we knit EVERYTHING with the help of CV

Round neck formation

To start decreasing loops to form a round neck, we make the following calculation:

a) determine how many loops are in a segment equal to 7.2 cm according to the construction of the drawing: 3 loops X X7.2 and 22 loops;

b) we calculate how many rows will be knitted at a distance of a segment equal to 8.2 cm: 4.2 rows X 8.2 yes 34 rows.

Consider decreasing the neck loops when knitting a one-piece front (for a sweater, jumper, dress). We calculate the decrease of loops for one half of the neck.

In our example, it is necessary to reduce 22 loops in each half of the neck. We decrease the loops in approximately the following sequence: the first time we decrease 6-8 loops to the right and left of the middle of the neck, the second time - 3-4 loops each (you can repeat two or three times), the third time - 2-3 loops each (you can repeat three or four times). Decrease the rest of the loops one by one.

We distribute the decrease, regardless of the number of loops, to the middle of the depth of the neckline, i.e. at a distance of the first 3-4 cm.

In our example, we decrease 22 loops at a distance of 16-17 rows in eight receptions (6, 4, 3, 3, 2, 2, 1 and 1 loop). We knit the remaining 17-18 rows evenly.

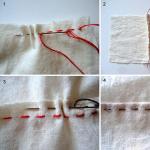

We begin to decrease the loops on the front side of the work (Fig. 271).

271 (Fig. 271) Scheme of decreasing neck loops with round neckline

Having knitted according to the pattern to the neckline, we divide the entire number of loops into two equal parts and then we knit in the following sequence:

1st row (front side) - from the beginning to the middle of the row we knit with the thread of the main ball. In the center of the neck, we attach a thread from an additional ball, close 6 loops with a pigtail (as when fixing the sample) and knit the front row to the end;

2nd row (wrong side) - knit according to the pattern. From the side of the neck, we knit the last two loops together from the wrong side (to get a smooth line of decreasing loops), leave the thread of the additional ball, take the thread of the main ball, close 6 loops with a pigtail (purl loops) and knit the row to the end;

3rd row (front side) - having knitted to the neck, we knit the last 2 loops together with the front one, leave the thread of the main ball, take the thread of the additional one, close 3 loops with a pigtail and knit the row to the end;

4th row (wrong side) - knit to the neck, knit the last 2 loops together, leave the thread of the additional ball, take the thread of the main one, close 3 loops with a pigtail and knit the row to the end;

5th and 7th rows - from the side of the neck we knit 2 loops together with the main thread, and then we close 2 loops with a pigtail thread of an additional ball;

6th and 8th rows - from the side of the neck, we knit the last 2 loops together with a thread of an additional ball, then we close 2 loops with a pigtail with a thread of the main ball.

So gradually decrease 22 loops on each side of the neck. Then we knit evenly.

The reduction of the neck loops in the shelves, which are knitted simultaneously with the bar, is carried out in the same way as indicated in the calculation for the whole front, but in the first row we close all the loops of the bar with a pigtail in one step. We decrease the rest of the number of loops, counting them from the center of the bar, according to the pattern.

Reduction of the neck loops can be done by partial knitting. In this case, open loops are kept along the neckline for further knitting of a stand or a one-piece collar.

Consider decreasing the loops in each half of the neck with partial knitting:

1st row (front side) - at the beginning we knit the loops of the right half of the front, on the left knitting needle we leave the loops of the left half plus 6 loops from the right half of the neck unknitted. We turn the work to the wrong side and knit according to the pattern;

3rd row - at the beginning we knit the loops of the right half of the front, on the left knitting needle we leave the loops of the left half of the front untied plus 10 loops (6 loops + 4 loops) from the right half of the neck. We turn the work to the wrong side and knit according to the pattern.

So gradually, on the left knitting needle, we leave all the loops that are intended to form the cutout of the right half of the neck, i.e. 6, 4, 3, 3, 2, 2 and 1 loop, untied. Further from the side of the neck we knit exactly 17-18 rows. Having finished knitting the right half of the front (when all the loops along the shoulder bevel are reduced), we proceed to knitting the left half. To do this, with the right knitting needle, we draw out new loops from the edge loops of the even part of the neck. In the even part of the neck, 18 rows were knitted, which formed 9 pigtail loops along the side edge (18:2). Therefore, we stretch 9 additional loops along the side edge and get 31 loops in the right half of the neck (22 loops 4-9 loops). We knit all the loops to the end of the row and from the wrong side of the work with partial knitting we begin to carry out the left half of the cutout. We knit the left half in the same way as the right. Having finished knitting the left half and having received 31 loops on the knitting needle, we knit all the loops of the neck (31 loops + 31 loops = 62 loops). We finish knitting with an auxiliary thread or transfer the loops to a spare knitting needle.

When making the neck of products without a fastener, increase the neckline by 2-3 cm around the entire circumference. For this neck shape, it is recommended to distribute the reduction of loops along the entire length of the oval. In this case, the loops are reduced at a distance of 34 rows, i.e. for 17 receptions, which means that the reduction of the loops will have to be done not in each row, but after a certain number of rows.

In our example, we need to decrease 22 loops in the following sequence: 7, 5 and 3 loops through a row and seven times 1 loop in every 4th row.

Reduction of loops along the line of the collar of the head of the sleeve

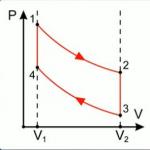

Having knitted to the line of the armhole, we calculate the decrease of the loops along the line of the okon of the head of the sleeve. To correctly calculate the decrease in the loops of the sleeve head, we divide the height of the sleeve head into three equal parts (Fig. 272).

