When installing the front door to an apartment, you need to remember two popular sayings: “ greeted by their clothes..." And " It's the retinue that makes the king" What is this for? Upon entering the premises, the guest forms his first impressions of the owners and the accommodation based on the doors. Therefore, they should look presentable, emphasizing the wealth in the house, harmonize with the decoration of the hallway and, at the same time, provide reliable protection from uninvited visitors.

However, this effect cannot be achieved without work on constructing slopes both outside and inside. They are the same previously mentioned retinue that turns even the most ordinary door into the most important element of the apartment’s interior. If anyone has any doubts, they can look at the photo below, which shows a doorway without finishing door slopes.

Why are slopes needed?

There is always a part of the unfinished wall near the installed entrance door. Along its plane from the side landing and apartments are installed with platbands. Slopes are placed on the front part of the doorway. They are needed for several reasons:

- give the door an aesthetically finished look;

- isolate the hallway from the penetration of noise and cold from the entrance;

- ensure a harmonious transition from the front door to the inner surface of the wall;

- hide the mounting elements of the door frame from intruders;

- Seal recesses, cracks, and gaps in the doorway.

When installed

Installation of slopes on the front door is carried out:

- when replacing a door block. Carry out installation new door It won’t be possible without damaging the nearby walls, especially since the installation recommendations directly mention the need to remove old slopes;

- damage to the material from which the slope is made: cracks, shedding, deep scratches, etc. appear. Defects can appear both as a result of mechanical impact and during operation of the door due to microvibrations;

- changing the interior of the hallway. Finishing the slopes of the entrance door from the inside with your own hands is also carried out with a new corridor design, when the doorway begins to fall out of general style. What slope affects general view premises, began to pay attention only recently;

- the appearance of mold or mildew. Quite an unusual reason, but one that appears with enviable regularity. It is almost impossible to get rid of such a scourge without replacing the slopes. Treatment with antiseptics does not help, since the problem is hidden inside the finishing materials.

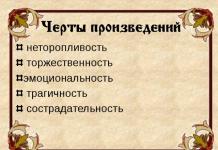

Options for finishing entrance door slopes

The options for finishing the jambs can be very different, unusual, but harmoniously fitting into the design of the apartment.

Plaster

One of the most conservative methods of finishing slopes is plastering. It was first used several centuries ago and immediately became the undisputed leader. With the advent of new finishing materials, the popularity of plastered slopes has fallen sharply. The method has many advantages:

- no power tools are used in the technological process;

- lower finishing cost compared to alternative options;

- high strength - at the same time strengthens the ends of the walls in the doorway;

- insulates the technological gap;

- easy to clean from dirt;

- tolerates fluctuations in temperature and humidity without consequences;

- long service life.

Reverse side of the process:

- the work is labor-intensive;

- a lot of dust and dirt;

- plasterer skills required;

- it takes several days for the solution to gain strength;

- not the most attractive look - you can only paint or wallpaper it.

The last point is debatable. The appearance of reflective decorative film with a 3D effect largely eliminates the problem. In addition, you can use decorative plaster, which is not cheap in any sense.

Drywall

Finishing slopes with plasterboard leads by a huge margin among budget options. And this is not surprising, since the method has many positive aspects:

- low cost of finishing;

- high heat and sound insulation;

- environmentally friendly materials;

- simple installation technology accessible to novice builders;

- GCR can cover openings of any shape;

- long period of operation.

Experts include the following disadvantages:

- poor resistance to water - if the apartment is flooded, in 90 cases out of 100 you will have to change the slopes. They will certainly draw in moisture from below, even if moisture-resistant types of drywall are installed;

- necessity finishing(priming, puttying, painting, wallpapering, decorative films);

- low strength.

The last point can and should also be argued. There are several ways to increase the strength of drywall sheets several times:

- plant it on solid glue, without the formation of voids;

- buy gypsum plasterboard with a thickness of 12.5 mm (wall);

- When installing the sheathing, do not allow distances between the profiles of more than 20 cm.

Tree

Another the old way finishing of slopes - lining them with natural wood. For many, strangely, this seems to be a manifestation of provincialism.

But expensive wood species with their capabilities artificial aging, in several ways, make it possible to obtain a very beautiful, rich-looking coating with a very long service life, both for metal entrance doors and for wooden ones. All minor damage can be restored. A few more advantages:

- with their help, almost perfect insulation of the space between the door frame and the opening wall is carried out;

- environmentally friendly material;

- You can buy it in a store, or you can make slopes for the front door with your own hands, using the most original design ideas in practice.

In apartments, this method is rarely found due to its high cost, unlike villas and cottages, where it comes first.

Laminated MDF panels

Slopes made of laminated MDF panels are gaining popularity. Accessories made from this material are especially in demand.

For reference: you can seal the jambs with non-laminated MDF boards, which is much cheaper. The only problem that arises is: how to finish the slopes of the front door inside the apartment - paint or paste over it.

Using MDF panels for arranging slopes has many advantages. They:

- withstand moderate impacts without breaking. When bringing heavy and bulky pieces of furniture into the apartment, the risk of damage is reduced to zero;

- are issued in various designs by design (relief, color scheme, imitation valuable species wood, etc.), which makes it easy to fit into any interior, from classic to high-tech;

- easy to install by one person;

- have good noise and heat insulation properties;

- can be installed with both wooden and metal doors.

There are few disadvantages, but they are significant:

- the panels are very expensive, second only to wood, as well as natural and artificial stone;

- sharp objects leave scratches;

- constant care is required - accumulated dirt is difficult, and often almost impossible, to wash off;

- cannot be installed in rooms with high air humidity, which, however, has nothing to do with apartments.

PVC panels

Attempts to transfer the experience of installing slopes to plastic windows from polyvinyl chloride panels on entrance doors does not give the expected result, despite simple installation, varied design and low cost of PVC. Here are several reasons:

- thin material comes into disharmony with the door material, although if you try hard, you can choose acceptable types of panels;

- easily deformed and damaged - there is no gentle operating mode, like on windows;

- does not hold geometry well on deep slopes.

Sandwich panel

The slope fabric of sandwich panels is made of plastic. But it has a significant difference from slopes made of PVC panels: the interior is not hollow with stiffening ribs, but is filled with polyurethane sealant. On sale you can find material with a thickness of 10, 24, 32 and 40 mm and a width of up to 1.5 m.

Among the undoubted advantages:

- beautiful appearance;

- easy care - the most undemanding material in this regard;

- not afraid high humidity And sharp changes temperature;

- simple installation technology - all work is performed in one step;

- no finishing required;

- allows you to finish wide slope, up to 1.5 m, one sheet;

- has absolutely flat geometry.

High-quality panels have the same disadvantages during operation as PVC panels: they are scratched and difficult to wash. Inexpensive sandwich panels turn yellow over time and also crack when mechanical impact(beats).

Natural and artificial stone

Fashion is a capricious lady. Either he comes without asking, then he leaves. This fully applies to slopes made of natural and artificial stone. They were very popular at the end of the last century, but then faded away. Now the fashion for them is returning. They buy not only inexpensive, sandstone-like stone, but also natural, very expensive marble and granite.

