In order not to get wet in the rain and not languish in the sun while you open the front doors, you need some kind of protection. Usually they make a canopy over the porch or just over the door. In some cases, the canopy may also cover steps and even a path or part of it. How to make such a structure, from what materials we’ll talk further.

Species and types

If we talk about the structure as a whole, the canopy or canopy over the porch consists of a frame and roofing material (cladding). There may also be support posts that support the outer edge of the canopy. They are an optional element. They are needed when there is no confidence that the structure without additional supports will be able to retain precipitation.

Precipitation generally means snow. In regions with a large number snow, you can either make the slope of the canopy steep so that the snow melts quickly, or install additional supports. You can do both, as is usually done - the margin of reliability/strength reassures and instills confidence.

Frame and stand materials

The frame and supports of the canopy over the front door are made from:

Most popular in lately material for making the frame of the canopy over the porch - profiled pipe. With equal dimensions and wall thickness with a round pipe (if we compare the diagonal and diameter), the profile has greater rigidity. At the same time, he is the most different sections- a square and a rectangle with different sides, it can be bent into arcs, it is easier to weld and attach to walls, it goes well with elements of traditional or cold forging, durability is the same as others steel products. In general, it is the profiled pipe that is in favor today.

What is the lining of the canopy over the porch made of?

If we talk about materials for cladding the canopy over the porch, the choice is very wide. Very often the canopy over the entrance to the house is made of the same material as the roof. And this is correct, since in this case the result is a harmonious design of the house. With this solution, any roofing material is used:

The second option is to use the material that is used in the fence. In this case, both the design style and decorative elements should be recognizable. This will create a single ensemble with the site. Here the materials can be like this:

- slate (usually flat, but not a fact);

- corrugated sheeting;

- polycarbonate;

- wooden board.

And the third option for designing a canopy over the porch is to install a canopy that is “neutral” in style and material. This may include:

Glass is used less often. It is necessary to use reinforced types such as triplex, and not only are they expensive, they also weigh heavily, so additional suspensions or powerful support columns are definitely required. And if you consider that sheet polycarbonate or plastic is not much different in appearance from glass, it becomes clear why glass is unpopular.

Shapes of canopies

There are more than a dozen forms of canopies over the front door. The easiest one to make is a lean-to canopy. Requires a minimum of effort and materials, and can look very good. The downside is that when the snow melts, a snowdrift will end up in front of your door and will urgently need to be removed. Other models with slopes tilted forward suffer from the same “disease”. These are excellent options for regions with little snow in winters, but with hot sun - not quite for our latitudes. Although, if you are not afraid of the need for urgent snow removal, you can do any of the options.

It’s a little more difficult to make a gable canopy (which is the house) and simple arch. They are good because the melted snow ends up on the sides of the entrance and, even if there is a large amount of it, there is no need to urgently remove it. So for regions with a lot of snow, these are the best models.

How to connect the canopy over the porch and the wall of the house

One of the most difficult moments is to join the covering of the canopy over the porch so that water does not flow down the wall. Usually used standard methods roof joints - using a fender strip. This method is suitable for any roofing material, as well as sheet metal and wood. You just need to choose the right color. There are two approaches: to match the wall or to match the roofing covering visor The options are equal, so it’s up to you to decide/choose.

A groove (5-7 mm deep) is made under the fender strip in the wall. The edge of the plank is inserted into the recess, secured, and the seam is sealed with moisture-resistant sealant for external use. The other edge of the strip rests on the roofing material. When water runs down the wall, it flows onto the plank, from it, bypassing the joint, onto the roofing material and further into or directly onto the ground - depending on how it’s done.

If you use metal tiles, sellers have a special wall profile. It can also be used with other materials - it is important to choose the color. The standard unit includes rubber seals, which are placed a couple of centimeters from the outer edge. In this case, when strong wind, water and debris do not fall under the bar.

If the canopy over the front door and porch is made of polycarbonate, glass or sheet plastic, the method described above is unacceptable - it looks too rough. In this case there are two options:

Others good options No. You can only combine both proposed ones for reliability.

How to fix if the wall is multi-layered

Recently, more and more buildings have multi-layered external walls - ventilated facades, insulation... The load-bearing part of the wall turns out to be covered with a couple of layers of materials, the load-bearing capacity of which is only enough to hold its own weight. You won't be able to attach anything to them. The entire load must fall on the load-bearing wall.

Even if the outer layer is a finishing brick, it costs nothing to attach to it. Masonry is usually carried out in half a brick. So it only looks durable on the outside. Even the smallest and lightest canopy cannot support the weight, and the supporting columns do not help either.

Therefore, with any multi-layer wall, holes are made in all finishing/insulating layers, and the structural elements are attached to the load-bearing wall.

Single-pitch canopy: design features

Oblique or straight single-pitch canopy- the simplest thing that can be. We rarely see straight ones - they are not very functional, but there are quite a lot of single-slope inclined ones.

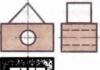

The inclined single-pitch canopy is based on right triangle. A right angle is adjacent to the wall, and the length of the sides depends on the desired slope.

In the simplest case, you can weld three identical triangles from a profiled pipe (as in the figure above), make holes in them for fasteners (at least three). These three elements can be combined into a single whole using sheathing for roofing material - as in the figure. Or you can weld cross members from the same pipe (but of a smaller cross-section) or a strip or corner. This option - with metal jumpers - is more suitable for a canopy over a porch made of polycarbonate or plastic. It is also good for metal sheets - it will be convenient to weld it or screw in self-tapping screws.