272 (Fig. 272) Scheme of decreasing loops along the line of the okon of the head of the sleeve

According to the construction of the drawing, the segment is 16 cm: 16 cm: 3 \u003d 5.3 cm.

We get points K and K1. Draw a horizontal line through point K1. The points of intersection with the okat line are denoted by the letters K2 and K3 (see drawing). Segment KChK3 - control line. We determine how many rows will be knitted in each part: 4.2 rows X 5.3 ~ 22 rows.

The size of the segment GKhG2 (the width of the sleeve along the armhole line) is 36 cm, or 108 loops (3 loops X 36 cm = 108 loops). Therefore, 108 loops must be reduced along the sleeve line. We calculate the decrease in the loops of the head of the sleeve for each half separately.

Consider the decrease in loops from the back, i.e., on the left. On the finished drawing, we measure the value of the segment K2K: K2K1 \u003d 8.1 cm, or 3 loops X 8.1 "24 loops.

The segment G, G is equal to 54 loops (108 loops: 2). We determine how many loops need to be reduced from the armhole line to the beginning of the third part, that is, to the control line K2K3. To do this, subtract the number of loops in the KK1 segment from the number of loops in segment G: 54 loops - 24 loops = 30 loops.

Thus, it is necessary to distribute the decrease of 30 loops at a distance of 44 rows (number of rows of the first and second parts).

From the armhole line, first we decrease the number of loops equal to the first 4-5 decreases made along the lower edge of the back armhole (segment G1G2). In our example, in the left half of the head of the sleeve we will decrease: 5, 3, three times 2 and 10 times 1 loop in each 2nd row, i.e. through a row. and then three times 1 loop in each 4th row. Decrease stitches begin at the beginning of a purl row.

Consider the decrease of loops along the line of the sleeve head from the front, i.e., on the right.

The segment G2G is equal to 1/2 of the segment G1G2 or 54 loops (108 loops: 2).

The KKH segment when measured is 6.9 cm: 3 loops X 6.9 "21 loops.

Therefore, we decrease 33 loops on the right (54 loops - 21 loops). From the line of the armhole, first we decrease the number of loops equal to the first 3-4 decreases made along the lower edge of the armhole in front. In our example, in the right half of the head of the sleeve we will decrease: 6, 4, 3, 2 loops and 17 times, 1 loop in each 2nd row. We start decreasing loops at the beginning of the front row.

We calculate the decrease of loops in the third part. On the line K2K3 we have 45 loops (24 loops + 21 loops), which must be reduced at a distance of 22 rows.

It is recommended to leave a flat part in the upper part of the eyelet (8-12 loops), which means that only 37 loops need to be reduced (45 loops - 8 loops).

On the left we decrease the loops in the following sequence: seven times 1 and three times 4 loops in each second row, and on the right eight times 1, two times 3 and once 4 loops in each 2nd row, close the remaining 8 loops in one braid.

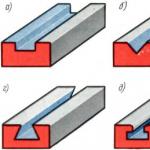

Additional tuck in the armhole

Starting from the 48th size (in cases where the product is knitted in stocking stitch), we recommend that you perform an additional tuck in the armhole. The length of the tuck for all sizes is within 3-5 cm, and its depth does not exceed 1.5-2.5 cm. We perform the tuck with partial knitting in elongated rows, which we knit from the middle of the fabric to the outer edge of the armhole.

To perform the tuck, we perform the following calculation:

a) determine how many loops will be along the length of the tuck: 3 loops X 5 = 15 loops « 16 (round up to an even number);

b) we calculate the number of rows according to the depth of the tuck. The depth of the tuck, equal to 2 cm, is 8 rows (4.2 rows X 2), or 4 phases;

c) determine how many loops we will lengthen each row when knitting an additional tuck: 16 loops: 4 = 4 loops.

Consider knitting an additional tuck in the right shelf.

The width of the shelf together with the strap for the fastener is 29 cm, or 87 loops (3 loops X 29 = 87 loops).

We start knitting an additional tuck after we perform the first 4 decreases (phases) along the lower edge of the armhole, i.e. when 15 loops (6, 4, 3 and 2 loops) are not knitted on the left needle at the end of the front row, and 8 rows will be knitted from the armhole line (Fig. 270). Then we knit like this:

9th row (front side) - we knit 45 loops, we do not knit the remaining 42 on the left knitting needle. We turn the work to the wrong side. Thus, on the left needle, all loops of the lower edge of the armhole and loops intended for additional tuck remain unknitted (26 loops + 16 loops = 42 loops);

10th row (wrong side) - we knit 45 loops in a pattern;

11th row - we knit 49 loops (45 loops + 4 loops), we do not knit the remaining 38 loops on the left knitting needle. Turning the work to the wrong side

270 (Fig. 270) Scheme for decreasing loops in the armhole and knitting an additional tuck

Completed the 1st phase of partial knitting with elongated rows);

12th row - we knit 49 loops in a pattern;

13th row - we knit 53 loops (49 loops + 4 loops), we do not knit the remaining 34 loops on the left knitting needle. We turn the work on the wrong side (completed the 2nd phase);

14th row - we knit 53 loops in a pattern;

15th row - we knit 57 loops (53 loops + 4 loops), we do not knit the remaining 30 loops on the left knitting needle. We turn the work to the wrong side (completed the 3rd phase);

16th row - we knit 57 loops in a pattern;

17th row - we knit 72 loops:

Thus, 15 loops remain untied on the left knitting needle, as before the start of knitting an additional tuck.

