Add site to bookmarks

- Kinds

- Choice

- Installation

- Finishing

- Repair

- Installation

- Device

- Cleaning

Features of the installation of a water "towel-ladder"

Today it is hard to imagine a modern bathroom without heated towel rails. No bathroom interior is complete without them. These useful attachments are designed for drying towels and other small laundry items. In addition, they create a good microclimate in the bathroom, as they help get rid of the high humidity and dampness that is often present here.

In order for the heated towel rail to be not only a decorative part of the interior, it must be connected correctly and competently. Properly done installation of any equipment ensures its maximum functional use.

Any person who is at least a little familiar with plumbing work can connect a heated towel rail. For its installation, no special skills are needed and the simplest hand tool is needed. If you want to install a heated towel rail in your bathroom with your own hands, then here you will find useful tips and tricks.

There are two types of these heating units: snake and ladder. In this article we will talk about how to properly connect a heated towel rail ladder. This type of connection has several variations.

Connection methods

The heated towel rail can work both from system of heating, and from system of hot water supply.

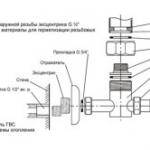

You can connect a heated towel rail ladder in three ways: in series and in two parallel variations. They differ in that in one version there is a bypass, that is, a pipe that creates a short path for the flow of water. Its presence can ensure that the heated towel rail is disconnected from the system without the need to shut off the entire system. The second connection option does not imply the presence of a bypass. Water, entering from the upper corner, goes through the entire ladder to the diagonally opposite edge.

There are various options for connecting to the heating system. Can be diagonal, direct and lower connection to the heating system. But in order to make a quality installation, appropriate preparation is necessary. Any installer will need certain tools and materials.

Back to index

List of tools and materials

Let's start with materials. To connect the heated towel rail, you will need the unit itself. Today there is a huge selection of this product, but do not rush to buy. The fact is that imported heated towel rails are not adapted for installation in the plumbing system. That is why it is better to give preference to domestic production, since they fully comply with all the requirements of GOST. If you are installing a heated towel rail in a country house where you yourself carried out water and heat supply, then in this case you can also use foreign heated towel rails.

To properly install, you will also need pipes and valves. Pipes can be stainless or plastic. If you provide a bypass in your system to which you connect the heated towel rail, or if the heated towel rail is connected in parallel, you can mount a pair of valves with which, if necessary, you can easily turn off the heated towel rail, which will not affect the operation of the entire system. Of the materials, fittings and bushings can be useful.

The tool that is needed for mounting the heated towel rail ladder is a regular plumbing tool, wrenches of various sizes. To install a ladder, you can not do without a special tool, such as welding for metal pipes or a soldering iron for plastic ones, a puncher, as well as a grinder with a cutting wheel. When all this tool is ready, you can proceed directly to the installation. But before that, you will probably have to dismantle the old one.

Currently, there is a catastrophic situation with unskilled intervention in the operation of general house systems, in particular, during the installation or alteration of heated towel rails (PS) connected to hot water risers.

This article describes the principles of the functioning of the PS, provides examples of both competent connection, and initially non-working or unstable options, explaining the reasons for their inoperability.

I will make a reservation that the article will talk about relatively new houses in which heated towel rails are connected to the same hot water riser, from which hot water is supplied to apartments. But in some houses (the overwhelming percentage of the secondary housing stock), a separate hot water recirculation riser is intended for heated towel rails. Or the riser of heated towel rails is powered by central heating, i.e. PS do not work in the summer. The topic of this article does not apply to such houses.

All diagrams and photos increase when you click on them.

A bit of history, old types of PS.

Twenty years ago, the substation "from the developer" was a monolithic riser pipe, curved in the form of the letter P or M.

Figure 1: U-shaped substation, which is part of the riser A.

Figure 2: M-shaped SS, which is part of the riser.

Despite the unsightly appearance, this type of substation had undeniable advantages: it was constantly hot, did not introduce any noticeable hydraulic resistance, and did not allow residents to disturb the operation of the hot water supply (DHW) riser in any way.

However, time passed, and the tenants in the old housing stock, making repairs, changed the old and ugly substation to a new and shiny one. In a good scenario, it turned out like this:

Figure 3: New substation, which is part of the riser, a competent replacement.

The diameter of the substation corresponds to the diameter of the riser, the connection is made without narrowing and without stop valves (cocks).

