Accurate data will allow you to get a table of thermal conductivity of building materials. Proper construction of buildings contributes to optimal climatic parameters in the room.

It is better to start the construction of each object with the planning of the project and careful calculation of thermal parameters. Accurate data will allow you to get a table of thermal conductivity of building materials. Proper construction of buildings contributes to optimal climatic parameters in the room. And the table will help you choose the right raw materials that will be used for construction.

Purpose of thermal conductivity

Thermal conductivity is a measure of the transfer of heat energy from heated objects in a room to objects with a lower temperature. The heat exchange process is carried out until the temperature indicators are equalized. To designate thermal energy, a special coefficient of thermal conductivity of building materials is used. The table will help you see all the required values. The parameter indicates how much heat energy is passed through a unit area per unit time. The larger this designation, the better the heat transfer will be. When erecting buildings, it is necessary to use a material with a minimum value of thermal conductivity.

The thermal conductivity coefficient is a value that is equal to the amount of heat passing through a meter of material thickness per hour. The use of such a characteristic is necessary to create the best thermal insulation. Thermal conductivity should be taken into account when selecting additional insulating structures.

What affects the thermal conductivity?

Thermal conductivity is determined by such factors:

Porosity determines the heterogeneity of the structure. When heat is passed through such materials, the cooling process is negligible;

An increased density value affects the close contact of the particles, which contributes to faster heat transfer;

High humidity increases this indicator.

Using the values of the thermal conductivity coefficient in practice.

Materials are represented by structural and heat-insulating varieties. The first type has high thermal conductivity. They are used for the construction of ceilings, fences and walls.

With the help of the table, the possibilities of their heat transfer are determined. In order for this indicator to be low enough for a normal indoor microclimate, walls made of some materials must be especially thick. To avoid this, it is recommended to use additional heat-insulating components.

Thermal conductivity indicators for finished buildings. Types of insulation.

When creating a project, all methods of heat leakage must be taken into account. It can exit through walls and roofs, as well as through floors and doors. If you do the design calculations incorrectly, you will have to be content with only the thermal energy received from the heating devices. Buildings built from standard raw materials: stone, brick or concrete need to be additionally insulated.

Additional thermal insulation is carried out in frame buildings. At the same time, the wooden frame gives rigidity to the structure, and the insulating material is laid in the space between the uprights. In buildings made of bricks and cinder blocks, insulation is carried out outside the structure.

When choosing heaters, it is necessary to pay attention to such factors as the level of humidity, the effect of elevated temperatures and the type of structure. Consider certain parameters of insulating structures:

The thermal conductivity index affects the quality of the heat-insulating process;

Moisture absorption is of great importance when insulating external elements;

Thickness affects the reliability of insulation. Thin insulation helps to save the useful area of the room;

Flammability is important. High-quality raw materials have the ability to self-extinguish;

Thermal stability reflects the ability to withstand temperature changes;

Environmental friendliness and safety;

Soundproofing protects against noise.

The following types are used as heaters:

Mineral wool is fire resistant and environmentally friendly. Important characteristics include low thermal conductivity;

Styrofoam is a lightweight material with good insulating properties. It is easy to install and is moisture resistant. Recommended for use in non-residential buildings;

Basalt wool, unlike mineral wool, is distinguished by the best indicators of resistance to moisture;

Penoplex is resistant to moisture, high temperatures and fire. It has excellent thermal conductivity, easy to install and durable;

Polyurethane foam is known for such qualities as incombustibility, good water repellency and high fire resistance;

Extruded polystyrene foam undergoes additional processing during production. Has a uniform structure;

Penofol is a multilayer insulating layer. Contains polyethylene foam. The surface of the plate is covered with foil to provide reflection.

Bulk types of raw materials can be used for thermal insulation. These are paper granules or perlite. They are resistant to moisture and fire. And from organic varieties, you can consider wood fiber, linen or cork. When choosing, pay special attention to such indicators as environmental friendliness and fire safety.

NOTE! When designing thermal insulation, it is important to consider the installation of a waterproofing layer. This will avoid high humidity and increase resistance to heat transfer.

Table of thermal conductivity of building materials: features of indicators.

The table of thermal conductivity of building materials contains indicators of various types of raw materials that are used in construction. Using this information, you can easily calculate the thickness of the walls and the amount of insulation.

