IN last years More and more chimneys are being made from sandwich pipes. The point is a relatively low price, long service life, and quite attractive appearance. It is also important that it is possible self-installation sandwich chimney. This is not a very simple matter - there are many nuances, but you can do it yourself, without the involvement of specialists.

What is a sandwich pipe and what are they?

The sandwich pipe was named so for its multi-layer nature: there are two layers of metal, between which there is insulation. This structure solves many of the problems that were inherent in a simple chimney made of a metal pipe. Firstly, the insulation layer does not allow the outer metal casing to heat up to critical temperatures, and hard radiation does not emit from the pipe. More than one is created indoors comfortable conditions. Secondly, the same insulation significantly reduces the amount of condensation that forms when the pipe is brought outside. Thirdly, since the outer casing is no longer at such a high temperature, it is easier to make the chimney pass through the roof or wall.

Sandwich pipe is two metal cylinder, the space between which is filled with insulation

What materials are they made from?

Sandwich pipes are made of galvanized or stainless steel. Galvanized sandwich pipes for chimneys are rarely used. Perhaps for the removal of combustion products from a low-power wall-mounted gas boiler or gas water heater. Can be used for insulated ventilation. They are unsuitable for more serious heating devices - at high temperatures, zinc burns out, steel quickly rusts, and the chimney becomes unusable.

Sandwich pipes for high temperature flue gases made from stainless steel. Moreover, stainless steel is used in different grades - from alloys with a small content of alloying metals to highly alloyed heat-resistant ones. The thickness of the metal can also be different - from 0.5 to 1 mm, as well as the thickness of the insulation - 30 mm, 50 mm and 100 mm. It is clear that the scope of application will be different, and so will the price.

The main grades of steel that are used in the production of sandwich pipes for chimneys, their purpose and main characteristics are summarized in the table.

| Stainless steel grade | Main characteristics | Application area |

|---|---|---|

| AISI 430 | Has sufficient resistance to atmospheric influences, but does not tolerate high temperatures well | Used for outer casings of sandwich pipes |

| AISI 439 | Contains titanium, which increases resistance to elevated temperatures and aggressive environments. | Suitable for gas boilers, low-power solid fuel units (up to 30 kW) |

| AISI 316 | Alloying additives - nickel and molybdenum - provide high resistance to acids and increased heat resistance. | Optimal for gas boilers of any type. |

| AISI 304 | More cheap option AISI 316 with less alloying additives | Economy option for gas boilers of medium and low power |

| AISI 316I, AISI 321 | Withstands temperatures up to 850°C | Can be used for heating solid fuel stoves |

| AISI 310S | Increased heat resistance - up to 1000°C (and price) | For sauna and pyrolysis solid fuel stoves |

As is clear from the table, different grades of stainless steel have different purposes. Cheaper alloys are used for the outer casing, more heat-resistant and expensive ones for the internal casing. This is necessary to reduce the cost of products, and high resistance to temperatures outside the chimney is not needed. There are even more budget options— the outer casing is made of galvanized steel. Externally, these products are inferior to stainless steel, but serve normally (with normal insulation and its thickness).

Insulation and its thickness

There is insulation between two layers of metal. Most often this stone wool. The thickness of the insulation varies from 30 to 100 mm:

- With 30 mm thick insulation, the flue gas temperature should not exceed 250°C. Such temperatures are only given gas boilers small and medium power.

- A 50 mm insulation layer can withstand temperatures up to 400°C. Scope of application - any gas and liquid fuel boilers, wood-burning, provided that the chimney is vented to the street (through the wall).

- A 100 mm layer of stone wool can withstand temperatures up to 850°C. Such a sandwich chimney can be installed on any type of solid fuel boiler, in fireplaces and hearths.

In addition to the thickness of the insulation, you need to pay attention to its brand, or rather, to temperature Range, in which he can work. Not every stone wool can withstand heating up to 850°C, but only some special brands. If you need a chimney for solid fuel boiler, you will also have to take into account the heat resistance of the insulation.

Connection types

Sandwich chimney elements can be connected to each other in two ways: with sockets and corrugated edges. A socket connection requires a slightly wider chamfer on one side. With this implementation it is achieved high degree chimney tightness. This type Sandwich pipes are well suited for gas boilers where it is important to prevent leaks. There is also a minus: installation requires high precision.

The corrugated edge of the sandwich allows you to assemble the chimney without problems. The disadvantage of this solution is that to ensure tightness, a significant amount of high-temperature sealant is required, and it costs a lot.

It is also worth paying attention to the longitudinal seam. It can be welded or folded. If the seam is welded, it must be made in an argon protective environment (so that alloyed metals do not burn out). This type of connection is necessary for solid fuel boilers, sauna stoves and fireplaces. For all others, you can use a seam connection.