There is also an option with a variable tilt angle. This is a rectangular frame with sheathing lintels to which lightweight roofing material is attached. This frame is attached above the entrance using a wall beam fixed to the wall (we described above how to make the connection).

Depending on the required angle of inclination, struts are made. They can be made of metal or wood. Fixed to the frame.

If desired, this option can be made with an adjustable tilt angle. Make the fastening of the frame and struts to the wall movable (on hinges, for example), make several holes in the frame. By rearranging the struts into different holes, you can get a different angle of inclination. This feature is not very relevant for doors - except for glass ones - to block out too bright sun, but for windows it can be useful.

Gable canopy frame

There are at least two ways to assemble a canopy with two slopes: from two or more (depending on the length of the canopy) triangular rafters or from two rectangular frames with sheathing, secured with crossbars. The second option is shown in the figure below, and the first will be a little further.

A canopy with a house is one of the popular options

Method one

Two quadrangles are assembled from timber or thick boards, which are connected by a ridge board. The angle of inclination of the slopes is set by cuts on the ridge, fixed by crossbars - a spacer bar. Since the roofing material is laid from the ridge down, the sheathing strips are laid in the opposite direction. A continuous flooring is required under soft tiles. It can be moisture-resistant plywood or.

Also, brackets are assembled on the ground - stops that will transfer the load from the visor to large area walls. It is better to assemble the structure on the ground (without fastening the roofing material). In order to lift and secure the canopy, assistants or the services of a manipulator will be required.

Method two

The second option is the assembly of individual rafter structures. Maybe this option will seem easier to you - all gable roofs are assembled according to this principle.

Here, too, a frame is assembled from timber and brackets are needed. But the frame lies in horizontal plane, leaning on the brackets. Two or three triangles are assembled from rafters, which rest on a ridge beam, and it rests on a stand, the other end of which is fixed to the frame. It turns out a mini-model of a conventional rafter system.

To improve appearance, mows are placed near the stand. In the photo above they are curved, but this is far from necessary. You can simply make it from timber, sawing it at the desired angle. It is also better to assemble the system on the ground - it will not be possible to connect it smoothly at a height.

Made of metal

If the visor frame is made of metal pipe, everything is much simpler. The pipe has a large bearing capacity, therefore there are much fewer supporting and auxiliary elements.

Two identical triangles are cooked - according to the size of the future canopy. They are connected by jumpers, the length of which is determined by the “depth” of the visor. To prevent the cladding from bending, additional crossbars are welded.

The finished canopy structure is complemented by brackets - stops. In the picture above, the canopy over the porch has only a stop without slopes. For regions with little snow in winter, this is enough, but to hold a significant mass of snow, you will need a mow or stand. Or maybe both (as in the diagram below).

Decorative elements are an optional part. There may be an ordinary triangle here.

Arched canopy over the porch: manufacturing features

A canopy over the front door in the form of an arch cannot be called difficult to manufacture. It is more convenient to make this form from steel pipe, and from the profile, rectangular section. Using (you can do it manually, but it’s more difficult) you make several arches of the same size. They are connected by jumpers, the length of which is determined by the desired size of the roofing part.

Arched design is the simplest option

The first and last arches are connected by horizontal jumpers, brackets or, as in the figure above, ordinary stops are welded to the last one.

You can often see double arches with decorative and not very decorative filling. They are typical for large structures. Still, the windage and snow load turn out to be large and it is better to play it safe by making a safety margin than to do everything all over again.

Photo ideas

The canopy over the porch is not only over the front door, but also over the terrace too

Wooden canopy over the entrance in the form of a house - options with support pillars under the tiles

The first thing guests see when they come to your home is the porch and front door. This is where the main impression of the house as a whole is formed. The canopy on the facade was originally designed to protect the entrance and door leaf from rain and sun, but its decorative role comes first.

Options for entrance canopies

To get as beautiful as on magazine photo, a canopy over the porch of a private house, it is worth approaching its arrangement with all responsibility and seriousness.

Types of mini-awnings by installation type and design

The main purpose of the canopy over the porch is to protect the entrance doors and threshold of the house from rain, snow and sunlight. Canopies can be classified according to the type of installation, design, roofing and frame material, size and shape.

Methods of fastening canopies over the door

Usually a small canopy is hung over the door, commensurate with the dimensions of the porch. However, you can also build a wide canopy, which in the summer will serve as a terrace. Wide canopies with closed sides provide good protection from the wind.

Example of a support structure

Based on the type of installation, canopies are divided into two types:

- Supporting. These are massive structures that require reliable fixation. Such canopies are attached to the house on one side, and installed on metal or wooden supports on the opposite side.

- Mounted. Lightweight, small structures that are mounted directly above the door. Such canopies are easy to install, but often play more of a decorative role, because a small shelter is unable to protect, for example, from rain or heavy snow.

Hinged canopy - sketch

Photos of ready-made structures will help you make a canopy or canopy over the porch with your own hands. Looking at the work, it’s easier to decide what you want your canopy to look like. There are many roof design options.

Variety of shapes and design solutions

Single pitch roof. The most simple design- functional and without any frills. It can be done even by a person with only initial experience in construction. This shape is ideal for wide supporting canopies made of corrugated sheets or slate, as well as for open terraces. When constructing a lean-to structure, it is important to make a sufficient slope so that precipitation or leaves from trees do not accumulate on the roof.

