The word "chaise lounge" is immediately associated with comfortable rest Outdoors. In addition, a comfortable portable chair will emphasize the style and individuality of a country or garden plot. A store-bought chaise lounge can be quite expensive, but you can easily assemble it yourself from improvised materials.

Chaise lounge - the general principle of design, varieties

Any deck chair is a folding chair on a frame, often with an adjustable backrest. The word "chaise lounge" comes from the French expression Chaise-longue - "loafer".

Variety by purpose

Depending on the purpose, sun loungers have a different configuration.

- For cottages and home gardens.

- For beach.

- Baby chair.

Variety by design

By design, sun loungers can be seated and recumbent.

- Standing folding chaise longue made of wood with a solid seat. Most often made from wooden slats rather than plywood or sheet plastic to facilitate the design.

- Standing folding made of wood with fabric.

Fabric seat can be easily removed for washing or transport

- Standing folding out aluminum tubes with fabric seat.

- Lying folding with a wooden seat.

- Recumbent chaise lounge made of aluminum tubes with a fabric seat. In fact, it is very close to the cot so familiar to all of us.

- Hanging deckchair.

Photo gallery: the variety of sun loungers has no limits

Eco-friendly products are popular with summer residents

Eco-friendly products are popular with summer residents  Chaise lounge with a plastic seat in a classic crate is suitable for the beach

Chaise lounge with a plastic seat in a classic crate is suitable for the beach  Chaise longue may be a variety upholstered furniture

Chaise longue may be a variety upholstered furniture  Chaise lounge "Leonardo" is equipped with a mattress

Chaise lounge "Leonardo" is equipped with a mattress  The fabric for the seat should be strong and dense, not subject to stretching.

The fabric for the seat should be strong and dense, not subject to stretching.  The simplest folding garden chaise lounge "Valdai" - the most a budget option

The simplest folding garden chaise lounge "Valdai" - the most a budget option  Non-folding sun loungers are best used permanently

Non-folding sun loungers are best used permanently  Chaise longue Cosatto - minimalistic plastic and metal

Chaise longue Cosatto - minimalistic plastic and metal  Chaise lounge CHAISE LONGUE is made of thick plywood

Chaise lounge CHAISE LONGUE is made of thick plywood

The choice of design and material for construction

You need to clearly understand what you would like to receive and what opportunities you have. If needed solid construction, but has no weight of great importance, then you need to focus on a metal or wooden deck chair with a wooden seat. The easiest way is to make such a seat from pallets - there are already finished assembly boards on the frame, but the boards themselves are of poor quality and will require long processing after assembly - sanding, painting. Making a deck chair from bent steel pipes requires skills in handling the welding machine. The finished structure will be very strong, but heavy. If, on the contrary, you need an extremely lightweight and space-saving design, then think about a deck chair from the frame of an old folding bed.

But the easiest option to make is the usual wooden deck chair with a fabric seat.

Future deck chair - drawing and description

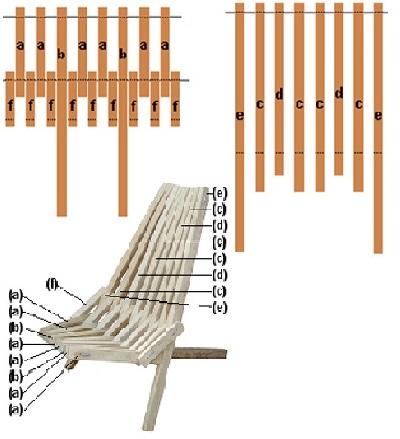

We settled on a simple wooden structure: bars connected by bolts with nuts and washers. The strength of this deck chair is given by three slats in the back, they also allow the chair to transform. The seat made of durable tent fabric is fixed on two round bars.

Tools and materials

We need tools:

- saw;

- drill;

- wood file and sandpaper.

Metal fittings and other little things:

- bolts and nuts - 4 pieces;

- washers (under the bolt head and nut) - 8 pieces;

- joiner's glue;

- screws;

- reinforced thread for a sewing machine.

Ingredients for wood preparation:

- impregnation against decay and moisture;

- primer (linseed oil or other);

- paint or stain.

Table: necessary parts for a sun lounger

It is necessary to carefully approach the choice of fabric for sitting, it should be hard and comfortable, should not wear out quickly. The best option- awning fabric; but any other dense fabric is also suitable - tarpaulin, denim, canvas. Well, if it is bright and not light. It's smarter and more practical.

Preparation for work

All bars must be sanded, starting with coarse-grained skins, ending with the smallest. It is advisable to impregnate them with a special anti-rotting impregnation or water-repellent impregnation, then prime and paint or stain. Then the deck chair will serve you for many years in any conditions.