Installation methods

There are two ways to vent the chimney outside. The first is to run the pipe through the wall, and then along external wall raise to the required level. The second is up, through the ceiling and roof. Both are imperfect.

If the chimney is outdoors, condensation actively forms in it due to temperature changes. Therefore, a tee with a condensate collector (glass) and a cleaning hole must be installed in the lower part of the chimney. This unit allows you to maintain the chimney without much difficulty: the glass is unscrewed and the condensate is drained. Also, soot periodically gets knocked off without any problems - you can run a special chimney brush through the cleaning hole.

If the chimney will be discharged through the roof, several passage units will be needed - according to the number of ceilings. If the house is one-story, you will need one passage through the ceiling, and a second through the roof. You will also need a flash master or an apron for round pipe made of galvanized steel.

Installation of a sandwich chimney on the street requires only one pass-through node- through the wall. But it will be necessary to attach it to the wall every 1.5-2 meters. If the walls of the building are flammable (wooden house or frame), the walls in mandatory protected by a non-flammable screen.

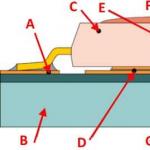

By smoke or condensation

As mentioned above, one side of the sandwich pipe is slightly wider, the other is slightly narrower. Due to this difference in diameter, the modules are connected to one another. If the wider end is turned upward (in the figure on the right), the assembly is called “condensate”. With this installation method, drops of condensate flow down unhindered. The disadvantage of this method is that if the joints are not properly sealed, smoke can leak into microcracks. This type of sandwich chimney installation is used when the pipe is routed through a wall. This is where the free drainage of condensate is required, and small smoke leaks are not scary - they are not critical on the street.

If the narrower edge is turned upward, the second element is put on top of it with the wider part. This type of assembly is called “by smoke” (in the picture on the left). In this case, condensate flowing down the wall may leak through a joint that is not sealed well enough. But the smoke passes freely. This type assembly is used if the pipe goes indoors (out through the roof). Condensate flowing through the pipe, of course, spoils appearance, but it is not as dangerous as flue gases leaking into the room. Moreover, if the joints are well sealed, condensation will not leak out.

In order for the connection of the sandwich chimney modules to be reliable, each of them is usually coated with a heat-resistant sealant and then tightened with a clamp.

Options

Sandwich chimneys are good because they have a modular structure, which allows you to assemble any configuration, with any parameters. Before you go to the store, you need to know the required chimney diameter, pipe height, and those additional elements that will be needed.

Chimney diameter

When choosing the diameter of a sandwich pipe, a simple rule applies: it cannot be less than the diameter of the boiler outlet pipe. If your outlet pipe is 120 mm, then the internal diameter of the sandwich should be the same or larger. It may be wider, but definitely not smaller, and the narrowing cannot be done along the entire length of the chimney. If the chimney is slightly wider than the pipe, an adapter is purchased, which is placed directly at the boiler outlet, and then it's already underway working size.

If you don’t have a boiler yet, but you know its power, you can choose a chimney based on these data:

- boiler power up to 3.5 kW - internal diameter of the sandwich - 80 mm;

- from 3.5 kW to 5.2 kW - at least 95 mm;

- more than 5.2 kW - 110 mm and more.

But it’s better to buy (or at least choose) a boiler, and then decide on the chimney, because many manufacturers insure themselves by making the outlet pipes wider to improve draft.

Pipe height

The height of the chimney above the roof surface depends on the location of its outlet, but at the same time its minimum height should be 5 m. That is, if the height of the house is small, in any case, bring the pipe to a height of 5 meters. If the height of the house is higher than 5 m, then the pipe should rise above roofing material to the following height:

- Should rise 50 cm above the ridge if it comes out at a distance of less than 150 cm from it.

- If the distance from the ridge to the pipe is more than 300 cm, then the pipe may be lower than the ridge level, but the angle should be no more than 10° (see figure).

- If the chimney exits at a distance of 150 to 300 cm from the ridge, its height can be at the same level as the ridge element or higher.

Under such conditions, normal traction is ensured. The smoke will go away normally regardless of weather conditions. To prevent leaves from getting into the chimney, they install special umbrellas, weather vanes, and in windy places - deflectors, which further improve draft.

If it is not possible to bring the pipe to such a height, they install a smoke exhauster - a forced draft is obtained. A fan will not be needed all the time, but in some conditions when natural draft is not enough, forced exhaust saves the situation.

Installation of a sandwich chimney through a wall

When venting a chimney through a wall, there are two ways. The first option (pictured on the left) is to raise it in the room closer to the ceiling and take it out there. The second is to draw a conclusion at the level of the smoke pipe from the boiler. In this case, almost the entire chimney ends up on the street.