From this row we continue the interrupted decrease of loops along the lower edge of the armhole. At the end of the front row, we leave unknitted another seven times, 1 loop each (see “Reducing loops along the lower edge of the armhole in front”). When 22 loops are not knitted from the side of the armhole on the left knitting needle, we knit the front row, and at the beginning of the next we close 22 loops with a pigtail.

Then we knit strictly according to the pattern and, according to the calculation, we decrease four more times, 1 loop in each 4th row from the side of the armhole, that is, a total of 26 loops are reduced along the lower edge of the armhole in front.

When knitting an additional tuck, you can reduce the distance from the armhole line to the beginning of the shoulder bevel by 1 cm.

Thus, when knitting a front for large-sized products, any type of darts can be used. You can combine a side tuck and an additional, side

and horizontal, but the entire length of the finished product should be taken into account.

We calculate the decrease of loops along the shoulder bevel and perform it in the same way as when knitting the back.

Decrease stitches along the bottom edge of the front armhole

We decrease the loops along the lower edge of the armhole on the segment G6G7. We determine the size of the segments G in the same way as when calculating the back. If you need to reduce a small number of loops along the lower edge of the armhole (16-18 loops), we do this in the same way as when knitting the back. But when knitting large-sized products along the lower edge of the armhole, it is required to reduce a larger number of loops - from 25 to 45 loops, depending on the density of knitting and the size of the segment. In our example, the length of the segment is 8.5 cm: 3 loops X 8.5 ~ 26 loops.

The size of the G7PA segment is 8.5 cm, or: 4.2 rows X 8.5 "36 rows.

Therefore, it is necessary to decrease 26 loops at a distance of 36 rows, or in 18 receptions (phases).

You can reduce loops using partial knitting in short rows or closing them with a pigtail, as at the end of knitting, that is, in the same way as in the back.

We decrease the loops in approximately the following sequence: the first time we decrease 6-7 loops, the second time - 4-5 loops each, the third time - 3-4 loops each (you can repeat two or three times), the fourth time - 2-3 loops each (can be repeated two or three times). We decrease the remaining loops, closing 1 loop each time, i.e. knitting 2 loops together.

In our example, we decrease 6, 4, 3, 2 loops, seven times 1 loop in each 2nd row and four times 1 loop in each 4th row.

Closing the loops of the last row, you can pull off the last row or knit 2-3 loops together to get a slight fit of the fabric along the bottom edge of the armhole.

We add 4 to 6 loops to the line of the shoulder bevel at the distance of the segment (if required by the pattern). We calculate the addition of loops in the same way as when knitting the back (at the distance of the segment). In some cases (very narrow shoulders) from the armhole line we decrease the loops to the beginning of the shoulder bevel.

The formation of a horizontal (radial) tuck

When knitting products with a sewn-in sleeve of small sizes, we lengthen the shelf, as in a jacket with a raglan sleeve. If we knit a product of a large size, starting from the 50th, it is recommended to use a horizontal tuck.

We obtain such a tuck by partial knitting with elongated and shortened rows (it is recommended to use the second method of partial knitting). The tuck line is located at a distance of 4-6 cm from the armhole line. To proceed with the tuck, you should make the following calculation:

a) determine the depth of the tuck. In our example, the tuck depth is 3 cm (see "Product Balance Calculation");

b) determine the length of the tuck. We set the length of the tuck in the same way as when knitting a jacket with sleeves

raglan (see "Horizontal tuck"). In our example, the length of the tuck is 15 cm. We calculate the number of loops along the length of the tuck: 3 loops X 15 = 45 loops;

c) set how many rows need to be knitted at a distance of 3 cm (tuck depth): 4.2 rows x Z ~ “12 rows (round up to an even number of rows).

The tuck is performed by two types of partial knitting. We distribute for each type of knitting 6 rows (12 rows: 2 or 3 phases.

We determine how many loops we will lengthen or shorten the row in one phase: 45 loops: 3 = 15 loops.

Consider the technology of knitting a horizontal tuck in the right shelf (Fig. 269). We perform the first half of the tuck in elongated rows from the middle of the canvas towards the side line, and the second - in short rows from the side line to the middle of the canvas. The width of the shelf together with the strap is 29 cm, of which 25 cm (3 loops X 25 cm = 75 loops) we knit with a shelf pattern and 4 cm (3 loops X 4 cm = 12 loops) with a strap pattern. For the entire width of the shelf, we collect 87 loops (3 loops X 29 cm = 87 loops).

Having tied up to the tuck line, we begin to knit in elongated rows:

1st row (right side) - at the beginning of the row we knit 57 loops along the pattern (of which 15 loops are intended for tucking), we do not knit the remaining 30 loops on the left knitting needle until the end of the row. We turn the work to the wrong side;

269 (Fig. 269) Scheme of knitting a horizontal tuck

2nd row (wrong side) - we knit 57 loops according to the pattern;

3rd row - at the beginning of the row we knit 72 loops along the pattern (of which 30 loops are intended for tucking), we do not knit the remaining 15 loops on the left knitting needle to the end of the row. We turn the work to the wrong side;

4th row - we knit 72 loops according to the pattern;

5th and 6th rows - we knit all the loops of the row to the end.

We knit the second half of the tuck in short rows;

7th row - at the beginning of the row we knit 72 loops along the pattern, the remaining 15 loops on the left knitting needle are not knitted to the end of the row. We turn the work to the wrong side;

8th row - we knit 72 loops according to the pattern;

9th row - at the beginning of the row we knit 57 loops, the remaining 30 loops on the left knitting needle are not knitted to the end of the row. We turn the work to the wrong side;

10th row - we knit 57 loops according to the pattern;

11th row - at the beginning of the row we knit 42 loops, the remaining 45 loops on the left knitting needle are not knitted to the end of the row. We turn the work to the wrong side;

12th row - we knit 42 loops according to the pattern;

13th row - we knit all 87 loops of the row to the end.