Single-pitch canopy above the door

Gable or tri-slope canopy. The “house” roof will decorate the porch in both classic and rustic style. Gable wooden or tiled porches look especially nice. Most often, such a porch is made with support pillars so that the structure can withstand the considerable weight of the roof. A three-slope canopy is a more complicated option gable roof. It is not so easy to make, but it also looks more interesting.

The three-slope visor looks noble

Semicircular visor. Previously, such visors were made of metal. Nowadays, as a rule, they use cellular polycarbonate. This material bends well, is easily attached to the frame and overall looks very presentable. The lightness of the design allows it to be mounted, and different colors polycarbonate gives scope for design delights. You can make a semicircular canopy over the door or a large-scale structure covering the entire facade.

Semicircular structures are made of polycarbonate

Curly awnings. To make a porch with a custom roof, you will need extensive construction experience. Such canopies are complex in execution, but always attract attention and cause admiration. For their construction, roofing materials are chosen that are easiest to create complex shapes with, for example, tiles, cellular or monolithic polycarbonate.

The design can be very different - in the form of a simple or elongated dome, polygonal, concave or any other shape.

The canopy can be very unusual

Variety of materials for the visor

What the canopy is covered with will determine its functionality and durability. The modern market offers a lot of options for roofing materials. Before you make a canopy over the porch with your own hands, you should familiarize yourself with their properties and only then make a choice.

Modern polycarbonate roofs

Recent years This material has gained enormous popularity. Polycarbonate sheets come in different colors, so you can easily build a canopy that fits into the overall color scheme of the building.

Polycarbonate transmits light well

Polycarbonate has a lot of advantages:

- transparency, due to which it practically does not obscure the facade of the house;

- variety of colors;

- light weight of sheets combined with sufficient strength;

- ease of installation;

- flexibility, which is important when building semicircular and complex-shaped canopies.

Stylish asymmetry

Despite all the advantages, polycarbonate also has disadvantages. Perhaps the main one is low impact resistance compared, for example, with tiles or corrugated sheets. The polycarbonate canopy can easily withstand snow cover, but can become wrinkled or even crack if a heavy branch falls on it.

You can make a canopy over your porch from polycarbonate various designs- flat single-pitch, arched, gable or any other shape you like.

A hinged forged canopy with a polycarbonate roof is considered a classic.

Large canopy with supports

Combination with forging

Classic metal roofing

Metal tiles combine classic design and the most latest technologies for the production of roofing materials. Metal base is responsible for strength and durability, and the polymer coating prevents corrosion.

Advantages of metal tile canopies:

- service life up to 45 years;

- strength;

- resistance to the external environment;

- easy installation.

Metal tiles have one drawback - high price compared to other materials.

A single ensemble of roof and canopy

It is advisable to make tiled canopies at the stage of building a house, together with the main roof. The remains of tiles, which always remain after large-scale work, are quite suitable for the visor. In addition, the roof and canopy in the same style will look very stylish. Considering the considerable weight tiled roof, it is better to place the porch on supports.

Metal roofing combined with forging

Practical and reliable corrugated sheeting

Conventional galvanized profiled sheets are not particularly decorative, but recently a profiled sheet with a polymer coating has appeared on sale different colors.

The roof over the porch made of corrugated sheets is distinguished by the following features:

- strength and impact resistance;

- relatively light weight;

- ease of installation;

- low price compared to other roofing materials.

Canopies made of corrugated sheets are strong and durable

Considering that the sheets have quite large sizes(width 0.75-1.0 m and length up to 12 m), corrugated sheeting is advisable to use for large-scale metal canopies over the porch of a house. It is not profitable to buy a full-size sheet for a compact canopy, so small structures are covered with scraps of corrugated sheeting left over from a large construction project or other materials are used.

Good old wave slate

Until recently, slate was almost the only and ubiquitous roofing material. Now slate is not so popular, however, modern masters continue to use it in construction.

Slate awnings are valued for the following qualities:

- resistance to environmental influences;

- heat-insulating properties (slate is little heated by the sun's rays);

- durability.

However, slate has a lot of disadvantages:

- heavy weight;

- fragility of sheets;

- difficult installation (due to their fragility, the sheets are not easy to cut and drill holes for fastenings in them).

When making a slate canopy over the porch with your own hands, you need to take into account its considerable weight, so be sure to provide a strong frame and reliable fastening to the facade.

Plastic slate for canopy

An alternative to traditional slate is plastic and euro slate. They also have a wavy sheet surface, but are more practical, weigh less and look more attractive, as they are produced in various color options.

Eco-friendly wooden canopies

Wood never goes out of style. Wooden canopy above the porch has not lost its relevance from ancient times to the present day. This design looks especially good in combination with a log house or a house with wood trim.

Wooden canopy in eco-style

The advantages of wooden canopies are obvious:

- environmental friendliness;

- highly decorative;

- reliable protection from the sun - it is always cool under such a canopy;

- simple installation process.

Unfortunately, wooden structures are susceptible to rotting and can be destroyed by bark beetles. In order for a canopy made by yourself from wood over the porch to last as long as possible, you will have to cover it with several layers of special impregnations.

Quite often, combined canopies are erected over the entrance, where the supports and beams are made of wood, and the roof is covered with corrugated sheets or tiles. Wood is ideally suited for the manufacture of figured or carved structures, because it is malleable to processing and in the hands of a master can turn into a real work of art.