The second option is preferable - it has only one knee, which means, under equal conditions, the traction will be better. Also, with this structure there is less chance of soot plugs forming.

If the outlet of the smoke pipe is located not at the back of the stove, but at the top, the installation diagram changes slightly - a 90° elbow is added, then a straight section for passing through the wall, and then the same as in other diagrams.

The stove itself is placed on a non-flammable base, and the wall behind the stove is covered with a non-flammable screen. The easiest way is to fix a sheet of metal to the wall. Can be mounted on ceramic insulators 2.5-3 cm in height. There will be a layer of air between the sheet of metal and the wall, so the wall will be safe. The second option is to place a thermal insulation material under the metal - for example, mineral wool cardboard. Another option is an asbestos sheet (as in the photo).

A hole is made in the wall. Its dimensions are determined by SNiP - the distance from the pipe to non-combustible walls must be at least 250 mm on all sides, and to combustible walls - 450 mm. It turns out to be a solid hole, especially if we talk about walls made of flammable materials. There is one way to reduce the size of the opening for the passage of the sandwich: make the dimensions according to the standards of non-combustible walls and sheathe the opening with non-combustible material.

The opening can be round or square, as long as it is maintained fire safety standards. Square holes are easier to make and cover, which is why they are made more often.

A passage unit is inserted into this hole - a box made of non-combustible material. The sandwich chimney pipe is inserted into it and fixed in the center. All gaps are filled with heat-resistant insulation, the hole is closed on both sides with non-combustible material. This is usually a sheet of metal.

One important point: the chimney must be designed so that there is no junction of two pipes inside the wall. All joints must be visible and serviceable.

Next, you need to make or install a ready-made support bracket that will support the entire weight of the pipe. The design may differ in details, but the main idea is the same - a support platform, which, with the help of stops, transfers weight to the wall.

Homemade support platform for an external sandwich chimney from corners 50*50 mm and 40*40 mm

A similar structure can be welded from profile pipe small section 25*25 mm or 25*40 mm.

As you can see, a tee is connected to the pipe that goes through the wall. At the bottom there is a removable glass in which condensation accumulates. Some models have a fitting at the bottom with a small tap. This is even more convenient - you don’t need to remove the glass, you can connect a hose to the fitting, drain it into some container (it is very toxic, so there is no need to drain it near the house) and drain it by simply turning the tap.

Next, the tube is brought to the required level. Since in in this case the distance to the ridge will obviously be more than 3 m; it is possible that the height of the chimney should be slightly lower than the ridge - no lower than 10° relative to the horizontal line drawn from the level of the ridge.

But since this house is located in a low area; to ensure traction, the pipe was raised even higher than the ridge. It was attached to the wall with stainless steel clamps, in increments of a little more than a meter. The roof is equipped with guy wires made of steel rods with a diameter of 6 mm. To install guy wires, there are special clamps “with ears” to which the guy wires are attached.

Attaching guy wires to a chimney from sandwich tubes

Another important point that many people forget: at the place where the pipe is installed, a snow retention section must be installed on the roof, otherwise in the spring the pipe may be blown away by snow (if the pipe is not routed towards the gable, as in the photo).

How to install a chimney through the roof

When venting a chimney from sandwich pipes through the roof, it is necessary to take into account the location of the floor beams and rafter legs on the roof. It is necessary to arrange it so that the pipe passes between these elements. The minimum distance from the outer wall of the pipe to the combustible element must be at least 13 cm, and this is provided that the combustible element is protected by insulation. To meet this requirement, the pipe often has to be displaced. This is done using two 45° angles.

Please note that the installation of a sandwich chimney from a solid fuel boiler begins with a metal pipe without insulation. In the photo above it is black. After this, an adapter is placed on the sandwich, and a chimney with insulation enters the passage unit.

A hole is cut in the ceiling that meets fire standards - 250 mm from the edge of the pipe, if the ceiling is protected thermal insulation material. Having cut a hole, its edges are covered with non-flammable heat-insulating material. Minerite is best suited for this (it is nailed or secured with wood screws).

The gray material around the perimeter of the hole is mineralite

The sandwich chimney pipe is inserted into the resulting box. It should be directed strictly vertically, without the slightest deviation. You can’t fix it rigidly, you can only give it direction by installing several bars that will hold it, but it can move up/down without difficulty. This is necessary, since when heated its length increases significantly.

