Any enterprise working with meat products prepares meat in accordance with a certain technological cycle. The primary processing of meat involves a number of operations - from thawing and drying to cutting. Let's consider each stage in more detail.

Thawing meat

This is the slowest process. Thanks to this, the meat juice, which is contained in the form of crystals, is absorbed into the muscle fibers during slow thawing, and this allows the meat to almost completely restore its properties. Slow thawing leads to the fact that the meat loses only about 0.5% of the weight if it thawed in half carcasses. The primary processing of meat and offal begins with thawing, while this process requires compliance with a number of rules:

- meat must be thawed before being cut into pieces;

- thawing takes place in chambers where the humidity is 85-90% at a temperature of 4-6 degrees;

- thawing in chambers takes 2-3 days.

Meat can be thawed in a quick way, but already at a temperature of 16-18 degrees. After thawing, the meat is kept in the chamber for about a day, but already at a temperature of +2 degrees.

Defrost Features

The primary processing of meat begins with defrosting, which makes it possible to restore its original properties. It is impossible to defrost meat in water, cut carcasses into small pieces, since in this case the raw material loses meat juice significantly, decreases, and the quality of semi-finished products becomes worse.

An important role in defrosting is played by washing the meat. It is necessary in order to remove microorganisms, spores, microbes and bacteria from its surface, which can be very numerous. When washing with warm water, surface contamination can be removed from the meat by almost 99%.

Washing and drying

The technology of primary processing of meat necessarily includes washing and drying. In muscle fibers, the product is practically sterile, which cannot be said about its surface. If the surface is not treated in time, microorganisms from the surface of the meat will get inside the semi-finished products, and they will be spoiled. Washing with warm water is used to reduce bacterial contamination and remove mechanical impurities from the carcass. This is enough to reduce surface contamination by microorganisms by 95-99%. Washing is performed twice, and the same water cannot be reused.

The technology of primary processing of meat and meat products involves washing by hanging the meat on hooks and rinsing with clean running water from a hose, hose or a special shower. Meat washing can also be done in bathtubs using nylon or herbal brushes. The washed carcasses are chilled using cold water. After that, the meat is dried.

Drying

The primary processing of meat involves drying the carcass. For this, circulating air passed through filters at temperatures up to 60 degrees is used. If the enterprise is small, then the meat can be placed on grates under special washing baths or hung on hooks, after which it is dried either in the air or by rubbing with cotton napkins. The task of the process is not only to dry the surface of the meat, but also to prevent the reproduction of microbes.

Division into parts

The stages of primary processing of meat are as follows:

- thawing meat;

- washing;

- drying;

- division into parts;

- deboning;

- trimming and cleaning;

- production of semi-finished products.

The cutting of carcasses into parts is carried out in accordance with the properties of muscle and connective tissue and taking into account how exactly the meat will be used in the future - for frying, boiling, stewing, and so on. Note that parts of the same carcass differ in nutritional value, chemical composition, calorie content, and taste properties. Therefore, the carcass is divided into commercial grades - that is, for trade or for catering networks.

Cut beef

The primary processing of beef meat also involves cutting the carcass. This is done as follows: the half-carcasses are cut into the back and front halves, and the division is carried out along the last rib. The front half carcass is divided into cuts in the form of a shoulder blade, neck, dorsal and thoracic part, and the back half is divided into cuts, hind leg and loin. In culinary cutting, the parts of the beef carcass that are cut belong to three varieties:

- The first grade is loin tenderloin, dorsal and lumbar parts, posterior pelvic part. They are used most often for frying, since such meat contains 3-4% of connective tissue.

- The second grade is the shoulder blade, brisket and hem. This meat is used for stewing and boiling.

- The third grade is cutlet meat, knuckle. There is already up to 23% of connective tissue, so this meat is used in the preparation of cutlets and broths.

For cutting, a special cutting grade is used and tools such as a butcher's ax or a circular band saw. The cutting chair can be either round or square. They are made from solid wood.

Cuts of various meat products

There are different types of raw meat. The primary processing of meat and the quality of the finished product will differ in both nutritional value and the ratio of muscles, fat and bones. Accordingly, the carcass is cut into different varietal cuts. In Russia, there is a unified scheme for cutting carcasses that are offered for retail. A separate scheme is used for culinary cutting when smoked meats and sausages are produced. Beef, according to the standards, is divided into 3 grades, veal - into 3 grades, pork - into two grades.

Deboning and trimming of meat

The primary processing of meat includes boning work. This process involves the removal of bones from half carcasses. Deboning is carried out on a special table using deboning knives. After this operation, trimming is performed, that is, the meat is finally cleaned of films, bones, cartilage, veins to obtain different types of meat. In these operations, the skill of the deboner and trimmer plays an important role, since the yield of marketable meat depends on the professional approach.