Wooden porch can become the main decoration of the house

How to build a canopy over a porch yourself

So, inspired by colorful photos of porch awnings, you decided to build your own structure. Where to start?

Design and important calculations

The whole process involves several important stages:

- Drawing up drawings and approximate estimates.

- Frame construction.

- Installation of the frame on the facade and, if required, construction of additional supports.

- Roof sheathing.

All measurements must be present on the canopy drawing, because the flow rate will be calculated from them necessary materials. When designing the canopy, it is necessary to take into account the width of the front door. Add another 30-50 cm to this figure and get minimum width roofs. For example, if front door has a width of 90 cm, then the canopy is made at least 110 cm. Also, be sure to think about the angle of inclination of the roof - it should be 20-30 degrees.

The wider the canopy, the greater the slope.

Drawing of a metal visor

Frames for visors are made from wooden blocks, a metal corner or profile, and can also be ordered ready-made forged products, which only need to be covered with roofing material to your liking.

Polycarbonate house canopies

Stages of construction of a protective canopy over the door

When constructing a frame, the basic rule is followed - the heavier the roof, the more powerful the supporting structure should be. For lightweight polycarbonate canopies, even reinforcement with a diameter of 5 mm or more is quite suitable as a frame. And for massive slate or tiled roofs you will need bars or a metal corner with a cross-section of 5-10 cm.

The finished frame is attached to the facade with anchor bolts. The junction with the wall of the house is covered with a protective strip. If required, support posts are installed, which are usually not just dug into the ground for strength, but also concreted.

Conclude construction work roof installation. The method of fastening it depends on the material used. The polycarbonate is secured with self-tapping screws through thermal washers, and the ends are sealed with a special tape. Corrugated sheets and metal tiles are screwed with self-tapping screws on the corrugated sheet or, in extreme cases, with ordinary wood screws. The slate is nailed to the sheathing.

Unusual canopy over the door

Regardless of which option for a canopy over the porch you choose, construction must be approached with all responsibility. Then the visor will become not only protection, but also a decoration of the house, and will also last for many years.

Video: Canopies over the entrance

Roof design begins with the collection of loads. Need to count total weight one square meter of the entire roof structure. To do this, you need to first draw roof drawings and calculate snow and wind loads according to the area where construction is taking place.

In order to correctly collect the load, you need to know specific gravity all materials used for roof construction, from the type of wood to the type of insulation and outer covering. This data is necessary for the correct selection of pitch rafter legs. The greater the load, the smaller the distance should be between the rafters.

The maximum distance that is allowed between rafters should not exceed 1200 mm. A distance of one meter is considered optimal. Next, you should select the cross-section of the beam.

To calculate the roof structure, there is a special algorithm consisting of many formulas, but all of them are intended only for analyzing the construction of large industrial buildings. For private construction, the process of selecting a section can be simplified.

The height of the beam is calculated from the maximum length of the rafter leg. 1/20 of the length will be optimal height timber. But 1/3 of the resulting height will be the required width of the beam. The result is a durable system that can withstand heavy loads.

IN wooden house upper strapping beam for frame house will serve as a support for the rafters. IN brick house Along the upper edge of the masonry, you need to install a mauerlat - a horizontal powerful beam, which is attached to the wall with crutches.

You can build a roof with your own hands in a few days if you plan the whole process correctly. At the junction of two different materials, for example, brick and wood, it is always necessary to install waterproofing. Instructions for constructing a roof begin with the correct installation of load-bearing beams. Then inclined rafters are installed at the angle specified in the project.

To secure the rafters, bevels and strapping boards are installed as part of the sheathing. Fastening all the rafters in single design make the wooden roof stable. At this stage, it is important to accurately align the position of the rafter legs; they must be in the same plane, strictly in the correct design position.

After securing the rafter legs, the sheathing is filled, which is a row of boards with a certain pitch, and then the final covering will be attached to them. If the roof is provided from soft materials, the sheathing is made of a continuous type from sheets of plywood. In all other cases, it is enough to nail the sheathing elements at a certain distance from each other.

Afterwards, protective materials are laid (insulation and vapor barrier) and the final roof covering is installed. In some cases, insulation is done inside the structure after installation of the roofing material. The rafter roof must be ventilated to ensure a normal microclimate for the structures and their durability.

Any work can be divided into stages. So, DIY roof step by step.

First step. Calculate the roof, collect the load, determine the cross-section of the beam and its length. Be sure to summarize all data in a material consumption specification.

Second step. Prepare all necessary tool, purchase materials, prepare storage space. Consider a mechanism for feeding heavy structures onto the roof. On the day of work, you may need to hire a truck crane.

Third step. Prepare the surface for work. Start installing the mauerlat, strapping beam and rafter legs. Carefully check the design position of the rafters. At the end of the working day, make sure that working structure securely fastened.

Fourth step. Supply of sheathing boards. Fastening the sheathing and laying protective materials under the roof. At this stage you will have to do a lot of trimming work. Working with a hacksaw is difficult and takes a long time, so you need to rent a parquet saw or jigsaw.

Fifth step. Installation of roofing material, checking joints. Here after graduation installation work, you can hem the box to eliminate wind pressure from the side of the wall under the covering structure.

Gable sloping roof significantly improves functionality attic space. Regular gable roof creates dead space with an inclined plane, in which you cannot stand at full height.