In case of an unsuccessful scenario - like this:

Figure 4: New substation, which is part of the riser, illiterate replacement.

Four extra constrictions from the used fittings appeared in the riser:

Figure 5: Internal section of a fitting for multilayer pipes.

But it gets much worse:

Figure 6: The new SS, which is part of the riser, is a completely illiterate replacement.

In addition to the narrowing already mentioned above, shut-off valves have been added. When any of them is blocked in the riser, the circulation stops completely, the pressure in the apartments following in the direction of supply drops to zero (water can somehow come from the “return” line), the riser cools down in the absence of water intake, when the mixer is opened, cold water has to be drained for a long time .

Installation of shut-off and control valves (faucets) on risers is strictly prohibited!

Branches from the DHW riser for heated towel rails.

Over time, developers began to use more modern technologies and, instead of a terrible bent pipe, they began to make two branches from the riser to connect the substation at the choice of the residents themselves. However, unfortunately, neither the type, nor the height of these outlets from the floor, nor the distance between them is in any way standardized. This leads to massive problems when connecting the PS, which will be discussed below.

Figure 7: Riser taps, unshifted and unrestricted bypass.

Figure 8: Riser taps, narrowed bypass.

Figure 9: Riser taps, offset open bypass.

Between the taps there is always a bypass - a pipe section with a diameter equal to the diameter of the riser or 1 step less.

The bypass at the heated towel rail solves several problems:

- Maintaining the normal circulation rate throughout the hot water riser (HW). Forced circulation in the riser ensures the supply of evenly hot water (according to the norms - 60 degrees) to any apartment, on any floor, regardless of its distance from the start of supply to the riser.

- Only part of the total flow (water) passes through one substation, the other part goes by, keeping more heat for the next bathrooms. After all, one or two dozen heated towel rails can work from one riser.

- It is possible to completely turn off the substation or adjust its temperature by residents without affecting the rest of the apartments (the latter requires the installation of an additional control valve on one of the outlets, since it is impossible to regulate anything using a ball valve).

Let's talk about physics. Gravity pump in PS.

If the performance of the substation at a narrowed or displaced bypass still somehow fits in the heads of plumbers who think in terms of “push through or not push through”, then the scheme without shifting the bypass and without narrowing the riser plunges them into a complete stupor: “All water passes by the towel! It won't go there! It can never work!"

However, the PS with this connection works great! At the heart of its performance is the "gravity pump":

improves the circulation of the PS, increasing the pressure of the "gravity pump" in the PS itself.

a.) Slows down the circulation in the entire riser (the temperature of hot water drops from the points of water intake in the apartments).

To improve the circulation according to this scheme, the local broadening of the unbiased (axial) bypass in the area of the upper branch to the substation can be improved. A photo of such a bypass is shown below.

Permissible options for the execution of scheme No. 1.

.

.

Figure 14: Side connection, example of correct execution.

The vertical substation is located entirely between the taps, no conditions for the operation of the circuit are violated.

Figure 15: Side connection, example of acceptable design.

The top of the PS is above the top outlet. It will be necessary to bleed air from the PS after turning off the water.

Scheme No. 2: bottom connection.

Less effective than lateral has its advantages and disadvantages.

Figure 16: Connection of a PS ladder running on natural circulation, without constriction and without offset bypass. Bottom connection.

Figure 17: PS-ladder connection operating on a combination of forced and natural circulation, with bypass offset. Bottom connection.

Figure 18: Connection of a PS ladder, operating on a combination of forced and natural circulation, with a narrowed bypass. Bottom connection.

Site author's opinion:In my opinion, the operation of schemes No. 16-18 may be unstable with a lower supply through the riser. Or even completely impossible.

Especially schemes No. 17-18. Therefore, I would not advise using these schemes, especially with a lower supply through the riser. Or when the riser supply is unknown.

Also, in my opinion, these circuits practically do not use pressure. And they use only forced circulation. Therefore, I personally do not like the bottom-bottom connection of the PS at all. And I do not advise anyone to use them only with gravitational circulation. And use only the lateral or diagonal top-bottom connection. And the bottom-bottom connection, from my point of view, to obtain a guaranteed result, can only be used with purely forced circulation, in private houses and apartments with individual autonomous heating.

Benefits of the scheme:

Works with any direction of supply in the riser.

