Hmm, I wonder how Carlson chose insulation for the roof? In cold Sweden, this clearly needed to be given special attention ... Or was he warmed only by buns and hot chocolate? Is this heater right for you? If you need something more serious, read on.

On our website, we have already devoted quite a few articles to the principles of choosing various thermal insulation materials. In this material, we will consider in detail which insulation to choose for the roof and we will look at the choice of insulation specifically in this section. Here are a few points to consider in connection with the roof.

- Roofing enclosing structures have increased requirements for heat resistance. For example, in 2010 in Finland the coefficient of such resistance for walls was 5.88 m2 * C / W, and for the roof 11, 11! Almost double the difference.

- The material on the roof is exposed more than others moisture. And, as you know, water is the enemy of thermal insulation.

- Roof insulation is installed, in fact, according to the principle of ventilated facades. This means that it is not protected from fire, for example, by concrete or plaster elements. In this regard, the insulation itself must have increased fire resistance.

- And it doesn’t matter if we are talking about a flat or pitched roof, the area of insulation is quite high, so the cost of the material should be reasonable and organically fit into the estimate for building or repairing a house.

These are the basic general requirements for thermal insulation for a roof. However, you need to consider the type of roof.

Types of roofing and insulation for them

When choosing a material for insulating the roof of a house, the difference between three types of roof structures matters:

- Pitched roof (cold attic);

- Mansard roof (floor).

Each of the three types of roofs requires a different approach in the choice of insulating materials.

Attic

Attic  flat

flat

A flat roof is most often exploited, which means that the thermal insulation of the roof must be rigid. For these purposes, extruded polystyrene foam is most often used, for example, foam plastic or rigid mineral wool insulation. Usually, each manufacturer has special solutions for this type of roofing. Slabs with cuts allow you to create the desired slope and special gutters for water discharge. It is enough to lay such a layer of insulation correctly and the roof can be considered insulated.

insulate pitched roof with cold attic, maybe by gender. However, in some cases, insulation is also inserted between the rafters. For these purposes, soft and elastic mineral wool slabs are most often used, which are inserted into the spacer. The attic floor is insulated with various materials, both sheet and loose and sprayed.

mansard roof- these are, in fact, the walls of the room, but they are not made of concrete or brick, but of rafters and, for example, tiles. This design is more expensive than a separate, ordinary floor. Roof insulation for a mansard roof should be environmentally friendly, because, in fact, we are talking about warming the room from the inside. There are also increased requirements for fire safety. In a separate article, we discussed in detail the use of . Most often, such roofs are insulated with mineral wool.

Does the most popular fit? - Styrofoam

It is worth mentioning that by foam we mean here both ordinary, white foam (PSB-15) and extruded polystyrene foam, the density of which can reach 35-45 kg per cubic meter.

It is worth mentioning that by foam we mean here both ordinary, white foam (PSB-15) and extruded polystyrene foam, the density of which can reach 35-45 kg per cubic meter.

So, PSB-15 is not used for flat roofs. Although it is much cheaper, it can still be damaged when insulation is being laid by simply stepping on the sheet. In addition, the foam is made without a quarter. But, for example, penoplex has special grooves along the edges, which are fastened together and create one indestructible layer of insulation on the plane.

The overlap of a cold roof is often insulated with foam plastic in the frame when it fits between the lags. For the same purposes, more moisture-resistant expanded polystyrene is also used, which, by the way, has much greater compressive strength.

The issue of using this material for a residential floor under the roof was discussed separately, and this is generally a whole topic.

Thermal insulation materials start with foam. But, alas, the title - the best insulation for the roof, it does not fit. That's why they mentioned it at the very beginning. Further - more interesting.

Roofing classics - mineral wool

By mineral wool, people most often mean:

- Stone;

- fiberglass;

- slag.

Stone wool is used for living quarters. Although it contains resins such as formaldehyde, their percentage is still negligible, moreover, it has undergone a polymerization process. This means that the resin has found and is now in a solid state with a closed molecular structure.

For flat roofs, as mentioned at the beginning, rigid mineral wool slabs with a density of 140-160 kg / m³ are used.

To insulate a pitched roof, soft plates are inserted between the rafters, cutting them. The same plates are inserted between the lags and covered with a protective coating on top in case of overlap. Mineral wool is most often used for roof insulation. This is due to its "breathable" structure. The fact is that any wooden structure should be well ventilated. And if a polymer insulation is adjacent to it, this procedure becomes much more complicated. That's why cotton is used. In addition, cotton wool is a non-combustible material. Being, in its essence, a kind of volcanic lava, cotton wool does not burn, I only melt, and even then at a huge temperature - above 1500 degrees.

However, the insulator is not without its shortcomings. It is associated with poor resistance to moisture. For example, if a cotton slab has a thermal conductivity of 0.036 W / m3 K, then when wet, this indicator can actually change by 2 times! And, as you know, the roof is a place where leaks can occur. In practice, this means that you will have to replace the section of thermal insulation that is wet.