Shoulder line formation

To determine in what sequence it is necessary to perform the decrease of loops along the shoulder bevel PHA2, we perform the following calculation:

a) according to the finished drawing, we set the value of the segment Pha: P ^ a \u003d 14 cm, or 3 loops X 14 \u003d 42 loops;

b) determine how many rows will be knitted in the segment A ^ a, equal to 5.8 cm (shoulder bevel height): 4.2 rows 5.8 ~ 24 rows;

c) we decrease the loops along the shoulder bevel, closing them with a pigtail, as at the end of knitting, or using partial knitting in short rows. In any case, we perform a decrease of 42 loops in 12 steps, or 12 phases (24 rows: 2);

d) determine how many loops need to be reduced at one time: 42 loops: 12 = 3.5 loops. When dividing, we get a fractional number, so we will decrease by alternating 3 and 4 loops.

Using the method of fastening loops with a pigtail, at the beginning of each row we close 2 loops, in the next decrease - 3, and at the end of each row we will knit the last 2 loops together. As a result of such a decrease, we get a smooth line of the shoulder bevel.

When decreasing loops with partial knitting at the end of each row on the left knitting needle, we leave 3 loops untied once, another time 4 loops - until 42 loops remain untied on each side. Then we knit all the loops along the shoulder bevel and close them in a row with a pigtail.

We reduce the loops of the sprout in the same way as when knitting a jacket with raglan sleeves.

Product balance calculation

A good product fit depends on the definition of balance, i.e. the difference between the length of the back to the waist and the actual length of the front to the waist.

In our example, the length of the back to the waist is 39.5 cm. The length of the front measured from the 7th cervical vertebra (Fig. 255) is 53.5 cm. [More...] To more accurately determine the actual length of the front to the waist, subtract from this value the distance along the curve from the 7th cervical vertebra to the highest point of the neck, i.e. the value of the segment AA2 (we measure it according to the drawing with a centimeter placed on the edge): AA2 = 7.8 cm.

Therefore, the actual length of the front will be: 53.5 cm - 7.8 cm = 45.7 cm.

Now, to set the balance, we subtract the length of the back from the actual length of the front: 45.7 cm - 39.5 cm = 6.2 cm.

Thus, the front should be 6.2 cm longer than the back.

We check what the length of the front to the waist is in the drawing. The proposed construction provides for an increase in the shelf for all sizes by 3.5-4 cm. This value includes 1 cm (allowance for the length of the back for the convexity of the shoulder blades) plus the height of the sprout (segment A1A2), equal to 2.5-3 cm. Therefore, the length the front in the finished drawing is equal to the length of the back to the waist (39.5 cm) plus the increase (1 cm + 2.5 cm = 3.5 cm): 39.5 cm + 3.5 cm = 43 cm.

In order to determine the amount by which it will be necessary to lengthen the front when knitting, the value taken to increase the shelf when constructing the drawing should be subtracted from the balance of the product. In our example: 6.2 cm - 3.5 cm » 3 cm.

Therefore, when knitting, it is necessary to lengthen the front by 3 cm. The resulting value can serve as the depth of the tuck.

You can also set the depth of the tuck in another way: from the actual length of the front to the waist, subtract the length of the front obtained when constructing the drawing: 45.7 cm - 43 cm \u003d "3 cm.

The second way to decrease armhole loops

The decrease of loops along the lower edge of the armhole can be done by partial knitting in short rows. To do this, at the end of each row, we leave the loops untied in the following sequence: 5, 3, 2 and 1 loop, i.e., the number of loops, which, according to the calculation, is reduced in each row.

To finish partial knitting, first on the front side of the work, and then on the wrong side, we knit all the loops to the end of the row, and at the beginning of the next we close 14 loops with a pigtail. The remaining loops that still need to be reduced (in our example 4 loops, i.e. 18 loops - 14 loops), we decrease 1 loop in every 4th row. In total, we decrease 18 loops on each side of the back.

Then we knit, adding loops along the G3P line (if the shape of the pattern requires it). To determine how many loops you need to expand the back to the beginning of the shoulder bevel, you should mark the point of intersection of the line of the beginning of the shoulder bevel with the vertical line A3G on the drawing of the back, with the letter P.

268 (Fig. 268) Scheme of decreasing loops along the lower edge of the back armhole

The value of the segment Pxp is measured according to the finished drawing. In our example, P1, n = 1.7 cm, or 3 loops X 1.7 "5 loops. Also, according to the finished drawing, we measure the value of the segment G3p: G3i \u003d 13.6 cm, or 4.2 rows X13.6 "~ 57 rows.

We determine how many rows we will add loops: 57 rows: 5 = 11 rows.

Therefore, in each 11th row on both sides we will add 1 loop.

The first way to decrease armhole loops

Consider in detail the decrease of 18 loops at a distance of 25 rows (Fig. 268). We start decreasing the loops from the front side of the work:

1st row (front side) - at the beginning of the row with front loops, close 5 loops with a pigtail, as at the end of knitting, and knit the row to the end;

2nd row (wrong side) - at the beginning of the row with purl loops, we close 5 loops with a pigtail, and at the end of the row we knit the last two loops together with the purl;

remember that if, when decreasing loops at the end of each row, 2 last loops are knitted together, then at the beginning of the next row, one loop less is reduced than indicated in the calculation.