A gable sloping roof expands the space due to the special design of the inclined plane. Thus, a complete interior space, which can be equipped as a bedroom.

According to the drawings, such a house roof is built by installing strictly vertical posts and horizontal ties, and hanging and layered rafters are lined up on the sides of the improvised rectangle. To provide the structure with the necessary strength, struts are installed from the floor beam to the middle of the layered rafter.

All other work is carried out similarly to the scheme described above. The main difficulty in building a structure for a gable sloping roof is choosing the right section of timber and installing all the elements according to the drawing. In most cases, insulation and vapor barrier are added to the roofing pie. This greatly complicates the process of installing a rafter roof, but without these elements it can be done attic room no point.

For a private home it is preferable to choose pitched roof, which has a slope greater than 2.5%. The simplest option is a pitched roof, but this is used only on utility-type buildings. The design is characterized by one flat sloping roof plane, which rests on two side walls buildings.

A gable roof is considered universal, which rests on two external walls at the same level, and the inclined planes are brought together in the middle into one ridge unit. The end part of such a roof is called a pediment and is usually sealed with the same material from which the load-bearing part of the house is built.

The hip roof is hipped roof without pediment. On all sides of the building, the roof slopes upward from the top edge of the wall. This type of roof is better suited than others to withstand wind and snow loads, but is quite complex to construct. All components of the roof frame must be built in compliance with the complex laws of statics of structures.

A hip roof looks something like a hip roof, but its main difference is that all four planes of the roof have a strictly triangular shape. As a result, from the center of the building, inclined planes diverge in four directions, forming a tent.

A broken or mansard roof is the creation of broken roof planes at an obtuse angle. The result is a fairly large room. mansard type, which can be used as residential.

All types of roofs have their advantages and disadvantages. Some look better, but require significant construction costs, others are simple to construct, but also unpresentable in appearance. The choice of roof is usually made after determining the snow and wind area. It is important to agree on the type of roof at the design stage.

In fact, building the roof of a frame house is no different from building a roof for other types of buildings. The only point concerns the fastening of the rafter legs to the supporting structures. Here, instead of a Mauerlat, a strapping beam is used.

The rest of the technique is similar. For ease of construction, before starting it is necessary to build a raised floor or install a full wooden floor. Installing rafters from scaffolding is inconvenient and labor-intensive.

For a frame house, it is recommended to choose the least massive roof structure so that it does not create critical pressure on load-bearing elements. Should not be built on additional elements on the roof, including dormer windows, if they are not provided for in advance in the project.

DIY roof. Design

Depending on the roof structure, you should select the amount of materials and the cross-section of the support beams. For a private home, especially frame type, the most effective are gable and gable sloping roofs. All other structures are quite complex and require a large number of supporting elements, which significantly weigh down the entire roof.

For a frame house it is better not to use natural ceramic tiles in the quality of the coating. In addition to the fact that it is very heavy, for installation you will need to pack the sheathing thickly. As a result, it will be necessary to further strengthen the supporting racks or reduce the pitch between them, which will lead to waste of materials.

The support beam serves to secure the rafters at the bottom. It is impractical to rest the rafters on the wall, so they use additional beam, which takes up the inclined load and transfers it to the supporting structures strictly vertically.

Sufficient timber should be used as a support beam large section. It must be firmly fixed to the wall. In the case when the roof, together with the supporting beam, simply lies on the wall, the roof can be undermined by the wind. Despite the heavy weight of the entire roof, it can fly away in heavy gusts of wind.

In the construction field, there are a large number of different projects that are aimed at creating canopies for the house with your own hands. Let's look at some of the possible options for constructing this type of extension over the porch and tell you all the nuances of the work process.

Many people talk about how to attach a canopy to a house with their own hands. experienced craftsmen and newcomers to this business, because, due to the diversity building materials on modern market, these structures can have a wide variety of configurations.

Polycarbonate has gained a high level of popularity among consumers, which protects well from sudden rains and also firmly resists snow cover in winter. Depending on the base used, these types of visors are distinguished.

Types and forms of do-it-yourself canopies for your house

- stone;

- forged;

- metal;

- wooden;

- combined.

Roofing materials such as slate, corrugated board, etc. can be used as a combination. In addition to functions such as shading and protection from precipitation, good canopy should fit as harmoniously as possible into the overall landscape design surrounding area.

Therefore, the production of multi-level structures is often practiced, and as a budget option use suspended structures. One of the most common classifications of canopies is the division by purpose. Read more about this in the table.

| For the veranda | This type of protective elements, as a rule, are placed either at the back of the house, facing the garden, or are erected from the facade of the building. If the area of the territory allows such a canopy to be made larger, then the veranda itself can be used as a recreation area. |

| For the terrace | DIY canopy over the house for the terrace can be made in several versions. In a simple way erection of a hanging element is considered a structure single-pitch design, for example, from polycarbonate. Even an inexperienced craftsman can do this; in addition, in construction stores you can purchase a ready-made structure that simply needs to be assembled. More difficult option gable buildings are considered; they most often have a roof similar to a house. Based on the layout of the terrace itself, and most often they are corner or across the entire building, the canopy can only cover part of the room. |

| For cars | Polycarbonate carports are popular among car owners. They are attached to the house in order to shelter cars from the sun's rays or protect them from rain in a passive state. Many factories offer fairly simple but durable designs at a reasonable price. When choosing this type of product, it is equally important to pay attention to the stylistic parameters of the extension. |

| Awnings | Awnings are a kind of house awnings, which are divided into retractable, with posts and basket. The first type operates due to a built-in electric drive and, in the absence of the owners, if not needed, is stored assembled in a special case. The second have an auxiliary support point, due to which they are distinguished by endurance and are able to withstand heavy loads. The third type is a frame covered with fabric. The shape of basket canopies can be semicircular or rectangular, complemented by stiffening ribs. |

Thus, a do-it-yourself canopy for a house is a structure that is rich in its diversity, but before choosing one or another form of construction, it is worth taking into account its purpose, as well as clearly understanding the purpose of the building, and calculating its functionality in advance.