The ability to run pipes somewhere hidden under the bathroom, without shoveling the walls.

The disadvantages of the scheme:

It is required to bleed air through Mayevsky's taps.

Less efficient than side or diagonal connections.

The upper branch of the riser with an offset or narrowed bypass must be below the connection point to the substation. This guarantees the independence of the work of the PS from the direction of filing.

The lower tap must be below the PS in all variants of this scheme.

The slope of the supply pipes must be observed (the direction is shown in the figure)

3 - 5 mm per meter.

There should be no “humps” (completely unacceptable, air will accumulate in them and

circulation will stop) or dips on horizontal routes (permissible only in

small limits, deep "pits" will air the liner to the substation).Pipe diameter for maximum circulation - preferably at least 3/4”

(32mm for PPR), ball valves - at least 3/4”. The use of pipes and taps smaller

section is allowed only with a small length of pipes leading to the substation, but in this case uneven heating may become noticeable

PS - hotter on top, colder on the bottom.It is highly desirable to place the supply pipes in thermal insulation. Besides what it is

a prerequisite for embedding pipes in the walls of the PPR, such insulationimproves the circulation work of the PS.

It is strictly forbidden to install any taps on the bypass - this is vandalismand wrecking yourself and your neighbors. Overlapping or excessive narrowing of the bypass:a.) It slows down the circulation in the entire riser (the temperature of hot water drops at the points of water intake of apartments).

B.) Radically worsens the water pressure in all apartments located further in the direction of supply. And with a certain location of the hot water outlet - and at the vandal himself. Indeed, when the bypass is narrowed by one pipe size, its throughput becomes approximately half as much.

B.) Does not improve the efficiency of the above scheme in any noticeable way.

Permissible options for the execution of scheme No. 2.

Figure 19: Bottom connection, acceptable design example 1.

All taps are below the PS, no conditions are violated.

Figure 20: Bottom connection, acceptable design example 2.

The top outlet is higher than the bottom of the substation.

Please note that this immediately imposes a restriction on the feed direction - only from above!

With a bottom feed, such a connection is unstable.Scheme No. 3: lateral and diagonal connections with a narrowed or offset bypass.

The vast majority of plumbers believe that there must be a narrowing between the taps on the substation - otherwise nothing will work. Firstly, this is not the case (see diagrams Nos. 1 and 2), and secondly, in the case of a lower water supply in the riser and poor circulation, the narrowing prevents the heated towel rail from working until it is completely cooled, despite the outwardly normal connection. Therefore, if possible, it is worth striving to ensure that the diameter of the bypass is equal to the diameter of the riser.

Figure 21: Connection of a PS-ladder operating on a combination of forced and natural circulation, with a narrowed bypass.

Side connection.

Figure 22: PS ladder connection operating on a combination of forced and natural circulation, with bypass offset. Side connection.

Figure 23: Connection of a PS ladder operating on a combination of forced and natural circulation, with a narrowed bypass. diagonal connection.

Figure 24: PS ladder connection operating on a combination of forced and natural circulation, with bypass offset. diagonal connection.

Note that the direction of supply in the riser is now unambiguously indicated by the top.

With the bottom feed, these options are categorically not recommended to use. the reasons will be described below.Cons of this scheme:

Stable operation is guaranteed for top feed only.

The advantages of this scheme:

Definitely and stably works at the top giving in a strut.

It is not required to bleed air from the PS after turning off the water.

The distance from the riser is arbitrarily large.Conditions for the scheme to work:

Once again, we recall that at the bottom feed, the narrowing / displacement between the taps prevents the operation of the PS up to its complete inoperability! At the top feed, the bypass can be narrowed by a maximum of 1 step from the diameter of the riser. Tapering of the offset bypass is never required at all.

The lower outlet of the riser should be below the bottom of the substation, and the upper outlet of the riser should be above the top of the substation.

It is necessary to observe the slope of the supply pipes (the direction is shown in the figure) of at least 3 mm per meter, but better than 30 mm per meter.

There should be no “humps” (completely unacceptable, air will accumulate in them and circulation will stop) or dips on horizontal routes (allowable only within small limits, deep “pits” will interfere with circulation).

Pipe diameter to ensure maximum circulation - preferably at least 3/4 "(32mm for PPR), ball valves - at least 3/4". The use of pipes and valves of a smaller cross section is allowed only with a small length of pipes leading to the substation.

