What to do if there is not enough time or energy to build a full-fledged bath? In this case, the principles of modular construction can be applied. It was they who formed the basis of the technology for the construction of a bath-barrel. You can make such a design yourself, and with proper skill and the availability of tools - even without a partner.

As the name implies, the body of the bath is a cylindrical structure made of boards with a groove connection. To strengthen it, tightening metal plates (analogue of clamps) are installed on the surface. At first glance, the design will ideally fit the functions of the bath. The low cost of construction, the possibility of purchasing ready-made modular elements and the high speed of construction speak for themselves.

However, upon closer analysis, the following shortcomings become apparent:

- Low wall insulation. AT winter period heat loss can negate all attempts to raise the temperature in the room to the desired level.

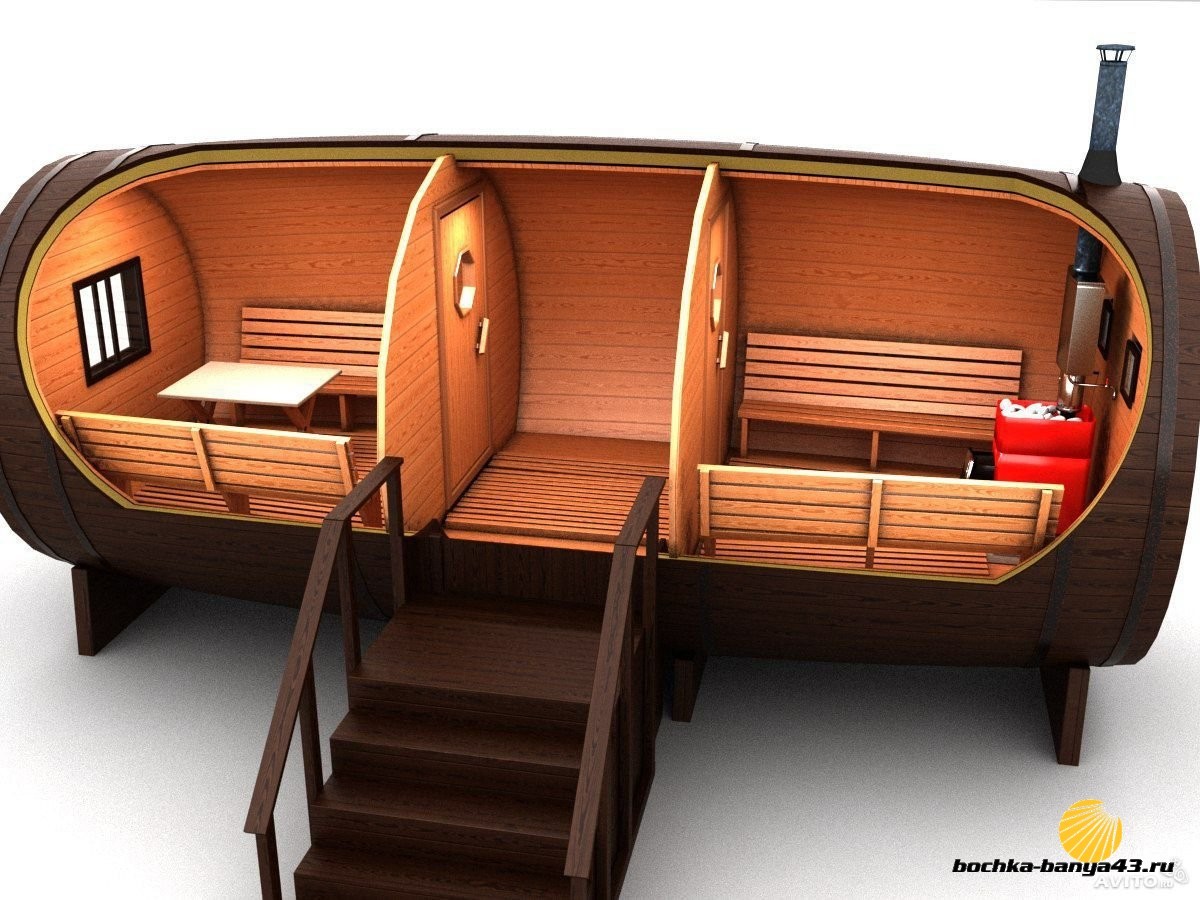

- Small area. Most factory models and standard drawings include a small dressing room and a steam room in the design. Together, their area can be up to 12 m², i.e. in fact, bath procedures can simultaneously take up to 3 people.

- Water supply and sewer connection. The implementation of these procedures is difficult, since in winter there is a high probability of freezing pipes and the formation of an ice plug in them.