Chaise lounge assembly

- You can start with the frame of the back of the deck chair. A beam with a section of 2 × 6 × 61 centimeters will be the main bearing link, so we fasten it very carefully. In the back of the seat we mount the crossbars. With the help of a stop that changes its position, the backrest tilt changes. At the same time, these crossbars work as stiffeners. You can not attach the planks, then in their place it is necessary to make cutouts 20, 25, 30 and 35 centimeters from the rear edge of the structure. Be sure to leave a centimeter gap between the two bars to secure the fabric seat.

- According to the drawing, we drill the necessary holes: on the back - two, from the edges - 41 centimeters each; on the seat from the top edge - 43 centimeters; on the bar to support the back - in the center.

- Then we combine the back and seat. We check the alignment of the holes. We connect them with bolts and nuts. Be sure to put washers between the wooden parts.

- We connect the elements of the frame. We mount the back support. A round bar is inserted into a hole drilled for it with glue.

- We fold the pre-cut rectangular piece of fabric in half and sew it with a reinforced thread with an indent of one and a half centimeters from the edge. We turn the stitched part inside out, make a drawstring for a round bar with a line. We do the same on the other side. We put it between the planks and fix it with a wooden rod. With this decision, it will be easy to remove the fabric seat and wash it, along with this there is no risk of falling out of the deck chair - the seat is firmly fixed.

Fabric can be removed without much effort

The nuts have the ability to unwind, but they cannot be tightened tightly - otherwise the deck chair will not be able to easily unfold and fold. To avoid untwisting, you can add one more locknut; or you can put nuts on glue or paint, only then do not touch the structure for some time so that the glue or paint dries. But at the same time, it is first necessary to adjust the tightening of the nut so that the parts move freely relative to each other.

Here is another approximate drawing of a slightly different design - all parts, dimensions and connections are clearly visible here.

Further care

If you carefully approached the preparation of wooden parts, then special care is not required. But over time, all sanding, impregnation, priming and painting should be repeated by removing the fabric seat. The removable seat can be removed when it rains and can be easily washed when dirty. You can also make it from washable fabric. For the winter, it is better to clean the sun lounger indoors.

The simple process of making a deck chair with your own hands will please any craftsman with a wonderful end result. A variety of materials and fabrics will allow you to be creative and create an original thing. And when proper care The chaise lounge will serve you for many years.

Do you want to make your vacation in the garden even more comfortable? Then use one of the many ideas and build a sun lounger with my own hands. In this article we will talk about what material to choose to work on creating this type of garden bench, and how to properly assemble the structure with your own hands. We will also compose step by step instructions how to make a sun lounger at home.

A variety of materials for the manufacture of deck chairs

If you literally translate the word “chaise lounge” from French, then you will get a “long chair”, for the manufacture of which they most often choose natural wood. But along with this material, plywood, durable fabric, plastic and wicker, etc. are actively used. Some craftsmen decorate their site with rocking chairs made from corrugated cardboard, as well as logs. As practice shows to production of this type garden furniture can be approached creatively, while using elementary, improvised materials that are no longer useful in the household. The table shows the characteristics, features, advantages and disadvantages of wood, plywood, fabric as a material for a do-it-yourself deck chair.

| Materials for making a sun lounger | |

| Wood | When choosing wooden material it is necessary to pay attention to its structure and the breed with which it is produced. Experts do not recommend buying spruce because of the smell of resin, which, under the influence sun rays will only get worse. As a base, it is better to use ash and larch, they are characterized by strength, durability and ease of processing, and therefore not difficult to install. It should be understood that the prices for natural wood are quite high, so saving on this material will not work. Wooden furniture needs to be treated antiseptics, because without proper care, it quickly rots and deforms. |

| Textile | feature fabric furniture considered to be environmentally friendly and safe. Such structures are relatively light in weight and are as mobile as possible. Along with these advantages, the following disadvantages can be distinguished: fragility, instability to ultraviolet radiation. Fabric deck chairs are not able to withstand heavy loads. For comfort, it is best to choose natural materials, without various additives, pigments. |

| Plywood | Fairly common construction material, which is actively used for the manufacture of a variety of furniture, including sun loungers. For this purpose, one of the varieties of plywood FK is purchased, it is intended for interior decoration and does not contain toxic impurities. Structures made of this material are lightweight and have affordable prices. However, plywood products cannot be called durable, and besides, they are not suitable for people with a lot of weight. |

Craftsmen with weaving skills can use wicker, bamboo, and rattan as a material for a deck chair, which make the furniture look attractive, mobile and safe. As a rule, finished structures of this type are characterized by high price. The disadvantage of wicker products is their instability to precipitation and prolonged exposure to sunlight.