It is desirable to place the supply pipes in thermal insulation. In addition to the fact that this is mandatory when embedding pipes in the walls of the PPR, such insulation will improve the operation of the substation in certain cases (sagging pipes or "pits" on them).

It is strictly forbidden to install any taps on the bypass - this is vandalismand wrecking yourself and your neighbors. Overlapping or excessive narrowing of the bypass:

a.) Slows down circulation throughout the riser (hot water temperature drops).

B.) Radically worsens the water pressure in all apartments located further in the direction of supply. And with a certain location of the hot water outlet - and at the vandal himself. Indeed, when the bypass is narrowed by one pipe size, its throughput becomes approximately half as much.

C.) It does not noticeably improve the efficiency of the above scheme, and with a lower feed, on the contrary, it interferes with the operation of the PS.

Why is my PS not working?

Let's analyze typical PS connection errors (the section will be gradually updated with links to real examples).

Figure 25: Side connection, INCORRECT example 1.

Figure 26: Bottom connection, WRONG example 2.

PS is located below the lower outlet. The water that has cooled in the SS and descended down is trapped in the lower part of the SS and the pipe (the stagnant zone is from the SS bottom to the level of the lower outlet), and is not pushed back into the riser, because lighter hot water presses on it from above.

The substation connected with such a violation operates until a certain height difference “lower outlet - bottom of the substation” is exceeded (it is impossible to predict the exact value) - then the natural circulation in the substation stops.

Figure 27: Side connection, INCORRECT example 3.

The upper pipe forms a loop in which air accumulates - the circulation in the PS stops. Operation is possible if there is an air bleeder (automatic or Mayevsky) at the top of the pipe.

Figure 28: Side connection, INCORRECT example 4.

A combination of previous non-working cases, usually formed when trying to lay one pipe behind the ceiling, and the second in the floor screed.

The upper pipe forms a loop in which air accumulates, and the water cooled in the PS ends up in the “sump” formed by the lower pipe loop and is not pushed back into the riser. The circulation in the PS stops.

Figure 29: Side connection, INCORRECT example 5.

The performance of the side connection with an offset or narrowed bypass and a BOTTOM supply is critically dependent on the circulation in the riser.

At a low circulation rate, the PS does not work, because in the lower outlet due to displacement / narrowing, the pressure is greater than in the upper one - the circulation pump tends to supply water to the PS through the lower outlet, and the "gravity pump" inside the PS tends to lower the cooling water down. Mutually opposite flows decelerate each other and the circulation in the PS stops.

If the riser has not yet been mutilated by neighbors, and there is a powerful circulation pump in the basement, then, as a rule, the pump “wins” and circular circulation starts in the substation: hot water rises along the left collector, and cooling water descends along the right collector, gradually mixing with hot water in the left manifold through the horizontal jumpers.

However, if someone puts, for example, a barbaric tap on the bypass, the circulation rate may drop so much that the substation will stop working. Either it will either work or not, depending on the time of day (different water intake from the riser).The diagonal connection here is even worse than the side connection. The chances of a successful launch are less, because the hydraulic resistance of the PS increases, which the pump has to overcome, and the resistance of the pump remains the same.

Reprint is not allowed

with attribution and links to this site.If you have any questions - ask them in the forum topic of this site "How to connect a heated towel rail" - LINK

Therefore, questions and answers this article is currently closed. Please ask questions in the above forum topic of this site.

The heated towel rail, installed in the bathroom, not only dries clothes, but also creates a favorable microclimate that prevents the formation of an unpleasant odor, fungus and dampness. Today, the market for this plumbing equipment is overflowing with models with various design solutions and functions. From this article you will learn how to properly connect a heated towel rail to a hot water riser. A diagram and a detailed description of this plumbing equipment are also in this publication.

Design features

The water heated towel rail can be in various configurations. The simplest among them is a coil, which is connected to a common hot water supply system. Usually this option was provided in Soviet-built houses. In relatively new buildings, it is possible to connect a heated towel rail to a hot water riser (diagram below) via a separate outlet. This allows you to install this equipment of various modifications - from the classic U-shaped heated towel rail to the popular "ladder".

Most often, the latter option is preferred: the hostesses have already appreciated its convenience in everyday use and functionality. Connecting the heated towel rail "ladder" is carried out using the following elements:

- Valves for shutting off water.