If you remember that the room is planned as a budget option for a bath, you can not take into account all these shortcomings. The most important advantage of the design is the possibility of its transportation, which cannot be done with.

Project planning and material selection

First, it is necessary to develop at least an elementary project documentation- a drawing of the building and a list of materials for its manufacture.

Now you can find many standard drawings of a barrel bath. Despite the apparent diversity, they all include the following main elements:

Base

It is made of boards, the thickness of which should be at least 5-6 mm. At the first stage, a recess is made on each of them, into which the boards will be installed. To strengthen the structure, the edges are upholstered with fixing formwork.

Assembly elements - edged boards with groove connection

It is best to choose high-quality material - larch or cedar. Their length must be overall size finished structure. Mounting recesses are made on the surface for installing partitions. It is not recommended to divide the components along the length, as this will lead to loss thermal insulation properties designs.

Partitions

On the wooden base boards are stuffed, and then cut in such a way that the result is a round structure. Its diameter should be less than the outer bath by the thickness of the wall boards. If manufactured internal partition and an external entrance, you should leave room for a doorway.

Additional elements

These include slatted flooring and floors. They are also made from wood.

Next, equip the installation site of the structure. To do this, choose any place on land plot, but it is recommended to mount the bath on a hill. A small hole is dug up to a depth of 0.5 m and dimensions exceeding the dimensions of the bath by 40-50 cm. Sand and gravel which is carefully packed. After the final alignment, you can proceed with the assembly.

On the installed frame the bottom row of boards is nailed. It is necessary to track the location of the mounting recesses - they should be one common groove. After that, partitions are installed and fixed. Their plane must be strictly perpendicular to the level of the sand deck.

After that, the rest are nailed wall boards. A correction rail is installed between the first and last. It should be in the shape of a wedge. With its help, it will be possible to adjust the gap in case of swelling or thermal expansion of the boards. Further, the entire structure is pulled together with a metal tape. Holes are drilled on the floor surface to remove water. This is done in at least 3 places. On this, the construction of the body of the barrel bath is completed.

At the final stage, floors, flooring and doors are installed. Particular attention should be paid to safety when installing the boiler. This area must be covered with fire-resistant material. For convenience, holes are made in the wall of the bath for the supply of water and electricity. The resulting structure, if necessary, can be transported by any convenient way- on a trailer or in a truck.

A lot of owners country houses dreams of a cozy and compact bath, which will not take up much space and will neatly fit into any landscape of the backyard. The best option in conditions of limited space, there will be a miniature barrel bath, which you may have already heard about somewhere. Today we will discuss possible models of mobile structures, talk about the construction technology, including the design stage, designate the materials of manufacture and decoration, and also share all the nuances of the arrangement.

What people are just not ready to invent, just to equip it on their own personal plot miniature and comfortable bath without spending too much. The bath-barrel has become such a masterpiece of architecture - it is extremely simple in everyday use, convenient and compact design, capable of radically transforming the area near the house with only its appearance. And the aroma of natural wood and healing properties baths, which everyone knows about, will bring many pleasant moments of relaxation and healing. Yes, you can work hard for this!

Comparing a barrel bath with traditional steam rooms, it is worth noting several of its advantages:

- Relatively a light weight. The structure, made of larch, weighs only 1.5 tons, while stationary model from brick - up to 5 tons.

- Mobility. At any time, you can change the location of the structure on the site.

- High heating rate. It will take only a quarter of an hour to warm up the bathhouse to 90ºС (in summer).

- Compactness. For the construction and installation of a bath-barrel on the site, you will need only 8-10m², which is very convenient if you have a very small area.

- Unusual architectural solutions and extraordinary finishes. In such a bathhouse it is not only pleasant to relax, but it can be used as a separate decorative element within the available territory.

- Economy of construction. The construction of any other bath will cost you many times more: just remember the cost of foundation work and the cost of materials.

- Ergonomic space. Despite its small size, it can easily fit up to 6 people inside.

The persistent effect of a thermos, which is ensured by the multi-layer structure, its rounded geometry and high-quality thermal insulation. All this ultimately ensures economical consumption of fuel resources and electricity.

Variety of barrel baths

Needless to say, in our country such a steam room is still perceived as a sort of know-how, despite the fact that in Europe and Scandinavia such designs have already become familiar. In fact, a barrel-bath is a barrel-shaped log house equipped with a mobile steam generator stove that works both on wood and on electricity.

There are several types of barrel baths:

1. An ordinary Russian bath, combining a steam room and a washing room.

2. Steam room with dry steam, which will ideally harmonize with a cool water font.

3. Ofuro (Japanese variety), very similar to a font, but equipped with a heating system from a stove.

Russian bath

Habitual and familiar to all ordinary bath, consisting of a steam room and washing.