The remaining space is filled with basalt wool (check the temperature range). Another option is to pour expanded clay or granulated foam glass. Previously, sand was still poured in, but sooner or later, it all spilled out through the cracks, so now this option is unpopular. On the front side, all this “beauty” is covered with a stainless steel sheet, under which a non-combustible material is placed (between it and the ceiling). Previously, it was an asbestos sheet, but since asbestos is recognized as a carcinogen, mineral wool cardboard began to be used.

There is another option. Trim the edges of the hole mineral wool, and then insert the finished stainless steel ceiling-passage assembly. It immediately contains both a box and a decorative stainless screen.

Having brought the pipe into the attic, make a hole in roofing pie. All films in the passage area (vapor barrier and waterproofing) are cut crosswise. The resulting triangles are wrapped and secured with staples from a stapler. This way the damage is minimal. The exposed sheathing is cut so that it is at least 13 cm from the pipe.

How to bring a chimney through the roof - passage ceiling and roofs

In the right photo above, the passage through the roof is incorrect - the distance between the pipe and the boards is too small. In a good way, you need to cut them according to the standard, and cover them with the same mineralite. The result should be something similar to the following photo.

Master flash for a sandwich chimney - a rubber cap with a flexible “skirt”

The joint between rubber and pipe is sealed with heat-resistant sealant. The roof surface under the “skirt” is also coated with sealant.

Please note that each connection of the sandwich modules is tightened with a clamp. This is also true for the internal chimney.

The chimney in a private house is most often built invisible to the eye. This can be done even at the planning stage of building a house. If there are several chimneys in the house, then they are combined into one or two devices.

Device steel chimney in a private house

The design of the chimney depends on functional features devices for which they are intended. The complexity and configuration of the chimney depends on their location and power.

Types of chimneys:

- ventilation,

- gas outlets,

- smoke

Ventilation systems

Main function ventilation pipes is that they help remove polluted air masses from the room.

Originally made brick ventilation chimney

Originally made brick ventilation chimney Ventilation ducts must be in those places where the room is least ventilated. It is especially important to place such pipes in the kitchen area, bathroom, and toilet.

Gas exhaust systems

Gas exhaust chimney pipes are used if the house uses gas system heating. They remove combustion products outside the room, and thus ensure the safety of using the heating system. Pipes must be able to withstand a variety of influences harmful substances. As soon as combustion products enter the chimney, they immediately react with the moisture that is already in the pipe. As a result of this, an oxidation process occurs, which can cause destruction or internal deformation of the pipe. Also, such a chimney helps to increase draft.

Diagram of the device and design of the flue pipe of the chimney

Diagram of the device and design of the flue pipe of the chimney Smoke pipes

Chimneys are used when heating equipment is installed in the house, which operates on solid fuel– these can be stoves or fireplaces. There are most of them in the house, which is why they are often combined into one or more.

device diagram and design of a brick chimney

device diagram and design of a brick chimney Chimney pipes

The chimney device is quite simple, it involves the use of special pipes, through which polluted air or combustion products are removed from the premises.

Pipes are:

- brick,

- metal,

- ceramic,

- polymer.

Distinctive features of a brick chimney

Despite the fact that today it is very a large number of materials that can be used to construct a chimney, brick chimneys have still been very popular for many years.

Brick chimney

Brick chimney This type of chimney has its advantages. It cannot be plastered inside, which will help save on finishing materials. It is also worth considering that the masonry brick chimney should have a seam of 1 cm. If it is recommended to use cement-lime or lime mortar indoors, then in the upper part of the building you can already use ordinary concrete mixture for masonry.

Advice. In order to use a brick chimney in a house, it is necessary to make a more powerful foundation for the building - brick will add extra load to the walls of the building and to its foundation.

In addition to the advantages, there are also a certain number of design disadvantages. Brick, due to its rough surface, can accumulate dirt. That is why such a pipe becomes clogged with soot very quickly.

Since combustion products exit through a brick chimney, oxygen condensate is formed, which causes brick pipe subject to destruction. It happens that a piece of brick breaks off and falls into the pipe. All this can significantly narrow the chimney channel and make it difficult for air masses to escape.

To ensure a long service life of a brick chimney, it is recommended to insert an asbestos-cement pipe inside. The gap between the brick and the pipe is filled with concrete mortar.

An example of using an asbestos cement pipe

An example of using an asbestos cement pipe Ceramic structures

Ceramic pipes are ready-made structures for constructing a chimney. They are for sale modular design. Its inner tube is made of acid-resistant, heat-resistant and durable ceramic.

Ceramic chimney pipes have a number of advantages and have a very smooth surface. Thanks to this, soot does not accumulate on it, which is formed as a result of the passage of contaminated air masses formed during the combustion process.

Installation of a ceramic pipe for a chimney

Installation of a ceramic pipe for a chimney Like brick chimneys, ceramic chimneys are quite heavy. It is for this reason that it is worth using a foundation for the structure.