- Water circulation system - supply and return pipelines.

- Stopper plug.

- Air release valve (during installation, the Mayevsky crane is located on top).

- Bracket designed for wall mounting.

Varieties

How is the heated towel rail connected to the hot water riser? The installation scheme depends on the type of device. To date, there are three types of this plumbing equipment on the market: water, electric and combined. Let's consider them in more detail.

Aquatic

This option has been known to us since the days of the USSR, when such equipment was installed in all bathrooms. Such models remain the most popular to date. In this case, the heated towel rail is connected to the hot water riser (the diagram will help to do this correctly) or the heating system.

Valves are installed on the device itself, with the help of which water is blocked during replacement. These models are usually made of stainless steel, brass and copper. And most importantly, they have a low cost.

Electrical

This model is used if it is not possible to connect a water heated towel rail. There are two main options - wall and floor. The first of them has the most diverse design and is used in small rooms. Having given preference to this option, it is necessary to pay special attention to calculate in advance the approximate costs of electricity. In this case, the connection diagrams for the heated towel rail can be as follows:

- Open - a plug and socket is used.

- Closed - the wiring fits into the wall structure.

The main features of electric towel warmers:

- Often such devices are equipped with temperature control.

- They can be installed not only in the bathroom, but also in other rooms.

- Thanks to a variety of design solutions, you can choose a model that fits perfectly into the design of the room.

Combined

This model combines the properties of electrical and water equipment at the same time, however, in terms of design, they are close to water models. Hot water flows in this plumbing fixture, and there are also heating elements that allow it to function even when the heating is turned off. Unlike conventional models, such a heated towel rail will cost several times more.

Tools and materials

To connect the heated towel rail to the riser, you will need the following tools and materials:

- Towel dryer.

- Brackets required to mount the device.

- Polypropylene pipelines.

- Polypropylene fittings and couplings.

- Knife for cutting propylene.

- Apparatus for welding.

- Ball valves - 2 or 3 pieces.

Main stages

Connecting a heated towel rail "ladder" or any other type is as follows:

- Dismantling the old device.

- Stand replacement.

- Installation of ball valves and bypass (crosspieces).

- Welding of polypropylene pipelines.

- Installation and subsequent connection of the heated towel rail.

Dismantling

Sometimes, before connecting a new heated towel rail, it is required to dismantle the old one. Currently, there are two main schemes for connecting an old-style heated towel rail:

- Modern devices.

- Coils of the old sample.

Dismantling of the modern structure

If modern equipment has been correctly installed, then it will not be difficult to replace it. It is important that the new plumbing device is similar to the old one and has the same dimensions in the centers of the connecting pipes.

New equipment must be aligned with the center of the connecting pipes. It is necessary to remove the heated towel rail, which has already served its purpose, and then install a new one on the mating parts of the connectors, connect it to the system and fix it on the wall.

Dismantling the old coil

It is much more difficult to replace the old Soviet coil. In this case, a heated towel rail with side connection is installed in conjunction with the replacement of the riser. At the same time, it can be partial (in your apartment) or complete. However, it is not advisable to change part of the old pipeline, it is desirable to completely replace the riser. To do this, you will need to agree with the neighbors from below and above, so that they can connect a new riser. This is quite often practiced, as it is very dangerous to leave old pipes in the ceiling.

Riser replacement

As soon as all issues are agreed upon, it will be necessary to turn off the water supply. In most cases, this procedure is carried out jointly with the service organization. Further, with the help of a grinder, a riser is cut out along with a coil: first in your apartment, then in neighboring ones. After that, you need to cut the threads on the pipeline at the lower and upper neighbors, connect the pipes and enter them into your bathroom through the ceilings.

Jumper setting

The jumper is a kind of lifesaver in unforeseen situations. Its installation is optional, but highly desirable. So, for example, at the junctions of the heated towel rail, a leak has formed, which is becoming more intense every minute. And there is absolutely no time to call and wait more than an hour for their arrival.

So, in order not to depend on such situations, they install a bypass. Outwardly, it is an ordinary section of the pipeline. To install it, ordinary ball valves are mounted on the ends of the heated towel rail, with which you can block the flow of water if necessary.