Poultry processing

The sequence of the primary bird is somewhat different, since the main task of the initial stage of processing is to reduce the amount of blood in the carcass. The presentation of carcasses and the features of their further storage depend on the degree of bleeding. If the carcasses are poorly bled, the tissues will partially or completely turn red, this will be especially noticeable in the neck and wings. And if blood remains in the blood vessels of the carcass, this creates favorable conditions for the development of microbes.

The technology of primary processing of meat also involves the removal of plumage, the quality of which determines the quality of carcasses. Breaks, scratches affect the decrease in chicken grade. Before removing the plumage, the poultry is subjected to heat treatment during production. When scalding, the bird is immersed in a heat treatment bath, where water is actively circulating. This loosens the bonds between the feather and the skin so the feathers can be easily removed. The temperature of the water in the bath is maintained at the desired level thanks to automatic regulation.

Depending on the cooling methods, heat treatment can be soft or hard. Soft modes are used for cooling broiler chicken carcasses, and hard modes are used for cooling eviscerated carcasses. Depending on whether the heat treatment technologies are observed, the quality of scalding will also change. If the heat treatment temperature is below normal, the removal of plumage will be more difficult.

Plumage removal is carried out with the help of machines and machines of various types, due to which about 95% of the feather cover is removed automatically. During the operation of the machines, water is constantly supplied, the temperature of which is 45-50 degrees. The removed feathers are washed off with water into a special chute, which is mounted on the floor of the workshop. After the plumage is removed, the carcasses are fed to the re-plucking area, which is performed manually. With a special knife, the remaining feathers are first removed from the wings, neck, back and other parts of the carcass. The hairy feather is removed by the gas scorching chamber.

gutting chicken

The quality of meat is affected by the quality of evisceration of carcasses. During the primary processing of raw materials, close attention is paid to this process. All procedures are carried out at a carefully cleaned workplace of a veterinary expert, equipped with special equipment. Most often, evisceration is carried out manually using a number of automatic systems. All technological operations must be carried out correctly so as not to damage the intestines, gallbladder - otherwise this will lead to contamination of the meat with microbes and a deterioration in its quality.

Features of freezing chicken

For long-term storage or transportation, chicken meat is frozen. For this, already cooled and chilled carcasses are taken. Freezing must be performed quickly, which will affect the even distribution of ice crystals in muscle tissue. Slow freezing will result in the formation of a small amount of ice crystals, which will disrupt the composition of the fabric and will affect the reduction of juiciness and tenderness of the product. At large enterprises, freezing is carried out in chambers and apparatuses in which air acts as a heat carrier. Depending on the bodyness of the chicken, the freezing time can be up to 72 hours. The consumer receives chicken meat either chilled or frozen. If the carcasses were stored and transported correctly, this will not affect the deterioration of the taste properties of the chicken.

How semi-finished products are created

After the primary processing, the meat is divided into different parts that go to production. Cleaned cuts of meat are also used for the production of semi-finished products. Most of these products are created from minced meat. It, in turn, is prepared and crushed. Then the primary one is performed and its task is to bring the product to a state of culinary readiness, while destroying microorganisms and increasing the resistance of products to any storage conditions. Due to the heat treatment of meat and meat products, the product undergoes a number of changes - physical and chemical.

by-products

After the primary processing of meat, internal organs remain, which are valuable from a culinary point of view. The nutritional value of the tongue and liver is not inferior to the value of meat, and the nutritional value of the lungs, ears, trachea is low. By-products are used in the preparation of a number of culinary products. Thus, after primary processing, the meat is divided into a number of products that are used for commercial purposes. Subject to the technological process and all its stages, meat products are cut and delivered to the shelves in proper condition.

Another text written some time ago, rather long. and no pictures at all.

In general, I have been repeatedly convinced and continue to be convinced that understanding the basic processes that occur when cooking meat improves the taste of meat dishes incomparably better than any, even the best recipe.

I. What does meat consist of.

For starters, what is the meat. The main components that we are primarily interested in are:

1. Muscle fibers, which consist of thin cells, as thick as a human hair. cells, in turn, are made up of protein and water.

2. Connective tissue, which consists mainly of collagen and connects individual muscle fibers to each other, forming bundles of fibers, which in turn form muscles. Connective tissue also "binds" muscles to bones and performs a number of other functions that are not of interest to us yet.

3. Fat. I think you can do without explanation.

4. Meat juice. That is, a liquid that is predominantly water-bound protein myoglobin. It is this fluid that is often erroneously referred to as "blood". It is probably not worth repeating that there is no blood in the meat of a normally slaughtered animal and cannot be.

II. Heating meat.

And now let's see what happens in general terms to a piece of meat when heated. For simplicity, let's imagine that we are heating meat of animal origin (for example, beef) in a way that provides an even temperature increase throughout its volume.

