- 05.07.2017

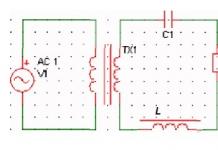

The proposed method for calculating a transformer power supply makes it possible to calculate its main parameters, such as the capacitance of a smoothing filter, the main parameters of diodes and a transformer. This calculation method allows you to calculate a power supply with an output current of up to 1 A. For the calculation, you need to set only three parameters: Constant output voltage of the power supply Maximum load current Coefficient ...

- 28.09.2014

This voltmeter can be used to measure DC current and voltage from 0 to 100V and from 0 to 10A. The voltmeter range is divided into 4 ranges: 0 ... 1V, 0 ... 10V, 0-100V, 0 ... 10A. The maximum displayed number is 999. An ADC with a maximum output voltage of 999mV is assembled on the NTE2054 chip, the ADC provides outputs for dynamic ...

- 20.09.2014

Electrical wiring must be appropriate to the environmental conditions, the value of the building and its architectural features. The insulation of wires and cables must correspond to the rated voltage of the network, and the protective sheaths must correspond to the laying method. Neutral wires must have insulation equivalent to that of the phase wires. The cross-sections of the wires are selected based on the values of the permissible voltage loss, the permissible heating of the wires by the load current ...

- 06.11.2016

When powering devices from batteries, sometimes there is a need for a two-polar voltage source. Of course, you can use two batteries, but you can also make a simple converter of one polar voltage to two polar ones. The proposed circuit allows you to get a negative voltage of -9 V from one element with a voltage of 9 V (Krona). Converter circuit ...

Very accurate LC meter on the PIC16F628A microcontroller. This design is slightly different from other similar meter circuits found on the Internet. At the heart of the LC meter is a kind of frequency meter with an LC oscillator, the frequency of which fluctuates depending on the measured value L or C, and as a result is calculated. Frequency accuracy up to 1 Hz.

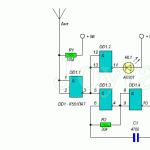

Diagram of the inductance and capacitance meter on the PIC16F628A

Relay RL1 is used to select L or C mode. The counter works on the basis of four basic equations. For both unknowns L and C, equations 1 and 2 are general. You can use any 5V relay - it will work fine. The operation of the relay is only to select the measurement mode L or C.

Instrument calibration

When power is applied, automatic calibration will occur. The default operating mode is inductance. Wait a few minutes to warm up, then press the " zero" to force the recalibration to take place. The display should now show ind = 0.00. Now connect a known inductance value, such as 10uH or 100uH. The LC meter should show an accurate value (within +/- 10% error). Now you need to adjust the counter to achieve a result in the region of +/- 1%. For this, there are 4 jumpers Jp1 ~ Jp4 on the circuit. Jp1 and Jp2 add + and - value. Once configured, the controller will remember the calibration until you change it again.

On the seemingly obsolete 2051 controller, we have repeatedly thought about how to assemble a similar meter, but on a more modern controller, in order to provide it with additional features. Basically, there was only one search criterion - these were wide measurement ranges. However, all similar circuits found on the Internet even had a software range limitation, and quite a significant one at that. To be fair, it is worth noting that the above-mentioned device for 2051 had no limitations at all (they were only hardware), and it even had the ability to measure - mega and -giga values in software!

Somehow, once again studying the circuits, we discovered a very useful device - LCM3, which has decent functionality with a small number of details. The device is able to measure inductance, capacitance of non-polar capacitors, capacitance of electrolytic capacitors, ESR, resistances (including ultra-small ones) in the widest range, evaluate the quality of electrolytic capacitors. The device works on the well-known principle of frequency measurement, however, it is interesting that the generator is assembled on a comparator built into the PIC16F690 microcontroller. Perhaps the parameters of this comparator are no worse than those of the LM311, because the declared measurement ranges are as follows:

- capacitance 1pF - 1nF with 0.1pF resolution and 1% accuracy

- capacitance 1nF - 100nF with 1pF resolution and 1% accuracy

- capacitance 100nF - 1uF with 1nF resolution and 2.5% accuracy

- capacitance of electrolytic capacitors 100nF - 0.1F with a resolution of 1nF and an accuracy of 5%

- inductance 10nH - 20H with 10nH resolution and 5% accuracy

- resistance 1mΩ - 30Ω with 1mΩ resolution and 5% accuracy

We liked the solutions used in the meter, and we decided not to assemble a new device on the Atmel controller, but to use PIC. From this Hungarian meter, a circuit was partially (and then completely) taken. Then the firmware was decompiled, and a new one was written on its basis, for our own needs. However, the author's firmware is so good that the device probably has no analogues with it.