The stone has many advantages:

- there is no need to level the surface of the jamb;

- You can do all the tiling work yourself - the technology is similar to laying tiles;

- the material matches any interior;

- stones have unique designs, shades and textures;

- not afraid of water, frost and fire;

- safe for the health of apartment owners;

- durable - difficult to damage;

- has a long service life, exceeding the service life of the doors.

Among the disadvantages:

- Very high price for most types of stone, including artificially created ones;

- requires masterly work when finishing walls at the border of two materials: slope stone and wall material.

If finances allow and everything is done correctly, according to the instructions, then the stone slopes look fantastically beautiful. This is the case when the price matches the quality.

We have reviewed basic options finishes that are quite common. In practice, many other finishing materials are used ( laminated chipboard, ceramic tiles, parquet, one-sided sandwich panels, etc.).

There is no point in considering them separately - they are derivatives of those considered (laminated chipboard is similar in installation technology and characteristics to MDF panels, tiles with natural stone, one-sided sandwich panels with double-sided ones, etc.). There are also rarely used materials: laminate and lining.

Lining

Any wood material has undoubted advantages. In the case of lining for slopes, experts and designers talk more about the disadvantages:

- difficult to fit into the interior;

- making small slopes is problematic;

- is capricious about changes in humidity;

- treatment with antiseptics and fire-fighting impregnations is required;

- high price, approximately equal to MDF and slightly lower than natural solid wood.

As a result, experts advise that in such cases it is better to spend a little more money, but make a choice in favor of natural wood.

Another option for finishing slopes “for an amateur” is laminate. He has:

- sufficiently high strength;

- large selection colors and textures, which makes it easy to choose the necessary material for the design of the hallway;

- good thermal insulation properties;

- easy care.

Among the disadvantages:

- good conductor of noise;

- afraid of changes in both temperature and moisture;

- service life does not exceed 15 years - one of the lowest indicators among all materials used for sealing jambs.

Instructions for finishing slopes with your own hands

All technologies for constructing slopes can be divided into three basic types, which are found with variations in everyday practice.

Materials and tools

1. Plastering using a cement-sand mixture. This is the cheapest, but at the same time labor-intensive method. To work you will need:

- cement with sand or dry cement mixtures;

- deep penetration primer;

- putty;

- fiberglass or serpyanka;

- metal perforated corner to strengthen the outer corner;

- finishing finishing materials (paint, wallpaper or decorative film);

- masking tape to protect the door frame;

- short rule;

- level;

- trowel;

- paint brush (roller) for priming the wall;

- primer tray;

- container for stirring the solution;

- electric drill with a mixer attachment for mixing the solution;

- set of spatulas;

- grater;

- fine sandpaper or paint mesh.

2. Gluing finishing materials to the wall using various adhesive mixtures. This finishing method is more expensive, but simpler and shorter in duration than the plastering process. In addition, it provides huge selection design solutions when decorating the interior of the hallway and front door. To work you will need:

- finishing materials (plasterboard, PVC panels, chipboard, MDF, natural wood boards, etc.);

- adhesive mixture (specialized glue, putty, polyurethane foam, dry gypsum plaster);

- primer;

- antiseptic solutions;

- level;

- set of spatulas;

- paint brush;

- primer cuvette;

- construction pencil;

- roulette;

- a long, flat object for drawing a cutting line on panels or plasterboard;

- cutting tool (drywall knife, panel saw or grinder with cutting wheel);

- a container for stirring the solution or glue, if it was purchased dry;

- construction mixer or electric drill with an attachment.

When working with drywall, you will need a perforated corner to strengthen the corners and a sickle to seal the joints of the upper slope with the side ones.

3. Fastening the slopes to the sheathing. The method is only available if there is a significant gap between the doorway jamb and the frame. If it is 2-2.5 cm, then the only option is glue.

The method has many advantages: quick installation, a convenient opportunity to hide various cables, the ability to make an opening with a significant “dawn” and install hidden lamps to illuminate the internal doorway. Neither consumers nor experts note any disadvantages of the method.

During the work you will need:

- facing materials;

- block for the frame - made of wood, metal or metal profile;

- dowels with self-tapping screws for attaching the sheathing to the wall;

- self-tapping screws or “liquid nails”;

- antiseptic;

- hammer drill with a set of drills;

- screwdriver or Phillips screwdriver;

- construction knife for drywall;

- grinder for cutting metal;

- wood saw;

- level;

- plumb line;

- roulette.

When working with gypsum boards, you will additionally need the materials listed in paragraph 2.

With everything you need at hand, you can get to work. Let's look at how to make front door slopes with your own hands from various materials.

Plastering

The work is performed step by step in the following order:

- The ends of the walls are prepared for the application of cement-sand mortar: the old plaster and remaining fasteners are removed, the surface is cleaned of dirt, loose pieces of brick and exfoliated concrete. The foam protruding from under the box is cut off;

- The door jambs are primed twice. The second layer is applied after the first has dried. The beam above the door is processed with Benonokontakt, also twice;

- The outer corners are reinforced with a perforated corner, which will also serve as a beacon when applying the solution. It is secured with putty;

- a second beacon, also from a plaster corner, is placed near the door on self-tapping screws;

- the frame and door leaf are covered with plastic film, which is secured with masking tape;

- CPS is diluted in a 1 to 1 ratio of sand and cement to apply the “spray”;

- spray is applied;

- After the first layer has dried, the second layer is applied - primer. The solution for it is prepared according to the instructions, with the addition of fiber to reduce shrinkage and prevent cracking. The soil layer should not exceed 3 cm - otherwise the procedure must be repeated;

- after the soil has gained strength, but has not completely dried, the finishing operation is carried out - a thin, 1-2 mm layer of liquid mortar is applied, or in plasterer's parlance - a covering, which allows you to obtain a smooth surface. If the slopes are covered with wallpaper or decorative film, this is enough. The surface of the plaster is puttied under the paint.

Plastering technology is discussed in detail in the work: "".

Drywall

The technological process for installing plasterboard slopes completely coincides with the technology for installing panel slopes made of MDF and chipboard. Both can be mounted with glue or on a frame.

Therefore, using the example of gypsum plasterboard, we will show a step-by-step algorithm for attaching it to glue, and MDF to the lathing.

When working with glue you must:

- clean the surface of the walls from dust and dirt, remove excess mounting foam, and then treat with an antiseptic and primer (or a primer with an antiseptic already added at production);

- draw slope lines on the floor and along the door frame with a pencil;

Attention: if you plan to run drywall behind the profile of the box, then the width of the sheet should be 1 cm larger, the slope line is drawn only on the floor, and a groove is cut in the polyurethane foam for the slope.

- measure the slopes, then cut the gypsum board sheets to size;

- glue the upper slope, for which apply the adhesive mass in piles (when using polyurethane foam, it is applied with a thin snake);

- for better fixation of the slope, two or three stops are installed;

- After the glue has set, the side slopes are attached, the joints are sealed with sickle tape and putty. After the putty has dried, they are sanded with fine sandpaper, after which the surface of the drywall is puttied;

- After the putty has completely dried, the slopes are painted or covered with decorative film.