How to make a canopy for your house with your own hands from polycarbonate

A polymer such as polycarbonate is perfect even for beginners in the construction field, and it also has good performance qualities and has a fairly affordable price. It is easy to cut and process with tools, and the variety of types of material allows you to customize structures made from it to any countryside and private territory. For those who are going to make a canopy at home for the first time, experts recommend taking a lean-to version of the structure as a basis, and then deciding on the type of base material. To choose a canopy for your house with your own hands, photo projects recommend using a variety of construction portals, where you can get an online consultation on any issue of interest.

Polycarbonate is divided into cellular (cellular), monolithic and profiled. The first is considered the most common in the field of private and commercial construction, and is characterized by its low weight and low cost.

Due to its plasticity, the polymer is suitable for the manufacture of structures of various shapes and is available for the work of even one craftsman. As for monolithic polycarbonate, it is distinguished by its strength, and is similar in appearance to glass, both transparent and colored, but is considered more resistant to stress. Profiled polymer is used as a roofing material on roofs, and its characteristics are no worse than its monolithic form.

You can make a canopy for your house with your own hands according to the drawings that are presented on the Internet, but it is important to pay attention not only to the type of polycarbonate, but to its required thickness, take into account the bending radius, as well as technical indicators.

If a person has special skills, then the working project can be individualized by specifying the locations and number of support posts, etc. Also, a correctly developed drawing at the initial stage of construction allows you to correctly calculate the materials that need to be purchased, so that there are no extra costs or you do not have to make a new purchase.

List of necessary materials and tools for creating a polycarbonate canopy with your own hands

In order for a cheap do-it-yourself canopy to have good strength, professionals recommend constructing it using a metal frame, and purchasing polycarbonate with a strength of more than 6 mm. So, the list of necessary materials and tools for creating a canopy with your own hands is as follows:

- polycarbonate;

- shovel for preparing holes for concreting racks;

- welding machine and electrodes;

- grinder and wheels for it;

- thermal washers for fastening the polymer;

- roulette and building level;

- sand, cement, gravel;

- profiled pipe with a cross section of 80*80.

In order to obtain a solid foundation when constructing a canopy, racks are used, they are also mortgages or supports, they are poured cement mortar, therefore, it is additionally necessary to prepare a container for its preparation, as well as purchase paint and a brush for painting metal structural elements, thus protecting them from damage by corrosion.

Stages of work on building a canopy with your own hands

To build a canopy in the courtyard of a private house with your own hands and see the result of your labor in a few working days, the owner needs to complete the following stages of the construction process:

2. Install the racks.

3. Assemble the frame structure.

4. Secure the polycarbonate sheet.

Stage 1.

According to a previously prepared or selected drawing, the master needs to mark the work area using rope and pegs. Some workers mark the foundation areas by pouring chalk, others additionally hammer in the reinforcement, regularly checking the marks diagonally with a level to avoid distortion of the structure.

The area must be cleared of possible debris in advance in order to prepare a sand cushion on it. To do this, remove the top layer of soil and fill it with gravel, compacting the stones tightly.

Stage 2.

In places of future supports, holes are dug of appropriate depth (1 - 1.2 m). Typically this process uses either a shovel or hand drill. It is with the installation of the basics that the installation of the future polycarbonate canopy begins. Before inserting the support into the hole and concreting it, it must be made in the ground gravel bed, and then fill the stand with solution.

The layer of stones should be about 20 cm. To prepare the mixture for pouring, use percentage 4:1 (sand: cement).

In order for the voids between the stones to be densely filled, the prepared solution should be liquid in consistency, not thick. Fill it to the level of the ground cover. To continue installation process you need to wait until the concrete dries.

Stage 3.

Next, a polycarbonate canopy for the house is created with your own hands by assembling the frame. To do this, to installed supports longitudinal crossbars are attached, they are usually called mauerlats. If the owner’s budget allows, he can purchase such structures in finished form. The purchased elements are fastened with special bolts, and the structure assembled at home requires the presence welding machine, with which the parts are connected. All joints are degreased, after which metal surface painted.

Stage 4.

At this stage, the master works with the polymer, cuts it into the required pieces, lays it on the surface, fastens it, installs end strips etc. Sheets up to 8 mm thick can be cut using conventional construction knife, and more durable material is processed with an electric saw. The fastening elements are located on the profile sheet in increments of about 40 cm. Special metal strips are used as polycarbonate connectors.

Thus, a canopy attached to a house with your own hands will be perfect only if the owner does the work step by step, using not only theoretical materials, but also watching a video with practical recommendations on the installation process.

Recommendations for making a wooden canopy for your house with your own hands

A do-it-yourself wooden canopy for the house provides protection for the adjacent area of the building and also protects from exposure to sunlight. But be that as it may, this hanging element must be stable, durable and reliable, therefore it is often made from such a material as wood with a combination of corrugated roofing, soft tiles etc.