Click to enlarge

LCM3 meter features:

- when turned on, the device must be in the capacitance measurement mode (if it is in the inductance measurement mode, then the corresponding inscription on the screen will ask you to switch from another mode)

- tantalum capacitors should be with as little ESR as possible (less than 0.5 ohms). The ESR of the 33nF CX1 capacitor should also be low. the total impedance of this capacitor, inductance, and mode button must not exceed 2.2 ohms. The quality of this capacitor as a whole should be very good, it should have a low leakage current, so you should choose from high-voltage (for example, 630 volts) - polypropylene (MKP), styroflex-polystyrene (KS, FKS, MKS, MKY?). Capacitors C9 and C10, as written in the diagram, are polystyrene, mica, polypropylene. The 180 ohm resistor should be 1% accurate, the 47 ohm resistor should also be 1%.

- the device evaluates the "quality" of the capacitor. there is no exact information on which parameters are calculated. this is probably the leakage, dielectric loss tangent, ESR. "quality" is displayed as a filled cup: the less it is filled, the better the capacitor. for a faulty capacitor, the cup is completely painted over. however, such a capacitor can be used in a linear regulator filter.

- the choke used in the device must be large enough (to withstand a current of at least 2A without saturation) - in the form of a "dumbbell" or on an armored core.

- sometimes, when turned on, the device displays "Low Batt" on the screen. In this case, you need to turn off and turn on the power again (probably a glitch).

- There are several firmware versions of this device: 1.2-1.35, and the latter, according to the authors, is optimized for an armored core choke. however, it also works on a dumbbell choke and only in this version is the quality of electrolytic capacitors evaluated.

- it is possible to connect a small attachment to the device for in-circuit (without soldering) measurement of the ESR of electrolytic capacitors. It lowers the voltage applied to the capacitor under test to 30mV, at which the semiconductors do not open and do not affect the measurement. The diagram can be found on the author's website.

- The ESR measurement mode is activated automatically by plugging the probes into the appropriate socket. If at the same time a resistor (up to 30 Ohm) is connected instead of an electrolytic capacitor, the device will automatically switch to the low resistance measurement mode.

- press the calibration button

- release the calibration button

- close the probes of the device

- press the calibration button

- wait for the message R=....Ohm

- release the calibration button

- wait for the message about the end of the calibration

- close the probes of the device

- press the calibration button, the screen will display the voltage applied to the measured capacitor (recommended values are 130 ... 150 mV, curled from the inductor, which must be placed away from metal surfaces) and the frequency of measuring ESR

- wait for message R=....Ohm

- release the calibration button

- the resistance reading on the screen should go to zero

Then:

- connect circuit (or close vpp and gnd)

- turn on the device and press the calibration button, the value of the calibration capacity will appear on the screen

- use the DN and UP buttons to adjust the values (perhaps, in different firmware versions, the main calibrate and mode buttons work for faster adjustment)

- depending on the firmware version, another option is also possible: after pressing the calibration button, the value of the calibration capacity appears on the screen, which begins to grow. When it reaches the desired value, you need to stop the growth with the mode button and open vpp and gnd. If you didn’t have time to stop in time and jumped the desired value, then you can reduce it with the calibration button

- disable circuit (or open vpp and gnd)

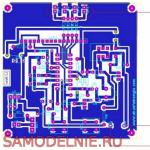

PCB: lcm3.lay (one of the options from the vrtp forum).

On the supplied printed circuit board, the display contrast of 16 * 2 is set by a voltage divider on resistors with a resistance of 18k and 1k. If necessary, you need to choose the resistance of the latter. FB - ferrite cylinder, instead of it you can put a choke. For greater accuracy, instead of a 180 ohm resistor, two 360 in parallel are used. Before installing the calibration button and the measurement mode switch, be sure to check their pinout with a tester: there is often one that does not fit.