Since the Russian bath involves the use of water, the barrel design project should provide for the organization of a drainage system. A slight tilt of the structure will help eliminate the possibility of stagnant water.

When designing and building a Russian bathhouse, the stove should be placed between the steam room and the washing room. The part of the oven equipped with a tank for heating water must go into the washing room. In the steam room there will be a container with stones heated from the firebox. In order not to get burned in the washing room on the design of the firebox, it should be fenced off.

The stove itself should be small in size, since the space in the barrel bath is very limited. From all sides, the stove is sheathed with heat-resistant materials.

Steam room on dry steam

This is a bathhouse with one room and a nearby pool, natural pond or font.

Barrel - sauna

Experts say that organizing a sauna barrel is an order of magnitude easier than a regular steam room. All that is required to ensure the tightness of the structure is the absence of cracks in the walls and on the floor surface. A small hole is often made on the roof, which is partially or completely (depending on desire) closed with a valve.

Drainage in the sauna is not necessary. The room is equipped wide benches and a stove with a heated heater.

An electric stove can also be installed in the sauna barrel.

Interesting. Such a sauna can be placed on the site both vertically and horizontally. With the latter option, the area of \u200b\u200bthe room doubles!

Bath Ofuro from Japan

The Japanese version of the bath is very easy to use, and its main feature is the absence of a roof, which does not interfere with enjoying the harmony of fire, water and air even in winter.

Barrel a little elongated shape placed on a wooden deck. Inside, the construction is equipped with all necessary amenities: a stove and wooden benches. The stove is often taken out to a safe distance and equipped with a special partition that protects against burns.

However, at the same time, it will take more time to warm up the water in the bath and maintain it at the same level, which means that fuel consumption will increase.

Choosing a material

The operational properties and convenience of a barrel bath largely depend on the wood from which it will be built. If almost any material is used for the construction of an ordinary bath, and wood is selected only for interior decoration, then in our case it is better to decide on the choice of suitable wood right away.

Take your choice of wood very seriously!

For example, do not consider conifers. They are enriched with resinous components, which, when the wood is heated, are released and often burn the skin.

Prices for unedged boards

unedged boards

Material preparation

It is not enough to know which wood is better to use for the construction of a barrel bath. It is important that the wood is of high quality and pre-treated.

First of all, all the boards selected for the bath must be adjusted to one size. If the wood will be processed independently, then it is better to choose boards 90 mm wide and 50 mm thick.

If you do not have your own woodworking equipment, then it is better to contact the master who, based on the drawing, will produce lumber the right sizes. Once again, we note the painstaking process of manufacturing blanks for a bath: all boards must be the same size.

Depending on the expected diameter of the barrel, the number of boards is calculated. For a more accurate calculation, a drawing is made on which a circle is drawn. Then it is exactly divided by the width of the board. The length of the boards determines the size of the room (2.5-6 meters).

Installation is not complete without fasteners (nails, stainless steel screws).

Do-it-yourself barrel bath: step by step instructions

Working with the base

Since the weight of the finished structure is not too large, it is quite possible to do without making a foundation. The most important thing is to find a solid and even platform where the barrel bath will be placed in the future, to build a reliable foundation, thanks to which our structure will be held.

Asphalt or paved will perfectly cope with the role of the site paving slabs plot. At worst, a rammed surface covered with turf is also suitable.

To create the base, high-quality edged boards with a thickness of 5 mm or more are used. The support boards are fixed at a distance of 1.5 meters, so their number is directly determined by the dimensions of the structure. Rounded recesses are made on the transverse slats, corresponding to the contours of the future bath. For drawing contours, cardboard patterns are used. The width of the remaining part of the bar must exceed 10 cm.

All prepared boards are fixed to each other with screws as firmly as possible, and to give additional rigidity they are used metal corners. They are fastened at the corners of the structure and at the junction of the transverse and longitudinal strips.

To fasten the elements of the bath-barrel, it is convenient to use screws and a screwdriver.

Attention! Before bonding all parts, do not forget to treat them with a special impregnation. After assembly, it will be problematic to do it qualitatively!

Screw prices

Construction of the front and back walls

As you move on to the next step, there are a few things to keep in mind.

Both walls must be perfectly shaped.

The back wall should provide for the presence of windows (one or two, depending on the project), and the front wall - a doorway. The location of these elements determines the area for placing the bars on which the boards are fixed. They are attached across the structure.

Making a doorway is not an easy task (Fig. 28)

Using bars and boards, an equilateral square is made. Its middle is determined, and then a circle is drawn, which is carefully cut out jigsaw.

In the finished circle, markings are made for doors and windows, and it is also sawn out. For reliability, the holes obtained can be reinforced around the perimeter with wooden bars.