On the modern market there are many ready-made plastic deck chairs, which differ in price, shape, type (monolithic, portable). plus plastic products can be called insignificant weight and variety design ideas, embodied in the manufacture. The disadvantages of plastic rocking chairs are fragility and instability to aggressive climatic conditions.

Chaise lounges are distinguished by structural strength, the frame of which is made of metal and treated with anti-corrosion agents. When using aluminum, the structures are light and practical. In combination with a metal frame, fabric materials are most often used.

Chaise lounge drawing options

On the Internet, on sites related to the construction industry, there are variety of options sun lounger drawings. Leisure garden furniture on wheels, with a canopy, with adjustable backrest, etc. will become indispensable after a hard day's work and will allow you to relax with a cup of tea, or reading a good book.

Regarding the appearance, the designs of deck chairs are usually divided into three categories:

- soldered with inserts;

- monolithic;

- portable.

Monolithic models are structures that cannot be disassembled, as they consist of solid elements. They have an attractive appearance, can be decorated with a variety of inserts from combined materials. As a rule, monolithic deck chairs are characterized by their strength and relatively large weight, rather big dimensions. The disadvantage of such products is not an adjustable headboard, backrest.

Designs that can easily change the position of the backrest, etc. are called portable. This type of product is considered mobile and very convenient, they are called a progressive option. Due to their folding abilities, this type of deck chairs is easy to transport. Any of the above designs can be supplemented with mattresses or original pillows that will ensure a comfortable stay.

To make a deck chair at home, beginners can use ready-made projects and drawings that the Internet is rich in and which have been tested in practice. For example, original version it is considered to assemble a Kentucky chair (from bars) with your own hands, as well as a deck chair from wooden bars, the manufacture of which will take a little time.

Features of making a simple wooden deck chair with your own hands

The most common dimensions of sun loungers, which can even be called standard, can be called 60 by 190 cm. Next, we will consider the manufacturing process of a simple wooden rocking chair with a flat base, but at the same time with an adjustable back. Wooden furniture this purpose most often has enough big weight, because of which it is difficult to move it around the site, but this problem can also be solved at home, for example, attach roller wheels to the legs.

So, for the production of a wooden deck chair with your own hands, you need to purchase and prepare the following tools and materials:

- wooden bars and boards;

- galvanized screws;

- drill;

- jigsaw;

- roulette;

- drills and screws;

- a hammer;

- corner;

- brush and varnish.

It is possible to carry out work on assembling a wooden folding chair in several stages, which are as follows:

- the manufacture of the base;

- sheathing the frame with wooden gratings;

- fixation of support legs.

Now we will consider each of the stages in more detail, but first we will answer the most common question among home craftsmen: How to properly mark a tree with your own hands? So, marking wood is needed in order to significantly reduce the percentage of material waste, that is, to use it as rationally as possible. To do this, the master needs to own a drawing, which details constituent elements designs and their exact dimensions. For marking, the master needs to prepare a sheet of graph paper and draw the necessary details on it, then the blank is transferred to thick cardboard, cut out and marked on a wooden material according to the contours. The cut elements must be sanded and treated with antiseptics in order to significantly extend their service life.

To make a base for a wooden deck chair, you will need bars, the cross section of which should be 45 * 45 centimeters, while drill diameter will be 40 millimeters. Start off assembly process necessary from the preparation of two long and two short sidewalls. They connect with each other metal corners and screws. Further outside the bases are sheathed with carved wooden gratings, the number of which varies relative to the length of the frame. Not the last place in this business is occupied by the processing of parts and fasteners for making a deck chair with your own hands. On long slats equal distance, places are marked for the legs, they are made of wooden block, to the bottom of which the wheels are attached, using screws. An adjustable backrest on a handmade wooden deck chair can be made using a door hinge.

For this, the lattice is divided into two groups: the first plays the role of a headboard, the second of the base. A cross rail is used as fastening. After the complete assembly of the structure, the master needs to use a grinding machine and process the sunbed with it, and then use a brush to open it with varnish, let it dry completely. As a result - a ready-made, comfortable, adjustable deck chair of our own production.

Features of making a fabric deck chair with your own hands

Fabric sun loungers are very popular among consumers, which, due to their folding design, are very convenient to use. As practice shows, many craftsmen make such products with their own hands, bringing to life a wide variety of ideas, turning home rest into a holiday. Due to their low weight, fabric sun loungers are easy to fold and carry around the territory, take them to the beach, etc.

The frame for a fabric product can be made of wood or metal. Let's consider both options. To assemble a product for this purpose, you will need the following materials and tools:

- wooden bars (oak, birch or beech);

- nails;

- sandpaper;

- drill and drills;

- PVA glue;

- durable fabric (jeans, camouflage, etc.);

- roulette;

- bolts;

- round sticks.