You can also use a combined method: a wooden block is attached near the box. The gypsum board is attached to it with self-tapping screws. From the side of the apartment, the sheet is taken with glue. The only thing you need to remember is to lay insulation between the wall and the plasterboard on the side of the door, 2/3 of the width of the slope.

The process is described in detail in the work "".

MDF panels

The frame method is used when the technological gap is more than 3 cm. For frame elements under plasterboard, you can use all types of timber, including metal profile, for panels only wood.

The work is performed in the following sequence:

- the tree is treated with an antiseptic and then cut to size;

- using self-tapping dowels, the block is vertically attached to the opening close to the frame and flush with the edge of the wall on the other side;

- horizontal strips are attached if the panels will be fastened with liquid nails (when fastening with self-tapping screws, two vertical strips are sufficient);

- all cells are filled with insulation - the procedure is mandatory;

- the dimensions of the slopes are measured;

- the panel is cut in accordance with the obtained measurement results;

- Using liquid nails or self-tapping screws, the MDF is attached to the sheathing.

PVC panels

A more or less erudite apartment owner knows that plastic panels are mounted using special profiles fixed to the wall. These stripes are always visible and taken for granted. But not in the case of slopes.

Here the panels can be attached to a special frame (they will be positioned horizontally) or glued. However, there is a limitation here: the width of the slope cannot exceed the width of the panel, because no connecting seams are provided.

Operations are performed in the following sequence:

- The wall surface is being prepared. If the height differences are more than 2 mm per meter, the surface is plastered or puttyed. The type of work depends on the curvature of the surface: a large difference is eliminated with plaster, up to 1 cm - with putty;

- The walls are measured, after which the slopes are cut. As in the case of drywall, when the panel is launched behind the door frame, its width increases by 1 cm. It is necessary to cut from the tenon side;

- to increase adhesion (adhesion), the wall is treated with a primer, and the plastic with back side sandpaper;

- the adhesive mass is applied around the perimeter with a continuous tape, and inside the panel - with a snake;

- the slope is pressed against the wall and immediately comes off. In this way, glue is applied to the wall, which is absorbed into the pores and sets. After 5-7 minutes, the slope fragment is completely glued.

Laminate is available for flooring. However, Russian craftsmen found another use for it: lining slopes. The process completely repeats the technology of constructing slopes from polyvinyl chloride panels. The slats can be glued (only polyurethane foam is used) or installed in a pre-installed frame.

Artificial stone

When working with stone, artificial or natural, the main thing is to draw up a diagram of the location of each element, draw it in real scale on the slope and wall, if it comes in the form of a platband, and also lay it out on the floor.

The stone is secured with glue or a special mixture using a seamless method. Seams are present when facing slopes ceramic tiles. The wall should not have differences exceeding 1 cm. If more, then the DSP is leveled.

Lining

The lining is attached to the wooden sheathing with self-tapping screws. To prevent the material from cracking, holes for self-tapping screws are pre-drilled with a drill. The diameter of the drill should be 1-2 cm less than the cross-section of the screws. Hats can be sunk and sealed special composition, or they can remain visible. It's a matter of the owner's taste.

Conclusion

The choice of slopes has become a headache for the owners due to the huge number possible options. Can be used:

- plaster, including decorative;

- drywall;

- natural wood;

- laminated MDF and chipboards;

- PVC panels;

- artificial and natural stone;

- lining;

- tile;

- laminate;

- Sandwich panels are single- and double-sided.

For fastening the facing material it is used glue method and frame. The main thing when choosing is to fit the slopes into the interior of the apartment.

Video on the topic

The front door forms the first impression of your home, so it must be both reliable, aesthetically attractive, and well-installed. At the same time, the full installation cycle includes stages that are often neglected out of ignorance. These include finishing the slopes of the front door, which is necessary not only for the beauty of the structure, but also for quality operation for a long time.

What is it?

As practice shows, slopes are often confused with platbands, since platbands are their external, decorative part. By themselves, they serve only an aesthetic function. But the slopes are involved in ensuring tightness, sound insulation and thermal insulation, and increase the resistance of the front door to burglary.

By definition, slopes are the internal and external parts of the wall that “surround” the door frame. Slopes are also considered to be the left, right and top sides of the doorway in which a door is supposed to be installed, but is not installed. Not for all types doorways there are slopes on both sides. Sometimes they may be absent from outside, but from the inside there is in most cases.

The structure of the door slope is quite complex. High-quality slopes are not just parts of the wall protruding beyond the frame, they are optimal combination materials, each of which is necessary to perform a separate function. Materials are applied according to the “layer cake” principle.

The first layer is rough. To create it we use:

- Primer. It is applied to the cleaned wall surface as a pre-finishing coating. Primers are necessary to level out the absorbent properties of the surface, as well as for improved “adhesion” the following materials with her.

- Foam plastic. This layer is not required, but is desirable in cases where the wall needs to be insulated. This is true for apartments on the lower floors and private houses.

- Plaster. The primer improves the adhesion of materials to the wall, but does not level the surface. Plastering is necessary to fill irregularities, depressions or cracks in the wall. This process is the most labor-intensive and time-consuming and requires certain skills and abilities.

As an alternative, you can use a material that is easier to use - drywall. This option allows you to quickly prepare the surface for further types of finishing, but it is not suitable in all cases. In the Russian climate, it is more often used for interior decoration or in warm regions with high humidity.

- Reinforcing corners. These thin but strong metal corners are necessary to protect the plaster on the corners of the slopes. The front door is a place with a lot of traffic, and the corners of the opening are often touched, hit, or scratched. Without proper protection, plastered corners will quickly begin to crumble and lose their presentable appearance.

- Putty. With its help, all defects are smoothed out after installing the corners. Putty compounds are applied in an uneven layer, so after they dry, the surfaces of the slopes need to be cleaned. For this purpose, fine-grained sheets of sandpaper or low-power sanders are used. Furniture is also suitable if it reaches hard-to-reach places.

- Re-priming before application decorative covering.

The second layer is finishing, or front. Strict rules There is no choice of finishing options. It depends only on individual preferences and financial capabilities. The only condition that must be met is to choose a finish that is harmoniously combined with the door leaf and wall decoration.

How to decorate the inside of the apartment?

Slopes protrude from both the outside and inside of the door. Accordingly, there are two types of finishing - external and internal. The external one, as a rule, is less variable. The main focus is on design door leaf, and the slopes echo either it or the wall decoration. More often these are practical and concise options that do not attract attention.

Inside an apartment or house, the finishing of slopes becomes part of the interior. It plays a decorative role, so the types of materials and methods of decoration are of great importance.

Finishing with facing materials from the inside can be of the following types:

- Plastering the surface.

- Gluing finishing materials.

- Frame sheathing.

- Coloring.

For the first type, plaster, primer, water and that’s it. necessary tools. This process takes a lot of time, but makes it possible to putty all the unevenness, insulate the structure, and make a layer of the required thickness. Decor from other materials is often applied on top of plaster, but in itself it is already considered finished finishing, therefore refers to basic repair techniques.