How to use the table of thermal conductivity of materials and heaters?

The heat transfer resistance table of materials shows the most popular materials. When choosing a particular option for thermal insulation, it is important to consider not only physical properties, but also such characteristics as durability, price and ease of installation.

Did you know that the easiest way is to install penooizol and polyurethane foam. They are distributed over the surface in the form of foam. Such materials easily fill the cavities of structures. When comparing solid and foam options, it should be noted that the foam does not form joints.

The values of the heat transfer coefficients of materials in the table.

When making calculations, you should know the coefficient of resistance to heat transfer. This value is the ratio of temperatures on both sides to the amount of heat flow. In order to find the thermal resistance of certain walls, a thermal conductivity table is used.

You can do all the calculations yourself. For this, the thickness of the heat insulator layer is divided by the thermal conductivity coefficient. This value is often indicated on the packaging if it is insulation. Household materials are self-measured. This applies to thickness, and the coefficients can be found in special tables.

The resistance coefficient helps to choose a certain type of thermal insulation and the thickness of the material layer. Information on vapor permeability and density can be found in the table.

With the correct use of tabular data, you can choose high-quality material to create a favorable indoor climate. published

We will send the material to you by e-mail

Any construction work begins with the creation of a project. At the same time, both the location of the rooms in the building and the main heat engineering indicators are calculated. From these values depends how the future building will be warm, durable and economical. It will allow you to determine the thermal conductivity of building materials - a table that displays the main coefficients. Correct calculations are a guarantee of successful construction and the creation of a favorable microclimate in the room.

In order for the house to be warm without insulation, a certain wall thickness will be required, which differs depending on the type of material.

Thermal conduction is the process of transferring thermal energy from warm parts to cold parts. Exchange processes occur until complete equilibrium of the temperature value.

The heat transfer process is characterized by a period of time during which the temperature values are equalized. The more time passes, the lower the thermal conductivity of building materials, the properties of which are displayed in the table. To determine this indicator, such a concept as the coefficient of thermal conductivity is used. It determines how much heat energy passes through a unit area of a certain surface. The higher this indicator, the faster the building will cool down. The thermal conductivity table is needed when designing the protection of a building from heat loss. This can reduce the operating budget.

Therefore, when building a building, it is worth using additional materials. In this case, the thermal conductivity of building materials is important, the table shows all the values.

Helpful information! For buildings made of wood and foam concrete, it is not necessary to use additional insulation. Even using low-conductivity material, the thickness of the structure should not be less than 50 cm.

Features of the thermal conductivity of the finished structure

When planning a project for a future home, it is necessary to take into account the possible loss of thermal energy. Most of the heat escapes through doors, windows, walls, roofs and floors.

If you do not perform calculations for heat saving at home, then the room will be cool. It is recommended that buildings made of concrete and stone be additionally insulated.

Helpful advice! Before insulating a home, it is necessary to consider high-quality waterproofing. At the same time, even high humidity will not affect the features of thermal insulation in the room.

Varieties of insulation structures

A warm building will be obtained with an optimal combination of a structure made of durable materials and a high-quality heat-insulating layer. Such structures include the following:

- building from standard materials: cinder blocks or bricks. In this case, insulation is often carried out on the outside.

How to determine the thermal conductivity of building materials: table

Helps to determine the thermal conductivity of building materials - table. It contains all the values of the most common materials. Using such data, you can calculate the thickness of the walls and the insulation used. Table of thermal conductivity values:

To determine the value of thermal conductivity, special GOSTs are used. The value of this indicator differs depending on the type of concrete. If the material has an index of 1.75, then the porous composition has a value of 1.4. If the solution is made using crushed stone, then its value is 1.3.

Losses through ceiling structures are significant for those living on the upper floors. The weak areas include the space between the floors and the wall. Such areas are considered cold bridges. If there is a technical floor above the apartment, then the loss of thermal energy is less.

The top floor is made outside. Also, the ceiling can be insulated inside the apartment. For this, expanded polystyrene or heat-insulating plates are used.

Before insulating any surfaces, it is worth knowing the thermal conductivity of building materials, the SNiP table will help with this. Insulating flooring is not as difficult as other surfaces. Materials such as expanded clay, glass wool or expanded polystyrene are used as insulating materials.