Step-by-step instructions for making a sun lounger with your own hands in this case looks like that:

1. To assemble the base of the sun lounger, three frames are prepared different sizes: the first - 1200 mm * 600 mm, the second - 1100 mm * 550 mm, the third - 650 mm * 620 mm. Holes are made in them, due to which the structure will be connected.

2. First, the first and third frames are connected, bolts and round sticks are used to fasten them, then the first and second blanks are attached, the joints are treated with glue.

When choosing a fabric base, you should pay attention to its composition, manufacturer, structure and quality. It is necessary that the selected material be durable and natural, this will extend the service life homemade sun lounger. The master has the opportunity to acquire the basis of the desired color, to embody his state of mind and mood into the product as much as possible. Also portable, a fabric chaise longue can be a great addition to home decor.

Many beginners are interested in the question: how to properly assemble a structure with a metal frame with your own hands? Why is this option so popular? The fact is that metal base it is maximally adapted to changing positions and is easily subjected to various upgrades. Finished products of this type are quite compact, they are easy to remove and store when not needed.

The assembly of a deck chair with a metal frame is practically the same as the previous one, wooden version, only in this case it will not be required bars, but metal frames, for the manufacture of which it is better to use steel or aluminum. Do not forget about the treatment of the material with anti-corrosion agents, otherwise rust will soon appear, which will not only spoil appearance products, and damage the fabric base.

In order for fabric lounge chairs to retain their original qualities for a long time, professionals recommend using a variety of impregnations that create protection from the active effects of ultraviolet radiation, repel moisture, etc. Usually such funds are valid for up to 4 weeks.

Most good way to relax after gardening is to lie in a sun lounger and drink juice. Wherein importance it matters whether such an armchair will fit into the environment around and whether it will give a feeling of peace. If you can’t buy furniture for a summer residence, then you can make it yourself.

But even before make your own sun lounger, you need to choose the type of this country furniture. It should also be taken into account that the craftsmen do not recommend using plastic as the basis for a deck chair due to the lack of quality and fragility of this material. And here wooden base flat and smooth fit perfectly, although such a chair will be heavy. But this disadvantage can be compensated by the rollers installed on the legs of the deck chair.

The type of this furniture depends on the design of the lounge chair, namely:

- Monolithic deck chair.

- Monolithic deck chair with inserts.

- Portable product.

- Chaise lounge chair on a base made of metal.

A monolithic chaise lounge is an armchair, the components of which are joined together during the manufacturing process of the product and can no longer be disassembled. Such furniture is durable, hardy and can withstand a significant load. But using this deck chair is not very convenient. It cannot change the slope of the back, it cannot be folded, and therefore it is very difficult to move from one place to another.

Monolithic chaise longue with inserts- this type of country furniture, made by hand, will certainly be beautiful, aesthetically attractive and neat. But these additionally inserted parts, which can be made from different materials, reduce the strength and reliability of the entire product.

A portable product that is designed to a mechanism that allows you to quickly and easily change the position and configuration of the entire sun lounger. The inclination of the footrest, the inclination of the headrest and the back of the chair can be changed. And yet such a product can be folded and made compact when transported to the country.

Chaise lounge chair on a metal base. This type of country furniture is difficult to do on your own, so it is usually bought ready-made. This product has a frame made of aluminum or steel, and a canvas made of fabric is already attached to it. This country product is light, compact, resistant to pollution and easy to carry.

What you need to work

In order to independently make a country deck chair out of wood, the following tools and materials should be available:

For sun loungers made by hand, it is best to use sheets of wood spruce or other needles. Such material is moisture resistant and not subject to negative influence temperature fluctuations. Such wood is sold in building materials sales centers or made to order by carpenters.

Chaise lounge dimensions and the beginning of the process of its creation

Chaise lounge made of wooden material can be done with the size of your body or according to the size of the future owner. But you can use the standard size of the product, namely, sixty by one hundred and ninety centimeters. First you need to make all the necessary drawings. So, do-it-yourself deck chair drawings can be found on our website.

Chaise lounge made of wooden material can be done with the size of your body or according to the size of the future owner. But you can use the standard size of the product, namely, sixty by one hundred and ninety centimeters. First you need to make all the necessary drawings. So, do-it-yourself deck chair drawings can be found on our website.

After you have decided on the dimensions, you can start making a deck chair: form the sides of the deck chair from the bars and form the frame of the product, fixing its details with the help of corners; board everything outer sides created frame; carry out the following assembly steps.

Stages of work on the independent creation of a summer lounger

It is necessary to prepare the legs of a deck chair from the bars required height. standard height for the legs of the product from about five to ten centimeters, but if necessary, you can use a different height.