“Clean” slopes after plastering can be easily painted in any color. suitable color, while they are polished until smooth or, on the contrary, left in relief.

The following materials can be used for decoration:

- Ceramic tiles (tiles). It is characterized by rigidity, moisture resistance, hygiene, low price and wide range colors, shapes and textures. The ceramic surface is easy to care for, but the tiles can crack or break off due to mechanical damage, and during the replacement process you will have to work hard to avoid damaging neighboring elements.

The undeniable advantage of tiles is the many possibilities for design. The mosaic looks especially original. It can be made from solid tiles small size or from small pieces. Mosaic fragments are obtained artificially from tiles by cutting them into pieces required sizes, and handymen can use broken tiles, which are considered unsuitable, for this purpose. The result is original and unique, and the cost of materials is minimal.

Any construction adhesive is suitable for gluing tiles. Apply it evenly with a plastic spatula, and the seams are rubbed down after a day with a rubber spatula.

- Porcelain tiles. This material is often confused with ceramic tiles. Indeed, in the manufacture of porcelain stoneware, the same composition of the substance is used as for tiles, but the production technology is very different. As a result, the tile has a colored coating only on top and becomes unsightly when chipped, while porcelain stoneware has a uniform color throughout the entire thickness of the slab and damage to it is less noticeable. Also, its structure is denser, so it is more resistant to damage. In addition to being moisture-resistant, environmentally friendly and durable, it is also frost-resistant. In appearance, this material is more noble, but the color spectrum is very limited and its cost is higher than for ceramic tiles.

- Decorative stone. It is truly an interior decoration, although it is not always appropriate and is expensive. The peculiarity of this material is that it can be used to imitate real masonry. It has an attractive appearance, adds zest to the interior, and is impeccable in terms of performance. The stone does not chip, is easy to clean, and is a durable and safe material. To fix it on the surface of the slopes, construction glue is used, but there are also ways to “cover” the surface with decorative stone.

- Wallpaper. Wallpapering is perhaps the easiest to perform and budget method decor. It is most convenient to stick wallpaper on slopes with plasterboard trim. The glue will “grab” on the plaster, but the surface will have to be leveled especially carefully so that “bubbles” do not form on the wallpaper.

Considering the large traffic at the entrance to the room, it is better to choose wallpaper that is washable and in dark colors.

The openings are sheathed using the following materials:

- MDF. Panels made from fine particles are very popular in all types of finishing. They are universal for any interior, look aesthetically pleasing and have a number of other advantages: durability, variety of coatings that imitate different breeds wood, ease of installation, improved sound insulation and thermal insulation in the room.

- Chipboard. Finishing chipboard is the easiest way to tidy up part of the doorway if, after installing the door, it looks bad. In this case, you won’t even need a primer or putty. It is enough to sheathe the surface with even sheets that match the tone and pattern of the door leaf.

- Laminate. Laminate siding is widely used for two reasons: it is inexpensive and looks much more solid than non-laminated materials made from reclaimed wood. The basis of the coating is fiberboard or chipboard (therefore, “sewing up the slopes with chipboard” means the same as laminate), and on top it is decorated with a polymer film. The most common option is stylization to look like precious wood, but there are also other shades in a dark and light palette. It has a number of advantages inherent in all wood-based materials, as well as certain disadvantages. Thus, among the most common disadvantages are hydrophobia (the material can delaminate and swell from water) and average wear resistance.

- Extras. Covering internal slopes with additional wood is more of a necessity than a decorative element. Extensions are narrow plates made of different materials, which are necessary for masking slopes whose width is more than 7 cm. As a rule, they are used when the door and slopes must be sheathed in the same style and with the same materials.

- Drywall. The choice of drywall is relevant when you need a high-quality and budget-friendly result that is convenient to work with your own hands. In addition, plasterboard perfectly levels the surface for decorative finishing in the future and enhances the insulating properties of the front door.

- Plastic. No matter how versatile MDF, laminate and similar materials are, plastic door requires decoration of the adjacent space with PVC-based materials. The use of sandwich panels is especially popular. They have variable widths - from 5 to 150 cm, which allows you to cover each side of the slope with just one piece.

Performance characteristics the products are also at their best: aesthetic appearance that lasts for a long time, biostability, resistance to humidity and temperature changes, the presence of air sections inside the panels that ensure the preservation of heat in the house, hygiene.

Modern plastic manufacturing technologies guarantee it environmental safety and non-toxic.

- Siding. The characteristics of siding panels are very diverse, because they are made from various materials - from aluminum to plastic. Aluminum, copper, wood, basement and vinyl siding are used for finishing slopes.

The best option is vinyl. It is a monolithic PVC panel, main feature which is flexibility. It can be given absolutely any shape, ideally adjusted to corners without joints or gaps. Vinyl is not subject to rotting and burning, is not afraid of water, does not crack due to temperature changes, is easily cleaned of dirt, and is not of interest to fungi and insects. The front side of the panels can be plain, with a pattern, stylized as stone, wood or brick.

Frame cladding implies preliminary installation metal (aluminum) or wooden profile along the perimeter of the doorway, to which any material is subsequently attached using self-tapping screws. This method is considered the most labor-intensive, since before attaching the profile it is necessary to prime and level the slopes with cement mortar.

Some types of materials (plaster, chipboard, MDF and plasterboard without a decorative coating) need to be painted to blend harmoniously with the interior of the room.

For these purposes the following are used:

- Acrylic paints. They are convenient to add to the composition for plastering the surface. This simultaneously reduces the number of finishing steps, since surface leveling and painting occur simultaneously, and makes damage less noticeable, since the entire layer of plaster is painted over;

- Water-based. Such paints can be added to the plaster or painted on the wall over the leveling layer. When using acrylic and water-based paints, it is important to remember that they must be primed on top, otherwise the surface will get dirty. You can dilute the primer yourself using PVA and water in a ratio of 1:5;

- Latex based paints can also be used in two ways, but their advantage is that a final primer is not needed. Latex compounds are not hydrophobic and are easy to clean;

- Alkyd and oil. These compounds are indispensable in conditions of high humidity. They are more wear-resistant and dense, but they are more difficult to work with due to thick consistency and toxic odor.

How to insulate?

Thermal insulation and sound insulation are the functions of the front door, which partly depend on the type of finishing of the slopes. To insulate a room, you don’t have to run to the store to buy a heater. First you need to take care of maximum tightness, and you should start with the front door. This will not only increase the level of comfort in the house, but will also help in the future to save money on utility bills.

Insulation of slopes from the inside is carried out step by step:

- Selection of materials. The leading positions are occupied by sandwich panels, plasterboard, polystyrene foam, mineral wool, and polystyrene. Experts recommend choosing polystyrene, which is superior to other materials in many respects. At a relatively low cost, it is capable of thermoforming and vacuum forming, is resistant to moisture and chemical treatment, does not smell, environmentally friendly, can be different types processing. If there is no polystyrene, it can be replaced with a mineral slab (wool).

- Preparatory work. They include all cleaning measures work surface. It is necessary to cut off the polyurethane foam, remove the old coating, if any, and eliminate irregularities as much as possible. After removal old plaster the surface must be dusted with a vacuum cleaner and a damp sponge.