So, we get the chilled meat from the refrigerator. The meat is heated to plus five degrees and falls into the so-called "danger zone" - the temperature range from +5 to +60, in which the bacteria feel most comfortable and quickly increase in number.

It is worth noting here that it is the surface of the meat that poses the greatest danger, since in the process of cutting the carcass, transporting, storing and deboning, the largest number of bacteria is on the surface of individual pieces and penetrates deep into the meat to a depth, usually not exceeding a few millimeters.

What if we make stuffing? In this case, the bacteria from the surface will be distributed throughout the entire volume of minced meat and, once in a favorable environment for reproduction, will make the entire minced meat as unsafe as the surface was. That is why the temperatures to which minced meat products (hamburgers) should be heated are much higher than the temperatures to which whole pieces of meat (steaks) can be heated.

We continue to heat up. The next temperature that we are interested in is 30-45 degrees. Around this range, fats become soft and begin to melt. It should be noted that the melting point of fat depends very much on the type of meat, the age of the animal and the cut. This range is also optimal for many bacteria that begin to grow rapidly and double in number in just 20 minutes.

Further, 54-57 degrees. Despite the fact that these temperatures are within the "danger zone", at them the growth of bacteria stops, the bacteria begin to die, but very slowly. For example, beef must spend at least an hour and a half at 55 degrees to be safe to eat.

Next stop - 60 degrees. this is a very important temperature, because when it is reached, a number of processes begin:

1. The protein myoglobin, breaking down, gives the meat a grayish tint. It is worth noting that the color of the meat depends not only on the temperature, but also on the time that the meat spent at a particular temperature. But in the general case, we can assume that the color begins to change significantly at a temperature of 60 degrees and by 74 degrees the meat becomes almost completely gray.

2. Meat juice also loses its pink color and begins to become transparent.

3. Collagen shrinks and squeezes fluid out of the cells. The meat begins to intensively lose juices.

4. Fats begin to become liquid.

5. The growth of bacteria is almost completely suppressed, the bacteria begin to die faster.

We continue to heat up. 72-74 degrees. At this temperature, bacteria die almost instantly. It is up to these temperatures that it is necessary to heat any minced meat products. It is up to at least 74 degrees inside that you need to heat any poultry dishes.

Let me also remind you that when temperatures reach 72-74 degrees, the meat quickly acquires a gray color.

The next very important temperature range is 72-82 degrees. Collagen heated to this temperature begins to break down and forms gelatin. This is a very long process - it takes up to several hours for the connective tissues to become gelatin.

The next stop is 100 degrees, the boiling point of water. With a few exceptions, the temperature is practically unsuitable for cooking meat, since at one hundred degrees collagen breaks down intensively, the water inside the meat boils and expands, breaking the bonds between the fibers. The meat begins to easily break down into fibers, but at the same time it becomes completely dry in taste.

155-160 degrees - the beginning of the Maillard reaction, during which the protein quickly breaks down into numerous amino acids, resulting in a beautiful brown crust on the surface of the meat.

By the way, the most common myth in cooking says that the crust prevents the loss of meat juice. Say, the meat is "sealed" and the juices remain inside. This is absolutely not true.

III. Cooking temperatures.

Now, when we imagine what happens to meat when heated, a reasonable question arises. To what temperature should the meat be heated to get the most delicious result?

I must say that there is no answer to this question. Each person has an individual taste and lovers of weak roasts are unlikely to find a common language with lovers of well-done. But what can be said for sure is one thing. When it comes to the temperature treatment of meat, in no case should we forget that temperature is directly related to safety. So don't listen to anyone. Don't listen to trendy chefs talking about low rares. Don't trust famous TV chefs who talk about supposedly safe temperatures. Don't trust anyone. Don't believe me either.

And make it very simple - take a table of safe internal temperatures, which is compiled by the Food Safety Inspectorate of the US Department of Agriculture. And follow her. Believe me, these people have been doing very serious food safety research for a very long time, which is the result of this table.

But here the next question arises - how to understand that the temperature inside the meat has reached the minimum safe temperature? There is exactly one answer to this question - buy a thermometer after all. Better electronic. And in no case do not trust any old-fashioned methods - by hand, by a loose bone, and so on. Only a thermometer can accurately determine the temperature.

Well, now that we have a general idea of the processes occurring during heating, we can move on to the most interesting and consider several practical issues.

IV. Q&A.

Why is there no universal way to cook meat?

It's all about the connective tissue, which after 60 degrees begins to shrink and squeeze out juices, and after 72-74 it begins to turn into gelatin. If you take tough beef, in which there is a lot of connective tissue, it must be heated to temperatures of about 80 degrees and kept at these temperatures for a long time. Otherwise, the meat will not be chewed. If you take a good, soft beef with a low content of connective tissue - the same heating to 80 degrees will make it gray, dry and rather tasteless.