Metal chimneys

As for metal pipes for the construction of a chimney, due to their ease of Lately began to enjoy great popularity. They also have a smooth surface, which eliminates the accumulation of soot. Accordingly, the air will flow much better.

Read also

If the apartment is hot: tips on how to solve the problem

High-quality thermal insulation is quite simple. For this purpose it is used basalt wool, which is laid inside the pipe. It will only be necessary to correctly determine the thickness of the material, since a large thickness can completely or partially block the pipe and it will be very difficult for air masses to escape.

Installation of a metal chimney pipe

Installation of a metal chimney pipe As a rule, metal chimneys are made of stainless steel, which is very resistant to all climatic, weather and other influences.

Modern chimney pipes are polymer structures. The pipe itself is very soft and has quite a heavy weight. The chimney will be distinguished by its practicality and durability. You can install the pipe yourself, and any beginner can handle it.

Modern polymer chimney

Modern polymer chimney Most often used polymer pipes if the house has a system gas heating(boilers or columns). Such pipes can only be inserted into a chimney that is made of brick.

Types of chimneys

Today there are two types of chimney structures: a structure located inside the building and a chimney outside the house. They differ not only in the materials from which they can be constructed, but also in size and type.

Drawings and design of internal and external chimneys in a private residential building

Drawings and design of internal and external chimneys in a private residential building Typically, to build a chimney inside a house, brick or ceramic pipes. It is more rational to use metal chimneys outdoors, as they are resistant to temperature changes and are not exposed to moisture.

A chimney inside the house can also be made in two ways, more about this in the video

The chimney can be used in both brick and wooden building. Only chimney in wooden house must be properly constructed, as wood chars very quickly. Eat special technology construction of a chimney in a wooden building.

Construction of a chimney in a wooden house

Most often, there are several chimneys in a wooden house. But the number of such structures largely depends on the amount of equipment used in the house. The house must have a heating system with a separate chimney and may have a fireplace, which also has a separate chimney.

All chimney structures in the house must be installed on the roof of the building and made in compliance with all norms and standards.

Chimney in a wooden house

Chimney in a wooden house In order to properly build a chimney in a wooden house, you need to draw up project documentation and contact specialists in this field who can correctly draw up a chimney project.

The life safety of everyone living in the house depends on a properly built chimney, and the equipment itself will work better. The latter applies to gas heating boilers and pipes for fireplaces.

The chimney in a wooden house should only be in a vertical position. Of course, there is an exception to the rule. You can build it with a deviation that is no more than 30 degrees from the vertical position. If it is necessary to bring the pipes outside, and this cannot be done without moving the chimney pipe, then the size of such a transfer can be no more than 100 cm.

Options for building a chimney in a wooden house made of timber

Options for building a chimney in a wooden house made of timber As for the removal of the chimney on the roof of the building, it will largely depend on the type of roof and the type of roof itself.

Advice. When building a chimney on the roof, it is worth considering the direction of the wind, which is most common in this region. This is necessary due to the fact that if the chimney pipe is connected to a heating boiler, then wind masses can enter the pipe and thereby cause intermittent combustion of the fuel substance.

If there is, then the smoke exhaust pipe must be constructed with high quality. This will prevent smoke from entering the room and allow it to escape outside.

Recently, a chimney for a fireplace in a wooden house is quite complex design, which uses pipe-in-pipe technology.

The chimney itself consists of three components:

- stainless steel pipes;

- layer of thermal insulation material;

- steel pipe.

Initially, a stainless steel pipe is wrapped in thermal insulation material, which can be secured to it using wire or any other material. After this, the finished structure is inserted into metal pipe, which will have a larger diameter than the inner one.

Methods for installing chimney pipes in a wooden house

Methods for installing chimney pipes in a wooden house In addition to this method of constructing a chimney, there is another way; a plastic stocking is used for this. Its main advantage is that it heats up very quickly and cools down quickly. It can also be used when it is necessary to make a fairly large number of chimney passages.

The heating system in any building includes two elements. This is the installation of the heat generating unit itself - a boiler running on gas, liquid or solid fuel, and a system that facilitates the removal of combustion products. The installation of these elements requires close attention. The supply of heat in the house and the safety of people depend on the operation of the system as a whole.

In this article we will look at how to properly install an external chimney with your own hands and present a number of expert tips on installing a chimney. If the chimney is installed incorrectly outside the house, this can lead to unpleasant consequences: reverse thrust exhaust gas exhaust systems (combustion products entering the room), this can cause a fire and people can be injured. There may also be insufficient heating. If you have come to the conclusion that you are quite happy with an external chimney, there is an opportunity to make it yourself without resorting to outside help and save a significant amount of money.