- Primer and putty. It is necessary to prime the surface of the slopes. This will ensure high-quality adhesion of subsequent layers to the wall, and also minimize the likelihood of fungi and bacteria appearing on the wall. Any deep soil will be suitable for this purpose. After applying it, the surface should be allowed to dry for 3-4 hours. Repeated application of primer to plaster is acceptable.

It is not necessary to putty the slopes, but it is advisable, especially if the surface has many defects, chips and depressions. All these minor gaps greatly affect the insulation properties of the front door.

- Installation of insulation. At this stage it is the turn of the insulating material. Polystyrene boards and mineral wool glued with specialized adhesives. The glue is applied to the slab with a spatula, then it is applied to the surface of the slope and adjusted to the level. The drying time for the glue is at least 24 hours. After this, the plates are secured with dowels.

- Fastening the insulation. Ideally, polystyrene or mineral boards should be covered with plastic mesh for interior finishing work. This will protect against cracks and unevenness in the future. The glue is applied to the mesh in layers, each layer dries to hardness in 6-12 hours.

- Leveling the surface. Here again you will need putty. You can level the surface with up to 2-3 layers. Then you need to let it dry for the time indicated in the instructions on the container, and treat it with fine-grained sandpaper. The grain number on the sandpaper package is at least 100.

- Final finishing. Includes the application of a colorless primer followed by painting or any other method of decoration.

It is important to consider that finishing materials have not only their own characteristics that affect thermal insulation, but also their weight. It is necessary to calculate in advance whether the insulated slope, for example, will withstand the weight of porcelain stoneware or lining, or whether it is worth giving preference to paint, plastic, or wallpaper.

How to make a slope on the front door from MDF panels with your own hands, watch the next video.

Colors

Slopes are a small detail that can either support the style in the interior or completely break out of it. An inappropriate color of decoration will become an element that violates the integrity of the overall picture, so it is important to choose the right color in accordance with the design of the door and the decoration of the walls, floor and ceiling in the room.

As a rule, renovations in an apartment affect almost everything. It may also include replacing windows and doors.

In order for the doors to look neat, it is necessary that the finishing of the slopes from the inside of the front door be done with high quality.

Since indoors it is possible to constantly maintain the same temperature regime, then the finishing of the entrance doors from the inside can be done with any finishing material.

For this they often use:

- Plastic panels.

- Siding.

- Plaster.

- Decorative stone.

- Wooden lining.

Decorating the front door with plastic panels

At the moment, plastic panels are very popular. All this is due to their high technical characteristics.

They are quite easy to attach and give a neat look to any surface.

Plastic properties:

- Practicality.

- Durability.

- Easy installation.

- Easy to clean.

- Moisture resistant.

- Not subject to temperature changes.

- Resistant to high temperatures.

- Do not fade in direct sunlight.

But these are all the properties that plastic panels have. In order to fix them on the surface, you will not need to pre-level it, which cannot be said about the application decorative stone in finishing doorways(see Beautiful decoration of doorways with decorative stone).

Installation of plastic panels on the internal slopes of the entrance door

To install PVC panels on the entrance door slopes, you will need some tools and additional materials:

- Wooden bars.

- Self-tapping screws for wood.

- Screwdriver.

- Plastic panels.

- Internal plastic corners.

- External plastic corners.

- Sealant.

- Construction stapler.

- Starting guides.

For reference. Plastic is considered a universal finishing material that can be used in any interior.

So:

- The plastic is attached to the sheathing. Initially, you will need to evaluate the surface; if there are significant irregularities on it, then they are eliminated using a spatula or sandpaper to ensure level mounting lathing on the surface.

- The lathing for mounting plastic panels is made of wooden blocks. Each element is fastened to the other using self-tapping screws and a screwdriver.

Advice. It is best to assemble the sheathing directly on the surface of the slope. Only here it is worth considering the fact that the wall finishing work should be carried out only after finishing the door slopes, since the plastic will protrude several centimeters on the surface (due to the sheathing).

- The lathing is made strictly according to the level, so that plastic panels can then be evenly mounted on it.

- The plastic is also very easy to cut. This can be done using a regular stationery knife or a hacksaw.

- If the slope has a large width, then the plastic panels are fastened together using special locks, which are located at the end of this finishing material.

- As soon as the sheathing is properly fixed to the surface of the slope, it will be possible to begin installing the plastic panels. Initially, a starting strip for installation is attached to the sheathing; it will become the starting line for subsequent actions.

- It is leveled and attached at the top of the slope to the sheathing using self-tapping screws and a screwdriver or a construction stapler.

Advice. It is best to use for such actions construction stapler, since its staples will not hide the place in the very starting strip of plastic.

- After the starting strip for installing plastic is ready, you can insert plastic panels into it. If the plastic matches the dimensions of the slope, then the finishing process will not take much time.

- The panel is inserted into the strip and secured with a stapler. To prevent the staples of such a tool from being visible, you will need to select a color to match the color of the finishing material itself.

Advice. If more than one strip of plastic panels is used in finishing the entrance door slopes, then the joints of such finishing material will need to be treated with a sealant to prevent condensation from collecting on the wall surface.

- Internal corners are attached to the internal corners of the door slope and along its entire perimeter.

- The outer corners will serve as external decor for finishing the slope. They need to be attached after finishing the finishing work on the wall surface, so that they can be used to hide the transition of the finishing material and give it a neat appearance.

Installation of plastic panels is so simple that you can do it yourself. In order to avoid any additional questions about how exactly to attach plastic panels to the surface of the entrance door slopes, you can look detailed video, which shows the entire finishing process.

Finishing the internal slopes of the entrance door with siding

Siding has been used for many years not only for exterior finishing work. It has found very wide application in interior decoration.

Today there is a large selection of materials that come in a variety of colors and sizes. You will only need to choose the best option.

It has the same technical characteristics and can be used not only for interior decoration of entrance door slopes, but also exterior.

Siding and its advantages:

- Durable.

- Large selection of material shades.

- Practical.

- Easy to clean.

- Easy to install.

- Moisture resistant.

- Fire resistant.

- Resistant to temperature changes and climatic conditions.

Advice. Do not use abrasive cleaners to clean siding and plastic, as they can damage the surface of the finishing material. Can be used to clean surfaces plain water and rags.

The surface of these finishing materials is not capable of absorbing dirt and they will be removed from the surface very easily.

To attach the siding you will need:

- Wooden Boerskis.

- Siding.

- Starter strips for attaching siding.

- Self-tapping screws.

- Internal and external corners for finishing slopes.

- Construction stapler.

The process of installing siding on the surface of door slopes is similar to the process of attaching plastic panels. You will also need to first make a wooden sheathing and only then attach the starting strip to it.

But here you will need to take into account the fact that siding can be attached vertically and horizontally, like plastic panels. But it would be more rational to mount the panels along the slope in order to save on finishing materials.

So:

- The siding is fastened to the sheathing with a construction stapler, the staples of which can be matched to the color of the finishing material.