Bath-barrel walls: preparation of boards

At this stage, boards are being prepared for cladding the walls of the bath-barrel. On each board at the installation level of the front and rear wall grooves are made. Their width is comparable to the thickness of the boards from which the walls are made, and the depth is 8-10 mm. These grooves will fix the "bottoms" of the bath. If the steam room will consist of two rooms, then the grooves will have to be cut not in two places, but in three, because the separating partition will also be fixed in them.

Creating windows and doors

The absolute tightness of closed rooms is one of the most important points in self-manufacturing.

It is still better to entrust this painstaking and precise work to the master, providing him with all the calculations and sizes.

Bath assembly stage

The base for the steam room is mounted on a solid base with a slight slope. A drain pipe must be connected to it in advance.

On the basis of the prepared arcs, the middle is marked. The first board of the bath-barrel will be attached to it.

On both sides of the first board, the rest are installed along the entire length of the base arc.

Attention! Be sure to ensure that all cut grooves form one recess. This closes the floor.

The next step is the installation in the grooves of the fixed boards of the back and front walls. Make sure they fit snugly and can stand without support! Thanks to these walls, the geometry of the building will be formed.

Subsequent boards are attached to the installed walls (front, middle and back). Work is carried out in parallel on one side and the other.

After the boards are installed, the structure must be pulled together with metal hoops. This will provide additional rigidity to the structure. Instead of hoops, ribbons are often used, at the ends of which holes are made. A bolt is passed through them, tightly tightened and twisted with a nut.

Windows and doors are being installed.

At the final stage, roofing. Most often installed on the roof flexible tile and metal sheets. Looks very impressive gable roof. Finishing slopes is done using metal tiles or corrugated board.

If the barrel bath project provides for a veranda, then it's time to start arranging it and installing benches.

We equip the bath-barrel from the inside

Before equipping the interior of the bath, the walls are covered with a special linen compound. The oily liquid will reliably protect the wood from excess moisture, deformation and cracking.

Linseed oil is a reliable wood protection.

Linseed oil - reliable wood protection (Fig. 38)

Attention! Not only the wall is processed, but also all wooden elements.

Organization of water drain (Fig. 40)

Drainage features

If you plan to build a bathhouse where it will be consumed a large number of water, then without reliable system drainage is indispensable. You can, of course, drill small holes in the floor through which the liquid will seep into the ground. But with frequent use of the bath, the liquid can simply accumulate, which will lead to rot and bad smell dampness, then the floor boards will become unreliable and in the end it will simply fail. It is for this reason that experts recommend taking care of the organization in advance. quality system drainage.

To do this, the bath-barrel is mounted at a slight tilt back. In this case, the water will not accumulate, but will all drain to the very end of the washing room, where a drain will be installed in advance - a special hole with a pipe leading to drain hole. The pipe connected to the floor must be insulated. Otherwise, it will crack from the temperature difference at the most inopportune moment.

The construction of a barrel bath will take you only a few days, and it will delight you with endless heat for years. This is a very good option for country house and dachas.

Video - building a do-it-yourself barrel bath

Many people dream of having their own plot, but not everyone will have the opportunity. In addition, the construction of a bath is painstaking work, and if you decide on this, then the barrel bath will be the most convenient option. In this article we will look at how to make a barrel bath with your own hands.

AT recent times such baths are gaining more and more popularity, and this is due to the following factors:

- In terms of dimensions, this is a small structure, and you do not need a lot of space. This is true for owners of small plots.

- Again, due to its compact size, the construction takes place quite quickly, and the arrangement of a complex foundation is not required.

- Inside such a bath, the air warms up quickly.

- In spite of small size, all healing properties in the bath-barrel are preserved.

Consider what materials are best to choose for such a bath.

Wood

The best material for construction will be a dry board conifers(fur tree, pine tree). If you purchase a structure ready for assembly, it is better to choose the tenon-groove mounting option. The most expensive but quality materials considered cedar.

Base

As mentioned above, the foundation is not required here, and 50X150 beams are suitable for the base. Such a foundation will be enough to support the structure.

Waterproofing

Since the tree is affected environment, then after the construction of the bath, the barrel needs to be processed. And given that chemical compositions use is categorically inappropriate, it is better to impregnate the wood with linseed oil.

Correctly calculate the dimensions

If you are thinking about the size, then first of all be guided by the number of guests in the house, and how many people will take bath procedures at the same time. Despite its small size, the interior can be from 3 to 5 meters, depending on the design chosen.

To increase the design and give the bath a finished look to the barrel, it can be supplemented with an extension-veranda. To maintain the unity of style, it is better to use the same materials for it as for the construction of a bath.