Currently, thermally insulated external chimneys are popular; they are usually called “sandwich” (see).

They have their advantages:

- Good traction (helps increase Thermal efficiency installations).

- Rapid overcoming of the condensation threshold.

- Minimal soot deposits on the walls.

- Durability of the structure.

- The external chimney is easy to maintain.

- Minimum weight.

- Installation in wooden houses is allowed.

- Meets standards fire safety.

The sandwich chimney has three components:

- outer pipe;

- inner pipe;

- layer of thermal insulation.

There are three types of connection of such systems:

- flanged;

- bayonet connection;

- type of connection “cold bridge”.

Attention: The main requirement for all types of connections is one: high tightness. Pay special attention to this.

Before starting installation yourself, you must know the structure of the external chimney. The main thing is to decide what elements you will need and their quantity. Make a drawing and add everything you need to the list.

- Any unit t for heat production - boiler.

- Bends– regulate the movement of exhaust gases. The name of the knee contains information about the angle of inclination. Welding of bends is carried out using argon welding or a tungsten electrode in an argon environment. It is possible to install dampers in them various types and viewing windows.

- Dampers, which are to be installed in bends, pipes, tees and transitions.

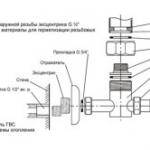

- Tee stand, made from a square stainless steel tube. Fastening to the wall is done using dowels. To do it correctly, you need the right stand for the tee. Be sure to indicate the distance between the chimney and the wall when ordering.

- Tee 45 thermally insulated, stainless, required for connecting the boiler to the bottom of the chimney, vertical direction. A condensate drain pipe and an inspection window can be installed on the side of the structure, or at the bottom of the tee. To comply with all requirements for the installation of chimneys after assembly, the inspection window door should be placed on silicone. There are continuous, solid and prefabricated tees, connections to them are made at different angles.

- Brackets, are made from stainless steel tube. When ordering, be sure to indicate the distance from the wall to the chimney (to comply with fire safety regulations).

- The external chimney must be thermally insulated. Chimney, together with thermal insulation, is placed in a protective casing and thereby forms a so-called sandwich. Standard size half-meter or meter-long pipes; for the manufacture of the casing, not only stainless steel and galvanization are used, but also the customer’s material. Ceramic wool or basalt fiber is used for thermal insulation.

- Dowel bracket reinforced, used when installing reinforced fastening. This helps with lateral loads; they are used to install unloading and expansion cups.

- Top, heat-insulating pipe in a protected casing. The diameter of the casing itself gradually decreases and approaches the diameter of the pipe, this helps protect the insulation from external influences.

- Cap, stainless steel, which is given the required shape by welding with a tungsten electrode.

Now you have an idea of the components and will be able to correctly select all the chimney parts for the heating boiler. Correctly calculate the length and cross-section of the structure.

Attention: At the development stage of the chimney system, parameters such as cross-sectional size and height should be taken into account. The thrust increases with greater length; the higher the pipe, the stronger the thrust. However, a very high chimney will create a large aerodynamic drag moving combustion products. The placement of chimney pipes is clearly regulated SNiP 2.04.05-91. Important has a chimney section. As a rule, it is determined: the ratio of the internal diameter of the chimney to the maximum dimensions of the fireplace firebox opening (height/width) will be 10:1.

When you select the diameter of the smoke channel, you should take into account that, according to GOST 9817-95 the area of the smoke channel along the cross-section of the pipe must be at least 8 cm 2 per kilowatt of power heating unit(fireplace, boiler or stove). And the calculated value of the velocity of exhaust gases in the boiler itself should have an interval of 0.15 - 0.6 m/sec.

Installation of the structure

The external chimney (its main part) is installed outside the building, which is connected by a horizontal pipe through the wall of the building to the heating unit. After installing the heating boiler, it must be connected to a chimney pipe, which will be located outside the building. It's not as difficult as it seems at first glance. However, some rules must be followed.

Rules for performing work

The chimney is installed in all cases from the heating boiler, or rather, from the hob upwards. The gas exhaust pipe is always put on top of the previous one, this avoids the penetration of moisture onto the insulation.

- To seal the structure, a heat-resistant sealant is used, not less than 1000*C.

- Clamps should be used on waste connections, tees and pipes.

- At a distance of two meters, the external chimney must be rigidly attached to the wall with special brackets. They should also be used when fastening tees.

- Horizontal sections of the chimney pipe are not allowed to exceed one meter.

- Avoid contact of gas pipes with chimney ducts and electrical wiring.

- When passing a pipe through a flammable structure, use special fire-fighting pipes.

