used as a place to store working tools and equipment on your summer cottage. In this situation, the presence of any amenities is most often not provided for.

Naturally, for each of these options a separate project must be prepared, taking into account factors such as:

- the material used in construction (the frame of the cabin can be made of either wood or metal);

- the type of foundation, the choice of which is determined by the type of material used, as well as its purpose;

- the size of the building, the conditions for its placement and other nuances.

Based on the conditions for the use of a change house that we have already discussed, then if it is used as a place of temporary residence for workers, it can be installed anywhere on your land plot. But at the same time, you need to make sure that the location you choose is located at a certain distance from the construction site, storage areas, as well as routes for the delivery of building materials and lines for laying future communications.

In the event that your trailer will be used as a room for storing equipment on a summer cottage, taking into account all the factors listed above is not at all necessary.

Before building a shed in a particular place garden plot, you should decide on its dimensions, the choice of which is also determined by its purpose. So, if several workers are supposed to rest in the cabin and materials that need drying are stored, you will need a structure measuring at least 2.5 by 6 meters. If the trailer will be used as storage for work clothes and tools, as well as as a place to shelter from bad weather, a size of 2 by 4 meters is quite sufficient. Such dimensions should also suit those summer residents who plan to use the change house as a temporary summer kitchen.

When choosing the size and location of the trailer, you should also consider the possibility of moving it to another location or potential sale, which is associated with the need to organize transportation. It should be taken into account that on Russian roads, without special permission, it is allowed to transport cargo of certain dimensions (width - no more than 2.55 meters, height - no more than 4 meters from the level of the roadway).

It is also necessary to take care of simplifying the work associated with loading and unloading the cabin in the event of transporting it to another place.

Taking into account all the above restrictions, the dimensions of your future building should be as follows:

- width – about 2.4 meters;

- height – no more than 2.5 meters;

- length - no more than six meters.

At the same time, the weight of the cabin should not exceed five tons, which will allow you to use a regular manipulator to transport it.

Choosing the type of foundation

In any of the design options we have considered, there is no need to prepare a powerful foundation for the cabin trailer using or, for example. In such a situation, the main task of the foundation being constructed is to protect the future structure from moisture spreading from the ground.

A fairly effective and cost-effective option for this case is the use of special asbestos-cement glasses, cinder blocks or used sleepers as a base.

Laying a foundation using any of these construction products is done as follows:

- First carried out earthworks, starting with clearing the site selected for development from debris and grass.

- Then, in its corners, as well as in the places where the supports are planned to be placed (6–8 of them are enough for a change house), the top layer soil.

- After this, a cushion is made of a mixture of crushed stone, screenings and sand over the bare soil, which is slightly moistened with water and then thoroughly compacted using a special tamping device.

- When using asbestos cement glasses as foundation racks, it is allowed to lay paving slabs, which allows you to slightly increase the area of the supporting base.

- Cinder blocks or sleepers are placed on a cushion with the obligatory check of their horizontal positioning; for this you can use any suitable level.

- For reliable protection wooden frame buildings from soil moisture, pieces of roofing felt are laid on the supports (preferably in several layers).

Such a foundation is quite simple to manufacture and can be prepared independently in just a few hours. Well, if the need arises to move the change house to a new location, its dismantling from such a base will be extremely simplified.

Construction of walls and their decoration

Upon completion of the foundation arrangement, it will be possible to proceed directly to the construction of the cabin itself, which we will consider using the example of making a wooden trailer frame.

This work begins with laying the bottom trim beam on the supports and securing them to them, which can be a board with a cross-section of 100×150 mm. This beam is securely attached to the foundation supports using special anchors, and then corner and intermediate posts are mounted on it.

After installing all the racks provided for by the project, you can proceed to the installation of beams top harness. When carrying out all these similar operations, you must adhere to the following recommendations:

- It is most convenient to use boards with a cross section of 50×150 mm as racks, for fastening of which simple (or screw) nails or self-tapping screws are used;

- It is advisable to carry out the nodal ligaments by cutting the posts into the harness and then reinforcing this place with metal corners;

- to temporarily fasten the racks after leveling them, you can use long boards (jibs);

- the floor joists cut directly into the beam of the lower frame. If you want to insulate the floor, you will have to prepare its lining along the bottom cut of the joists, on which slabs or mats of insulating material will subsequently be laid;

- when choosing the distance between the racks, you should proceed from the fact that insulation boards can easily be laid between them;

- It is advisable to immediately decide where the door and windows of the change house will be located.

Once the frame of the trailer is ready, you can proceed to covering its outer surface in a way suitable for your conditions. facing material (OSB sheets, For example).