Over time, mineral wool also crumbles, forming dust that can enter the room. Someone does not like this material precisely for this feature of it.

Chip - "plates in rolls"

Manufacturers are increasingly trying to facilitate the installation of insulation. Now more and more often you can find the form factor of mineral wool, which is called "slabs on a roll." Such material has sufficient density to feel good in the frame. In this case, it is enough to fix the roll in the upper part, between the rafters and roll it out below. For example, about Izover Profi, it is even stated that it does not need to be cut (it is clear that we are talking about a not very significant change in the width between the rafters), but simply tighten it and the cotton wool will take the desired shape. It is more convenient to use such rolls than to insulate with plates. Installation of plates takes more time.

When deciding how to insulate the roof of a house, most owners or developers choose mineral wool

Bulk roof insulation

This type of insulating material for the roof in the house attracts many people by three factors:

- Low price;

- Environmental safety;

- Lack of interest in rodents.

It should be noted right away that it is possible to insulate the roof with the help of bulk heat-insulating materials only on the floor. They are poured into the frame. Therefore, the material is suitable for covering the attic. Most often used:

- Sawdust;

- Expanded clay.

Sawdust

By themselves, sawdust is a fairly inexpensive material. Its advantage can be called absolute naturalness. But there are two problems with its use:

- Rodents;

- Shrinkage.

Both are solved in the same way. Adding lime to sawdust. Gypsum is also used to impart viscosity to the mass. It is added in the amount of not more than 5% by weight of sawdust. The resulting mass becomes viscous and is perfectly applied and holds its shape.

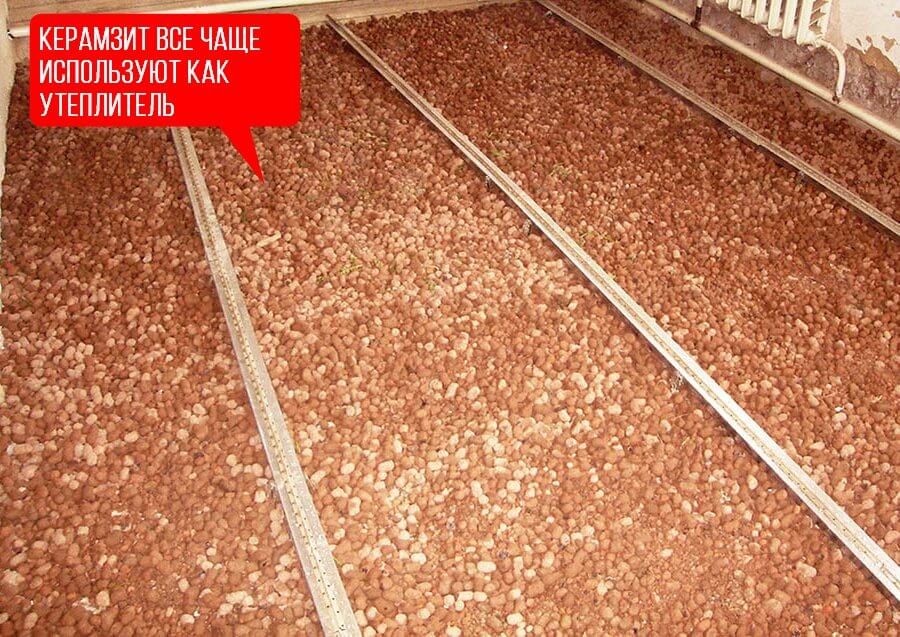

Expanded clay

Expanded clay is a small crushed pebbles of different fractions (size). They fall asleep between the lags. Expanded clay is not afraid of either steam or rodents. In a sense, it is the ideal insulating material for roofing.

Besides, it is not expensive enough. We will talk in more detail about the use of this type of thermal insulation for the roof in a separate article. Here, the mention was necessary to understand the overall picture of possible insulation options.

Spraying and blowing

There are two main representatives in this family of roofing materials:

- polyurethane foam;

- Ecowool.

PPU

Polyurethane foam is one of the most effective heat-insulating materials. It is sprayed or blown into a white foam. To blow PPU, you need a special suit and a compressor. This material does not let steam through and you need to use a crate to blow it.

PPU - is a synthetic material, ecowool - ecological. Both of these materials are resistant to rodents and both require special equipment to inflate. A specially trained master can correctly apply PPU.

Ecowool

Ecowool has been used in Western countries for about 50 years. This insulation on the roof came to the territory of the CIS relatively recently. Ecowool is a cellulose fiber and is made from recycled paper. There are special machines for crushing raw materials and "cooking" such cotton wool. Wool is delivered by special pneumatic transport to the place of blowing, where, for example, it is placed between the lags.

Another obvious advantage of ecowool for roof insulation is that it is easy to blow it into the narrow space between the rafters. Laying even mineral wool rolls in this area is very problematic.