- Install a removable door for cleaning (this must be done twice a season) of the structure at the base of the chimney.

Installation

When everything is known about the design and the material is ready, you can begin the main work.

- We connect the chimney to the heating boiler pipe using an elbow, pipe or tee (depending on the design).

- We connect the pipe to the chimney using the necessary transition unit.

- We treat the joints with sealant and install clamps.

- The passage through the wall is carried out using a special passage pipe (joining is prohibited in the place where the wall passes).

Attention: All sections of the chimney pipe should be pushed tightly into each other without gaps, the insertion distance should be at least 0.5 of the pipe cross-section (fitting depth).

- We are preparing the installation of the vertical part of the structure. At the end horizontal pipe leading through the wall, we attach a tee with fasteners for vertical pipe. If we use an elbow, it is necessary to create conditions for cleaning the horizontal gap of the connection. When using a tee, the lower outlet is blocked by a plug, which is removed or we use a tee with revision. How and to what to attach the chimney depends on its location. The pipe is attached to the wall with wall brackets every 2 meters. If the main pipe is heavy, the elbow should be supported. It often happens that it is impossible to fasten to the wall along the entire length of the structure; in this case, braces are used.

- We install a clamp with ears, attach clamps to the ears and attach guy cables of the required length to them. In this case, the guy rope must have a diameter of at least 3 mm.

- In the places where the guy wires are fastened, we install eye-pins or anchors (we choose based on the mounting surface).

The next step is to lift and secure the entire vertical pipe structure. It is possible to install it in parts, but this is unsafe work at height, and sometimes completely impossible. As a rule, the pipe is assembled on the ground, fasten all parts with clamps, prepare fasteners for braces and brackets.

- To facilitate this process, we use a hinge.

- We select the desired elbow for connection and fasten the hinge to the edge outer pipe, weld it.

- We raise the finished end of the pipe to the level of the joint and also attach the hinge to the end of the elbow.

- We lift the entire structure using attached cables and a fork. This should be done in good weather; it should not be done in gusty winds.

- We carry out fastening in accessible places.

- For stability, we secure the stretch marks lightly.

- Unscrew the nuts that secure the hinge. We use a grinder to cut off the bolts themselves and knock out the ends.

- We knock out the hinge and fasten the remaining bolts at the joint.

- We perform full tension on the stretch marks. We adjust the tension using the lanyard screws.

The installation has come to an end. We fasten the joint and seal the joint. Afterwards we insulate the vertical pipe and make insulation (this way we will avoid the appearance of condensation). Now you can rest assured about heating your home.

The heating system in any building consists of two parts. This is the heating device itself and the combustion product exhaust system. Installation of these parts requires special attention, because heat transfer into the house and safety depend on them. If the external chimney is installed incorrectly, backdraft may occur and combustion products will enter the room.

Today, external double-circuit thermally insulated chimneys (“sandwich”) are the most popular.

Advantages of double-circuit chimneys:

- There is practically no soot deposited on the walls

- Good draft increases the efficiency of the heating device

- No condensation will form

- Robust design, long service life

- Ease of maintenance

- Light weight

- Possibility of installation in wooden structures

- Compliance with all safety standards

The “sandwich” chimney consists of three parts: the outer and inner pipes, thermal insulation.

Structure of the external chimney:

- Heating device

- Bends for controlling gas movement

- Valves for pipes, bends, tees

- Tee stand

- Tee for connecting a heating device to the lower compartment of the chimney. The tee must be made of stainless steel.

- Stainless steel pipe brackets.

- External chimney pipe with thermal insulation made of ceramic wool.

- Bracket for high-strength dowels for reinforced fastening.

- The top is a part of the pipe in a protected casing with thermal insulation.

- Stainless steel cap.

The diameter of the smoke channel must be at least 8 cm2. per kilowatt of heating device power, at a rate of gas removal from the boiler at intervals of 0.15 - 0.6 m/sec.

Features of installation of an external double-circuit chimney

Most of the external chimney is located outside the building and connects to heating device using a horizontal pipe passing through the wall.

The chimney is installed from bottom to top (from the boiler). To prevent moisture from getting on the insulation, you must always put the gas outlet pipe on top of the previous one. The heat resistance of the sealant must be at least 1000°C. Clamps connect the joints. Every two meters the chimney is attached to the wall using a bracket.

The tees are also attached to the wall with brackets. Horizontal sections of the chimney should not be more than 1 m. You also need to remember that the chimney does not come into contact with gas pipes or electrical wiring.

Our professionals will quickly and efficiently install an external chimney in your home.

The chimney is one of the main heating elements country house. Depending on the location, internal and external chimneys are distinguished. You can do the installation of the chimney yourself. No special knowledge is required to carry out this work. Our article will tell you how it is done.