The thermal conductivity of building materials (a table of its values \u200b\u200bwill be given in the article below) is a very important criterion that you absolutely need to pay attention to during such a stage of organizing construction work as: the purchase of raw materials.

This indicator should be taken into account not only when building an object from scratch, but also during repair work, including the installation of walls (both external and internal).

Basically, the future level of comfort indoors depends on the thermal conductivity of the selected materials. However, this criterion also affects some technical indicators, which can be found in more detail in this article.

Thermal conductivity - definition

Before determining the thermal conductivity of a particular material, it is important to know in advance: what is this term in general.

Before determining the thermal conductivity of a particular material, it is important to know in advance: what is this term in general.

As a rule, under the definition of "thermal conductivity", it is customary to understand the level of heat transfer of a certain material, expressed in watts / meter kelvin.

In simpler terms, this coefficient shows the ability of the material to receive energy from more heated bodies, and the level of return of its energy to bodies with a lower temperature. As a rule, this indicator is calculated according to one of two main formulas: q = x*grad(T) or P=-x*.

What affects thermal conductivity

The thermal conductivity coefficient of each building material is determined strictly individually, which should be given special attention, and it depends on several basic criteria:

The thermal conductivity coefficient of each building material is determined strictly individually, which should be given special attention, and it depends on several basic criteria:

- density;

- porosity level;

- structure and shape of pores;

- natural temperature;

- humidity level;

- chemical structure (atomic group).

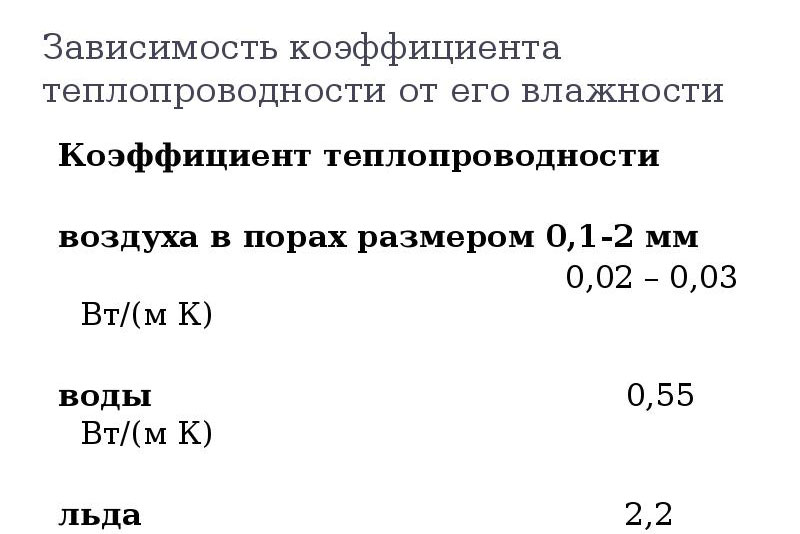

For example, if there are a large number of small pores in the structure of the material, of a closed type, its level of thermal conductivity will decrease significantly. However, in the variant with large pores, this coefficient will, on the contrary, be increased due to the occurrence of convective air flows in the pores.

Table

As mentioned earlier: each building material has an individual thermal conductivity coefficient, which is calculated based on some characteristic criteria.

For a clearer picture, we give in the table examples of the thermal conductivity of some of the most common materials used in construction:

| Material | Density (kg*m3) | Thermal conductivity (W\(m*K)) |

| Reinforced concrete | 2500 | 1,69 |

| Concrete | 2400 | 1,51 |

| Expanded clay concrete | 1800 | 0,66 |

| foam concrete | 1000 | 0,29 |

| Mineral wool | 50 to 200 | From 0.04 to 0.07 respectively |

| Styrofoam | 33 to 150 | From 0.03 to 0.05 respectively |

| 30 to 80 | From 0.02 to 0.04 respectively | |

| Expanded clay | 800 | 0,18 |

| Foam glass | 400 | 0,11 |

Varieties of insulation structures

Vermiculite

The selection of material for insulation of any structure is primarily carried out based on its type: external or internal. In the first variant, substances that are not susceptible to weather conditions and other external factors are well suited as a heater, namely:

- expanded clay;

- perlite gravel.

For greater effect, the insulation can be applied in two layers, where the above materials will be considered a protective layer, and as a base, they can well act:

- Styrofoam;

- penoizol;

- expanded polystyrene;

- polyurethane foam.