Comparative table of roofing insulation

Having analyzed 6 popular types of materials for insulation, it's time to conclude: what is the best way to insulate the roof of a house? A comparison table of the characteristics of several materials will help you see everything clearly.

| Material | Density, kg/m3 | Thermal conductivity | |

| From | Before | ||

| Styrofoam | 15-25 | 0,032 | 0,038 |

| Extruded polystyrene foam | 25-45 | 0,032 | 0,04 |

| Mineral wool | 15-190 | 0,036 | 0,047 |

| Expanded clay | - | 0,16 | 0,20 |

| Sawdust | 230 | 0,07 | 0,093 |

| PPU | 27-35 | 0,03 | 0,035 |

| Ecowool | 30-70 | 0,038 | 0,045 |

Insulation thickness

More enclosing structures about what the thickness of thermal insulation should be, we talked in a separate article. Here we can say that there are generally accepted standards that establish the coefficients of thermal resistance of the roof in different regions.

In other words, how strongly the roof should be able to resist the escape of heat from the house. It is necessary to divide the coefficient required to obtain the coefficients of thermal conductivity of the thermal insulation materials of the roof. Thanks to this calculation, you can find out what thickness of insulation for the roof of the house should be on the roof. A little later, we will add a calculator that will allow you to calculate this important indicator.

Manufacturers

On the market you can find domestically produced materials for insulation, as well as heaters from the USA, Finland, Germany, France and other countries.

There are following brands:

- TechnoNicole;

- Knauf;

- Isoroc;

- isover;

- Paroc;

- rockwool;

- Ruspanel;

- Soudal;

- Tytan;

- Ursa;

- Actorm;

- Penoplex;

- Penofol;

- Tepofol;

- Tilith;

- Other.

Go to any well-known online store and use the filters to look at the characteristics of each individual product.

As you can see, there are very different ways of warming, but the price always remains an important issue.

Choose by cost

The cost of insulation changes very quickly. Therefore, for example, we give a small plate with the cost of some popular heaters.

PPU blowing will cost 200-300 rubles per square meter (labor and material). Ecowool will cost 3000-4000 rubles per cubic meter. The cheapest insulation is probably sawdust 300-500 rubles per cubic meter. Using the figures given, you can calculate the approximate cost per square meter of insulation.

Life time

How long does an insulator laid on the roof last? All our options have a service life of 50 years. (Except sawdust). However, in reality, most materials have to be changed within 10 years. After all, the insulation is not the weakest point of the roof. He suffers from its other elements. The rating of the most durable, nevertheless, begins with EPPS. It can stand in the roof and 70 years.

findings

So, what is the best roof insulation? You can choose the option, like most, and use mineral wool. If we are talking about floor insulation on the roof - pay attention to ecowool. When calculated, its cost is not so high. But this is an environmentally friendly material that is not afraid of rodents. And this is a big plus. We have given enough general penetrations to help you choose a heater. However, no matter how correctly the selected material is chosen, when laying the insulator it is important to adhere to, which we described separately.

As we found out, roof insulation can be not only buns with hot chocolate, but at least 6 more good materials. Choose and let your roof be as warm as Carlson's.

In order for the roof to perform its functions qualitatively and serve for a long time, it must be insulated. There are many materials and methods for installing a heat-insulating layer, and the choice of the appropriate technology is always carried out individually. This article will discuss how to properly install insulation on the roof of a private house.

The need for roof insulation

Of course, the final decision on whether to insulate the roof is made by the owner of the house - but before that, you need to weigh all the pros and cons. The latter include additional costs for the arrangement of the roof and the effort required to install the heat-insulating layer.

However, the financial costs and efforts will pay off in the future. The main advantage of roof insulation is that after installation, the level of heat loss of the entire building is reduced by an average of 15%. If the under-roof space is not intended to be used as residential, then the roof itself does not need to be insulated - the thermal insulation of the roof of the house in this case will be mounted on the floor of the attic or the ceiling of residential premises. In order for the structure not to rot, high-quality ventilation of the roof will be required.

The most relevant roof insulation will be when arranging a residential attic, especially if the building is located in a region with a harsh climate. In such cases, if the attic is used all year round, you will have to pay special attention to the issues of its insulation and heating. Less stringent requirements are imposed on the insulation of summer attics.

How to properly insulate a flat roof

When insulating a flat roof, it must be borne in mind that thermal insulation can be both on the inside and on the outside. It is advisable to start with external insulation, and after the first winter, decide whether it makes sense to insulate the roof along the rafters from the inside.

The roofing pie of a flat roof consists of:

- vapor barrier layer;

- insulation layer;

- waterproofing layer;

- Bulk layer.

For the arrangement of external thermal insulation, basalt mineral wool is most often used, which is optimally suited for these purposes. However, you can choose from any type of rigid insulation - for example, expanded polystyrene would be a good option. It is also worth remembering that roofing that is prone to fire cannot be insulated with polymer heat insulators.