At a distance of five to seven centimeters from the edges of the long bars, it is necessary to fix the legs long with screws. In the center of the legs, the rollers should be fixed with smaller screws (about three centimeters).

Electric jigsaw you should cut parts of the lattice for a summer lounge chair made by yourself. by the most a suitable size for planks is eight by sixty centimeters. Then you should screw the planks to the frame of the deck chair for giving with the help of spacers to obtain the desired gaps (from one to two centimeters). After completing all these steps, the deck chair must be sanded and painted.

Electric jigsaw you should cut parts of the lattice for a summer lounge chair made by yourself. by the most a suitable size for planks is eight by sixty centimeters. Then you should screw the planks to the frame of the deck chair for giving with the help of spacers to obtain the desired gaps (from one to two centimeters). After completing all these steps, the deck chair must be sanded and painted.

If a decision is made to make a sun lounger on your own, which will be folding, then the wood grate will need to be divided into two parts, then connecting them with door hinges. Moreover, it is necessary to remember about the fastener bar, which should rest on the rack fixed with screws.

The process of creating a deck chair based on a frame made of dense fabric

One of the most popular and yet in a simple way self-creation country chaise longue is to make it from dense fabric on the frame. For summer cottages, this is a light and very comfortable product that can be quickly turned from a deck chair into a chair and back into a sunbed.

Materials and tools for work:

Must use dense fabric, resistant to wear, to water, to the influence of the sun. It can be denim, canvas, tarpaulin. In this case, the slats must be birch, oak or beech (as they are hard and durable).

To make your own light summer cottage deck chair it is necessary to prepare slats of the required length and grind them. And then you need to collect all the details.

Stages of product assembly

Follows the drill make holes on long rails for selected bolts(from the edges you need to retreat from seven to ten centimeters); all defects must be sanded with a file. Holes must be drilled at the head of the frame in order to be able to change the position of the backrest.

Follows the drill make holes on long rails for selected bolts(from the edges you need to retreat from seven to ten centimeters); all defects must be sanded with a file. Holes must be drilled at the head of the frame in order to be able to change the position of the backrest.

In order to make a seat, two more holes should be drilled at the ends of the rails with a large length; their diameters should match the diameters of the round rails; for their more reliable fixing, the ends must be coated with polyvinyl acetate glue.

Then you need to combine the structures with screws that pass through the top holes, and then fix it.

After that, you need to stretch the fabric, wrap its edges on the crossbars and sew it with a strong thread (if this is done before final assembly sun lounger, according to the firmware of the fabric can be done on sewing machine).

Armchair Kentucky

This chair is original, it is completely assembled from bars. It can be folded up and put away for storage.

To make your own kentucky chair you will need the following materials:

The assembly of the Kentucky chair is as follows. Finished the bars should be processed to give them strength and beauty and also to protect against ultraviolet rays, water and wind. To do this, the wood is treated with stain (Beitz). For a sun lounger, you should purchase an outdoor stain based on oil and wax. You can use parquet oil, which is suitable for any wood product.

After completing the preparation of all the bars, you need to clean all their faces with fine-grained sandpaper.

After reading this article you can make a summer deck chair with your own hands without using the services of masters or the advice of their friends. It is not difficult if you do everything according to the instructions and carefully follow all its points. Learn to do everything with your own hands and improve your skills!

It is so nice to relax in the country after a hard day full of worries. It is best to do this in nature. A deck chair will help you to sit comfortably on the site or near the pond. It is not necessary to buy it in a store, it is possible to reproduce this piece of furniture with your own hands without much difficulty. Do-it-yourself chaise longue for summer cottage will help not only to relax the owner, but also transform the style and design of the garden plot.

Benefits of a sun lounger

A deck chair, in essence, is the same chair, only lower and more stable. Thanks to its elongated shape, it helps to rest and relax all muscle groups of the body. A very important advantage of a deck chair is that its back can be fixed in any convenient position.

In a sun lounger it is very convenient to relax in the bosom of nature. Such relaxation brings only pleasant and positive thoughts to the human body. Since most sun loungers are made of wood, these items are completely eco-friendly.

Wooden deck chairs are easy to use, light and do not require much maintenance. For the summer, such an armchair can be taken out into the yard, and in the winter it can be stored in the basement or in the house.

The manufacture of a deck chair can also be made from rattan or plastic, but in this article we will talk about how to assemble a wooden deck chair yourself.

Options for creating sun loungers

On the this moment There are a huge number of variations in making a deck chair made of wood with your own hands. Some of them will be considered below.