Water heated towel rail: side connection

This design option allows plumbing fixtures to be installed in a standard towel rail or in an existing hot water supply. In other words, it does not require the preparation of an additional drainage system. However, water heated towel rails with side connection have one small drawback - the presence of welded elements. But with the proper quality of plumbing equipment, this model will last a long time.

When connecting this device, the following parameters must be taken into account:

- Correspondence of pipeline diameters.

- Center spacing - the distance between the outlet and inlet holes.

It is allowed to carry out lateral connection of the heated towel rail "ladder" using water couplings. At the same time, it is forbidden to make the transition from pipelines with a large diameter to pipes with a smaller cross section, as this can lead to an increase in pressure in the device, which will provoke leaks or completely break the welded joints.

In addition, side-connected water heated towel rails are installed in situations where it is planned to close the water pipes with tiles. During installation, it is necessary to ensure reliable waterproofing of the pipeline and the connected device. For this, gaskets and couplings are used, which are pulled together using the appropriate diameter.

When installing a heated towel rail with a side connection, it is important to remember that the water supply is carried out under pressure, respectively, the connection points must withstand sudden drops and a strong pressure of the water supply.

How to connect correctly?

It is necessary to install equipment in the bathroom in accordance with accepted standards. Thus, the scheme for connecting a heated towel rail to a riser must meet the requirements of SNiP 2-04-01-85. A similar design is connected to the heating system in private houses, which are equipped with an individual heating system.

In multi-apartment buildings, it is more expedient to carry out installation in full accordance with the project, if necessary - to a separate riser. This approach is fully justified, because the central heating system functions only in the cold season, and water is supplied constantly.

The type of heated towel rail does not affect the principle of connection: it is important to correctly ensure the supply and outflow. As a result, a regular supply of water will be produced. Depending on the design features, the following connection methods are possible:

- Top connection device.

- Heated towel rail with bottom connection.

- At the bottom of the plumbing fixture.

- Diagonal connection (used for "ladders").

Thus, the scheme for connecting a heated towel rail to a riser directly depends on the installation conditions and the type of structures.

Basic moments

To connect any equipment in the bathroom, you must have professional skills. Since measurement errors of a few millimeters can lead to big troubles and problems with operation. If there is a need to install a heated towel rail, then you should contact an experienced specialist.

It is important to take into account the features and subtleties of the work:

- Taking accurate measurements.

- Determination of the location of the structure.

- The presence of couplings, fittings, brackets and other additional parts.

- Select a connection method.

Installation belongs to the category of difficult plumbing work. Therefore, if you are not sure, you do not need to tempt fate and try to install it yourself. The consequences can be very different: from banal leaks of pipelines covered with ceramic tiles, to damage to tiles in the process of hanging brackets.

Before starting work, it is important to decide whether such work is within your power or not. Even if you decide not to do it yourself, at least you will know the installation sequence, which will allow you to control the quality of the installation of hired specialists.

Engaging professionals is the most correct and balanced decision, so you will not only save time and nerves, but also get an excellent result. Quick drying of laundry will become a pleasant reality, towels will be fresh and dry, and the bathroom will be comfortable.

Add site to bookmarks

- Kinds

- Choice

- Installation

- Finishing

- Repair

- Installation

- Device

- Cleaning

How to make a towel rail insert

How to choose the right way to install a heated towel rail in a riser in order to embed it and connect it with high quality with your own hands

The most common type of heated towel rails are water, you can buy combined ones, that is, electric and water at the same time, there are only electric ones. You can connect them in two ways:

- To the water pipe.

- To the heating stand.

Most often they stop at the option of inserting the device into a hot water pipe. The disadvantage of inserting a heated towel rail into the riser of the heating system is the seasonal heating of the room and the lack of hot water in it. In the event of a malfunction of the coil, it may be necessary to turn off the water supply to the heating system. This is extremely undesirable in the winter period, since the entire riser will be frozen as a result of the shutdown.

It is best to provide a jumper in order to close the hot water coming through the heating system. At the same time, the use of radiator valves in such a system where there is a separate riser is unacceptable. Adjustment of the water flow should not occur throughout the entire riser of the system, which is provided for by the operating conditions of the tap, because the owner of the heated towel rail does not have the right to do so.

Tapping a heated towel rail into a pipe is based on the concept of thermal expansion, which requires that the appliance and pipes are made of the same materials.

The best option is to use Teflon gaskets. If the pipes in the water supply system are plastic, then any type of heated towel rail can be installed to them.