Pitched roof insulation

The thermal insulation of the pitched roof is installed on the truss system. Before laying the insulation on the roof, it is necessary to design it in advance in order to avoid installation errors.

The pitched roof consists of the following elements:

- roofing;

- waterproofing layer;

- Thermal insulation;

- vapor barrier material;

- Interior decoration (optional).

Mineral wool is most often used as a heat-insulating material, which has high performance characteristics and is relatively inexpensive. The main disadvantage of mineral insulation is the ability to absorb moisture, due to which the thermal insulation properties are lost over time. In addition, the presence of moisture under the roof leads to the gradual destruction of wooden parts.

To compensate for the described disadvantage, the design must be supplemented with ventilation, hydro and vapor barrier. The insulation itself on the roof of the house is laid on the wrong side of the roof during its arrangement or repair. If we are talking about repairs, then damaged wooden elements should be replaced, and new ones should be treated with protective compounds before installation.

In addition, for effective insulation and reliability, the roof must be well ventilated, so you need to equip ventilation ducts between:

- Waterproofing layer and top coat;

- Thermal insulation and waterproofing layer;

- Vapor barrier material and inner lining.

Materials for insulation of pitched roofs

For roof insulation, various materials can be used, among which the most popular are:

- Mineral wool;

- glass wool;

- polyurethane foam;

- Styrofoam.

The characteristics and features of the materials are different, but they all adequately protect the roof from temperature effects. It is only worth noting that it is best to select materials released in the form of plates - they are much more convenient to mount.

For the arrangement of the waterproofing layer, an ordinary roofing material or a special waterproofing membrane is most often used, which does not allow water to pass through, but ensures the removal of moisture from the heat insulator. When installing waterproofing, you need to ensure that the tightness of the material has not been violated.

Vapor barrier can be equipped from different materials, including:

- Ruberoid;

- Polyethylene film;

- glassine;

- foil materials.

However, if we are talking about a high-quality vapor barrier layer, then the best option would be a vapor barrier membrane, which works on the principle of one-way moisture transmission - condensate is removed from the insulation and does not enter the internal cavities of the roofing pie.

Roof insulation algorithm - how to lay thermal insulation

Installation of a roof with insulation is reduced to the following sequence of actions:

- First, the installation step of the rafter legs is measured. Plates of heat-insulating material are cut in accordance with the dimensions obtained, but 1 cm is added to them - this will enable the insulation to stay in place on its own. You can simplify this stage of work when arranging a new roof by calculating it so that the distance between the rafters corresponds to the width of the insulation boards.

- A waterproofing layer must be installed in the space between the rafters and the finish coat. The membrane must be attached to the rafters so that it envelops them. For fixing, you can use a construction stapler, with which the waterproofing is attached to the rafter legs and the crate. Waterproofing material must be brought to the eaves so that the collected moisture goes beyond the roof. The described method of fastening does not allow to equip full ventilation, therefore, only a special waterproofing membrane should be used as a material.

- If the waterproofing is already installed under the upper part of the roof, then nails are driven into the rafters every 10 cm so that the distance between them and the membrane is at least 3-5 cm. waterproofing and thermal insulation material. In the event that the insulation itself is fastened with a cord, then the nails will also need to be hammered along the outside of the rafters.

- When using heaters released in the form of plates, installation comes down to inserting them into the space between the rafters (naturally, they will have to be squeezed a little so that they go into the gap). More rigid materials must be carefully adjusted to fit the gaps in the rafter system before properly insulating the roof. For maximum efficiency, it is worth installing a two-layer insulation.

- When installing narrow fragments that require joining along one of the planes, you need to make sure that the joints of the first and second layers of thermal insulation do not coincide with each other. The layer of thermal insulation should not extend beyond the rafters, and if this happens, then additional timber will have to be filled on the rafters.

- To fix the insulation, a cord stretched between the nails or a crate made of slats can be used. These slats need to be nailed to the rafters at a distance of 30-40 cm from each other. In this case, the vapor barrier layer must be fixed before the crate is installed - due to the thickness of the rails, an air gap is provided.

- When installing a vapor barrier, you need to make sure that the material is installed tightly. To do this, the joints must be closed with two layers of adhesive tape. Particular attention should be paid to the points where the material is connected to the wall and chimney. When all structural elements are installed, you can proceed to the final stage - the installation of the skin.

Conclusion

Roof insulation is a very important part of the structure, which allows you to increase the thermal efficiency of the roof. Knowing how to properly lay the insulation on the roof, and the high-quality performance of all work will allow you to create a reliable and high-quality structure that will perform its functions throughout the entire period of operation.

Roof insulation has been a concern for people since time immemorial. Even in the most primitive buildings, various tricks were used to keep the heat from the fire from leaking out. With the development of construction technology has changed. Not so long ago, the upper sections of buildings were insulated with clay concrete or furnace slag, including ordinary shavings and cement. Today, such materials are gradually becoming a thing of the past. It was replaced by modern products and methods of isolation.

What do you need to know about materials?