Building instructions

Foundation preparation

As mentioned above, the foundation for such a bath is not needed. It is enough to level the area and fill it with gravel to prevent contact of the base with the soil.

On a leveled area, you first need to lay a beam that will serve as a foundation. The number of bars is calculated based on the size of the structure. Experts recommend laying them at a distance of 1 to 1.5 meters.

The top of the beam is sawn under the circumference of the barrel bath so that the remaining ends are at least 20 cm.

The timber that will be used under the base must be impregnated special composition to protect it from moisture.

Board preparation

The grooved board is cut according to size future design, grind the end parts and treat with an antiseptic.

End wall assembly

They are assembled from prepared boards, which are fastened with a transverse beam. During assembly, if a window is to be installed in the end part, the crossbars must be fixed so that they do not interfere with their installation.

Construction assembly

You need to dial the walls of the barrel bath with support boards. They are placed on the bottom equal distance, fastening with each other. When you get enough circle to install the ends of the walls, install them and continue to assemble the structure. After completing the assembly of the circle, secure the structure with metal hoops.

When assembling the barrel body, allow Special attention material quality and connections. In particular, boards need to be re-sorted, and those with more knots and cracks are better used for interior finishing.

We equip the interior

What can be placed inside the barrel bath? Everything is the same as in a regular bath: dressing room, washing room, shelves and stove. Interior decoration should be from eco-friendly tree hardwoods.

When laying the floorboard, it is necessary to provide for a slope in the direction where the water outlet will be located. To improve circulation and ensure proper floor heating, a grate is installed in two places.

When using the bath only in the summer, additional thermal insulation is not needed. In the case of year-round operation, additional vapor barrier will be required. To do this, it is better to use modern materials.

The layout is your choice. If the site has water supply, then you can install a small shower.

Which oven to choose

Of course, for such a small space the best choice there will be an electric oven. Its main advantage is its compactness and the absence of a chimney. And if we talk about power, then 6kW will be quite enough.

If you are building a bath-barrel of large dimensions, then you can install a solid heater with a chimney. Such a stove will also serve as additional protection for the ceiling and walls from overheated air.

Furnace types

The choice and installation of the stove is considered the main stage of work, because a good stove is the key to a comfortable, health-improving steam. Today, metal, brick or combined stoves are considered classics of the genre. If we talk about homemade ovens, they can be divided into four types:

- A furnace made of sheet iron.

- A stove-heater, the body of which is finished with a metal sheet.

- A stove made from an iron barrel.

- The furnace is remote, the heating tank is located on the street.

In order for the stove to produce more steam, trim the area around the heater with sheets of stainless steel or aluminum. When heated, the steam from this material will diverge more intensively throughout the room.

Moisture protection

It is not necessary to mount the roof on a barrel bath if you have impregnated the boards with an antiseptic beforehand. But still additional protection will not hurt, besides, it will give the design a more aesthetic appearance. As a material, any modern materials are suitable.

Bituminous tiles look beautiful; today they are widely used in low-rise construction.

Proper care

- After each visit, remove all debris and rid the premises of excess water.

- AT summer time the room must be well ventilated by opening the door for a while.

- AT winter time the room is ventilated through an open window.

Video

This short video will show the process of assembling a barrel bath.

Taking a steam bath after a hard day's work is the dream of almost any person. But going somewhere to the steam room, renting a room and paying for it, by the way, really a lot of money, will not please everyone. If you have built your own house and are thinking about how to equip the site, then be sure to consider creating your own bathhouse, which you can visit at any time convenient for you with minimal cost for fuel. In addition, it will be possible to take a steam bath in the company of friends who also like this format of recreation. But if you appreciate this idea, but don’t know where to start, then first of all, check out the existing building projects and choose among them the one that you like best. Recently, barrel baths have begun to be especially popular, which have a lot of advantages, in addition to obvious accessibility and practicality. In this article, we will consider all the features of creating such steam rooms, as well as materials that you cannot do without.

The advantages of such facilities

Undoubtedly, for the construction of capital bath complex Near small cottage or a dacha, it is impractical, especially if you live in a house not all year round but only during the summer. In addition, it is worth noting that the bath is a somewhat expensive pleasure. Yes, such a construction will pay for itself quite quickly, but no one has canceled the initial expenses, which, alas, cannot be dispensed with. But what about those people who do not want to give up the idea of creating a bath, but do not have necessary funds? In this case, it is recommended to pay attention to the budget options of the complexes, which in terms of their functionality and durability are in no way inferior to massive outbuildings.

A barrel bath is a structure that you can create on your own without much difficulty, spending a minimum of finances and your precious time on it. You can build a steam room in a matter of days, and it appearance at the same time will be very attractive and completed due to the finishing works. The most important thing is to adhere to the chosen scheme and the advice of specialists in the field of construction and design.