What is juiciness in meat and where does it come from?

Obviously, juiciness is determined by the presence of liquid inside the meat, or rather a combination of certain liquids. Accordingly, juiciness is taken from the following sources:

1. Juiciness of meat juice. For example, steak. To achieve this juiciness, you need to cook in the range of 60-70 degrees and be sure of the quality of the meat.

2. The juiciness of gelatin, or rather the juiciness of collagen that has become gelatin. For example, Irish stew. In order to get maximum juiciness from collagen, you need to cook the meat for a very long time at a temperature of about 80 degrees.

3. Juiciness of fats. If we have a non-fatty piece of meat, which, for safety reasons, must be cooked to a minimum internal temperature of 72-74 degrees or even higher (pork, game), then you can make it juicy very simply - stuff it with fat (lard), if it is minced meat - add a fair amount of bacon, if it is a barbecue - alternate pieces of meat with pieces of lard. The melted fat will add juiciness to the meat. Examples are sausages for frying, roasts, hamburgers, the already mentioned shish kebab from not very fatty pork.

4. Juiciness of the medium in which the meat was cooked. If the meat is cooked in the liquid for a long time at a high temperature, then the bonds between the fibers weaken and the meat begins to absorb the liquid in which it is cooked. An example is meat in pilaf, which is cooked in zirvak for a long time.

There are several other sources of juiciness, such as industrial water pumping, brining, and so on ... And there are several illusions of juiciness - but more about them later.

But what about the low rares of our favorite steaks? They are juicy, almost red inside - does this mean that the meat has not heated up to 60 degrees?

Absolutely right. But let's dwell on the low-rare steaks in a little more detail. First, as already mentioned, the vast majority of bacteria is on the surface of the meat pieces. As the steak cooks, the surface heats up to temperatures that are guaranteed to kill surface bacteria. Secondly, statistically, beef is a relatively safe meat. And thirdly ... I think now you understand well why steaks cannot be cooked from any kind of meat, and even more so they can be eaten in places where they do not pay due attention to the appropriate handling of meat in general and sanitation in particular.

Topic: Primary and heat treatment of meat.

Lesson Objectives:

- introduce the types of primary and thermal processing of meat;

- to form and develop skills in the heat treatment of meat;

- to inculcate the skills of a culture of work;

- develop respect for food.

Lesson type: combined.

During the classes.

- Organizational moment (3-5 min.)

ü Check readiness for the lesson.

ü Checking the payroll.

ü Communication of the topic and purpose of the lesson.

- 2. Repetition of the material covered (3-5 min.)

ü Describe the nutritional value of meat.

How is meat stored?

What types of meat do you know?

ü Describe individual types of meat.

- 3. Explanation of new material (25 min.)

Primary processing of meat.

Starting the processing of products, you need to determine their freshness and quality. It is advisable to preserve high-quality products in their natural form during cooking. Every housewife should know that only with the help of careful primary processing of products can a delicious dish be prepared.

The primary processing of meat includes defrosting, cleaning contaminated areas, removing the surface film, large tendons, stigmas, removing adhering paper, and washing.

You need to defrost the meat at room temperature, gradually. Do not defrost meat in water, as this loses a significant amount of nutrients.

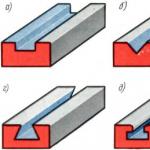

In the preparation of semi-finished products, techniques such as cutting, beating, cutting tendons, breading, stuffing, pickling are used.

You need to cut the meat across the fibers at a right angle or an angle of 40-45 °, so that the pieces look good, less deformed: for goulash - always with pieces of fat, for roast - with a tubular bone or joint, for stew - with a bone. The meat is beaten to loosen the connective tissue, smooth the surface and give the pieces the appropriate shape, which contributes to uniform heat treatment.

Semi-finished products are breaded to reduce juice leakage and moisture evaporation: roll the pieces of meat in flour or breadcrumbs until the surface of these pieces ceases to absorb the breading material. Breading should be a thin even layer over the entire surface of the product. To keep the breading better, semi-finished products can be moistened in a lezon - an egg-milk mixture before breading. The lezon is prepared as follows: raw eggs are mixed with milk or water, salt is added. For one egg you need "/z a glass of milk or "D a glass of water, a pinch of salt. Breading promotes the formation of a crispy fried crust.