It is necessary to insulate the roof in any case, heat losses are too great. Click on the photo to enlarge.

Insulation materials are made from different raw materials. The choice of products often depends on the type of thermal insulation itself. For example, periodically use glass wool. Although such material is well known to many, it is not without a number of shortcomings. One of them is low environmental cleanliness. Of course, it cannot be said that it does not meet the set standards, but without observing a number of rules, cotton wool from glass industry waste can cause a lot of trouble.

In addition, glass wool roof insulation technology is not very reliable. Especially when arranging pitched roof structures. The fact is that such cotton wool quite often slides off surfaces with a slope located horizontally.

Despite the shortcomings, glass wool continues to be used. Why? First of all, most homeowners are satisfied with the price of insulation. For lovers of savings, this is often considered a decisive factor. If you choose glass wool, be sure to consider the issue of protecting the material from moisture.

The situation is completely different with mineral wool or polystyrene. They are completely devoid of the shortcomings of the material described above. Plus, they have a number of other advantages. Styrofoam, for example, has good strength, mineral wool perfectly insulates rooms. True, this almost does not affect the order of work. Waterproofing still needs to be done. As well as many other events.

Does the roof need to be insulated?

Mandatory, except for rare exceptions. But first, let's look at the issue of temperature fluctuations. The latter have a very noticeable effect on the roof of any type. If we take the lower section of the attic, which, in fact, is located under the roof structure, the temperature there is approximately the same as in the room itself.

From the outside, everything is completely different. Here the temperature varies, depending on the weather conditions. Insulation just solves the problem of temperature difference. What is it expressed in? Warm air masses do not leak out, external, on the contrary, do not get inside.

Temperature and many other features must be taken into account when choosing materials. Such nuances include moisture resistance of the structure, humidification of the capillary or diffusion type, and the loads exerted on the surface. Not to mention resistance to fungal formations and environmental friendliness.

The question of whether it is necessary to insulate the roof, as such, should not be. If you want to use the attic space and live in a comfortable home, insulation is a must. Moreover, take into account both the climatic conditions of the region and the features of insulating materials.

Thermal insulation technology - which one to choose?

To date, three approaches are used for thermal insulation of the roof. The first is to lay insulation between the truss structures. The second is based on the installation of insulators directly on the rafters. Finally, the third involves laying the same foam or mineral wool under the supporting elements of the roof. In practice, the first method is most often used.

We will not describe in detail each of the above methods, on the basis of which the roof is insulated. Read more about this in other articles published on the site. However, we will give a couple of important recommendations. Hopefully, they will help you quickly cope with certain thermal insulation tasks.

- Any heat-shielding layer must be continuous in the following areas - adjoining window blocks, wall structures, pipes, etc.

- The size of the air layer must be calculated based on the minimum value of 20 cm. The layer includes both hydroprotection and thermal insulation itself.

- When using mineral fiber insulation, it must be remembered that after installation, its dimensions increase by about 20%;

- When the depth of the rafters is less than the specified one, it must be increased by means of blocks or boards. Instead, they sometimes use a special overlay. Another way out of the situation is to divide the heat-shielding layer into two parts. One is laid between the truss structures, the second is mounted on problem areas.

- It is better to buy ready-made insulation systems, since the creators have already thought through many important points in advance, from auxiliary materials to waterproofing.

- Questions like how much it costs to insulate a roof or how to properly perform insulation work should be addressed at the stage of building a house. We understand that this is not always possible. But if you are thinking about thermal protection now, while the building is being erected or being designed, be sure to protect the roof from the cold.

- When using a thermal insulator made from cellulose, a vapor barrier is not required.

- Compliance with the established technology guarantees the absence of deformation of the rafters and the finishing layer. The rule is simple, but worth mentioning once again. No need to rush anywhere or, even worse, do the work just to get off. You end up paying even more money when the system breaks down.

- Insulation materials must fill all the space allotted for their installation. Areas through which air leaks are unacceptable.

When is it really possible to do without thermal insulation?

If you live in a house with only one floor, most likely attic insulation is not needed. If the structure is built according to all the rules, and there are no attic spaces in it, the roof, in theory, should already be normally insulated. The way out of the situation is often the insulation of the ceiling. The air from the rooms does not have the opportunity to seep upwards, as a result of which heat is retained.

How much does it cost to insulate a roof?

The price of work depends mainly on the cost of the materials used and the type of roof.

It is impossible to immediately take and answer such a seemingly simple question. Why do we consider it simple? The market for thermal insulation works has long been formed. Many companies have been offering relevant services for many years and make professional insulation according to all modern standards. Knowing all the nuances of upcoming events, calculating the cost is not difficult.

Another thing is that it is impossible to indicate what the price of roof insulation will be in a given situation without seeing the object. Even if you show the masters a photo, it will give almost nothing. From the outside, everything looks good, but inside you need to almost re-do the truss system. Sometimes this happens too. If you still want to know at least an approximate cost, here are a couple of tips.