General rules for installing a chimney

Although installing a chimney yourself is a fairly simple task, you need to know certain rules when doing it. Let's look at them:

- The length of the chimney pipe from its connection to heating equipment to the final element must be more than 5 meters. Otherwise, the draft necessary to remove smoke and other combustion elements harmful to humans will not arise in the pipe.

- Pipe transitions through walls and other ceilings, as well as the smoke pipeline located in the attic of the building, must be reliably protected from overheating, which can cause a fire. For apply special materials resistant to high temperatures, for example, basalt mats.

Insulator for chimney pipe - basalt mat

- The design of the chimney must be clearly designed and calculated. The main indicators are: pipe cross-section and chimney height.

- For reliability, the chimney is attached to the wall with clamps, the distance between which depends on the material used. It is enough to fasten their stainless steel chimneys or sandwich pipes every 1.5 m, and the cast iron chimney duct is fastened every 0.8-1 m.

- All chimney pipe connections in unified system must be located within human visibility. This is required to control tightness.

All construction works for the installation of chimneys should be carried out based on fire safety standards.

Self-installation of a chimney

The installation of a chimney depends on the material from which it is made. Currently there are:

- brick chimneys. To install the structure you will need reliable foundation chimney. It is not recommended to assemble a brick chimney yourself;

- metal chimneys;

- smoke exhaust channels assembled from sandwich pipes;

- ceramic chimneys - mounted based on the diagram of a chimney assembled from sandwich pipes;

- polymer chimneys are mounted in the same way as smoke channels made from sandwich pipes.

Tools required for chimney installation

The chimney structure involves grooves for connecting all elements into a single system. However, to assemble the chimney you will need:

- For smooth cutting a grinder is used for pipes;

- It is more convenient to drill holes at pipe joints with a drill;

- screwdriver or set of screwdrivers;

- a jigsaw is used to cut holes for pipes passing through the ceilings;

- For subsequent sealing of holes, a trowel and spatula are used;

- For personal protection of the person assembling the chimney, goggles and gloves are used.

Set of necessary construction tools: 1- Bulgarian; 2- drill; 3- screwdriver; 4- jigsaw; 5- trowel; 6- spatula; 7- construction glasses; 8- construction gloves

It is not recommended to carry out any work without personal protective equipment.

Installation of metal chimneys

To mount metal chimney, necessary:

- adjust according to the right sizes all constituent elements;

- Make holes in the right places (walls, roof, etc.). If a stainless steel chimney is installed, the diameter of the holes should be 1.5 times the diameter of the pipe used. For cast iron chimneys, it is recommended to make holes twice as large larger diameter pipes;

- a chimney is installed;

- in the necessary places, the chimney is attached to a wall or other solid surface;

- the installed chimney is connected to the heating device;

- all necessary sections of the chimney;

- A cap is installed in the upper part of the chimney pipe, protecting the entire chimney channel from precipitation and foreign objects.

The chimney cap will protect the pipe from precipitation

A metal chimney installed in compliance with all rules and regulations will serve for a long time.

In order to improve the aesthetic appearance of the chimney, you can decorate it using non-combustible materials, for example, ceramic tiles or decorative stone.

Installation of a chimney from sandwich pipes

When building a chimney from sandwich pipes, you must complete all the steps described above. The nuances of assembling this type of chimney duct are:

- no need to make holes in the ceilings large diameter. Sandwich pipes are made in such a way that the necessary insulation is already provided for by the design and all that remains is to protect the surface of the floors from exposure to high temperatures;

- When connecting sandwich pipes together, construction adhesive is additionally used, which gives the connection additional strength and tightness.

Sandwich pipes are the most modern building material. In terms of their quality, chimneys assembled from sandwich pipes are not inferior to metal ones.

Installation of an external chimney

The installation scheme for an external chimney is somewhat different from the construction scheme for a chimney located inside the house. To build an external chimney, you will need:

- a hole is made in the wall at a distance of at least 50 cm from the outlet of the heating device;

- Fastening elements are installed along the entire length of the chimney along the outer wall, the distance between which should not be less than 1 m;

- According to fire safety rules, an elbow is mounted between the inner and outer parts of the wall. The connection to the walls is reliably insulated from overheating. The lower part of the chimney rests on the installed bracket;

- inside the house, the chimney is connected to the heating equipment;

- the outer component of the chimney is assembled and attached to the wall and to the transition elbow;

- the upper part of the chimney is protected by a cap.

For an external chimney, it is more advisable to use metal pipes.

Before you begin installing a chimney, you need to prepare all the necessary components of the system and tools. The chimney is installed according to the above diagrams. The main thing is compliance with fire safety standards.