It is worth considering that the canopy must be made on a slope so that precipitation does not linger on it.

Single-pitch wall-mounted wooden canopies are considered popular among consumers; as a rule, they are fixed to the facade of the building. But there are cases when the structure is attached to vertical supports, exposed on the sides of the house.

To create a wooden canopy, you will need both a wall-mounted supporting beam and bars for the racks. Boards for rafters and roofing base. Installation wooden supports produced according to similar instructions described in the version with polycarbonate. Rafter system and the sheathing is assembled using the “groove-to-groove” method.

Assembled wooden frame intended for fastening roofing material. IN in this case this is corrugated board.

When buying it at a hardware store, you need to clarify the thickness and brand; the choice of color rests solely on the taste of the owner. When laying it on boards, you should be careful about fastening and fix the corrugated sheet as tightly as possible with self-tapping screws.

The roof sheathing must withstand the fastening line and have a good aesthetic appearance.

Pay attention to the screws; their length must correspond to the selected brand of roofing and the cross-section of the timber used to make the sheathing.

It is worth noting that such a frame also requires additional processing; for this purpose, various varnishes, etc. are used. means to prevent wood rotting.

When choosing a canopy for the house with your own hands, projects that offer a lot, the master must take into account his abilities, and in case of uncertainty own strength, hire a professional team. published

If you have any questions on this topic, ask them to the experts and readers of our project.

P.S. And remember, just by changing your consumption, we are changing the world together! © econet

According to statistics, every second homeowner built his own home. According to their reviews, erecting a roof yourself is one of the most difficult stages for non-professional builders. Therefore, it is very important to approach this stage with a complete understanding of all the nuances of the process. To understand how to make a roof with your own hands, you need to study the device, installation technology, work order and features of fastening all components of the structure.

Types of roofs

First you need to decide on the form. Today the most popular types are:

Features of formsCovering the roof with one single slope will save nerves and materials, since structurally this is the simplest option. If you make such a frame yourself, the labor intensity of the work will be minimal and the installation speed will be high. But this form has a drawback - there is no possibility of arranging a full-fledged attic or attic, since the under-roof space is too low.

A gable roof is installed much more often. It is a little more difficult to manufacture, but allows you to get more space. Compared to the hipped one, it has less complexity and mass, but it will need to be done triangular gables at the ends of the building.

Gable - the most popular form

Gable - the most popular form Before you start self-construction roofs with four slopes will require serious preparation. This system has more elements compared to the previous two. In addition, it is not possible to make full-fledged windows in the attic, since the roof structure does not have gables and installation is difficult or cannot be avoided.

The hipped roof is complex in design, but savings are achieved due to the absence of gables

The hipped roof is complex in design, but savings are achieved due to the absence of gables For the attic excellent option there will be a combined design with . In this case, in the lower part the roof has a greater slope than in the upper section. This assembly allows you to raise the ceiling in the room and make the constructed house more comfortable.

Broken line - not the most “architectural”, but very effective in terms of space used

Broken line - not the most “architectural”, but very effective in terms of space used Calculation

Before starting work, you need to make a design calculation. It makes no sense to calculate the cross sections of all elements. In most cases they can be accepted constructively:

- Mauerlat - 150x150 mm;

- racks - 100x150 or 100x100 mm depending on the cross-section of the rafters;

- struts - 100x150 or 50x150 mm, taking into account ease of connection with the rafters;

- puffs - 50x150 mm on both sides;

- purlins - 100x150 or 150x50 mm;

- overlays with thickness from 32 to 50 mm.

Calculations are usually performed only for rafter and slope legs. It is necessary to select the height and width of the section. The parameters depend on:

- roofing material;

- snow area;

- pitch of the rafters (selected so that it is convenient to lay the insulation; for mineral wool, there should be 58 cm of clearance between the elements);

- span.

You can select the cross-section of the rafters using general recommendations. But in this case it is recommended to make a small reserve.

The calculation is usually performed for rafter legs

The calculation is usually performed for rafter legs If you don’t want to delve into the intricacies of calculations, you can use special ones.

If you are planning to do warm roof, then the height of the cross-section of the legs is selected taking into account the thickness of the insulation. It must be mounted so that it does not protrude above the supporting beams. You also need to take into account what is done for mineral wool ventilation gap 2-4 cm between it and the coating. If the height of the rafters is not enough for this, provision is made for installing a counter-lattice (counter battens).

Step-by-step instructions for performing the work

The sequence of stages of roof construction is as follows:

- taking measurements of the building box (dimensions may slightly differ from the design ones);

- preparation of materials and tools, treatment of wood with antiseptic;

- fastening the Mauerlat to the wall;

- installation of a ridge crossbar, if needed (for layered rafters);

- frame installation;

- strengthening the roof using racks, struts and tie-downs;

- waterproofing;

- sheathing;

- providing ventilation;

- installation of drips;

- installation of coating.

Fastening the Mauerlat

In order for the roof to be securely fastened, you need to take care of it reliable connection with the wall of the building. If a wooden house is being built, then a mauerlat is not required - the upper crown made of timber or logs serves as this element. In this case, fastening to the wall is carried out using special “floating” fasteners. They are sold ready-made, most often called sleds. This type of roof arrangement allows the entire structure to move slightly as the walls shrink without destruction or deformation.