Look on the Internet for what price quality heaters are sold. Knowing the cost, it is easy to calculate the amount for the purchase of materials, based on the total area. You are also free to sit down and make a detailed list of upcoming work in order to determine the approximate final version. Ask on specialized forums how much it will cost. Finally, simply call the masters from several companies at once. With the calculation of the price is better than a specialist, few people can handle it.

Insulation of the roof from the inside is carried out not only in order to arrange an additional room in the attic, but also to maximize the preservation of heat throughout the house.

If the building has a mansard roof, then the insulation is carried out directly on the roof itself, which is not only a roof for the future room, but also walls. If the structure or has one slope, then most often the thermal insulation is arranged in the attic floor.

The third option of thermal insulation measures is used in regions with a harsh climate, where both the roof itself and the ceiling are insulated from the inside.

Types of insulation used

The modern building materials market offers a lot of types of heaters, of which you can choose suitable for any thermal insulation work.

- Bulk materials are sawdust, expanded clay of various fractions, slag, dry leaves or needles. These heaters are used for backfilling in the attic floor, and they perfectly protect the lower rooms of the house from the penetration of cold, but they will not be able to make the attic itself warm.

- Mineral wool of various types, expanded polystyrene, penoflex and polyurethane foam are suitable for warming both attic floors and.

All these materials are light enough, so they will not make the structure of the roof and the whole house heavier, but will make it much warmer. The technologies for installing heat-insulating materials differ from each other, so it is worth considering some of them.

It should be noted that with the advent of auxiliary materials that facilitate the work process and are aimed at protecting the thermal insulation itself from external influences and maintaining their performance, it has become easier to carry out the installation process.

Video: mineral wool is an excellent material for roof insulation

Mineral wool prices

Mineral wool

Vapor barrier coatings

One such material is vapor barrier film. It is designed to protect wooden structures and insulation from exposure to vapors that occur during temperature changes and lead to the formation of condensate. Excess moisture provokes the appearance of mold, which destroys the structure of the tree, reduces the thermal insulation characteristics of the insulation and contributes to the appearance of an unpleasant odor in the room.

The vapor barrier membrane is fixed to the roof structure or ceiling before laying insulation materials.

When using a vapor barrier film in a heated room, it is placed only under the finishing layer of the walls.

To protect structures that are affected on the one hand by high temperatures, and on the other hand, low, the vapor barrier must be located on both sides. Such structures include wooden attic floors and roofing with its insulation. Concrete slabs do not require the installation of vapor barrier materials.

The protective film can have different thicknesses and be of different types - a regular non-woven material or a foil membrane. In the case of using the latter on the structure of the attic floor, it is laid down with foil, as it reflects the heat rising from below to the ceiling, thereby preventing it from escaping. Between themselves, the sheets of material are fastened with foil tape, which helps to create a tight seal.

Prices for different types of insulating films

Insulating films

Attic floor insulation

Any warming measures are best carried out during the construction of a house, but, unfortunately, very often it is done only when they feel the winter cold.

Before you fall asleep or lay the insulation, you need to carry out preparatory work. This is especially important if expanded clay of fine fraction, slag or sawdust is used.

- Previously, when there were no modern auxiliary materials on sale, the plank attic floor was prepared as follows:

- The boards fixed to the floor beams were carefully smeared with a solution of clay or lime, having a consistency of medium density. These natural materials create a good tightness of the ceiling, but at the same time they allow the whole structure to “breathe”.

- After the clay or lime had completely dried, insulation work was carried out. Previously, slag, sawdust, dry leaves, or a mixture of these materials were mainly used for this. They fell asleep between the beams on prepared boards.

It should be noted that the old traditional method is quite reliable, and therefore some builders even prefer it to modern ones to this day.

- In modern construction, mainly for flooring under insulation, a special vapor barrier film is used. Her canvases are laid completely over the entire attic area with an overlap of 15-20 cm, deepening between the floor beams and fixing them on boards and beams. It is recommended to glue the canvases together with construction tape.

The film will become an additional barrier to the exit of heat from the premises of the house through the ceiling, since the heated air, ascending, not finding a way out, will descend and remain inside the house.

- Further, insulating material is poured onto the film, mineral wool is laid, expanded clay is poured, or the openings between the beams are filled with ecowool. You can also use the insulation used earlier - slag or sawdust.

- To avoid the occurrence of cold bridges through wooden beams, they also need to fix a layer of thin insulation.

- On top of the insulation material, another layer of vapor barrier is laid, in the same way as before - overlapped. This layer of film is fixed to the floor beams with slats, which are more often called counter-battens.

- A coating of boards or thick plywood is laid on top.

Sometimes the vapor barrier can also be fixed from the inside of the room to the wooden ceiling, but in this case it will need to be finished, for example, with plasterboard. They will level the ceiling and become another additional insulating layer.

Insulation of roof slopes

When insulating roof slopes, as well as when insulating floors, apply mineral wool and styrofoam, but mineral wool in this case, it is preferable, since it has almost zero flammability.