Penoizol

As for the exclusively internal version of the insulation of structures, the following materials are quite suitable for this:

- mineral wool;

- glass wool;

- cotton wool from basalt fiber;

In addition to the scope, heaters differ significantly from each other and their cost, thermal conductivity, tightness, as well as service life, which should be paid attention to when choosing them.

When choosing a heater, first of all, it is important to pay attention to the scope of its application. For example, when choosing an insulation material for the exterior of an object, make sure that its density is high enough, and its structure has reliable protection against temperature changes, moisture, physical impact, etc.

When choosing a heater, first of all, it is important to pay attention to the scope of its application. For example, when choosing an insulation material for the exterior of an object, make sure that its density is high enough, and its structure has reliable protection against temperature changes, moisture, physical impact, etc.

Also, try to select such materials, the weight of which will not be very large, so as not to destroy the foundation of the building. After all, it is not uncommon that the insulation has to be mounted on a clay surface, or on top of an ordinary “fur coat”, which may well cause its rapid destruction.

Summing up, we can conclude that the selection of a suitable material for the insulation of any structure is a very difficult process that requires increased attention. Remember that in this matter, it is best to rely only on yourself and on your knowledge, since in most cases, store consultants can advise

You can buy high-quality expensive insulation where you can do without it (for example, under linoleum, or on internal walls). Therefore, make the choice yourself, based on the characteristics of the material, and on its quality. Also, it is important to remember that the price is not always an important criterion that you should focus on when choosing.

See the following video for an explanation of the thermal conductivity table of materials with examples:

The term "thermal conductivity" is applied to the properties of materials to transmit thermal energy from hot to cold areas. Thermal conductivity is based on the movement of particles inside substances and materials. The ability to transfer heat energy in quantitative terms is the coefficient of thermal conductivity. The cycle of thermal energy transfer, or heat exchange, can take place in any substances with unequal placement of different temperature sections, but the thermal conductivity depends on the pressure and temperature in the material itself, as well as on its state - gaseous, liquid or solid.

Physically, the thermal conductivity of materials is equal to the amount of heat that flows through a homogeneous object of established dimensions and area for a certain time period at a specified temperature difference (1 K). In the SI system, a single indicator that has a thermal conductivity coefficient is usually measured in W / (m K).

How to Calculate Thermal Conductivity Using Fourier's Law

In a given thermal regime, the flux density during heat transfer is directly proportional to the maximum temperature increase vector, the parameters of which change from one section to another, and modulo with the same temperature increase rate in the direction of the vector:

q → = − ϰ x grad x (T), where:

- q → - the direction of the density of the object that transfers heat, or the volume of heat flow that flows through the site for a given time unit through a certain area, perpendicular to all axes;

- ϰ is the specific coefficient of thermal conductivity of the material;

- T is the temperature of the material.

When applying the Fourier law, the inertia of the flow of thermal energy is not taken into account, which means that the instantaneous transfer of heat from any point to any distance is meant. Therefore, the formula cannot be used to calculate heat transfer during processes with a high repetition rate. This is ultrasonic radiation, the transfer of thermal energy by shock or impulse waves, etc. There is a Fourier law solution with a relaxation term:

τ x ∂ q / ∂ t = − (q + ϰ x ∇T) .

If the relaxation τ is instantaneous, then the formula turns into the Fourier law.

Approximate table of thermal conductivity of materials:

| The basis | Thermal conductivity value, W/(m K) |

| hard graphene | 4840 + / – 440 – 5300 + / – 480 |

| Diamond | 1001-2600 |

| Graphite | 278,4-2435 |

| Boron arsenide | 200-2000 |

| SiC | 490 |

| Ag | 430 |

| Cu | 401 |

| BeO | 370 |

| Au | 320 |

| Al | 202-236 |

| AlN | 200 |

| BN | 180 |

| Si | 150 |

| Cu 3 Zn 2 | 97-111 |

| Cr | 107 |

| Fe | 92 |

| Pt | 70 |

| sn | 67 |

| ZnO | 54 |

| black steel | 47-58 |

| Pb | 35,3 |

| stainless steel | Thermal conductivity of steel - 15 |

| SiO2 | 8 |

| High quality heat resistant pastes | 5-12 |

| Granite (consists of SiO 2 68-73%; Al 2 O 3 12.0-15.5%; Na 2 O 3.0-6.0%; CaO 1.5-4.0%; FeO 0.5- 3.0%; Fe 2 O 3 0.5-2.5%; K 2 O 0.5-3.0%; MgO 0.1-1.5%; TiO 2 0.1-0.6% ) | 2,4 |