The internal cavities of the frame formed in this case are filled with pre-prepared insulation boards, which are then covered with a layer vapor barrier film and lined with clapboard. If you wish, you can additionally protect the outer walls of the trailer from bad weather by covering them with corrugated sheeting, for example.

Construction of the roof, windows and doors

After the base of your house has been prepared, you can proceed to the installation of such floor structural elements as joists and rafters (the same board with a cross-section of 50×150 mm will do for these purposes). Upon completion of their installation, along the lower cut of the joists, a ceiling lining is made from inch boards, sheets of plywood or OSB.

After this, a layer of vapor barrier film is attached on top of the filing, onto which slabs or mats of insulation made of mineral wool, For example. Note that in cabins, as a rule, it is used pitched roof. When making a covering board, the battens are fastened across the rafters, after which sheets of the chosen material are laid on them. roofing material(for these purposes it is most convenient to use slate or galvanized corrugated sheet).

As for the arrangement of windows in the trailer, standard wooden frames can be used for their manufacture.

If your trailer will be used in the winter season, it is better to install plastic windows(preferably with double-glazed window). Entrance door for such a building it can be metal or wood, and for creating additional protection from the cold air in the house it will be possible to equip a small vestibule.

Approximate cost estimate

In the event that you plan to make a change house entirely from new purchased materials, the approximate amount of expenses can be about 20–25 thousand rubles, which is approximately half the price of buying a ready-made trailer. In most regions of the country, for the specified amount you can purchase all the basic materials for construction.

If you want to save on building materials, you can always use the remnants of old structures still usable, available at any summer cottage.

Video

Watch a video about the construction of a frame cabin:

Photo

A metal shed today is practically a necessity in most summer cottages. In addition, such a structure serves as an indispensable location for various rooms at the construction site. In addition, it is easy to make a change house yourself, since it consists of blocks, which, in turn, are made of a frame, and metal plates. Of course, such a building will be difficult to use for a long stay, but it is an indispensable option for a summer residence.

Modern project metal shed with windows and air conditioning

Such a trailer can often be found on construction sites. Considering that the majority construction work can last much longer than one year, a small building for workers can temporarily replace housing.

In such cases, a metal change house may contain minimum required amenities that will allow you to relax a little after a hard day at work or even provide the opportunity to take a hot shower. Therefore, it is difficult to overestimate the need for such a structure on a site where there is clearly not enough space for certain needs. That is why there are many projects in which you can independently assemble and install such a structure.

Self-production metal cabins are a fairly simple matter, but at the same time it must be taken with due seriousness.

Layout of a homemade metal shed

Layout of a homemade metal shed To do this, you should adhere to the basic rules when constructing such premises and use the material and tools that are listed below.

If you comply with all the conditions, you can be sure that the building constructed from metal blocks will serve you for many decades. And its high functionality and usefulness will pay for all costs in a matter of months of operation. In order to make a high-quality change house from containers and blocks with your own hands, you will need the following tools:

Before starting work, make sure that you have all the required material, as this will significantly speed up the manufacturing and assembly process, and will also help avoid unexpected difficulties during construction.

Materials required for the manufacture of metal cabins

Do-it-yourself construction of a metal shed

To carry out all the preparatory and construction work, you will need a little time, from several days to two weeks. The timing usually depends on the number of workers and their experience in the construction business. If you carry out all the work completely independently, you need to be prepared for a longer period. Therefore, it is worth carrying out all stages of construction correctly, which will help significantly save both time and finances.

If you want to build a high-quality structure from blocks, you will need to make some financial investments. But it is worth noting that such costs usually completely compensate for themselves in a few months.

Layout options for a shed made from a metal container

Layout options for a shed made from a metal container One of the most quality materials For the construction of such a structure, a construction container is considered. The metal shed is different high performance strength and durability of the structure, which is easy to assemble with your own hands.

Before starting work, it is worth carrying out the planning mentioned above. This type of work is a necessity when building a metal shed with your own hands. Compliance with this condition will help to build not only a room such as a change house, but will also be useful for or.

Installation of a metal cabin on a columnar foundation

Installation of a metal cabin on a columnar foundation In addition, with experience in construction planning, you can easily carry out renovation work almost any metal structures, containers, etc. Therefore, before installation, try to lay out all your thoughts, requirements and intended purpose of the change house on paper. With this method you can accurately calculate total area metal shed for a summer residence or construction site, which will allow you to find out exact quantity material. Such calculations will help you save money when building with your own hands, especially when compared with buying a metal shed.