The length of such a structure can be at your discretion - from two to six meters. If your budget is severely cut, you can create a compact "barrel" in which there will be only a place for a steam room and the stove itself. Speaking of well-equipped and big baths, then a rest room, a shower room, a simulated loggia, as well as almost any other room that your soul desires, can be planned in them.

In addition, it is worth noting the following advantages, namely:

- original appearance;

- a small amount of space is required for the creation of a structure;

- high-speed work performance;

- a barrel bath has exactly the same functionality as capital structures, in no way inferior to them;

- no need for a massive base;

- you can create a steam room from materials that remain, for example, after building a house;

- availability and low price;

- you can build a barrel bath according to drawings and diagrams yourself.

- if you wish, you can create individual project structures and realize it, based on their own wishes and preferences.

- Sauna barrel do-it-yourself drawings of which you can easily find on the net and choose among them exactly those that are suitable for your site, and, of course, the budget.

Choosing a building material

The most affordable and practical option are tongue-and-groove boards.

To create a bath barrel on your own, without involving a team of craftsmen, of course, you should use wood. You can choose the breed at your discretion, but pine, spruce and fir will be the safest for human health and the environment. But if we are talking about the creation of such a structure in the conditions suburban area, it is necessary to take into account climatic conditions, the amount of draft and the planned service life. That is why, for such objects, it is best to give preference to cedar, as well as larch, which, although they are not cheap, will last long enough and will please with their aesthetic characteristics.

It is especially important to carefully consider the form in which wooden blanks for the future bath will be made. Perfectly suited for these purposes planed edged board, having the type of fastening "thorn-groove".

To simplify the assembly process, construction experts strongly recommend processing the material so that it takes on slightly rounded shapes. To do this, you can use pre-created templates. The material should have a small thickness and width, so that it is most convenient and easy to work with it, both at the preparatory and at the final stage.

Barrel bath: do I need a foundation?

People who have thought about building their own barrel bath according to simplified drawings, first of all, think about whether it is necessary to create a foundation for this kind of construction? Often, no foundation is required. All you need to do is prepare the area. To do this, remove from it all debris, vegetation, as well as other objects that may interfere with installation. It is also important to level the surface. It should be placed supporting elements, which will serve as the base.

The support for the barrel bath can be:

- The territory that was previously concreted or asphalted; ;

- The area on which the tile was laid;

- Cover with a well-fixed shield (usually made of wood).

If you do not have the opportunity to carry out such work, then it is safe to say that the old one can be perfectly used as an impromptu foundation. reinforced concrete slab dimensions you need.

At the time of creating the foundation of the supports, try to follow a few tips:

- When creating bases, it is recommended to use a reliable edged board, which has a thickness of at least 5 centimeters, having previously been treated with high-quality impregnation in order to prevent the formation of fungi and mold.

- Make sure that there is not too much distance between each support. The most optimal is one and a half meters, and the number of boards varies depending on the size of the tank bath.

- When assembling the structure, make a small rounded notch on the transverse boards so that the support exactly follows the contour of the bath (it should not be created from the edge, but closer to the center, leaving at least 10 centimeters at the free edge).

- To make the foundation rigid, when creating the structure, all kinds of metal elements are used, which are fixed at the corners of each constituent base.

After that, boards of the most optimal length are laid alternately on the finished foundation (based on the parameters of the future bath). They are connected according to the principle of "thorn in the groove" in order to give the structure a rounded shape. Upon completion of these works, the end partitions are fixed, which are mounted at the site specified in the drawing.

Decoration of the interior of the bath

The necessary rigidity of such a structure is provided through the use of special metal hoops. To provide them secure fastening, it is recommended to purchase special clamps, which, after the timber has completely dried, will tighten the structure and prevent the appearance of gaps and cracks.

Exterior finish barrel baths are optional. If you still decide that you need it, then the usual soft roof which is installed directly on upper part structures. First, the surface should be treated with a special waterproofing material (the budget option is simple polyethylene), and shingles. After everything is ready, you need to wait a few weeks for the wood to dry completely. It will be possible to equip the steam room with everything necessary and start full operation in a month. Of course, this rule is not necessary to follow, but if you want the bath to please you with its practicality and durability, experts in the construction industry still advise taking these recommendations into account.

In this article, we have reviewed all the main features, as well as the advantages of barrel baths. Such structures are a really worthy alternative to capital buildings, so if you have a desire to build a sauna in your home, be sure to consider them.

Sometimes the construction of a capital bath on a suburban area is considered inappropriate and rather costly. In this case, a practical and cheap option for a structure that can be made by hand in as soon as possible, is a bath-barrel. Wherein finished building able to organically combine medicinal properties classic bath, beneficial effect of natural wood, design mobility and ease of use.