| Concrete mortar without aggregates | 1,75 |

| Concrete mortar with crushed stone or gravel | 1,51 |

| Basalt (consists of SiO 2 - 47-52%, TiO 2 - 1-2.5%, Al2O 3 - 14-18%, Fe 2 O 3 - 2-5%, FeO - 6-10%, MnO - 0, 1-0.2%, MgO - 5-7%, CaO - 6-12%, Na 2 O - 1.5-3%, K 2 O - 0.1-1.5%, P 2 O 5 - 0.2-0.5%) | 1,3 |

| Glass (consists of SiO 2 , B 2 O 3 , P 2 O 5 , TeO 2 , GeO 2 , AlF 3 etc.) | 1-1,15 |

| Heat-resistant paste KPT-8 | 0,7 |

| Concrete mortar filled with sand, without crushed stone or gravel | 0,7 |

| The water is clean | 0,6 |

| Silicate or red brick | 0,2-0,7 |

| Oils based on silicone | 0,16 |

| foam concrete | 0,05-0,3 |

| aerated concrete | 0,1-0,3 |

| Wood | Thermal conductivity of wood - 0.15 |

| Oils oil based | 0,125 |

| Snow | 0,10-0,15 |

| PP with flammability group G1 | 0,039-0,051 |

| EPPU with flammability group G3, G4 | 0,03-0,033 |

| glass wool | 0,032-0,041 |

| Cotton wool stone | 0,035-0,04 |

| Air atmosphere (300 K, 100 kPa) | 0,022 |

| Gel air based | 0,017 |

| Argon (Ar) | 0,017 |

| vacuum environment | 0 |

The given table of thermal conductivity takes into account heat transfer by thermal radiation and heat exchange of particles. Since a vacuum does not transfer heat, it flows with the help of solar radiation or other type of heat generation. In a gas or liquid medium, layers with different temperatures are mixed artificially or naturally.

When calculating the thermal conductivity of a wall, it must be taken into account that heat transfer through wall surfaces varies from the fact that the temperature in the building and on the street is always different, and depends on the area of \u200b\u200ball surfaces of the house and on the thermal conductivity of building materials.

To quantify the thermal conductivity, a value such as the coefficient of thermal conductivity of materials was introduced. It shows how a particular material is able to transfer heat. The higher this value, for example, the thermal conductivity of steel, the more efficiently the steel will conduct heat.

- When insulating a house made of wood, it is recommended to choose building materials with a low coefficient.

- If the wall is brick, then with a coefficient value of 0.67 W / (m2 K) and a wall thickness of 1 m, with an area of \u200b\u200bit 1 m 2, with a difference between the outside and inside temperatures of 1 0 C, the brick will transmit 0.67 W of energy. With a temperature difference of 10 0 C, the brick will transmit 6.7 W, etc.

The standard value of the thermal conductivity coefficient of thermal insulation and other building materials is valid for a wall thickness of 1 m. To calculate the thermal conductivity of a surface of a different thickness, the coefficient should be divided by the selected wall thickness value (meters).

In SNiP and when carrying out calculations, the term “thermal resistance of the material” appears, it means reverse thermal conductivity. That is, with a thermal conductivity of a foam sheet of 10 cm and its thermal conductivity of 0.35 W / (m 2 K), the thermal resistance of the sheet is 1 / 0.35 W / (m 2 K) \u003d 2.85 (m 2 K) / W.