Primary processing of by-products. Edible offal includes heads, brains, tongues, legs, liver, kidneys, spleen, udder, stomach (rumen), tails, ears, liver (heart, lung and throat). Frozen offal is thawed in the air. In water, you can thaw tongues, brains, kidneys, scars, udders. Brains are soaked in cold water for 1-2 hours to remove blood and swelling of the films. After that, the films are carefully removed without removing the brains from the water. Blood vessels are cut out from the liver (the film is removed from the beef), washed in cold water, periodically changing the water, then immersed in boiling water for 3-5 minutes, the mucous membrane is removed with a knife, washed again thoroughly. Fat is separated from the beef kidneys, the kidneys are cut lengthwise, soaked in cold water for 2-3 hours. Pork, lamb and veal kidneys are not soaked. The udder is cut, large vessels are removed, washed in cold water. Beef legs are singeed (if they are with wool), cleaned with a knife from the remnants of wool, the cornea is knocked off the hooves, cut into 2 parts and kept in cold water for 2-3 hours to eliminate the specific smell. For the same purpose, the tails of cattle, cut into separate vertebrae, are soaked in cold water for 5-6 hours. Leaver is divided into its constituent parts: heart, throat and lungs. The throat and heart are cut lengthwise, blood clots are removed from the latter. The lungs are cut through the bronchi. After processing, the liver is thoroughly washed in cold water. Tongues are washed with cold water, dirt is removed from the upper part. The heads are scalded with hot water, thoroughly cleaned and washed.

Heat treatment of meat.

- 1. Cooking.

On average, the duration of cooking is: beef 2-2 hours 45 minutes, lamb - 1.5-2 hours 10 minutes, pork - 1 hour 45 minutes - 2 hours, veal - 1 hour 20 minutes - 1 hour 45 minutes. The meat of older animals undergoes a longer heat treatment. The weight loss of meat products during cooking is on average 40%.

The loss of soluble substances in broths depends on the ratio of meat and water, the size of the pieces, the cooking time and averages 2.3-2.6% of the mass of meat. The smaller the pieces, the more soluble substances are extracted.

When cooking, up to 25% of fat passes from meat into water, and when frying, 23-28% is rendered. Cooks recommend cooking boiled meat for second courses as follows: water should be taken at the rate of 1.5 liters per 1 kg of meat, so that it only covers the meat. The meat is cut into pieces weighing no more than 2 kg, placed in boiling water and, when it boils again, continue to cook at a very low boil or without boiling at a temperature of 80-90 ° C. Roots (onions, parsley, carrots) are put in 30 minutes, and spices and salt 15 minutes before readiness. In order for the meat to be juicy and tasty, it must be cooked without boiling.

From beef carcass for cooking and cooking second courses, use the shoulder blade and subscapular part, brisket, hem, side and outer part of the hind leg. Boiled meat is stored in a sealed container in a small amount of broth at a temperature of 50-60 °. When portioning, boiled meat is cut across the fibers.

Sausages and sausages are immersed in boiling water. If the sausages are in an artificial casing, it is carefully pricked with a fork and after cooking it is easily removed. When the water boils again, the heating is weakened and heated without boiling for 5 minutes. It is not recommended to store boiled sausages and sausages hot for more than 20 minutes, as their shell may burst, and the minced meat will be saturated with water and tasteless.

- 2. Admission.

A method of heat treatment in which liquids are taken much less than for cooking. The products are placed in one layer in a greased stewpan or low saucepan, salt and spices are added, a little water or broth is added so that they cover the products by about 1/3 of their height. Then tightly close the saucepan with a lid and put it in a hot oven or on the stove. The product is brought to readiness under the action of steam.

- 3. Frying.

For the preparation of fried meat dishes, tender parts of beef carcasses are used - tenderloin, dorsal and lumbar parts (thick and thin edge) and all parts of veal carcasses. Products and semi-finished products intended for frying must be salted immediately before heat treatment.

The most common method of frying is in a frying pan or other utensil with a small amount of fat (5-10% by weight of the product) without adding water at a temperature. When frying, the product should be placed only in well-heated fat. Small pieces of meat, as well as portioned natural and breaded products, are fried for 8-20 minutes (temperature 140-160 ° C). For frying in a pan, the meat is cleaned, cut into a thickness of no more than 2 cm across the fibers. When pierced with a chef's needle, a colorless transparent juice should stand out from the finished products.

- 4. Extinguishing.

A combined type of heat treatment, in which the product is first fried, and then cooked with seasonings and sauces. You can stew all types of meat. Usually, from beef carcass, the lateral and outer parts of the hind leg, the shoulder blade, the subscapular part, the hem (from the carcass of the 1st category) are used for stewing. In an acidic environment, collagen quickly turns into soluble glutin. Therefore, during stewing, tomato is added to many dishes. The product is fried on all sides until a crust forms and placed in a deep dish for stewing.

- 5. Breezing.

A method of heat treatment, when the product is first stewed in a small amount of broth and fat, and then fried in the oven.

- 6. Baking.

A common method of heat treatment. Before baking, the meat is boiled, poached, fried or stewed. The product is sprinkled with breadcrumbs and greased. Roasting is carried out in ovens, ovens, at a temperature of 300-350 ° in metal forms, pans or dishes. The product is considered ready when it warms up to 80-95 ° and a golden crust forms on its surface.