Chaise lounge from a wooden lattice

This model of a deck chair is very common in seaside resorts. Now the owners country houses and dachas will be able to enjoy the rest on such a piece of furniture. Chaise longue, essentially flat, with an adjustable back. The only thing that makes it difficult to move around the site is its severity. But the problem can be solved if you mount rollers or wheels to it.

To assemble this piece of furniture with your own hands, you will need:

- Plates with a thickness of 1.8 cm;

Important! Plates are best used from conifers wood, as they are more weather resistant.

- For the frame, bars measuring 45 * 45;

- For sheathing the sidewalls of a board with a thickness of 2.5 cm;

- Screwdriver and jigsaw;

- To work with wood, several drills with a diameter of 4 cm;

- Screws (it is better to take those that have a countersunk head);

- Mounting corners for the bed in the amount of 4 pieces;

- Ten-centimeter rollers in the amount of 4 pieces;

- Grinding sheet with a grit of 120;

- Decorative coating (lacquer, paint).

The master himself can independently choose the size of the deck chair that suits him best. standard size 60 * 190 cm are considered. To begin with, it is best to prepare drawings.

The algorithm for making a sun lounger with your own hands is as follows:

- We mount the frame from the bars future design, fastening it with metal corners.

- We cover the outer side with boards for greater decorative effect.

- We mount the legs to the boards using screws 6 cm long.

- In order to get a wooden grate, you need to make boards of the same width from the plates using a jigsaw (the size of each is 60 * 8 cm).

- If you want to make the backrest adjustable, then you need to separate it from the design of the lounger and fasten it with a door hinge.

- Between the long bars in the headboard area we mount fixing bar. We attach the support stand to it with the help of screws.

- On this work on the manufacture of a sun lounger is completed, it remains only to walk on it grinder and cover with paint or varnish.

For more information on how to make a deck chair out of wood with your own hands, you can see in the video:

Wooden deck chair with fabric seat

This chair is also very popular. It is convenient in that it is very convenient to move this piece of furniture around the site, it does not cause any problems during transportation and storage, as it folds into a compact flat shape. Making such a deck chair with your own hands is not difficult.

For such a sun lounger you will need:

- 6 rails with rectangular section single size 25 * 60 cm, but different lengths: 2 by 120 cm, 2 by 110 and 2 by 62 cm.

- Five rails with a circular section of 2 cm. The number depends on the length: 65 cm - 1 piece, 60 and 50 cm, two rails for each length.

Important! Reiki should be used from wood species such as birch or beech. They have more strength.

- Durable fabric measuring 200 * 50 cm. Canvas, jeans or tarpaulin are perfect.

- Bolts and nuts for furniture with a diameter of 8 mm.

- PVA glue.

- The file is round.

The work is carried out in the following sequence:

- If there are no ready-made rails, then you need to cut them into the right amount and desired length. All cuts must be sanded.

- The main frame is drilled at a distance of 40 and 70 cm. Then the holes are processed with a round file.

- To change the inclination of the backrest, the other frame is equipped with four cutouts in increments of 7 cm.

- In order to mount the seat, 2 cm holes are made at both ends of the rails.

- crossbars round section at the ends are lubricated with PVA glue and installed in the prepared holes.

On this, the work on assembling the frame is over, now we turn to sewing the seat. Before that, you need to measure how long to take a piece of fabric. To do this, you need to fold the deck chair and measure the amount of fabric. In this position, it should sag a little, not be stretched.

In order to fix the fabric on the deck chair, you first need to process the edges on a sewing machine, and then, wrapping the transverse round bar, nail them with small carnations. From two sides.

It is also possible to make loops on both sides and attach the fabric to them to the cross bars.

Folding Kentucky Armchair

This original chair is assembled from bars, folds easily and does not take up much space when stored.

To make it, you need to prepare:

- Bars with a size of 45 * 30 The size of 50 * 33 cm is also used.

- Galvanized wire with a section diameter of 4 mm or studs with washers and nuts.

- Staples in order to clamp the wire in the amount of 16 pieces.

- Fine-grained sandpaper.

- Pliers and hammer.

For work total amount the length of the bars is 13 meters. All cuts and holes in the bars must be carefully sanded.

Works are carried out in the following sequence, as the drawings show:

Conclusion

A deck chair is a very comfortable piece of furniture that gives home comfort and some certain charm to the plot. Relaxing in this chair is a pleasure.

No need to buy ordinary plastic chairs for the site that look too simple or buy expensive ones. garden furniture, just take a little time to create your own unique pair of deck chairs, so you can save the budget and develop the skills of a carpenter, and make original decoration a plot with your own hands, which will later be pride. You can make several sun loungers of the same type, or you can try your hand at making all models at once and arrange them throughout the garden so that you can relax anywhere.