- After such work, the door slopes of the front door look not only neat, but also original, since you can choose not one, but several colors of the finishing material; the photo shows an example of the original finishing. Like plastic panels, siding is also very easy to attach and you can install it yourself, without making a significant effort and without having experience in this field.

Plaster for finishing the internal slopes of the entrance door

The use of plaster in finishing work requires special practical skills. Plaster can be used both inside and outside.

You just need to choose the right type and structure.

There is a very large selection of materials, also with his help. The surfaces are leveled and after finishing they acquire a neat and original appearance. All this is due to the fact that there is diversity in the construction market.

There is decorative plaster that is resistant to moisture and temperature fluctuations.

To finish the slopes of the front door you will need to use:

- Starting plaster.

- Finish plaster.

- Construction level.

- Two spatulas (large and small).

Initially, starting plaster is applied to the surface. It should be applied to the surface in several thin layers.

All this is necessary for more high-quality drying plaster.

So:

- You will first need to assess the condition of the slope surface. If there are significant and visible defects on it, then you will need to use starting plaster until such unevenness disappears under its layers.

After the starting plaster has completely dried, the surface is treated with sandpaper. - Then the finishing plaster is applied to the starting plaster. It helps to hide all the unevenness of the previous layer.

After drying, it should also be sanded. - After all the work, the entrance door slope can be painted or pasted over. Everything will depend on the design of the room.

You can use a layer of decorative plaster, various colors and textures. - In order to qualitatively finish the slopes of the front door using plaster, there are certain instructions that you can carefully watch in the video.

How to decorate the front door from the inside will depend on interior design premises. The price plays a big role in the choice of finishing material.

Cheaper options for finishing slopes are plastic panels and plaster. These finishing materials are practical and easy to use.

Read in 8 minutes.

Listen to the articleInstalling slopes is an important stage in installing the front door. If they are not installed, gaps may remain between the door and the opening, through which frost will penetrate into the house and heat will escape outside. A entrance group will not look aesthetically pleasing.

Methods for finishing slopes

You can trim slopes in different ways:

- Cement and carefully putty;

- Install slopes from a sandwich panel. This inexpensive type finishing. But sandwich panels are fragile and short-lived.

- Install MDF slopes. It is more expensive and at the same time reliable way finishing. MDF slopes are more durable. In addition, they can be matched to the color of the door. Torex produces slopes that fully match the selected door model in color and texture.

You can perform any of these options either independently or with the help of professionals. You can order the installation of MDF slopes from a certified Torex team. In this case we guarantee high quality completed work. Since installing MDF slopes is the most complex and time-consuming, you need to know a number of nuances. If you decide to do this yourself, use our instructions.

What will be needed to install slopes?

To install MDF slopes you will need the following tools:

- 1 – miter saw;

- 2 – roulette;

- 3 – pencil;

- 4 – angle;

- 5 – knife;

- 6 – hammer;

- 7 – masking tape;

- 8 – fastening elements;

- 9 – screwdriver;

- 10 – polyurethane foam;

- 11 – drill.

Stage 1. Control measurement of the opening after door installation

We make accurate measurements of the actual dimensions after installing the door - even if we know the exact factory dimensions. It is necessary to measure the width, height of the vertical and length of the horizontal extension.

Door extensions are decorative strips that cover the walls of the doorway. They are installed if the opening is wider door frame. Most often, MDF panels are used for this.

It is necessary to measure at three points vertically on each side and at two points horizontally (from above).

The additional element must be adjacent to the door frame, so we measure the length along the width of the door.

Stage 2. Setting aside and marking the required dimensions of the extensions

After we have measured required dimensions additions, put them aside on the blanks of additional elements. We make preliminary markings directly on the panel.

Using masking tape, mark future cutting lines.

On one blank for additional elements, you can put two parts - the threshold and the upper part of the additional elements.

In the same way, we set aside the dimensions of the second part, make preliminary markings on the workpiece and glue it with masking tape.

We re-mark the length of the extension directly on the masking tape.

If you do not glue the edge of the additional element with masking tape, chips may appear on it during sawing.

Once again we check the correctness of the markings.

Use a miter angle to mark a cutting line perpendicular to the edge of the panel.

Stage 3. Trimming the extensions to the required sizes

With the help miter saw We cut the blanks for additional elements exactly along the marks.

We saw off the first and then the second horizontal parts of the extension.

We repeat the procedure for the vertical parts.

Stage 4. Assembling the accessory box

Before installation, we assemble the extensions into a solid, rigid box.

Using a drill, we drill holes for self-tapping screws - for fastening from the inside. This is a mandatory step so that when screwing in the screw does not split the MDF panel.

We make several holes at a distance of 10–15 cm from each other.

Stage 5. Installation of the extension box

We install the extension box in the opening. We set it relative to the door so that the gaps between the door and the frame are the same on all sides.

Spacer elements are needed to fix the extension box in the opening. We cut them out of a wooden block. The thickness of the spacer element is selected according to the size of the gap.

A total of 10–12 spacer elements are required. 3-4 pieces for each vertical extension. Top and bottom – 2 pieces each.

Since in the future we will need to install platbands and close the gap, it is important that the spacer element does not protrude beyond the trim and the wall.

In the same way we hammer in all the spacer elements.

Stage 6. Installation of platbands

We attach the trim and mark the required length. The size is set according to the angle of the internal intersection of the horizontal and vertical extensions.

Similarly, we set aside the length of the second casher.

Mark the length according inner corner doborov.

We cut the trim using a miter saw at an angle of 45 degrees.

Polyurethane foam is used to fix the extension box. Gives the structure rigidity and additional sound and heat insulation.

It is important not to overdo it with the volume of foam, so as not to deform the extension.

At the same time, if there is too little foam, the opening will be leaky and not rigid enough.

To remove excess foam, you need to wait for it to cool and cut it off with a knife.

Try to avoid getting polyurethane foam on the boards, walls and flooring.

First we install vertical extensions, then horizontal ones.

We attach the casing to the trim using decorative nails.

To install the trim you will need about 20 decorative nails. They are clogged at a distance of 20–30 cm from each other.

On average, each vertical trim will require 7 decorative nails, and each horizontal trim will require 3–4.

We measure the size of the horizontal platband.

Starting from larger size, we cut at 45 degrees to reduce.

The horizontal casing is fixed to the extension box and the vertical casing.

We press the structure against the door frame and fix it with masking tape until the mounting foam hardens - for 1-2 hours. Exact time depends on the drying time of the foam, which can be found on the packaging.

After this, you can remove the masking tape. Your front door is ready!

Installation of slopes: video

If you have never installed doors and slopes before, we recommend contacting the Torex installation team, who will complete the installation as quickly and efficiently as possible. The results of our professionals' work are guaranteed.

If the slopes are made carelessly, even the most expensive and luxurious entrance doors will look unattractive. Why do we need slopes for entrance doors? First of all, they are used as a beautiful frame, a means of complementing and highlighting the main element - that is, the door itself. In order for you to be able to decide what material to make the slopes from, you must first of all pay attention to the design of the door structure itself, its style and color. After all, it is important that the slopes suit not only the design of the door, but also the overall design of the room.