The case for the device, following the tradition (one, two), is made of plastic and painted with black metallic paint. Initially, the device was powered by a 5V 500mA mobile phone charger via a mini-USB socket. This is not the best option, since the power was connected to the meter board after the stabilizer, and how stable it is when charging from the phone is unknown. Then the external power was replaced with a lithium battery with a charging module and a boost converter, the possible interference from which is perfectly removed by the usual LDO stabilizer present in the circuit.

In conclusion, I would like to add that the author has invested maximum capabilities in this meter, making it indispensable for a radio amateur.

I am sure that this project is not new, but this is my own development and I want this project to be known and useful as well.

Scheme LC meter on ATmega8 simple enough. The oscillator is classic and is based on the LM311 operational amplifier. The main goal that I pursued when creating this LC meter is to make it inexpensive and affordable for every radio amateur to assemble.

This project is available online in several languages. At this time, mathematics seemed too complicated. Then the overall accuracy will be limited by the behavior of the oscillator and one "calibration capacitor". Hopefully this follows the "well-known resonant frequency formula". The error was 3% for 22 uF capacitors. A greencap would be a suitable replacement, but a ceramic capacitor might not be a good choice. Some of them may have big losses.

I have no reason to suspect any strange non-linearities in low value component readings. The small values of the components, theoretically, are directly proportional to the frequency difference. Software inherently follows this proportionality.

Features of LC Meter:

- Capacitor capacitance measurement: 1pF - 0.3uF.

- Measuring the inductance of coils: 1mkH-0.5mH.

- Display of information on the LCD indicator 1×6 or 2×16 characters depending on the selected software

For this device, I developed software that allows you to use the indicator that the radio amateur has at his disposal, either a 1x16 character LCD display, or 2x 16 characters.

Another question about the project?

Now you can design a tuned circuit, build it, and let it resonate at the correct frequency the first time, every time. Please check this before emailing me. This might just answer your question. You need to measure the inductance, but you don't have a multimeter to do this, or even an oscilloscope to see the signal.

Well, no matter the frequency or how hard the bell strikes, it will ring at its resonant frequency. Now microcontrollers are terrible at analyzing analog signals. In this case it will be 5 volts from the arduino. We have been charging the circuit for some time. We then change the voltage from 5 volts directly to the point that this pulse will cause the circuit to resonate, creating a softened sine wave that oscillates at the resonant frequency. We need to measure this frequency and then use the formulas that get the value of the inductance.

Tests with both displays gave excellent results. When using a 2x16 character display, the top line displays the measurement mode (Cap - capacitance, Ind -) and the generator frequency, and the bottom line shows the measurement result. On the display of 1x16 characters, the measurement result is shown on the left, and the frequency of the generator on the right.

Schematic diagram of the capacitance and induction meter

The resonant frequency is related to the following situation.

Since our wave is a true sine wave, it spends equal time above zero volts and below zero volts. This measurement can then be doubled to get the period, and the inverse period is the frequency.

Capacitance measuring ranges

Since the circuit is resonating, this frequency is the resonant frequency. Solving for inductance will lead to the sailor's equation. After that, we stop the pulse and the circuit resonates. The comparator will output a square wave at the same frequency, which the arduino will measure with a pulse function that measures the time between each pulse of the square wave.

However, in order to fit the measured value and the frequency on the same character line, I reduced the display resolution. This does not affect the accuracy of the measurement in any way, only visually.

As with other known options that are based on the same universal circuit, I added a calibration button to the LC meter. Calibration is carried out using a reference capacitor with a capacity of 1000pF with a deviation of 1%.

Build the following circuit and upload the code and start measuring inductance. Remove this line after this capacity=. Capacitors and inductors can be combined to create resonant circuits that have pronounced frequency responses. The number of capacitances and inductance of these devices determine both the resonant frequency and the sharpness of the response curve that these circuits exhibit.

If capacitance and inductance are in parallel, they tend to pass electrical energy that oscillates at the resonant frequency and block, i.e. presents a higher impedance to other parts of the frequency spectrum. If they are in a series configuration, they tend to block electrical energy that oscillates at the resonant frequency and let other parts of the frequency spectrum through.

When you press the calibration button, the following is displayed:

The measurements taken with this instrument are surprisingly accurate, and the accuracy depends largely on the accuracy of the standard capacitor that is inserted into the circuit when you press the calibration button. The calibration method of the device consists only in measuring the capacitance of the reference capacitor and automatically writing its value to the memory of the microcontroller.