So, for example, at the beginning of the 3rd row, we close with a pigtail not 3, but only 2 loops. As a result of such a decrease, we get a smooth line of decreasing loops.

3rd and 5th rows (front side) - at the beginning we close 2 loops with a pigtail, and at the end of the row we knit the last 2 loops together with the front;

4th and 6th rows (wrong side) - at the beginning we close 2 loops with a pigtail, and at the end of the row we knit 2 loops together from the wrong side;

7th and 9th rows - at the beginning and at the end of the row we knit 2 loops together with the front one;

8th row - at the beginning and at the end of the row we knit 2 loops together on the wrong side;

10th row - at the beginning we knit the first 2 loops together on the wrong side.

Thus, in 10 rows, 15 loops were reduced on each side, therefore, 3 more loops must be reduced:

a) on the front side of the work in the 13th, 17th and 21st rows, we decrease 1 loop each, knitting at the beginning of the row 2 the first loops together with the front;

b) on the wrong side of the work in the 14th, 18th and 22nd rows, we also decrease 1 loop each, knitting the first loops together at the beginning of the row 2 on the wrong side.

Decrease stitches along the bottom edge of the armhole

According to the construction of the drawing, the value of the segment G, G2 (lower edge of the armhole) is 6 cm. Determine how many loops need to be reduced in the segment GKHG2: 3 loops X 6 = 18 loops.

We decrease the loops at a distance of the GKhG3 segment, equal to 6 cm. We determine how much

knitted rows: 4.2 rows x 6 \u003d ~ 25 rows.

Therefore, at a distance of approximately 25 rows on each side, we decrease 18 loops.

We decrease the loops along the lower edge of the armhole (when knitting any size) in approximately the following sequence:

a) for the first time we decrease (close with a pigtail, as at the end of knitting) from 4 to 6 loops;

b) the second time - 3 loops each (such a decrease can be repeated 2-3 times);

c) for the third and fourth times - 2 loops each (can be repeated 3-4 times). The remaining loops are reduced, closing 1 loop in every second row (or after 3 rows in the 4th).

In our example, we decrease 18 loops in the following sequence: 5, 3, 3, 2 and 1 loop in every second row, i.e. through a row. The remaining 4 loops are reduced by 1 loop through 3 rows in the 4th.

Knitting is a favorite needlework for many women. Someone is engaged in the manufacture of only small things - socks, mittens, scarves. Other craftswomen go further and make sweaters, skirts or dresses to order. To facilitate their work, such women should definitely purchase a knitting machine and learn how to use it.

On sale today there are a variety of models of such equipment, differing in functionality, device, degree of equipment, etc. In principle, a device such as a knitting machine is not too complicated to use. For beginner needlewomen, almost any model is suitable. But it is better, of course, to try your hand at equipment that has the simplest design.

Types of knitting machines

On the modern market, only two main types of such equipment are offered: industrial and intended for domestic use. All machines used at home belong to the flat knitting class. However, they may differ:

By the number of needles. For knitting things, single-line and double-line machines can be used.

By class. Each model is designed for a specific range of yarn thicknesses.

By type of management. Distinguish ordinary mechanical machines, punched cards and computer.

Single-loop machines: design features

A typical representative of this type of equipment is the domestic Neva-5 model, familiar to almost all experienced needlewomen. This one is the best for beginner needlewomen. The design of this device is very simple. The machine set includes:

Threaders and thread guides.

The carriage responsible, in fact, for knitting.

Row counter.

Metal needles with tongues.

Plates-rails on which the carriage walks.

A single-hole machine can be fixed on any table with the help of special screws.

Single-loop machines: principle of operation

This option for a beginner needlewoman will be just perfect. Single-loop machines can be used for all basic types of knitting. Learning to work on such equipment will not be difficult. The technique for manufacturing products using single-line machines is approximately as follows:

Yarn is pulled through the thread guide, thread guide and a special hole in the carriage.

With the help of a special ruler, the required number of needles is advanced forward.

The yarn is pulled on them not too tight (otherwise the carriage may break it).

With the help of a special screw, the required knitting density is set (depending on the thickness of the yarn).

The carriage levers are moved to the working position.

The first row is knitted.

In order for the loops not to jump off the needles during further work, a pull comb is hung on them (not in all models).

If you just drive the carriage to the right / left, you get the usual surface. To knit an openwork thing, you need to use a special tool, a decker, to outweigh the loops from one needle to another according to the pattern of the pattern.

Which single-line model should I buy

"Neva-5" is a very easy to use knitting machine. For beginners, in addition to this popular model, the Severyanka is also likely to be a good fit. Unfortunately, at present, the production of knitting machines in our country has been completely discontinued. Therefore, you can buy a domestic model, including the Neva-5 or Severyanka, only with your hands. The same needlewomen who prefer new equipment should take a closer look at the imported single-hole Toyota or Silver models. Brother brand equipment also enjoys a good reputation among knitters.

Benefits of double jet machines

Using a model with two needle beds allows you to knit better things. The fact is that only flat parts can be manufactured on a single-loop device. Sleeves and sides at the end of knitting have to be connected on a sewing machine. In addition, products made on such equipment have both a face and a wrong side. So, on the reverse side of things associated with the use of threads of several colors, ugly broaches remain. In a sock, such products will not be particularly comfortable. Putting on, for example, an ornamented sweater, the broach can be easily hooked and pulled out. At the same time, an ugly dent is formed on the front side. It will not work to knit on such a machine and elastic bands (only snags).