If, nevertheless, it is decided to use foam, then it is recommended to purchase an extruded version. Although it has a slightly higher thermal conductivity, it is not combustible, and this is very important for wooden structures.

Different systems are used to insulate roof slopes, but they always contain a layer of vapor barrier material, insulation, waterproofing and a counter-lattice.

1. This diagram shows one of the options for an insulating "pie". It is used in the construction of the roof and roofing flooring.

- It is laid on the rafter system. Usually, polyethylene is used for this layer, which has a high density (more than 200 microns thick) - it will also protect the roof not only from moisture, but from the penetration of wind under it. The film is laid with an overlap of 20 ÷ 25 cm and fixed to the rafters with staples and a stapler.

- On top of the film, a counter-rail with a thickness of 5 ÷ 7 mm is fixed to each rafter. It is necessary so that the roofing material does not adhere directly to the waterproofing film, and there is a small distance between them for air circulation.

- Further, if the roof slopes will be covered with soft roofing material, it is necessary to lay plywood on top of the counter-rails. In the case when slate or other rigid sheet material is used, a crate is arranged instead of plywood, the width between its slats is calculated from the length of the sheets of roofing material.

- When the crate is ready, the roof is covered with the selected coating.

After that, you can proceed to the insulation measures that are carried out from the inside, that is, from the attic.

- Mats of mineral wool or other insulation are laid between the rafters. They should fit as tightly as possible between the elements of the wooden structure. Installation of mats is carried out, starting from the bottom, gradually rising to the ridge. The insulation should have the same thickness as the width of the rafters or slightly less. her, by about 10 ÷ 15 mm.

- The laid insulation is tightened with a vapor barrier film, which is fixed to the rafters with slats. The film is also overlapped and glued with construction tape.

The last stage is the decorative decoration of the walls of the attic room

The last stage is the decorative decoration of the walls of the attic room - Further, if the attic is to be equipped as a living room, then the entire surface is sheathed with plasterboard or clapboard. In addition, in this case, in addition to the walls and ceiling, the floors are also insulated, that is, the attic floor.

2. Another option may be a thicker insulating "pie", which also fits immediately when the roof is being installed.

- In this case, a waterproofing windproof film is also laid on the rafter system.

- On top of it, a crate for roofing material is arranged.

- Further from the side of the attic, between the rafters, the first layer of insulation must have equal to the width of the rafters.

- Then, transverse slats are stuffed onto the rafters at a distance from each other equal to the width of the insulation of the next layer. In this case, the insulation is used already thinner. Its thickness should be equal to the thickness of the stuffed transverse rails.

- After that comes vapor barrier film, which is fixed to the rails with brackets.

- The interior trim material is then attached to the rails.

If the roof is insulated in an already built house, where the roofing is fixed, then a vapor barrier is fixed to the rafters from the side of the attic with brackets, and only after that the insulation is laid. Further, the process proceeds in the same way as in the previous versions.

Insulation of the roof from the inside with polyurethane foam

Insulation with polyurethane foam goes differently than bulk materials or mineral wool mats and polystyrene.

This method of thermal insulation has recently become more and more popular and is suitable for both ordinary attics and an attic, which will later become an additional room.

If the attic is ventilated, and there will be no living space in it, then only the attic floor is insulated. To do this, it is recommended to moisten the boards and beams for better adhesion, and a thin layer of polyurethane foam is sprayed on the wet surface between the beams. After it foams, increases in volume and solidifies, if necessary, another layer is applied. Such insulation will be quite enough to keep the house warm, as the foam penetrates into all the cracks and closes them hermetically.

If the attic allows for its height to arrange a room on it, or the attic is an attic superstructure to the house, in addition to covering with polyurethane foam, the roof slopes are also insulated.

Spraying starts from the bottom of the structure, gradually rising to the ridge. Foam is sprayed between the rafters, and its lower layers, rising and solidifying, will be the reference for the next upper applied levels.

A similar or attic creates a completely sealed non-ventilated space. Polyurethane foam will retain heat well inside the premises in winter and will not allow the attic to overheat on hot summer days. However, ventilation should still be provided, since the room must receive air flow.

This type of thermal insulation has the following advantages over other heaters:

- The polyurethane foam coating has no joints and seams over the entire insulated area.

- A significant reduction in temperature fluctuations in the attic and rooms on the lower floors is achieved.

- The building receives reliable protection from low and high temperatures affecting the house from the outside.

- This method of insulation shows a high payback in a very short time, by reducing heating costs due to the low thermal conductivity of the sprayed material.

- When spraying polyurethane foam directly onto the roof, it receives additional stiffness and strength, as roofing forms a reliable connection with the entire roof structure. At the same time, the polyurethane foam layer does not lead to a significant weighting of the roof.

- Convenience application - foam closes all hard-to-reach places of the roof and ceiling, penetrating into all large and small holes and crevices, expanding and sealing walls and floors.