We also note that the described elements perform not only aesthetic functions - they are also an insulating layer, because they cover the joints between the structure and the walls.

Basic materials for making slopes

To create slopes, you can use a variety of materials, although, as an option, you can bring existing slopes into a “divine form”.

Option one. Plaster

If the door structure is strong and reliable, but does not look very presentable, strengthen the corners and level the slopes using plaster. What is typical is that this is often done not only from the outside staircase, but also in the hallway itself.

Pay attention! The plastered slopes will look quite neat - if you wish, you can additionally paint them in the color of the room or the door trim.

Option two. Drywall

It is advisable to use this material if your slopes are wide due to the fairly thick walls. Thanks to the use of plasterboard, your walls will become warmer, and all existing joints will be securely closed. In addition, the slopes, again, will look very neat.

If you want, you can later paint the drywall or, alternatively, wallpaper it. One of the main advantages of the material is that its installation does not require labor-intensive surface leveling work.

Option three. Natural wood

If the wood matches the door trim, then you can use it for the slopes. It is no secret that wood has always enjoyed considerable popularity and, apparently, will never go out of fashion. The material fits perfectly into almost any interior design, and if necessary, you can easily change the tint of the material using folk/modern means.

In addition, wood can serve you for many years, while maintaining all its decorative and performance properties. Although, as a last resort, you can always paint it to match the color of the hallway.

Option four. Laminated lining

Such lining, made on the basis of chipboard, can be an excellent alternative to natural wood.

Due to the fact that this material is produced in the most different colors and can imitate the texture of various wood species, you can always choose the most suitable option for the decoration of the hallway. However, it is extremely undesirable to use lining when finishing external slopes, since it will simply quickly become unusable there.

Option five. Polyvinyl chloride panels

The next material with which they can be finished is slopes for entrance doors, are ready-made PVC panels. This material is produced in the most various colors, and the sizes of the panels can also be different. The production and sale of this kind of panels are carried out by specialized companies, which employ specialists who also install them (the panels).

This type of slope finishing looks attractive and respectable. The service life of polyvinyl chloride panels is quite long, but it is still advisable to install them on the hallway side, and on the reverse side - options No1 or No2 (they are described above).

Pay attention! If you are completely confident in yourself, you can finish the slopes with ready-made elements yourself.

Although it is worth noting that there is another application option for slopes polymer materials- speech in in this case goes about plastic lining. It also comes in different colors, so you can easily choose the most suitable option for decorating your hallway.

Option six. Chipboard panels

Yes, they are also widely used in the design of slopes. But, as a rule, only for thick walls. Although in fairness, we note that this option has not been very popular in recent years due to the emergence of a huge number of more modern materials, capable of replacing chipboard elements that are so difficult to install.

In any case, if you have a panel lying around suitable sizes, you can easily use it to decorate door slopes from the inside.

Pay attention! There are other materials used in the design of slopes (for example, laminate, installation instructions for which will be given at the end of the article), but only the most common options were discussed above.

What is required to design the slopes yourself?

Before you begin work, you must prepare all the necessary materials and equipment. So, if we are talking about plaster, then you should prepare:

- finishing putty;

- sandpaper (coarse and medium);

- primer;

- serpyanka tape, self-tapping screws and a mounting knife (if plasterboard sheets will be used for finishing);

- the plaster itself;

- iron perforated corner (it will be needed to align the corners);

- level;

- spatulas of different sizes;

- plumb line;

- rule (it is important that it be shortened);

- electric drill with a special mixer attachment;

- container of suitable size for mixing.

If panel materials are used for finishing, then the list of everything needed will look slightly different:

- the panels themselves of the material you have chosen, additional elements required for their installation;

- hammer;

- platbands, decorative corners;

- timber 2x3 or 1.5x3 centimeters (in case slopes for entrance doors will be finished with clapboard);

- screwdriver;

- dowels;

- electric jigsaw (as an option, you can use a simple hacksaw);

- hammer drill (for walls made of concrete);

- measuring instruments;

- self-tapping screws with which the panels will be attached.

When all the required equipment and materials are ready, you can begin preparatory work and directly finishing. Let's take a closer look at each of the possible options.

How to properly finish slopes for entrance doors - detailed step-by-step instructions

First, let's get acquainted with some features of the finishing process.

- Most of the materials described above are installed using the same technology.

- Some technologies are quite simple, and therefore the work can be done independently.

- The rest, on the contrary, can only be used if you have certain skills in working with materials and equipment.

In any case, the finishing work itself should begin only after the door structure has been installed and all joints between it and the wall have been sealed. We will also add that the previous coating should be removed from the slopes in advance, and the peeling areas should also be repaired. After carrying out all these activities, you can proceed directly to finishing, using one of the technologies presented below.

Option one. Plastering door slopes

If you decide to use for finishing plaster mixture, then proceed in accordance with the instructions.

Step one. First, prime the previously cleaned surfaces (if possible, then in two layers, but the second layer should be applied only after the first has completely dried).

Step two. After this, determine how smooth the slope angles are. In case of deviations from the norm in mandatory Take this point into account when installing reinforcing corners. Using the latter, you can easily align corners that deviate slightly from the vertical.

Step three. Next, using a level and plumb line, align the perforated metal corners in the corners. Ideally, they should be immediately attached to finishing putty (the latter can be purchased at finished form). Apply it using a spatula to the corners of the slopes - the mixture is necessary not only for attaching the corners, but also for leveling the slopes horizontally/vertically. Remove any excess solution that comes through the perforation immediately using the same spatula. When everything is perfectly smooth, you can rest for a while - the putty should dry completely.

Step four. In the case of uneven slopes, before installing the leveling corners, it is recommended to set the direction from the door jamb by fixing a plasterboard strip about 0.8-1 centimeter wide along it. To attach this material to the surface, use putty. If the putty you are using is gypsum, it will not take very long to dry completely.

Step five. Perforated corner and the edge of the drywall strip - in this case, these are the points that you must connect with putty and level with the plaster mixture.

Step six. We continue to finish the slopes for the entrance doors. When the elements that are correcting the walls are dry, dilute the putty (while following strictly according to the manufacturer's instructions) to ultimately obtain a paste-like mixture.

Step seven. Using a trowel, throw the resulting mixture onto the wall, moving from the floor upward. After throwing required quantity(about 100 centimeters high) level the putty using a short rule. A metal corner and a previously fixed plasterboard strip will serve as a kind of beacons.

Step eight. Pour the mixture onto the second section, level it, then proceed in the same way to the very top.

Step nine. Some difficulties may arise with putty on the upper surface of the opening. So, to apply putty there you will have to use a wide spatula, and to level it, use the same short rule. After this, putty the wall above the opening, then cover the top of the perforated corner with the mixture.

Step ten. Wait until the putty slopes are completely dry. The drying time depends on the composition, as well as on the thickness of the leveling layer.

Step eleven. When the layer has dried, check how high quality the surface is. If there are minor defects left, clean or chip them. After this, make the slopes as even as possible using finishing putty.

Step twelve. At the end, when the finishing layer has dried, coat it with a primer.

The resulting slopes can be covered with wallpaper, painted, or, alternatively, finished with decorative plaster.