There are many applications for resonant circuits, including selective tuning in radio transmitters and receivers and suppression of unwanted harmonics. An inductor and capacitor in parallel configuration is known as a tank circuit. The resonance condition occurs in the circuit when.

Verification and calibration

This can only happen with a certain frequency. The equation can be simplified to. From this information it is possible, knowing the capacitive and inductive parameters of the circuit, to find the resonant frequency. In general, an oscillator in an electronic circuit converts a DC supply voltage into an AC output, which can be composed of multiple waveforms, frequencies, amplitudes, and duty cycles. Or the output could be a fundamental sine wave without any other harmonic content.

I want to present a circuit for measuring capacitance and inductance of small values, a device that is often simply necessary in amateur radio practice. The meter is made in the form of a USB-attachment to a computer, the readings are displayed in a special program on the monitor screen.

Characteristics:

measurement range C: 0.1pF - ~1µF. Range switching automatic: 0.1-999.9pF, 1nF-99.99nF, 0.1µF-0.99µF.

The goal of building an amplifier is to design a circuit that will not go into oscillation. In an amplifier not designed to operate as an oscillator, a limited amount of positive feedback can be used to increase the gain. A variable resistance can be placed in series with feedback to prevent the circuit from oscillating. The distance between microphone and loudspeaker behaves like resistance to audio frequency waves.

They are similar to electromechanical resonators such as quartz crystal oscillators. The connection between the generator and the generator must be weakened. We tune the oscillator circuit to see the maximum voltage in the probe connected to the tank circuit.

measurement range L: 0.01µH - ~100mH. Range switching automatic: 0.01-999.99µH, 1mH-99.99mH.

Advantages:

The device does not require a driver.

The program does not require installation.

Does not require configuration (Except for the calibration procedure, which, by the way, does not require access to the circuit).

It is not necessary to select the exact values of the calibration capacitance and inductance (we allow a spread of up to ± 25%! from those indicated).

Here is the LC meter circuit

Now the circuit is in resonance, this frequency is the resonant frequency of the circuit. Then we measure the voltage of the generator circuit at the resonant frequency. We change the oscillator frequency slightly above and below resonance and find two frequencies: the voltage across the circuit is 707 times the value at resonance. The voltage at resonance is 707 times -3 dB.

The oscillator bandwidth is the difference between the frequencies corresponding to these two 707 points. The output of the signal generator is connected to a coupling coil having about 50 turns. For frequencies in the megahertz range, we place the coupling coil about 20 cm from the oscillator circuit. A distance of 20 cm should allow a free connection between the coil and the oscillator.

There are no controls on the diagram, all control (switching measurement modes, L or C, as well as instrument calibration) occurs from the control program. Only two terminals are available to the user, for installing the measured part in them, a usb connector and an LED that lights up when the control program is running and blinks otherwise.

We then connect the probe to the generator circuit. The ground connection of the probe must be connected to the body of the tuner capacitor. The probe is connected to an oscilloscope. Due to the 100x attenuation in the sensor, the output of the signal generator should normally be quite high.

Now the area trace runs from left to right and the left side is the start frequency and the right side is the stop frequency. A good place to start is with a sweep frequency of about 10 hertz. We can rotate the tuner capacitor and get the oscillator curve on the oscilloscope screen. The amplitude control of the sweep generator adjusts the peak height of the waveform. The big advantage of this method is that changes in the resonant frequency of the oscillator circuit can be directly seen on the screen.

The heart of the device is the LC generator on the LM311 comparator. To successfully calculate the value of the measured capacitance / inductance, we must know exactly the values \u200b\u200bof the set refC and refL, as well as the frequency of the generator. Due to the use of computer power in the process of instrument calibration, all possible values of refC ± 25% and refL ± 25% will be sorted out. Then, the most suitable ones will be selected from the array of received data in several stages, about the algorithm below. Due to this algorithm, it is not necessary to accurately select the values of capacitance and inductance for use in the device, you can simply set what you have and do not care about the accuracy of the ratings. Moreover, the values of refC and refL can differ in a wide range from those indicated in the diagram.

The Armstrong oscillator was originally used in vacuum tube transmitters. The coil can be adjusted so that the chain swing oscillates. This is actually a voltage divider, consisting of two capacitors connected in series. The active device, the amplifier, can be a bipolar junction transistor, a field effect transistor, an operational amplifier, or a vacuum tube.