- Polyurethane foam is highly resistant to moisture, to the appearance any forms of biological life, high and low temperatures, prevents the emergence and development of wood decay processes.

- Foam gives not only excellent thermal insulation to the premises, but also well insulates from extraneous noise from the outside.

- Polyurethane foam does not shrink, wrinkle or soften.

- The insulation has a fairly long service life, which is about 30 years.

- The material does not emit substances toxic to the human body and unpleasant odors.

The "cons" of the sprayed insulation include the following factors:

- The toxicity of the material during its application, so you need to work with the use of protective equipment.

Uncured polyurethane foam is quite toxic, so all work is carried out with mandatory protective equipment for the skin, eyes and respiratory organs

Uncured polyurethane foam is quite toxic, so all work is carried out with mandatory protective equipment for the skin, eyes and respiratory organs - Polyurethane foam is subject to the negative influence of ultraviolet rays, therefore, after applying the insulation, it must be covered with a finishing material, for example, clapboard, plywood or drywall.

- For installation work on insulation with polyurethane foam, it is necessary to have special expensive equipment. True, if you have the skills to work with this material, then the equipment can also be rented. But in the case when this work is unfamiliar, it is better not to take risks, but to invite specialists with equipment to spray the material.

Video: spraying polyurethane foam on roof slopes from the inside

Insulation of the attic and roof is necessary for buildings located in most Russian regions, so this process should not be postponed “for later”, but thermal insulation work should be carried out even at the stage of building a house. Excluding the method of spraying polyurethane, all other insulation measures can be carried out independently, observing the technology of work. If you enlist the help of a friend, then the insulation of the roof may well be completed in a few days.

Roof insulation from the inside is the best option for work for several reasons.

Roof insulation is done only for residential attic spaces, due to this, heat losses are significantly reduced and the comfort of living is increased. Today, companies produce a wide range of materials for insulation, all of which have both positive and negative sides. When choosing a specific insulation, it is important to know its features and take into account the characteristics of the building truss system.

There are many names of materials for insulation, but they are all divided into two large groups.

Table. Roof insulation groups.

| Name of heaters | Operational and Physical Characteristics |

|---|---|

| This group includes mineral wool from basalt, glass wool from recycled glass and ecowool from waste paper. Wool insulation can be pressed in the form of mats of standard sizes or rolled. There are options for spraying liquid ecowool. In terms of thermal conductivity and weight, the listed species almost do not differ from each other. The most expensive mineral wool. |

| Styrofoam, polystyrene foam, polyurethane foam, etc. All these heaters are made on the basis of the same polymer, they differ in production technology and some additives. Most often they have the form of plates of various thicknesses and sizes, they can differ significantly in terms of physical strength. The thermal conductivity is almost the same, slight fluctuations in practice have no effect. The price range is large. Can be used in liquid form (sprayed) or as slabs. |

For example, we will consider the two most common options for roof insulation from the inside. Examples are not only budgetary, but also effective. The process is divided into several stages, the final quality of the work depends on the correct implementation of each of them.

Styrofoam prices

Styrofoam

Inspection of the truss system and roofing

A very important stage of preparation for warming. Make an audit of all elements of the roofing system, check the condition of the roof covering. If problems are found, they must be fixed immediately.

Measure the distance between the rafter legs, this will help you navigate the choice of insulation. The fact is that all heaters have standard dimensions in width. This simplifies and speeds up installation work and reduces waste. The width of the insulation is 60 cm, but, unfortunately, some manufacturers allow fluctuations in one direction or another by several centimeters. The distance between the rafter legs should be within 56–57 cm. In practice, such correct roofs can rarely be found.

See if a windscreen is installed between the roof and the attic, if it has air vents for natural ventilation. This is very important in cases where insulation is planned to be done with mineral wool.

Prices for material for vapor barrier

Vapor barrier material

Selection and purchase of materials

The most commonly used materials for roof insulation are mineral wool and polystyrene foam, and we will focus on them in detail. If you have a simple gable roof, then its insulation is not very difficult technologically. A completely different situation is with a broken or hipped roof. These structures have many different stops, runs, ties and other elements that reinforce the truss system. During insulation, you have to cut the mineral wool or polystyrene, make various bends and bends. As a result, the complexity of the work increases and the amount of waste increases.

But this is not all the problems. Complicated roofs can never be hermetically sealed with a vapor barrier layer, there will always be places through which moist air enters the insulation. For mineral wool, this is a very unpleasant phenomenon. Experienced builders recommend insulating complex roofs with polystyrene foam, and not taking risks with mineral wool. Wet cotton wool not only almost completely loses its heat-saving abilities, but also accelerates the putrefactive processes of the wooden structures of the truss system.

Roof insulation work

The technology of work largely depends on the material chosen, but for all cases there are general tips.

If it is possible to work with an assistant - excellent, the warming process will go much faster. There is no such possibility - it's okay, all the work can be done independently.