Video - How to properly plaster slopes

Option two. We use drywall for finishing

This material is simpler and easier to work with than the plaster described above. However, you will still have to use finishing putty - in this case it will serve as glue for gypsum board sheets; although instead it is better to give preference to special gypsum adhesives, which are designed to work specifically with this material.

In case of limited space, plasterboard sheets are an ideal option for finishing slopes. The algorithm of actions in this case should be as follows.

Step one. First of all, measure each of the slopes separately.

Step two. Transfer the resulting numbers onto sheets of material, then, working according to the markings, open up the elements for subsequent fastening to the walls.

Step three. Install plasterboard sheets from the bottom of the opening. First, apply several “hills” of glue to the first sheet, as in the image, then firmly press the element to the desired location and additionally secure it with pre-prepared supports.

Step four. Similarly, finish the side slopes with plasterboard parts, not forgetting to check each of them for level. To fix it to the walls, you can use driven dowels, having previously made narrow through holes under them with a hammer drill.

Step five. Just as in the case of using plaster, cover the corners with iron corners, using the same putty to fix them.

Step six. Coat all joints with putty, level them thoroughly and, when it dries, clean them thoroughly so that the finished slopes for entrance doors looked as attractive as possible.

Step seven. To obtain a perfectly flat surface, apply a millimeter layer of finishing putty mixture. This way you will completely mask all the defects and holes for the dowels.

Step eight. When the mixture has completely hardened, you can sand the surfaces with fine sandpaper (if required) and finally begin decorating. For this, again, you can use paint, decorative plaster or high-quality wallpaper.

Pay attention! There is another method of attaching drywall - it is advisable in cases where, when leveling slopes, it is necessary to cover a considerable thickness of the wall.

- Attach metal corners to the slope or wooden blocks, thereby forming a sheathing in order to give the wall the desired direction. The main advantage of this method is that between the elements of the sheathing it will be possible to additionally lay thermal insulation material.

- Cover the sheathing with plasterboard sheets, using self-tapping screws for fixation. Everything else is not much different from the technology described above.

Video - Finishing slopes with plasterboard sheets

Option three. We use lining or panels

If you intend to use panels made of rigid materials (this includes many types of lining, MDF, particle boards, etc.), then you should know that they are all attached using almost the same technology. The advantage of this method is that such panels can hide even the most serious irregularities.

As for the specific algorithm of actions, in this case it will look something like this.

Step one. First, prime the slopes, mark the places where the bars or iron profiles will be attached. The step between them should be approximately 30-40 centimeters (if they are mounted across slopes). In our example, we use lining mounted parallel to the box. If a transverse arrangement is required, fasten the sheathing along the jamb. If the surface is wide enough, you can use not 2, but 3-4 planks at once.

Step two. The image shows another option - with the installation of the lining parallel to the door leaf.

Step three. You can lay thermal insulation material (foam plastic, mineral wool, etc.) between the lathing strips.

Step four. Install panels of the selected material over the finished sheathing.

Step five. To install laminated/plastic lining, use the metal fasteners shown in the image.

Step six. To fasten large panels, use self-tapping screws, recessing the latter by 0.15-0.2 centimeters. You can use putty to fill the resulting holes.

Step seven. Finally, install decorative corners. They must match the color of the cladding. Glue the corners on the horizontal as well as the outer ones vertical corners; finally, at the joints of the finishing material and the door frame itself.

Rules for creating vinyl slopes

Vinyl panels are rightfully considered one of the most modern materials that can be used for finishing slopes. They are sold in almost all specialized companies involved in the production and installation of this material. In case non-standard shape panels can be made to order for you, having previously measured the dimensions.

The finishing can imitate various natural materials, so in any case you will choose the most suitable option for yourself, regardless of the design of the door and the hallway itself.

Pay attention! The main advantage of such panels is that they are quickly installed, and there is little waste left after completion of the work. And this kind of decoration looks extremely attractive, neat and stylish.

This material is attached using a universal adhesive that can reliably connect materials of different properties (for example, brick and lining, concrete and wood, plaster and vinyl). In short, everything that can be used during finishing and construction work. Alternatively, slopes for entrance doors can be finished with vinyl using polyurethane foam.

The adhesive should be applied to the inner surface of each panel, and then pressed against the slopes. In this case, no holes need to be drilled in the walls or cladding, which can also be attributed to the undeniable advantages of this technology.

Using laminate is a worthy alternative

Laminate is widely used as a floor covering, it is easy to work with and is produced in various color options. For those who don’t know, laminate is an MDF panel covered with a special decorative layer. Why is this material so popular? This is because it has many important advantages.

- It is inexpensive and can be used for different surfaces, including for slopes.

- Some of its varieties are moisture resistant.

- The material looks attractive, and it goes well with other finishing materials.

- Laminate has excellent wear resistance. It does not wear off for a long time, in addition, it does not withstand very strong blows.

- Finally, the material is produced different types, textures and colors. Therefore, you will definitely choose the most suitable option for yourself.

Pay attention! The service life of slopes can reach 10 or even 15 years, which, you see, is not so little.

Sheathing slopes with laminate can be done in one of several ways: possible ways. Let's take a closer look at each of them.

- For glue. In this case, liquid nails or similar compositions can be used. However, the surfaces must first be leveled (using plaster or plasterboard sheets).

- Using a frame. The most labor-intensive method, which, nevertheless, allows you to obtain extremely even slopes without resorting to preparatory leveling of the walls. This method also makes it possible to lay a layer of thermal insulation material, which will help save heat in the apartment.

- On polyurethane foam. The simplest technology, which does not require preliminary alignment. All defects will be eliminated after the polyurethane foam swells.

Video - Laminate door slopes

As for the installation process itself, it - regardless of the specific method chosen - must begin with surface preparation. In our example, the laminate will be attached with glue. Algorithm necessary actions is given below.

Step one. First, foam all the gaps and apply a layer of plaster. Do all this on the plaster mesh. Later, when the plaster is completely dry, prime the slopes to provide additional protection.

Step two. This is where the most important stage of work begins, so approach the matter with the utmost responsibility. You need to mark and cut the laminate. Start from the top, then proceed to the sides. We recommend cutting the material electric jigsaw, although in the absence of one, an ordinary hacksaw may well be suitable.

Step three. Before gluing, install mounting spacers - a kind of boundary, thanks to which the material will not move.

Step four. Take the first lamella, place it against the upper slope, then open the door - the last one should not catch it. Then apply foam to the inner surface of the laminate, press it to the slope and secure with masking tape (the latter can only be removed after it has completely dried). You should not apply too much foam, because too much foam after swelling can lead to displacement of the element.

Step five. Install the side frames in the same way, regularly using a building level.

Step six. Having laid out all the slopes, wait until the polyurethane foam has completely dried and proceed to the final stage of work. Trim off excess foam and seal the openings with plaster. But this is not the end yet - so that slopes for entrance doors looked really attractive, cover the openings with a corner of a suitable color.

That's all, now you know about the most popular methods of finishing a door slope. We hope you found the article really useful.

Good luck in your work and, as usual, have a warm winter!