Below is a table of thermal conductivity for popular building materials and heat insulators:

| building materials | Thermal conductivity coefficient, W / (m 2 K) |

| Alabaster slabs | 0,47 |

| Al | 230 |

| Asbestos-cement slate | 0,35 |

| Asbestos (fiber, fabric) | 0,15 |

| asbestos cement | 1,76 |

| Asbestos cement products | 0,35 |

| Asphalt | 0,73 |

| Asphalt for flooring | 0,84 |

| Bakelite | 0,24 |

| Crushed concrete | 1,3 |

| Sand-filled concrete | 0,7 |

| Porous concrete - foam and aerated concrete | 1,4 |

| solid concrete | 1,75 |

| Thermal insulating concrete | 0,18 |

| bituminous mass | 0,47 |

| paper materials | 0,14 |

| Loose mineral wool | 0,046 |

| Heavy mineral wool | 0,05 |

| Cotton wool - a heat insulator based on cotton | 0,05 |

| Vermiculite in slabs or sheets | 0,1 |

| Felt | 0,046 |

| Gypsum | 0,35 |

| Alumina | 2,33 |

| gravel aggregate | 0,93 |

| Granite or basalt aggregate | 3,5 |

| Wet soil, 10% | 1,75 |

| Wet soil, 20% | 2,1 |

| Sandstones | 1,16 |

| dry soil | 0,4 |

| compacted soil | 1,05 |

| Tar mass | 0,3 |

| Building board | 0,15 |

| plywood sheets | 0,15 |

| hard wood | 0,2 |

| Chipboard | 0,2 |

| Duralumin products | 160 |

| Reinforced concrete products | 1,72 |

| Ash | 0,15 |

| limestone blocks | 1,71 |

| Mortar on sand and lime | 0,87 |

| Resin foamed | 0,037 |

| Natural stone | 1,4 |

| Cardboard sheets from several layers | 0,14 |

| Rubber porous | 0,035 |

| Rubber | 0,042 |

| Rubber with fluorine | 0,053 |

| Expanded clay blocks | 0,22 |

| Red brick | 0,13 |

| hollow brick | 0,44 |

| solid brick | 0,81 |

| solid brick | 0,67 |

| cinder brick | 0,58 |

| Silica based boards | 0,07 |

| brass products | 110 |

| Ice at a temperature of 0 0 С | 2,21 |

| Ice at -20 0 C | 2,44 |

| Deciduous wood at 15% humidity | 0,15 |

| copper products | 380 |

| Mypora | 0,086 |

| Sawdust for backfill | 0,096 |

| Dry sawdust | 0,064 |

| PVC | 0,19 |

| foam concrete | 0,3 |

| Styrofoam brand PS-1 | 0,036 |

| Styrofoam brand PS-4 | 0,04 |

| Polyfoam brand PKhV-1 | 0,05 |

| Styrofoam brand FRP | 0,044 |

| PPU brand PS-B | 0,04 |

| PPU brand PS-BS | 0,04 |

| Polyurethane foam sheet | 0,034 |

| PU foam panel | 0,024 |

| Lightweight foam glass | 0,06 |

| Heavy foam glass | 0,08 |

| glassine products | 0,16 |

| Perlite products | 0,051 |

| Slabs on cement and perlite | 0,085 |

| Wet sand 0% | 0,33 |

| Wet sand 0% | 0,97 |

| Wet sand 20% | 1,33 |

| burnt stone | 1,52 |

| Ceramic tile | 1,03 |

| Tiles brand PMTB-2 | 0,035 |

| Polystyrene | 0,081 |

| Foam rubber | 0,04 |

| Cement-based mortar without sand | 0,47 |

| Natural cork board | 0,042 |

| Light sheets of natural cork | 0,034 |

| Heavy sheets of natural cork | 0,05 |

| Rubber products | 0,15 |

| Ruberoid | 0,17 |

| Slate | 2,100 |

| Snow | 1,5 |

| Softwood with a moisture content of 15% | 0,15 |

| Coniferous resinous wood with a moisture content of 15% | 0,23 |

| Steel products | 52 |

| glass products | 1,15 |

| Glass wool insulation | 0,05 |

| Fiberglass insulation | 0,034 |

| Glass fiber products | 0,31 |

| Shavings | 0,13 |

| Teflon coating | 0,26 |

| Tol | 0,24 |

| Cement based slab | 1,93 |

| Cement-sand mortar | 1,24 |

| Cast iron products | 57 |

| Slag in granules | 0,14 |

| Ash slag | 0,3 |

| Cinder blocks | 0,65 |

| Dry plaster mixes | 0,22 |

| Cement-based plaster | 0,95 |

| ebonite products | 0,15 |

In addition, it is necessary to take into account the thermal conductivity of heaters due to their jet heat flows. In a dense medium, it is possible to “transfer” quasiparticles from one heated building material to another, colder or warmer, through submicron pores, which helps to spread sound and heat, even if there is an absolute vacuum in these pores.