Before installing a heated towel rail in the bathroom, you must select the appropriate connection method. If there is an old Soviet-era appliance, then a new model of the drying device will be required to replace it. The diameter of this design must match the diameter of the old one and connect from below.

In the case of a bathroom renovation, where the pipes are hidden in the wall, and their outlets are outside, it is best to install a water heated towel rail with a side connection. Mounting it is more difficult, but its appearance will be more acceptable. When installing this type of appliance, the connections should be carefully insulated, as it will be more difficult to fix leaks if the pipes are hidden in the wall.

Back to index

Do-it-yourself towel warmer insert

Back to index

What is a bypass for, use of fittings

A fitting is used to insert the heated towel rail into the plumbing system. Bypasses are one of the types of fittings. With the help of a fitting, various plumbing parts and pipelines are connected, securely fastening them into one system.

Insertion of water heated towel rails is carried out to the riser of the central heating system or water supply. The pipes used in the manufacture of heated towel rails are stainless steel with a diameter of 25 mm, the water supply riser itself is 32 mm in diameter. Exceeding the size of the conditional passage, which is common for each apartment through which the riser passes, above the conditional passage of the heated towel rail, is very common. "Narrowing" the central line should not be, as this can lead to a decrease in pressure and the efficiency of the device, which will not heat up. This also applies to neighboring apartments, as a result, complaints may arise. To establish equilibrium, it is enough to use a bypass or a jumper.

The bypass is a jumper with a smaller diameter than the dimensions of the riser and the heated towel rail itself. This is necessary so that water enters the device, and does not follow the path of least resistance, that is, directly.

The technology itself is based on the following sequence of work:

- Dismantling of the old device.

- Bypass installation, that is, jumpers,.

- Towel dryer.

A piece of pipe, which is a jumper or bypass, is equipped with connecting elements. This detail can help out in an unforeseen situation. Built-in ball valves will be able to stop the water passing through the bypass. If a jumper is installed, the water will continue to circulate even if the appliance is turned off.

Bypass, like other types of fittings, allows you to make pipe turns and branching, so it is used for. With the help of fitting elements, pipes of various diameters can be adjusted. The main requirement for these elements is a tight connection of any pipes. The fittings used will allow not to carry out welding when inserting a water heated towel rail to a water supply or heating system.

Bypass, like other types of fittings, is made from materials such as stainless steel, ordinary steel, cast iron, brass and others. Fittings are divided into:

- Squares.

- Couplings.

- Caps.

- Tees.

- Traffic jams.

The use of elbows is associated with a tie-in, if it is necessary to change the direction of the pipes at the required angle (45 o or 90 o). The use of couplings for tie-in will ensure a high-quality connection of pipes in a straight section or the union of pipes of different diameters. To plug the ends of the pipes, it is enough to take a cap with an internal thread. Plugs are used as a plug for the ends of a pipe with an external thread. A tee is necessary to ensure that water is drained in the same direction, equal to 90 o.

Since modern heated towel rails can have various geometric shapes, their insertion can be carried out using various fittings from those listed above.

Back to index

Necessary materials and principles for installing a water heated towel rail in the riser in the bathroom

In the process, when planning a major renovation of a bathroom or installing it in a country house, various materials can be used. It is important to know that:

- A metal-plastic pipeline will not be resistant to high temperature pressure drops. The size of the inner diameter of metal-plastic pipes is smaller than the diameter of other types. Its cost is cheaper than other pipes. Pipe connections are made by pressing.

- The use of copper pipes is associated with the highest costs, but they are more reliable, they are mounted by soldering, observing safety measures.

- Installation of the structure can be carried out using polypropylene pipes, the prices of which are most reasonable. They are connected by welding.

Do-it-yourself will require connection to two pipes. One pipe is used to supply hot water, and the other for its outflow. Often, the very design of a heated towel rail can be based on four connection points, the choice of which determines the intensity with which the device heats up. In this case, installation is possible on the basis of three connection schemes: bottom, side and diagonal. Or two, as mentioned above. The main condition for attaching a heated towel rail is that its pipes are located horizontally.

The inlet and outlet of the heated towel rail should be equipped with taps, you can use valves for adjustment. They will allow you to maintain the required heating temperature of the heated towel rail. This will make its operation safe, because as a result of its breakdown, the integrity of the device will be violated, hot water may come out. This does not eliminate the need to change gaskets. In order to replace the old appliance with a new heated towel rail, it will be enough to turn the taps.