Work on fresh air brings a lot of pleasure. But if you have to deal with a serious project that requires considerable physical effort, then at the end of the day there is a feeling of fatigue. You can quickly recuperate different ways. One of them is relaxing in a wooden deck chair with a glass of soft drink in hand. Similar furniture can be purchased at furniture showroom or make your own.

Types of structures

Traditionally, chaise lounges for summer cottages are made in the form of structures resembling chair-beds, in which the upper part looks like the back of a chair, and the lower part looks like a small sofa. The main advantage of such models is the ability to change the position of the back. Depending on the performance, several types of sun loungers can be distinguished:

- in the form of a rocking chair;

- suspended;

- anatomical;

- folding.

In order to facilitate the movement of wooden deck chairs, special wheels are often added to the structure, which allow them to be delivered to any place.

A special type of sun loungers are anatomical devices for giving, which exactly repeat the bends. human body

. You can talk about their convenience and practicality only after acquiring such pieces of furniture.

A special type of sun loungers are anatomical devices for giving, which exactly repeat the bends. human body

. You can talk about their convenience and practicality only after acquiring such pieces of furniture.

Some manufacturers are trying to offer non-standard wooden deck chairs for summer cottages, so they involve designers in order to jointly create recreational equipment. unusual shape. Such models are more expensive than usual ones, but if you want to surprise guests with bizarre forms of a deck chair, then you should still think about buying such furniture.

Thanks to the presence hanging mount sun loungers allow the wearer to rock while lounging on it. To install such a device on metal carcass a clamp is used, which provides it with high reliability. You can place such a structure in shady place or can be installed on top of a special part in the form of a small visor. Rocking in such a deck chair will bring only pleasure.

Instead of a stable solid support, rounded hoop legs can be added to the deck chair design.. Then it can be used as a rocking chair. similar model can be installed anywhere. If desired, it can be folded and moved to another part of the site or a special place that was chosen for recreation.

It is no coincidence that more and more summer residents are thinking about making a deck chair. This device attracts them with its functional features:

- Garden lounger provides maximum comfortable conditions to relax the spine and adjacent muscles. In the reclining position, the spinal muscles relax as much as possible, which are especially high load when working in the garden.

- Chaise lounges not only differ in convenience in use, but also easily develop that allows to transfer them from one place to another.

- Design features allow the owner to easily change the backrest from a sitting to a lying position.

- fine decoration suburban area, which will look great not only in the garden, but also on the veranda. Chaise lounge is able to give country house stylish and beautiful look.

- A great way to relax people of different builds. Due to their high reliability, such devices can easily withstand up to 100 kg of live weight.

Material selection

Traditionally, deck chairs for summer cottages are made of wood. They differ environmental safety, easy operation and reasonable price.

But wood is not the only material from which a deck chair can be made. Manufacturers also use other materials for their manufacture:

- plywood;

- the cloth;

- corrugated cardboard;

- logs;

- wooden pallets;

- rattan;

- plastic;

Plastic is quite often chosen for the manufacture of sun loungers, which are installed next to natural reservoirs and in pools.

Advantages and disadvantages

Wood is popular as a material for making sun loungers for summer cottages due to the following advantages:

- low price;

- availability;

- ease of care;

- environmental friendliness.

The only drawback is the low resistance to decay, which can be improved by special processing.

Often, deck chairs for summer cottages are also made of metal, which has the following positive properties:

- high strength;

- low weight, which can be achieved through the use of an aluminum frame in combination with a fabric middle.

To make such a deck chair, the owner must have welding skills to create a frame.. Another such sunbed must be processed anti-corrosion compounds otherwise it won't last long.

At plastic structures the following advantages can be identified:

- light weight;

- unusual design solutions;

- no need for special care;

- low price.

Plastic sunbeds have very low strength, they do not withstand the aggressive influence of the climate. Not everyone has enough experience and knowledge to independently build a sunbed for a summer residence from this material.

Preparation for work

Before you start making a deck chair, you need to think about the materials and tools that will be needed to create it. Much here depends on the chosen model. A fairly common option is when a deck chair is made from mixed materials - wood and fabric. To get a reliable and attractive-looking fabric chaise longue with wooden frame, you will have to prepare the following:

- durable fabric (denim, tarpaulin, canvas) 2 m long and 50 cm wide;

- 3 pairs of rails 0.25 x 0.6 cm long 62, 110 and 120 and cm;

- wood slats 2 x 2 cm (one 65 cm long and two 50 cm each);

- PVA glue.

You can’t do without certain tools during this work, and among them there should be mainly those that any owner has at home or can purchase:

- nuts with bolts suitable sizes;

- roulette;

- square;

- file;

- sandpaper with a minimum cross section;

- electric saw;

- drill.