Double-loop models are devoid of all these shortcomings. Knitting on a knitting machine for beginner needlewomen in this case will be more difficult, since there are two needle beds for devices of this variety. However, by adapting to such a model, you can make things in which both sides look like the front. Also, elastic bands are knitted using a two-line machine. The procedure in this case will be quite lengthy, and many operations will have to be performed manually. However, elastic bands knitted by machine are much more even and of higher quality than those made using knitting needles.

The best models of two-liner machines

Structurally, such equipment differs from single-line equipment only in that it has a special attachment that allows you to perform circular knitting. Such an addition, if desired, can be purchased for all the brands of knitting machines discussed above, with the exception of the Severyanka and Toyota models.

Knitting machine classes

Of course, before buying a knitting machine, you should decide what exactly it is for. The fact is that different models are designed to work with yarn of various thicknesses. If you only want to knit socks, mittens and thick sweaters, you should get a third class knitting machine. Such models are designed to work with yarn 100-200 meters / 100 grams. These machines can take such a thick thread due to the fact that their needles are far enough apart.

Class 5 models are designed for the manufacture of both rather thick and thin things (300-500 meters / 100 grams). Such a knitting machine for beginner needlewomen is best suited. With its use it will be possible to make both mittens or socks, as well as sweaters or scarves. It is to this group that, for example, the same Neva-5 belongs.

Class 7 machines are designed for making only very thin things from yarn 500-600 meters / 100 grams.

What is a punch card model

Today, there are also quite easy-to-use equipment on sale, with which you can make very beautiful products with patterns. A punch card model is also a good answer to the question of which knitting machine to choose for beginner needlewomen. In a device of this type, the selection of needles is carried out using special cards with holes, the location of which corresponds to the pattern of the pattern. The design of models of this variety, in addition to the main elements, includes a special device - a puncher, into which the card is inserted.

computer machines

PC-powered equipment is, of course, the most expensive and convenient variety. Needle control in such machines is carried out using not a punch card, but special software installed on a home computer. The convenience of electronic models lies in the fact that they can be knitted with a variety of patterns without limiting the loops and along the given contours.

Greetings! Today I will reveal a few "secrets" of knitting on a machine. I think this information will be very useful for those who are just going to start machine knitting.

In particular, we will talk about yarn that can be used when knitting on a machine. And also, about some important points of the knitting process, which open up over time, as a result of numerous mistakes and many hours of searching.

- What yarn is needed for knitting on a machine?

- Why are loops dropped?

- How to replace the spoke in the load carrier?

- How to rewind threads?

I am sure that many people who take up a knitting machine for the first time have similar questions.

The word "secrets" in this case is rather conditional, because no one specifically hides such information. Simply, over time, you begin to learn the true meaning of the expression that "the smart one learns from the mistakes of others." Indeed, this allows not only to save time, but also to save nerves, which are spent a lot in the early days of mastering the intricacies of machine knitting.

Therefore, I offer this article to beginners as information for reflection and an opportunity to avoid some problems when knitting on a Silver Reed 840 machine.

Read also the next article in this series « »

__________________________________________________________

The article is built in the form of an "interview", since the reason for writing it was some questions that came to the mail. If you also have new questions, please ask them in the comments, because I do not always have time to answer in a personal. And here the answers will be available to other visitors.

___________________________________________________________

First. Is it possible to knit on a machine with the yarn that is knitted and crocheted?

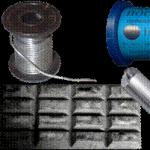

Yes, you can knit on a machine not only with special yarn - in bobbins. But also with threads intended for hand knitting. They look like this, i.e. sold in skeins.

But, this requires a winder. When we first assembled our knitting machine, of course, we immediately began to look for information about what kind of thread to knit with. Almost everywhere it was written that threads industrially assembled into bobbins should be used. The store where we first chose the yarn also said that we should buy a whole bobbin. When asked how to knit in several threads from such a large bobbin, we received an answer that we can order, and we will be rewound the right amount. Or, you need to purchase a winder.

It turned out that we had to constantly make an order in advance. Moreover, at that time we had no idea how many threads go into products, etc. Moreover, we could not even imagine how the ball should look like when it is rewound. Well at least, in the store itself there were such balls ready-made. So, at the first rewind, we already had some idea of what should happen in the end.

Second. What are winders? And where to buy such a device for rewinding?

As far as I know, there are different reels, including electric ones. But, today we are quite satisfied with the device for manual rewinding from the Camma company, which we immediately bought in the Verbena store (Ufa). Then, in 2012, its price was 1000 rubles. I was very happy about this, because I saw them on the Internet for 1500 rubles. Now, that is, in November 2014, I saw in a shop for 1300 rubles.

As for where to buy them, I will not give special advice, because everyone lives in different regions. One thing I can say from personal experience is that of all the shops where we buy yarn, we found them only in Verbena.

In addition, I saw that exactly the same ones are offered on the Odnoklassniki social network, also at a very reasonable price. True, I can’t give links, I don’t remember who I saw. But, if someone needs it, I can look.

I will quote part of the text from the specified page:

“Proper preparation of the thread for knitting is very important. This will facilitate the knitting process, make it more enjoyable. In addition, the quality of your products will improve markedly. It is impossible to knit with a thread from a skein or from a ball wound by hand. We recommend using a winder to wind the thread into balls suitable for machine knitting.”

Now, when we need to knit with a thread in two or three additions, we rewind from the main bobbin, that is, we prepare more hanks. And we knit, for example, in two threads, so.

Third. How to rewind knitting threads on a machine?

To knit with hand knitting yarn, it MUST be rewound. This can be done, for example, using a manual winder.