Building a cottage or country house is a complex and time-consuming process. And in order for the future building to stand for more than a dozen years, it is necessary to comply with all norms and standards during its construction. Therefore, each stage of construction requires accurate calculations and high-quality performance of the necessary work.

One of the most important indicators in the construction and decoration of a building is the thermal conductivity of building materials. SNIP (building norms and rules) provides a full range of information on this issue. You need to know it so that the future building is comfortable for living both in summer and in winter.

Perfect warm home

The comfort and economy of living in it depends on the design features of the building and the materials used in its construction. Comfort lies in creating an optimal microclimate inside, regardless of external weather conditions and ambient temperature. If the materials are chosen correctly, and the boiler equipment and ventilation are installed in accordance with the norms, then in such a house there will be a comfortable cool temperature in summer and warm in winter. In addition, if all materials used in construction have good thermal insulation properties, then energy costs for space heating will be minimal.

The concept of thermal conductivity

Thermal conductivity is the transfer of thermal energy between directly contacting bodies or media. In simple words, thermal conductivity is the ability of a material to conduct temperature. That is, getting into some medium with a different temperature, the material begins to take on the temperature of this medium.

This process is of great importance in construction. So, in the house with the help of heating equipment, the optimum temperature is maintained (20-25 ° C). If the temperature outside is lower, then when the heating is turned off, all the heat from the house will go outside after a while, and the temperature will drop. In summer, the situation is reversed. To make the temperature in the house below the street, you have to use air conditioning.

Coefficient of thermal conductivity

Heat loss in the house is inevitable. It happens all the time when the outside temperature is lower than the room temperature. But its intensity is a variable. It depends on many factors, the main ones being:

- The area of surfaces involved in heat exchange (roof, walls, ceilings, floor).

- Thermal conductivity index of building materials and individual building elements (windows, doors).

- The difference between the temperatures outside and inside the house.

- Other.

To quantify the thermal conductivity of building materials, a special coefficient is used. Using this indicator, you can quite simply calculate the necessary thermal insulation for all parts of the house (walls, roof, ceilings, floor). The higher the thermal conductivity of building materials, the greater the intensity of heat loss. Thus, to build a warm house, it is better to use materials with a lower indicator of this value.

The thermal conductivity coefficient of building materials, like any other substances (liquid, solid or gaseous), is denoted by the Greek letter λ. Its unit is W/(m*°C). In this case, the calculation is carried out for one square meter of a wall one meter thick. The temperature difference here is taken as 1°. In almost any building guide there is a table of thermal conductivity of building materials, in which you can see the value of this coefficient for various blocks, bricks, concrete mixtures, wood species and other materials.

Determination of heat loss

There are always heat losses in any building, but depending on the material, they can change their value. On average, heat loss occurs through:

- Roof (from 15% to 25%).

- Walls (from 15% to 35%).

- Windows (from 5% to 15%).

- Door (from 5% to 20%).

- Gender (from 10% to 20%).

To determine heat loss, a special thermal imager is used, which determines the most problematic areas. They are highlighted in red. Less heat loss occurs in the yellow zones, then in the green ones. Areas with the least heat loss are highlighted in blue. And the determination of the thermal conductivity of building materials should be carried out in special laboratories, as evidenced by the quality certificate attached to the product.

Example of heat loss calculation

If we take, for example, a wall made of a material with a thermal conductivity coefficient of 1, then with a temperature difference of 1 ° on both sides of this wall, the heat loss will be 1 W. If the wall thickness is taken not 1 meter, but 10 cm, then the losses will be already 10 watts. If the temperature difference is 10°, then the heat loss will also be 10 W.

Let us now consider, using a specific example, the calculation of the heat loss of an entire building. We take its height 6 meters (8 with a skate), width - 10 meters, and length - 15 meters. For simplicity of calculations, we take 10 windows with an area of 1 m 2. The indoor temperature will be considered equal to 25°C, and outside -15°C. Calculate the area of all surfaces through which heat loss occurs:

- Windows - 10 m 2.

- Floor - 150 m2.

- Walls - 300 m 2.

- Roof (with slopes on the long side) - 160 m 2.