When installing the device, you must follow the basic scheme and the following recommendations:

- A water supply is connected to one of the ends, and a pipe for the outflow of hot water is connected to the second.

- The design has a jumper that allows you to turn off the flow of water or loop it.

- When connecting, it is important to keep in mind that the hot water supply riser is separate from the water supply to the radiators if the heating is centralized.

- If you put a plug on a pipe in any of the apartments in the house, you can turn off all the equipment embedded in the riser pipe by breaking it.

- In order to prevent the riser from turning off, it is necessary to provide for a spare channel for the passage of water. In this case, the valve installed on the through pipe must be closed during the operation of the heated towel rail.

If there is a shortage of funds to buy a new heated towel rail in the bathroom in winter, then you can install an ordinary metal-plastic instead. It can be used indefinitely.

If the heated towel rail is inserted into the riser, and the flow is not broken, then the patency will not affect the supply of hot water to the riser. This is a reason to use radiator valves when adjusting the temperature of the device with the power of running water. This type of connection is used in autonomous heating systems, taking into account the possibility of doing it yourself.

Add site to bookmarks

- Kinds

- Choice

- Installation

- Finishing

- Repair

- Installation

- Device

- Cleaning

How to connect a heated towel rail

Currently, there are less and less bathrooms in which such a useful attribute as a heated towel rail would not be installed. After all, in addition to drying towels and a variety of linen, the heated towel rail creates a favorable microclimate in the bathroom, which allows you to avoid the appearance of fungus and unpleasant odors, the formation of dampness. Modern towel warmers have a striking design and stylish appearance, so you can choose the model that will look best on your bathroom wall. To ensure a comfortable temperature and normal humidity, they must work all year round. You can connect the heated towel rail yourself or by attracting professional plumbers for this. Whichever option you prefer, you still need to know at least the main points of this work. If you decide to do everything yourself, then before you connect the heated towel rail with your own hands, you need to choose the appropriate connection method.

The peculiarity of installing a water heated towel rail is that it must crash into a common water supply system.

Ways to connect heated towel rails: how to choose the right one?

There are 3 types of heated towel rails on the modern market: water, electric and combined models.

The most common are water heated towel rails. It is they who can be connected with their own hands without the involvement of specialists. To connect the same electric or combined model, you will need the services of a professional electrician.

There are 2 options for connecting a water heated towel rail:

- to the hot water supply;

- to the heating system.

Step-by-step diagram of installation and connection of the water heated towel rail "Ladder" (round profile).

Most often, option 1 is chosen, because. in this case year-round and round-the-clock heating is guaranteed. In the case of connecting to the heating system, you will encounter a number of inconveniences. Hot water in the system is only in the heating season. In addition, the question arises: how to attach and connect a heated towel rail in the winter, because no one will allow you to tie into the heating pipes (as a result of this, you can freeze the riser).

If a new heated towel rail is connected instead of the old Soviet-style model, it will be necessary to select a new device model of the same diameter, designed for bottom connection. If, during the repair of the premises, the pipes were “hidden” in the wall, and only exits remained outside, then in this case it is possible to install a water heated towel rail with a side connection. Installing such a model is more time consuming, but the device will also look much better.

The installation of such a heated towel rail requires a careful isolation of the connection, since the elimination of leaks in a model whose pipes are hidden in the wall is a very difficult job.

Back to index

Step-by-step instructions for installing a heated towel rail

If you need to perform several actions in the following sequence:

- dismantling the old device;

- installation of a jumper (bypass) and ball valves;

If a new device is being installed, the first step is skipped.

Prepare the tools needed to connect:

- wrench;

- pipe wrench;

- perforator;

- thread cutter;

- soldering iron for polypropylene pipes;

- Bulgarian;

- set of hex keys.

Back to index

Dismantling the old device

To turn off the old heated towel rail, you need to follow these steps:

- Close the hot water valve. This issue is agreed with the Housing Office.

- Remove the old towel warmer. If the device is not integral with the hot water pipe, unscrew the screw connection and dismantle it. If the unit is welded to the pipe, it must be cut with a grinder. Trimming is carried out with the expectation that the length of the pipe is sufficient for threading.

- Remove the old device from the brackets.