- 4. Practical work« Determination of the quality of meat by the organoleptic method "(visual, olfactory, tactile and gustatory) (45min.)

current instruction.

- 5. Fixing the material. Summing up the lesson. Reflection (5-7 min.)

ü What does the primary processing of meat include?

ü List the types of heat treatment.

Grading. Lesson analysis.

- 6. Homework (2 -3 min.)

Retell the notes in the notebook. Write 3 meat recipes in your notebook.

Working with the portal

For all questions related to educational spaces, please contact the technical support of the School in Kapotnya.

Hot meat dishes and snacks are very different from cold dishes and snacks. Their most important difference is that hot meat dishes are subjected to various heat treatments. This is the peculiarity of the preparation of hot dishes and snacks. Hot dishes and snacks are included in the menu after cold ones. They also differ in sharp taste and small volume. For their preparation, meat, meat products (ham, sausages), offal (tongues, kidneys, scars) are used. Any products used to prepare hot dishes are first heat tested. At the same time, large physico-chemical changes occur in them, which contribute to the improvement of taste and better digestibility of food. During heat treatment, the products are crushed, which makes them easier to chew; a large number of pathogenic microorganisms and some harmful substances are neutralized; new flavoring and aromatic substances are formed that contribute to the release of digestive juices.

The following main methods of heat treatment of products are used in catering establishments: boiling and frying. Combined and auxiliary methods of heat treatment are also used, in which several main methods are combined.

Boiling is the heating of food in a liquid. Cooking happens:

main way; (in plenty of water).

Admission; (in a small amount of water under the lid).

Steam cooking; (in special cabinets or on grids).

Roasting is the heating of a product without liquid in various amounts of fat.

Roasting happens:

main way; (in a small amount of fat).

Deep-fried; (high in fat).

In the oven; (in special cabinets at a temperature of 270).

On the grill (roasting on an open fire).

Combined methods of heat treatment.

Stewing is frying the product until golden brown, and then stewing with the addition of spices.

Roasting - boiled, fried, stewed or raw semi-finished products are poured with sauce and baked in an oven.

Breezing is the stewing of meat in a concentrated broth, and then frying in an oven.

Boiling followed by frying - the product is first felted, then fried.

Auxiliary methods of heat treatment.

Singeing - used for the primary processing of poultry, beef, lamb, pork and calf legs (on gas burners).

Blanching - laying food for a few minutes in boiled water.

Sauteing - frying foods in a small amount of fat and passivating.

The technological process of preparing a dish does not begin with heat treatment, but with the receipt of carcasses of slaughtered animals at public catering establishments. The meat comes chilled, chilled and frozen. Cooled meat is that which, after cutting the carcass at the slaughterhouse, cooled down in natural conditions or cooling chambers for at least 6 hours. Meat chilled to a temperature in the thickness of the muscle + 4-0 is called chilled. Meat artificially frozen to a temperature in the thickness of the muscle no higher than - 6 is called ice cream. Depending on fatness, beef and mutton are divided into two categories, and pork is divided into fatty (thickness of lard more than 4 cm) and meat (thickness of lard from 1.5 to 2 cm). Pig meat is divided into two categories. The first category includes milk piglets weighing from 1.3 to 5 kg., The second category includes - weighing from 5 to 12 kg.

The technological process of processing meat at catering establishments consists of the following operations:

Defrosting.

Washing and drying.

Carcass cutting.

Production of semi-finished products.

Frozen meat is thawed in its entirety by hanging the carcass on hooks, or stacking it on grates in special chambers - defrosters. Or in chambers at a temperature of +4 +6 for 3-5 days. Slow thawing of meat allows you to minimize the loss of meat juice to almost completely preserve the taste of the product. Preliminary processing of meat consists, first of all, in its thorough washing. The meat should be washed quickly under running water, and the entire piece intended for processing is washed. Do not wash the meat after it has already been cut, as this transfers contamination from the surface into the meat, first with your hands and then with a stream of water. If the meat is washed in small pieces, especially after the bones have been removed, this causes a loss of juices, and thus a decrease in the nutritional value of the meat. For the same reason, meat should not be soaked, as water-soluble proteins, minerals and B vitamins pass into the water. Washed meat should be dried. Dry the meat on wire racks or linen napkins. The dried meat is cut in several stages. At the beginning, the carcass is cut into quarters. Then, each quarter is divided into parts. The forequarter of the beef carcass is divided into the shoulder blade (shoulder and shoulder part), neck, dorso-thoracic part. The rear quarter of the carcass, having separated the tenderloin (iliac muscle), is divided into the posterior and lumbar parts. Pork, veal and lamb carcasses, having previously separated the tenderloin, are cut across into two halves - front and back. The front half is divided: shoulder blade, neck, loin, brisket; back - for two hams.