This is instead of tuning one of the capacitors, or by introducing a separate variable capacitor in series with the inductor. The difference is that instead of a center-touch capacitance coupled with an inductor, it uses a center-touch inductance coupled with a capacitor. The feedback signal comes from a center tapped inductor or series connection between two inductors.

The microcontroller, using the V-USB library, organizes communication with the computer and also calculates the frequency from the generator. However, the control program is also involved in the calculation of the frequency, the microcontroller only sends raw data from the timers.

The microcontroller is Atmega48, but it is also possible to use Atmega8 and Atmega88, the firmware for three different microcontrollers is attached.

These inductors do not need to be mutually connected, so they can be made up of two separate coils in series rather than a single center tap device. In the variant having the center-strike coil, the inductance is greater because the two segments are magnetically coupled.

In a Hartley oscillator, the frequency can be easily adjusted using a variable capacitor. The circuit is relatively simple, with a low number of components. A high-frequency stabilized oscillator can be built by replacing a quartz resonator with a capacitor.

Relay K1 - miniature with two groups for switching. I used the RES80, bending the legs with tweezers like the RES80-1 for surface mounting, with a trip current of 40mA. If it is not possible to find a relay capable of operating from 3.3v with a small current, you can use any 5v relay, replacing R11, K1, respectively, with a cascade drawn by a dotted line.

This is an improvement over the Colpitt oscillator where oscillations may not occur at certain frequencies causing gaps in the spectrum. Like other oscillators, the goal is to provide a combined gain greater than one at the resonant frequency to keep the oscillation going. One transistor can be configured as a common base amplifier and the other as an emitter follower. The follower output of the emitter, connected back to the input of the base transistor, maintains oscillation in the Peltz circuit.

The varactor is a flyback diode. In particular, the magnitude of the reverse bias determines the thickness of the depletion zone in the semiconductor. The thickness of the depletion zone is proportional to the square root of the voltage that reverses the bias of the diode, and the capacitance is inversely proportional to this thickness, and so it is inversely proportional to the square root of the applied voltage.

I also used a miniature quartz at 12MHz, even a little smaller than a watch one.

Control program.

The control program was written in the Embarcadero RAD Studio XE environment in C++. The main and main window in which the measured parameter is displayed looks like this:

|

Of the controls on the main form, only three buttons are visible. - Measurement mode selection, C - capacitance measurement and L - inductance measurement. You can also select a mode by pressing the C or L keys on the keyboard. - Zero setting button, but I must say, you will not have to use it often. Each time you start the program and switch to mode C, zero is set automatically. To set zero in the measurement mode L, you need to install a jumper in the terminals of the device, if at this moment zero appears on the screen, then the installation was completed automatically, if the readings on the screen are greater than zero, you must press the zero setting button and the readings will be reset. |

Accordingly, the output of a simple DC power supply can be switched through a range of resistors or variable resistance to tune the oscillator. Varactors are designed to take advantage of this property. A solid body with any degree of elasticity will vibrate to some extent when mechanical energy is applied. An example is a gong struck with a hammer. If it can be made to ring continuously, it can work as a resonant circuit in an electronic oscillator.

A quartz crystal is inevitably suitable for this role, as it is very stable with respect to its resonant frequency. The resonant frequency depends on the size and shape of the crystal. The quartz crystal as a resonator has the amazing virtue of reverse electricity. This means that when properly cut, grounded, mounted, and terminated, it responds to applied voltage by changing shape slightly. When the voltage is removed, it will return to its original spatial configuration, creating a voltage that can be measured at the terminals.

The instrument calibration process is very simple. To do this, we need a capacitor with a known capacitance and a jumper - a piece of wire of minimum length. The capacity can be any, but the accuracy of the device will depend on the accuracy of the capacitor used for calibration. I used a K71-1 capacitor, 0.0295µF, ±0.5% accuracy.

To start calibration, you need to enter the values of the set refC and refL (Only during the first calibration, later these values \u200b\u200bare saved in the device’s memory, however, they can always be changed). Let me remind you that the values \u200b\u200bmay differ by an order of magnitude from those indicated in the diagram, and their accuracy is also completely unimportant. Next, enter the value of the calibration capacitor and press the "Start Calibration" button. After the message "Insert the calibration capatitor" appears, install the calibration capacitor (I have 0.0295µF) in the terminals of the device and wait a few seconds until the message "Insert the jumper" appears. Remove the capacitor from the terminals and install a jumper in the terminals, wait a few seconds until the message "Calibration completed" appears on a green background, remove the jumper. If an error occurs during the calibration process (for example, the calibration capacitor was removed too early), an error message will be displayed on a red background, in this case, simply repeat the calibration procedure from the beginning. The entire calibration sequence in the form of animation can be seen in the screenshot on the left.