If there is a desire to make a deck chair from other materials, then a completely different amount will be required. consumable and a set of tools. To make metal products, you can not do without welding machine and Bulgarians. When creating structures from rattan, jute and or vines, you will need special weaving tools.

It is advisable to find as much information on manufacturing as possible before starting work. garden lounger with your own hands to learn about all the intricacies of the workflow and thereby avoid possible difficulties.

Now that everything you need to work has been prepared, you can proceed to consider the process of creating a long chair from a wooden material. The choice in favor of wood is quite logical, since it is the most affordable and environmentally friendly material. It can be freely purchased without incurring significant monetary costs. There will be no difficulties when working with wood, even for amateurs who, with minimal skills in working with this material, can create something with their own hands.

Now that everything you need to work has been prepared, you can proceed to consider the process of creating a long chair from a wooden material. The choice in favor of wood is quite logical, since it is the most affordable and environmentally friendly material. It can be freely purchased without incurring significant monetary costs. There will be no difficulties when working with wood, even for amateurs who, with minimal skills in working with this material, can create something with their own hands.

Work order

The very process of making a lounger will not cause difficulty to the owner of the site. If you approach the matter with all seriousness, then you can make a wonderful thing. Making a deck chair with your own hands looks like this:

- The first step is to make the main elements of the frame. From the existing lumber, it is necessary to make boards with the following dimensions 400 x 2.5 x 8 cm. In addition, three bars of 400 x 5 x 10 cm will be required. In addition to them, two fixing studs must be made.

- Every wooden detail the frame must be thoroughly sanded and coated with a special impregnation to protect against mold and decay.

- The frame is made of a wooden beam in accordance with the selected scheme.

- To build a seating area, it is necessary to cut boards 60 cm long each. Their number can be any and depend on the size of the gap between the boards. For standard models with dimensions of 60 x 200 cm, most often no more than 13 boards are required, which are placed at intervals of 1 cm from each other.

- Using a screwdriver, the boards must be attached to the frame, making sure that the wooden pieces are strictly parallel to each other.

- We begin to fasten the legs, after bringing each to the same length, which should be 35 cm. If desired, the deck chair can be made a little lower. Prepared bars must be fixed at the head and at the feet. From the side of the head, the legs can be made single.

- For the manufacture of the backrest, you will need to make a frame, which should freely enter the structure made in the previous stages. The frame should have the following dimensions - two pieces of 88 cm and 3 pieces of 39 cm. Do not worry about the fact that there will be gaps around the perimeter of the backrest inserted into the frame. They are necessary for the free reclining of the back.

- Directly on the back frame, it is necessary to fix the slats of the required length. They can be installed both across, fixed on the main part, and along. During installation, the screws are screwed in, sinking them into the body of the tree. This will make using the sun lounger safer. To make the product look attractive, upper part rails can be rounded.

- To ensure the most reliable fastening of the back to the base, you must first do through holes in these details, stepping back from the edge 9 cm down. They need to insert the mounting studs and secure.

- Before installing the supports, you will need to cut grooves in the main structure - 2 pieces on each side. The first is made at a distance of 9 cm from the hairpin with dimensions of 5 x 10 cm, and the second is cut with an indentation of 20 cm from the first, the dimensions of which should be 5 x 5 cm.

- To adjust the position of the back in this model, use wooden beam 60 cm long. It must be installed in the first or second groove, which will allow you to transfer the product from a half-sitting position to a reclining position.

- The final stage is the finishing of the product. You can use ideas borrowed from ready-made drawings or design the product using the materials available. A deck chair for a summer residence can be painted, varnished or decorated using decoupage techniques - any of these options will change the look of the deck chair and extend its service life.

The method of making a wooden deck chair described above is not the only one. Other options are also possible - for example, using a metal frame from an old clamshell as a base.

Finished product care

The service life and functionality of a country lounger largely depends on competent care for it.. In order for it to bring only pleasure to the owner for many years, the following events should be regularly carried out:

- wet cleaning of textile elements;

- lubrication of folding mechanisms;

- timely painting.

Many of our compatriots who own summer cottages arrange their holidays on it in different ways. Often on their sites you can find wooden deck chairs that provide them excellent conditions for relax. For the most part this homemade designs, which you can make with your own hands, even without experience in the construction industry. Due to the simplicity of the design, deck chairs can be made from improvised material. But to start without a drawing such work is still not worth it.

Many of our compatriots who own summer cottages arrange their holidays on it in different ways. Often on their sites you can find wooden deck chairs that provide them excellent conditions for relax. For the most part this homemade designs, which you can make with your own hands, even without experience in the construction industry. Due to the simplicity of the design, deck chairs can be made from improvised material. But to start without a drawing such work is still not worth it.