“Sliding” fastening in a wooden house

“Sliding” fastening in a wooden house

A similar situation arises with a frame house. In this case, the Mauerlat will be top harness walls It is attached to the frame posts with a gash using angles, staples or nails.

Methods of attaching rafters to the frame in frame house

Methods of attaching rafters to the frame in frame house The roof structure made of brick, concrete blocks or concrete involves fastening through a Mauerlat. In this case, there are several ways.

There are four ways to place the Mauerlat on the wall:

- on staples;

- on stiletto heels;

- on anchor bolts.

The Mauerlat can be secured to brackets. In this case, wooden blocks are placed into the masonry from the inside. They should be located at a distance of 4 rows from the edge. One side of the bracket is attached to the mauerlat, and the other to the same block in the masonry. The method can also be considered simple. It is not recommended for large buildings with high loads.

Fastening the Mauerlat to brackets. Antiseptic wooden blocks are provided in the masonry of the wall with a pitch of 1-1.5 m

Fastening the Mauerlat to brackets. Antiseptic wooden blocks are provided in the masonry of the wall with a pitch of 1-1.5 m When installing the roof yourself, fastening can be done through studs or anchor bolts with a diameter of 10-12 mm. The fasteners are laid in the masonry. The Mauerlat is temporarily placed on the sawn-off edge and lightly hit with a hammer. After this, indentations remain on the beam at the fastening points. You need to make holes for the studs along them. After this, the beam is put on the fasteners and the nuts are tightened. The method is ideal for walls made of lightweight concrete with a monolithic reinforced belt.

Attaching the rafters to the mauerlat

In houses made of brick or stone, it is more reasonable to perform it using rigid fastening of the rafters to the mauerlat. In this case, you can use both layered and hanging system. The design involves two methods:

- with notch;

- without cutting.

In the first case, the rafters are cut with a slope so that they are tightly adjacent to the mauerlat. To remove the cornice, fillies are provided. They are attached to the leg with an overlap of at least 1 m. Rigid fixation of the assembly should be done using self-tapping screws, nails or staples. But the assembled frame will be more reliable if metal corners with holes for self-tapping screws are used for fixation.

The method without cutting often does not involve the use of fillies. In this case, the beams themselves provide the frame extension. This option is simpler than the previous one, since it does not require high precision. It is suitable for beginners. In this case, stop bars or boards are used to ensure a tight fit to the Mauerlat. Rigid fixation, as in the previous case, is performed metal corners on both sides.

Attaching rafters to the wall

The completed frame must be secured to the frame of the building - this will prevent a strong gust of wind from tearing off the roof. To do this, the rule is to use a twist of two wires with a diameter of 4 mm. They are wrapped around the leg where it rests on the mauerlat, and then the wire is attached to the wall with an anchor or ruff about 4-5 rows before the cut. The element must be laid in the masonry in advance.

Wind protection

Wind protection For a wooden house, you can simplify the task. You can assemble the frame using staples. This option will speed up the process. But it is important to remember that this method is only suitable if the walls are made of wood.

Strengthening the system

How to strengthen the frame for spans of more than 6 meters? It is necessary to reduce the free span of the rafters. For this purpose, struts and racks are used. Reinforcement must be done taking into account the layout; it is important that these elements do not interfere with people’s stay and fit harmoniously into the interior.

The struts are usually placed at an angle of 45 or 60 degrees to the horizontal plane. The racks cannot be supported on the floor span. They can be installed on underlying walls or beams and trusses thrown between walls.

Tightening is necessary to reduce the thrust. Because of it, the rafters can simply move apart. This is especially true for systems with hanging beams. To assemble the frame, use two ties, which are attached on both sides of the rafters. Fixation is carried out using screws, nails or studs.

At the top point, the rafters rest on an intermediate or ridge run. Depending on the chosen system, location and width of the span, it is made of timber with a cross-section from 50x100 to 100x200 mm. Fastening is carried out on connecting metal plates, bolts or nails.

Lathing

Before starting work at this stage, it is necessary to lay waterproofing material. Builders recommend using a vapor diffusion moisture-proof membrane. It costs more than plastic film, but guarantees more reliable protection. Owning your own home is not a reason to save money.

The roof requires fastening of the sheathing. The type depends on the selected roofing material. For metal, a sparse sheathing of boards 32-40 mm thick will be sufficient. Under bitumen shingles you need a continuous sheathing made of 25-32 mm boards or moisture-resistant plywood.

Ventilation of the under-roof space

Before proceeding with the roofing stage, it is worth considering the ventilation of the under-roof space. This will protect structures from mold, mildew and destruction.

Correct arrangement ventilation under the roof will protect the structure from the appearance of fungus

Correct arrangement ventilation under the roof will protect the structure from the appearance of fungus For ventilation you need to provide:

- air flow through the cornice (the cornice is hemmed with a sparse board or special perforated soffits);

- air movement under the covering (there should be a gap of 2-3 cm between the insulation and the roof);

- air outlet in the area of the ridge (for this, a ridge and/or point aerator is installed on the roof).

Roof covering

The type of roof is selected for aesthetic and economic reasons. It is also worth studying the manufacturers’ proposals and finding out the permissible slope. For example, it is not recommended to lay bitumen shingles on a slope of more than 45°.

Seam roofing is a lightweight fireproof and durable covering

Seam roofing is a lightweight fireproof and durable covering The flooring material must provide reliable waterproofing. Its installation is carried out in strict accordance with the manufacturer's instructions. There are five most common types of coverage: roof insulation.