Upon completion of the calibration, all calibration data, as well as the values of the set refC and refL, will be written to the non-volatile memory of the microcontroller. Thus, in the memory of a particular device, settings are stored specifically for it.

Program operation algorithm

Frequency counting is done using two microcontroller timers. The 8-bit timer operates in the pulse counting mode at input T0 and generates an interrupt every 256 pulses, in the handler of which the value of the counter variable (COUNT) is incremented. The 16-bit timer works in the coincident cleaning mode and generates an interrupt every 0.36 seconds, in the handler of which the value of the counter variable (COUNT) is stored, as well as the residual value of the 8-bit timer counter (TCNT0) for subsequent transfer to the computer. The control program is already involved in the further calculation of the frequency. Given two parameters (COUNT and TCNT0), the oscillator frequency (f) is calculated using the formula:

![]()

Knowing the frequency of the generator, as well as the values of the set refC and refL, you can determine the value of the capacitance / inductance connected for measuring.

![]()

![]()

Calibration, on the part of the program, occurs in three stages. I will give the most interesting part of the program code - the functions responsible for the calibration.

1) First stage. Collection in an array of all values from the range refC±25% and refL±25%, at which the calculated L and C are very close to zero, while nothing should be set to the terminals of the device.

//Permissible zero spread during calibration pF, nH

bool allowC0range(double a) ( if (a>= 0 && a

bool allowL0range(double a) ( if (a>= 0 && a

bool all_zero_values(int f, int c, int l) ( //f- frequency, c and l - set refC and refL

int refC_min = c - c/(100 / 25);

int refC_max = c + c/(100 / 25);

int refL_min = l- l/(100 / 25);

int refL_max = l+ l/(100 / 25);

for (int a= refC_min; a//Search C with step 1pF

for (int b= refL_min; b//Iterate over L in steps of 0.01µH

if (allowC0range(GetCapacitance(f, a, b)) && allowL0range(GetInductance(f, a, b))) (

//If for a given value of refC and refL the calculated values of C and L are close to zero

// put these refC and refL values into an array

values_temp. pushback(a);

values_temp. pushback(b);

Typically, after this function, the array accumulates from hundreds to several hundred pairs of values.

2) Second phase. Measurement of the calibration capacitor installed in the terminals in turn with all values as refC and refL from the previous array and comparison with the known value of the calibration capacitor. Ultimately, one pair of refC and refL values is selected from the above array, at which the difference between the measured and known value of the calibration capacitor will be minimal.

Answer

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five http://jquery2dotnet.com/ centuries , but also the leap into electronic typesetting, remaining essentially unchanged.

CAPACITANCE AND INDUCTANCE METER

Diagram of LC meter

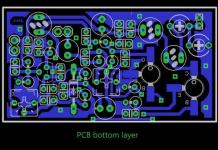

Printed circuit board

Inductance measurement ranges:

10nH - 1000nH

1uH - 1000uH

1mH - 100mH

Capacitance measurement ranges:

0.1pF - 1000pF

1nF - 900nF

A big plus of the device is automatic calibration at power-up, so calibration errors are excluded, which is inherent in some similar circuits of inductometers, especially analog ones. If necessary, you can re-calibrate at any time by pressing the reset button.

Instrument components

Too precise components are optional, with the exception of one (or more) capacitors, which are used to calibrate the meter. The two 1000pF capacitors on the input should be of good enough quality. Styrofoam is more preferred. Avoid ceramic capacitors, as some of them can have high losses.

Two 10 uF capacitors in the generator should be tantalum (they have low ESR series resistance and inductance). A 4 MHz crystal should be strictly 4,000 MHz, not anything close to that. Every 1% error in the frequency of the crystal adds 2% error to the measurement of the inductance value. The relay should provide about 30 mA of tripping current. Resistor R5 sets the contrast of the LCD display of the LC meter. The device is powered by a conventional Krona battery, since the voltage is further stabilized by the 7805 microcircuit.