I must say that this is another difficult moment that we had to overcome. It turned out that it was not enough to buy a winder. I had to figure out how to wind the strings around it. The store did not explain this, they said that there is an instruction, they say, everything is clear in it.

Yes, everything was clear, except for one thing - so what to wind on? If right on the cone of the winder, when you remove the resulting ball, it does not hold its shape, it strives to fall on the barrel. Although, in the photo in the Instructions, which was shown earlier, it seems that the tip of the thread is pulled out from the middle.

It was then that an idea came up that would seem strange to the uninitiated in the action of machine knitting (to say the least :). They began to use toilet paper sleeves as the basis on which the thread is wound. And, thanks to which it perfectly holds the whole ball.

If necessary, see the detailed photo-MK, which showed:

- What does a manual reel look like?

- how to use bushings as cones,

- how a skein should look like, ready for knitting on a machine, etc.

Fourth. Why put yarn in pots?

One day I received a letter with such a question. The girl was perplexed why on some sites it is recommended to put threads in pots while knitting.

This feeling of surprise was very familiar to us, because an unfamiliar kind woman in the store advised about the same thing when we, being quite beginners, were engaged in the choice of yarns: “Put the skeins in two saucepans and knit for yourself”.

The essence of the idea is not what to put the skeins in. It often happens like this: when the thread in the ball ends, this ball begins to “jump and jump” when passing through the next row. And, it can even fly off the table.

When the skein is full, the thread quietly slips off it, the bobbin does not even budge. But when the thread in the skein ends, it becomes very light. The carriage passes quickly, the thread must also unwind rapidly, i.e. the cone rotates at high speed, rushes around the table. When it "flies" off the table, it's troublesome to pick it up.

To avoid this, we put small balls and incomplete bobbins in advance in some kind of vessel. For example, in a cup (with a volume of two to three liters). Then, during rotation, they hit its edges, but do not fall. Accordingly, they do not interfere with knitting.

Fifth. What yarn can be knitted on a Silver machine?Is it true that cotton is not suitable for him?

Here I will answer briefly. The Silver Reed 840 is a great car. We knit on it with acrylic, p / w (wool mixture), linen thread, cotton.

Cotton perfectly fits both bobbin and handmade. elm (for example, "Coco", "Pelican"). Culinary smoothness, openwork, elastic bands - everything works out. The main thing is to choose them correctly according to the thickness (density) that the machine “takes”. More on this below.

Sixth. Can I use hand knitting thread on the Silver Reed 840?

To find the answer to the same question, at the very beginning of our training, we had to “shovel” a lot of different Internet resources. As for yarn in bobbins, designed specifically for machine knitting, there were no particular problems. In online stores selling threads, it is easy to read all the data on threads: composition, density, etc.

Regarding knitting with yarn intended for hand knitting, there was very little information. In the end, I had to find out by experience. They bought different yarn intended for hand knitting and started knitting.

And found out that for our machine Silver Reed class 5 suitable yarn within 300 - 600 m / 100gr. Let me remind you that before knitting, such threads are pre-rewound. Now we constantly knit hats, scarves, shirt-fronts with such threads.

We also tried thicker threads, 220-250 m / 100 gr. The machine knits, albeit with difficulty. But, the canvas is not very attractive, it costs a "stake".

Seventh. What to do if the loops from the edge of the canvas fly off all the time?

So that the thread along the edge of the canvas does not fly off the needles, every 10 rows we hang and rebalance edge weights.

We do it this way. When 20 rows are connected, from two edges, in turn, we feel for the beginning of knitting and carefully pull it down. At this moment, you need to look not under the typewriter (you can’t see anything there anyway), but at the needles of the place where you are doing the quickdraw. You can immediately see that they are aligned and the thread "falls" into the groove of the needle. They pulled it back by hand and hung the load. Repeated on the right side. Usually I knit standing up, so I squat down. If I'm sitting on a chair, I just lean to the left, then to the right.

The above applies to double knitting. Naturally, with one fountain it is easier to observe what happens in the process of knitting. Yes, and it is easier to outweigh the loads.

It may seem like a hassle to do all these extra body movements with outweighing. Yes, this is an additional load on all muscles. But, on the other hand, now we have practically forgotten about the dropped loops at the moment when part of the canvas is connected. It happens, but rarely.

By the way, we showed one more "secret" with a video lesson "". Seems like a simple question, but it's often asked.

Eighth. Why hang loads?

We, too, at first could not understand what the meaning of this action was. Why is it necessary to immediately hang the comb, and then the weights? What happens if you don't hang?

Now, of course, we understand that if this is not done in a timely manner, the loops can (and will) pop out of the needles. In general, knitting will not work. This has already been said above when it came to hanging edge weights, I will not repeat myself.

But, since we are talking about a mounted comb, I want to add some more information from personal experience.

In the comb of the load carrier, the spokes can be changed. They are sold in some stores. Let's say we bought it at Verbena. Sellers call this knitting needle plainly - "bar".

The fact is that as a result of our experiments with a thick thread, our rod quickly lost its shape, it all bent. As a result, we have a serious problem. Each time, threading it into the comb, I had to suffer. The needle stuck anywhere, did not want to thread through the holes. Especially at the end of the line, when there were 7-10 centimeters left.

It would seem that it is easier to replace everything. But, it was not easy to buy it. Firstly, because they are not sold in all the stores where we took the yarn. Secondly, a couple of times when we came to the store, where they can still be found on sale, and asked about the knitting needle, we heard that "they are already sold out." Recently, I finally managed to buy these precious rods (they took two at once, 120 rubles each) and breathe freely.