The formula for the thermal conductivity of building materials allows you to calculate the coefficients for all parts of the building. But it is easier to use ready-made data from the directory. There is a table of thermal conductivity of building materials. Consider each element separately and determine its thermal resistance. It is calculated by the formula R = d/λ, where d is the thickness of the material, and λ is its thermal conductivity.

Floor - 10 cm concrete (R=0.058 (m 2 *°C)/W) and 10 cm mineral wool (R=2.8 (m 2 *°C)/W). Now add these two numbers. Thus, the thermal resistance of the floor is 2.858 (m 2 * °C) / W.

Similarly, walls, windows and roofs are considered. Material - cellular concrete (aerated concrete), thickness 30 cm. In this case, R = 3.75 (m 2 * ° C) / W. Thermal resistance of the formation window - 0.4 (m 2 *°C)/W.

The following formula allows you to find out the loss of thermal energy.

Q = S * T / R, where S is the surface area, T is the temperature difference between outside and inside (40°C). Calculate the heat loss for each element:

- For the roof: Q \u003d 160 * 40 / 2.8 \u003d 2.3 kW.

- For walls: Q \u003d 300 * 40 / 3.75 \u003d 3.2 kW.

- For windows: Q \u003d 10 * 40 / 0.4 \u003d 1 kW.

- For the floor: Q \u003d 150 * 40 / 2.858 \u003d 2.1 kW.

Further, all these indicators are summarized. Thus, for this cottage, the heat loss will be 8.6 kW. And to maintain the optimum temperature, boiler equipment with a capacity of at least 10 kW is required.

Materials for external walls

Today, there are many wall building materials. But building blocks, bricks and wood are still the most popular in private housing construction. The main differences are the density and thermal conductivity of building materials. Comparison makes it possible to choose the golden mean in the density / thermal conductivity ratio. The higher the density of the material, the higher its bearing capacity, and hence the strength of the structure as a whole. But at the same time, its thermal resistance is lower, and as a result, energy costs are higher. On the other hand, the higher the thermal resistance, the lower the density of the material. Lower density generally implies a porous structure.

To weigh the pros and cons, you need to know the density of the material and its coefficient of thermal conductivity. The following table of thermal conductivity of building materials for walls gives the value of this coefficient and its density.

Material | Thermal conductivity, W/(m*°C) | Density, t / m 3 |

Reinforced concrete | ||

Expanded clay blocks | ||

ceramic brick | ||

silicate brick | ||

Aerated concrete blocks | ||

Wall insulation

With insufficient thermal resistance of external walls, various heaters can be used. Since the thermal conductivity values of building materials for insulation can have a very low indicator, most often a thickness of 5-10 cm will be enough to create a comfortable temperature and microclimate in the premises. Materials such as mineral wool, polystyrene foam, polystyrene foam, polyurethane foam and foam glass have been widely used today.

The following table of thermal conductivity of building materials used for insulation of external walls gives the value of the coefficient λ.

Features of the use of wall insulation

The use of insulation for external walls has some limitations. This is primarily due to such a parameter as vapor permeability. If the wall is made of a porous material, such as aerated concrete, foam concrete or expanded clay concrete, then it is better to use mineral wool, since this parameter is almost the same for them. The use of expanded polystyrene, polyurethane foam or foam glass is possible only if there is a special ventilation gap between the wall and the insulation. For a tree, this is also critical. But for brick walls, this parameter is not so critical.

Warm roof

Roof insulation helps to avoid unnecessary cost overruns when heating a house. For this, all types of heaters, both sheet format and sprayed (polyurethane foam), can be used. In this case, one should not forget about vapor barrier and waterproofing. This is very important, since wet insulation (mineral wool) loses its thermal resistance properties. If the roof is not insulated, then it is necessary to thoroughly insulate the ceiling between the attic and the top floor.

Floor

Floor insulation is a very important step. In this case, it is also necessary to apply vapor barrier and waterproofing. As a heater, a denser material is used. It, accordingly, has a higher coefficient of thermal conductivity than roofing. An additional measure for floor insulation can be a basement. The presence of an air gap allows you to increase the thermal protection of the house. And the equipment of the underfloor heating system (water or electric) provides an additional source of heat.

Conclusion

During the construction and finishing of the facade, it is necessary to be guided by accurate calculations of heat losses and take into account the parameters of the materials used (thermal conductivity, vapor permeability and density).