Advantages and disadvantages of a barrel bath

O private bath many homeowners dream of, because it does not require special permission, the construction of a separate foundation, log house and roofing system.

Like a stationary structure, a barrel-shaped bath has its pros and cons, which should be considered before construction begins.

- Mobility, compactness and convenience of a design. Compact dimensions and relatively low weight (up to 1.5 tons) allows you to install such a structure on any type of base and easily transport it over long distances. The average does not exceed 12 square meters. m, so the mobile structure can be used in the country or on frequent trips.

- Quick warm up. The heating rate of a bath in a barrel is twice as high as stationary structures. It takes 20 to 35 minutes to get the first steam, while the air is heated to a comfortable and safe temperature. human body temperature at 95 degrees.

- High heat capacity. This design prevents heat loss, so much less fuel is required to warm it up. So, if for kindling traditional bath 14 logs are used, then for a barrel-shaped bath - no more than 9.

- Economy and durability. To build a round bath, less finance will be required compared to the construction of a stationary steam room of a similar size. In addition, it does not require the mandatory construction of a foundation. It is enough to install massive beams interconnected, which will be a solid foundation.

- Ergonomics. Round design allows you to effectively use every square meter of space. Here you can equip a full-fledged steam room, dressing room (cloakroom) and shower. The capacity of a medium-sized bath is from 3 to 8 people.

- Year-round operation. Thanks to small area and effective work heaters, in a round bath you can maintain a constant temperature even in winter. Thus, the steam room can be operated throughout the year.

- Ease of maintenance. Another advantage that favorably distinguishes such a design from the background of stationary structures. Ease of cleaning due to the minimum number of corners and hard-to-reach places.

- Affordable cost. erection round bath will cost several times cheaper than the construction of a full-fledged stationary steam room.

The main disadvantage of mobile structures is the need for mandatory insulation for operation in the winter, which ultimately increases the cost of the finished project.

The main types of round baths

Depending on the size, design features and purpose, barrel-shaped baths are divided into three main types. Short review each of them:

- Russian steam room. Wet hot steam and a traditional attribute - a birch or oak broom. This structure consists of two functional areas- steam room and washing department.

- Finnish sauna. High temperature regime and dry steam. It is advisable to have a hanging bucket or font available for contrasting water procedures.

- Japanese ofuro. A spacious wooden vat equipped with a heater.

Russian steam room

The most popular type of bath, which can be organized on your own site. Bath procedures include a set of activities taking place in the steam room and washing room.

The sauna stove is installed in the steam room, which provides a quick heating of the building and promotes the formation of thick and humid steam. The washing room is used for contrasting water procedures after warming up the body in the steam room.

Since bath procedures require a large amount of water, a special waste disposal must be provided in the design of the bath.

The heating stove is mounted between two functional areas so that the chamber with the heater is located in the steam room, and the expansion tank and the firebox are in the washing room.

Since the Russian round bath is small in size, the heating equipment must be compact and safe. The inner surface of the walls should be covered with refractory panels.

dry sauna

Finnish sauna from a barrel with dry steam can be located in one room. Distinctive feature buildings - the presence of a font for contrast procedures. It is much easier to equip a round dry sauna than to build a full-length stationary bath.

Such a structure should be airtight, practical, safe and durable. In a dry steam room, unlike the Russian one, there is no drainage system. The main requirement is to provide ventilation openings with valves in the wall and floor base. The sauna is also equipped with comfortable benches and a compact heater.

The round sauna barrel can be mounted in a horizontal or vertical position. It is important to remember that the horizontal position provides for a significant increase total area buildings.

Ofuro

Types of wood for a barrel-shaped bath

The most popular material for the construction of a round bath is. For these purposes, it is better to use bath tree species: larch, oak, cedar, linden and aspen.

- Oak buildings- wear-resistant and durable. They are inert to decay, cracking and warping. The wood cut has an attractive texture and a pleasant aroma. The disadvantages of such wood are the high cost and complexity of pre-treatment.

- Linden buildings– practical and safe. Linden baths have a beneficial effect on the human body, promote rejuvenation and purification. Linden lumber is easy to process and assemble, in addition, it has a high heat capacity, but it is short-lived and susceptible to decay.

- Aspen buildings- available and cheap. By their own performance characteristics aspen is not inferior to linden, but at the same time it is resistant to overheating, cracking and deformation.

Do not use coniferous wood for the construction of a bath, which contains a large amount of resins that are released when the lumber is heated.

An exception is cedar lumber, which has a powerful healing effect on the body. The cedar bath is especially useful for people suffering from diseases of the respiratory system.