LECTURE #2-3

Topic: Technology of mechanical and thermal culinary processing of meat, fish and poultry

Presentation plan:

Technology of mechanical and thermal culinary processing of meat

Technology of mechanical and thermal culinary processing of fish

Technology of mechanical and thermal culinary processing of poultry

1. The technological process of primary processing of meat consists of the following operations: defrosting (thawing) - defrosting, washing and drying, carcass cutting (carcass division into parts - cut), deboning, trimming and cleaning of meat, preparation of semi-finished products.

Thawing (thawing) of meat. Frozen meat is first thawed in a defroster. At the same time, the temperature in the thickness of the muscles rises and the original properties of the meat are restored as much as possible. With slow defrosting, meat carcasses are hung on hooks in refrigerating chambers, the temperature is raised from 0 to 6-8 0 C, and the relative humidity is 90-95%. The duration of defrosting is 3-5 days. The meat is considered thawed if the temperature in the thickness of the muscles has reached 0-1 0 C. During quick defrosting, heated, moisturizing air is supplied to special chambers, the temperature of which is 20-25 0 C, relative humidity 85-95%. Defrost duration - 12-24 hours. In thawed meat, the temperature in the thickness of the muscles is - 1.5-0.5 0 C.

Large-sized semi-finished products, block meat can be defrosted on production tables at room temperature, while the loss of nutrients increases up to 10%.

It is not allowed to defrost meat in water, as this dramatically increases the loss of its nutritional value.

Thawed meat and semi-finished products cannot be re-frozen.

Washing. The stigma is cut from the surface of the carcass, contaminated areas are cleaned, and microorganisms are washed off.

Wash the meat first with warm water (at a temperature of 25-40 0 C). Carcasses are washed in limbo with brushes, pieces of meat are washed in running water or baths.

Drying. After washing, the meat is dried with towels or napkins, with a stream of circulating air, at an air temperature of 6 0 C. Natural drying can be used.

Before processing, the meat should not slip in the hands.

Division into cuts (parts). When cutting the carcass of cattle, they receive: shoulder blade (shoulder and shoulder parts); neck dorsal part (thick edge); hem; brisket; tenderloin; hind leg, inner, side, outer and upper parts, which are part of the hip cut; lumbar cut (thin edge); flank and shank.

When cutting a lamb carcass, they get: a shoulder blade (front leg); neck loin; brisket; ham (back leg)

Scheme for cutting lamb and goat carcasses:

1- shoulder blade (front leg); 2 - neck; 3 - loin; 4 - brisket; 5 - ham (back leg)

When cutting a pork carcass, they get: a shoulder blade (front leg); neck loin; brisket; ham (back leg)

Scheme for cutting pork carcasses:

I - shoulder blade (front leg), II - brisket, III - neck, IV - loin, V - ham (hind leg), VI - tenderloin

Zhilovka. This process is understood as the removal of cartilage and coarse connective tissue from meat.

Deboning - is the separation of the pulp from the bones. Waste that is formed after deboning (bones, tendons, cartilage) can be used to make broths.

Methods of heat treatment of meat:

Boiled meat. To prepare second courses, meat is boiled in pieces weighing 1.5-2.5 kg in a small amount of water (1.5-2 liters of water per 1 kg of meat). The meat is immersed in boiling water and boiled until tender at a low boil. With this method of cooking, juicy and aromatic meat is obtained. To improve the taste of meat, it is recommended to add raw carrots, parsley, celery, onions when cooking. At the end of cooking put salt and bay leaf.

For cooking, use the brisket, hem and parts of the front and hind legs of beef; shoulder blade and brisket of small livestock. The pulp of the shoulder blade is boiled rolled up in the form of a roll, tied with twine; at the brisket, the film is cut along the ribs. The ribs are removed from the cooked brisket while hot. The readiness of the meat is determined by puncture with a chef's needle. The needle enters the cooked meat easily, and the resulting juice is colorless.

Grilled meat. The meat is fried in large portions and small pieces - in the main way, in an oven, in a large amount of fat (deep-fried) and over burning coals. Prepared portioned pieces are beaten with a chopper before frying to mechanically soften the connective tissue, as well as to give the piece an appropriate shape.

When frying in the main way, prepared meat is placed on a frying pan or baking sheet with fat heated to a temperature of 120-150 ° in order for the proteins to quickly coagulate on the surface of the meat. As a result of frying, a specific crust is formed on the surface of the meat, consisting of complex organic compounds and having a characteristic taste and aroma. Many organic compounds of the crust have an exciting effect on the human digestive organs, as a result of which the digestibility of food increases. When fried, water evaporates from the meat, and soluble organic compounds and salts remain, thanks to which fried meat is tastier, more aromatic and nutritious than boiled.