So, the conclusion is this - it is better to handle the needle in the tension comb with care. It seems like a trifle, but it turned out not at all.

____________________________________________________________________

That's all for today. Thank you for your attention. I hope the article will be useful to those who are at the beginning of their creative journey in machine knitting.

Sincerely, Saule Vagapova

Seal

So, there was a long-awaited purchase of a knitting machine. However, it is quite difficult to figure out how to knit on a machine on your own. Today there are many knitting machines, each of which has its own advantages and features.

Where to start work?

If you decide to figure out how to learn how to knit on a machine, then you need to understand that in any type of work you must be guided by certain rules. Before you start working with the machine, you must read the instructions for it. First you need to understand what functions a knitting machine can perform.

Thread selection

So, the allowable thread density is determined by the class of the machine. So, there are cars of 3, 5, 7 classes. Each class of machines has its own number of needles, and the density of the thread depends on it.

The third class is equipped with needles in the amount of 120-150 needles. Large yarn can be used on this equipment. The fifth grade has 180-200 needles. In this case, the use of a medium type of yarn is allowed. The seventh class of machines is equipped with 250 needles. For such machines, only thin yarn can be used.

Testing

Naturally, for the first time, an inexperienced knitter will not be able to create a quality product. First you just need to learn how to handle the machine, and then gradually approach the most crucial moment, for which everything was started: how to knit on a machine. To do this, you need to take a small thread, which in terms of parameters corresponds to the class of the machine. It is desirable to take a thread of light shades so that it can be better seen in the process of work.

For the first time working on the machine, you need to take a yarn consisting of one thread. If you work with several thin threads at the same time, then tangling and delamination cannot be avoided. Ideal parameters for yarn that can be used for the first time when working with absolutely any brand of machine: 500-350 m. per 100 grams. Threads can be purchased at any needlework store, you just need to specify the necessary parameters to the seller.

Winder and needle bed

To work with the machine you will need a manual winder. It is necessary in order to rewind the hanks before starting work. With its help, the skein acquires a cylindrical shape, and this greatly facilitates the moment of threading the thread into the machine. Also, the winder will allow yarn to be fed into the machine without hooks and knots.

Further in the work, you need to pay maximum attention to the needle bed, as well as the carriage (the moving part of the machine). It is necessary to see where these parts are located at the first stage, at the beginning of work with the machine's instructions.

Initial exercises

It is better to start knitting on a machine with elementary exercises. One of these exercises is a set of loops on machine needles. After this exercise is mastered, you can move on to other more difficult ones. For example, you can start using different options for weaving threads. Then you can move on to more complex work options, namely, try to do the following manipulations:

- add one loop in the direction of the carriage;

- move the loops to implement openwork knitting;

- fasten the loops.

Production of the first product

After the basic techniques of working on the machine have been mastered, you can proceed to the manufacture of the first product. A product model is suitable, for the creation of which you need to use one type of thread and the same pattern. It is worth paying attention to patterns. For beginners, it is recommended to take models already with ready-made patterns, then mistakes can be avoided.

As a rule, if the pattern is taken from a popular magazine or book, then a complete instruction, which contains step-by-step actions for creating a specific model, is described there.

Common mistakes

When the model of the future product is selected, it is necessary to carefully consider all the patterns that will have to be performed. These patterns need to be created on a typewriter in the form of a sample. Samples are necessary so that errors in length and width can be avoided. With the help of samples, you can calculate how many loops you need to make in order to achieve the desired parameters. Do not try to neglect this stage of work, since the width of the loops on the needles will be completely different, which means that mistakes cannot be avoided in this case.

Sometimes you don't like the result. For example, the product does not sit on the waist. Then it is better to dissolve what happened. Products are usually unraveled using a special winder.

Making mistakes at the beginning of learning machine knitting is natural. Therefore, if something does not work out, do not despair. In order to understand how to knit on a knitting machine, you can seek help from craftswomen on special forums or purchase video tutorials for beginners.

Nowadays, the industrial clothing industry is multifaceted and such a thing as self-knitting, it would seem, should sink into oblivion. However, this hobby is gaining more and more development, which is not surprising, because even the most high-quality thing made on an industrial scale cannot replace the “heartfelt warmth” and individuality that hand-knitted things have. But even this process at home can be automated if we are talking about machine knitting.

The cloth knitted by hand will be more magnificent. The machine presses the product evenly.

Hand knitting has dozens of different patterns and knitting techniques, and although knitting machines are constantly being upgraded, they still cannot afford to have so many pattern modes. The speed of obtaining the finished product is also important. However, there is no automatic knitting mode without human participation in it.

Types of devices

How to learn to knit on a knitting machine

It must be understood that, despite its compact appearance, a knitting machine is a serious technical device, and if you seriously decide to learn and understand how to knit on a knitting machine, then you should be patient.

Of course, the first question that should be before us before we start using a knitting machine is what to knit from.

What yarn to choose

At the first stages, experts advise choosing soft yarn. The threads should be of medium size.

IMPORTANT. Threads for machine knitting are produced in separate spools and can be not only from natural wool, but also synthetic.

Next, it is important to prepare the yarn for knitting. In this case, it means that the yarn needs to be unwound and rewound into a ball. This will give our threads lightness, and knitting will take place evenly and without jumps, which, of course, degrade the quality of the product.

IMPORTANT. Spools of factory threads are usually wound very tightly, they must also be rewound into a new ball before knitting.

knitting process

It is believed that the first row is the most difficult test, after which many people give up their attempts to knit on their own. But after all, any undertaking is not easy, however, we only need accuracy and attentiveness.