Important! Softwood (spruce, pine) is suitable for assembling the frame, and hardwood is suitable for interior decoration.

For the manufacture of bathing equipment and furniture, more than cheap material- alder, fir and birch. But they are absolutely unsuitable for the construction of a bath.

Assembling the base for a round bath

The frame bath-barrel does not require the arrangement of the foundation. It can be installed on any flat surface- concreted, asphalted, covered with gravel, covered with turf or tiled.

For the base, a high-quality edged board with a thickness of 5 mm is used. The crossbars are mounted in increments of 150 cm, so the number is determined by the dimensions of the building.

Rounded recesses are made on the crossbars, which correspond to the contours of the bath. For this, special patterns made of durable material are used. The width of the rest of the lumber is 10 cm.

The parts are connected to each other with screws, and to reinforce the finished structure, metal corners are used, which are fixed in the corners and at the joints of the longitudinal boards and crossbars.

The technology of building a home bath-barrel

To assemble a simple design of a barrel-shaped bath, you will need the following tools and materials:

- Electric jigsaw and drill.

- Screwdriver.

- A hammer.

- Plane.

- Building level.

- Roulette.

- Steel clamps.

- Window and door structures.

- Heating equipment.

- Supporting wooden blocks.

- Roofing material.

- Furnace insulation material.

- Pipes for plumbing and chimney.

- Fasteners.

As the main material, a board for a bath of arbitrary width, 6 cm thick is used. Fixing method: tenon-groove.

To determine the required number of boards, the circumference is divided by the width of the board.

Example. The circumference is 7.5 meters, the width of the board is 9 cm. The number of boards = 7500 mm / 90 mm = 83.3. For work, you need 83 boards.

Lumber is carefully polished at the ends and treated with antifungal impregnations.

To do quality assembly baths with your own hands, it is recommended to prepare a working drawing of the future design, indicating the dimensions of all elements.

Stage number 1. Construction of the base for the barrel

The number of supports is determined by the length of the building. The beams are sawn to length equal to the diameter baths. If the diameter is 2.5 meters, all supports must be the same length. Supports are installed in increments of 1.5 meters.

Small recesses are made on top of the beams for mounting bath construction, the remaining parts of the supports should protrude 10 cm on each side.

The supports are installed on a prepared site with a slight slope for the withdrawal of drains.

Stage number 2. Fixing the floorboards

In the middle of the future structure, the first board is mounted. On both sides of the first element, boards are sequentially installed with a groove connection. All recesses in the support beams must be covered with floorboards.

Stage number 3. Installation of partitions and walls

The number of partitions depends on the number of functional areas in the bath. They are installed in the right places according to the working draft. Next, the outer walls of the required length are mounted, door and window openings are made.

The finished design of the bath must be airtight and reliable.

Stage number 4. Screed with steel clamps

To provide additional strength and durability of the bath, the finished structure is strengthened with steel clamps. Holes are made at the ends of the screed for its fixation to wooden frame fasteners, preferably with bolts and nuts.

The screed will not only ensure the strength of the frame, but also prevent heat loss during the operation of the building.

Stage number 5. Installation of door and window structures

Pre-ordered structures are installed in prepared openings, the joints are carefully caulked and sealed with sealant.

Stage number 6. Installation of the roof

To decorate the roof of a round bath, you can use soft or hard roofing material, and the installation process itself is much simpler and more affordable than in traditional buildings.

Arrangement of a mobile bath-barrel

At the final stage, work is underway to interior arrangement baths:

- A drain hole is made in the floorboards with the connection of drainage pipes.

- Performed wood flooring for ease of use of the steam room - a removable grate with technological gaps between the boards of 1.5 cm.

- Shelves are mounted along the perimeter of the walls; if there is free space, a table is installed.

- Surfaces are thermally insulated - walls, ceiling and floor using heat-resistant materials. Heating equipment, a chimney with an outlet to the street and an expansion tank for heating water are installed. The ceiling opening for the chimney is protected by thermal insulation material.

- The heating furnace is installed. In a mobile bath, it is more convenient to operate an electric heater with a power of 5 kW or more.

- The water tank is connected to the furnace. Water pipes are being installed.

- If the design provides for a shower, a tray is installed and necessary kit sanitary equipment.

- Electrical wiring is being laid in a waterproofing box with a connection to a switchboard.

- A font is installed for contrast procedures.

Wooden structural elements, as well as surfaces, are treated with a special composition based on linseed oil to protect against decay and deformation.

For safe operation barrel baths in winter, it is recommended to make high-quality thermal insulation of the structure from the outside in order to prevent heat loss and reduce fuel consumption.

erection mobile bath- a responsible event that requires a minimum experience with lumber and compliance with all stages of the technological process.