Canned stewed meat. The meat is stewed in large (portioned) and small pieces. Most often, beef (the pulp of the hind and front legs) and lamb are subjected to stewing. Before stewing, the meat is sprinkled with salt, pepper and fried in the main way until a crispy crust is formed. Side dishes for stews (in portions or small pieces) are cooked together with meat during stewing and served with meat. You can make side dishes separately from meat, in this case, when you leave it, they put it next to the meat.

Large chunks of cooked stew are stored at 50-60°C for 1-2 hours; cut the meat into portions before serving. If the meat needs to be stored for a long time (over 3 hours), then it is cooled and stored in the cold, and when it is released, it is cut into portions and heated in the sauce.

Baked meat. Meat products for baking are pre-boiled or fried until tender. Roasting is done with a side dish in portioned pans or dishes in an oven at a temperature of 250-350°C.

The finished baked product should be heated to 75-85 ° C, and have a fried crust on the surface. On vacation, pour over melted butter.

When processing fish, it is necessary to know its structure. A fish consists of a body, head, tail and fins. In the abdomen of the fish there are internal organs: the esophagus, stomach, liver, heart, lungs, caviar and milk, swim bladder, pancreas.

1 gill cover, 2 dorsal fin (hard), 3 dorsal fin (soft), 4 tail fin, 5 lateral line, 6 anal fin, 8 ventral fin, 9 pectoral fin.

Fish meat is white, red or pink, brown.

Mechanical culinary processing of fish consists in thawing, soaking, cutting, preparing semi-finished products.

Defrosting fish. Scaly and scaleless fish are thawed in water (2 liters of water must be taken per 1 kg). The tenderness of its meat, taste and aroma, the amount of nutrient loss depend on the correct defrosting of fish. It is better to defrost fish slowly in the refrigerator at a temperature of 5-7 ° C, or at a temperature of 15 ° C (in air) or in cold water in a package (plastic bag). Large fish species, frozen fillets can be defrosted in air at room temperature for 6-10 hours. To prevent the top layer of the skin from drying out, it is necessary to cover the fish with a film. When fish is defrosted in water, its meat becomes juicier and lighter, the water-holding capacity of muscle tissue increases, and the mass of fish increases by 5-10%. During thawing, the fish swells and loses minerals. To reduce these losses, a small amount of salt is added to the water (7-13 g per 1 liter of water). Salt allows you to increase the water-holding capacity of fish proteins and delays the development of microbes. It is impossible to defrost fish in warm water, the protein denatures and retains moisture poorly, the muscle tissue of the fish becomes flabby, with poor taste. You can thaw fish first in water for 20-30 minutes (depending on size and weight), then in air at a temperature of 17-18°C. When thawing fish in water, its nutritional value decreases. Whole fish is thawed until sufficient flexibility is obtained. The temperature of thawed fish should be no higher than 1 ° C; at elevated temperatures, the fish begins to deteriorate quickly. Thawed fish should be washed quickly to avoid nutrient loss. An accelerated defrosting method using microwave currents (defrosting) reduces nutrient losses.

Fish of mackerel families can not be thawed before cooking.

Large sturgeon fish can be thawed in the air, laying them on racks or tables, covered with plastic wrap, holding for 10-12 hours.

Defrosting fish:

1. In the air - at room temperature, all types of boneless fillets, large fish, gutted fish with loose tissue and carcasses of a special cut are defrosted. The fish is laid in one row on the tables, kept for 4-10 hours until the temperature is thicker - 2°C, the loss of fish is 2%.

2. In water - thaw scaly and scaleless fish at a water temperature of 10-15 ° C. For 1 kg of fish take 2 liters of water. Small fish are thawed for 2-2.5 hours, large fish 4-5 hours. The mass of fish increases by 5-10%. Salt is added to the water (from 7-13 g per 1 liter of water) to reduce the loss of minerals.

3. Combined method - some types of uncut ocean fish are defrosted. It is placed in cold water for 30 minutes, salt is added (10 g per 1 liter of water), then removed, the water is allowed to drain and continue to defrost in air to a temperature in the thickness of the muscles of 0 ° C.

Soaking salted fish. Salted fish contains salts from 6-20%, while cooking it is soaked to a salt concentration of 1-5%.

1. For soaking in changeable water, the fish is placed in a bath with a temperature of 10-12°C. Water takes 2 times more than fish. Water is periodically changed after 1,2,3 and 6 hours.

2. For soaking in running water, the fish is placed on a grate in a bath. Cold water enters the lower part, constantly washing the fish, water pours out through a pipe in the upper part of the bath. Salted fish is soaked from 10-12 hours.

Soaked fish is used for cooking, cooking cutlet mass and cold snacks.

Processing (cutting) of scaly fish.

They clean the scales in the direction from the tail to the head, first from the sides, then from the abdomen.