Traditional for mounting scaffolding use metal or wood. Wood structures are suitable only for one-time work. They have a simple device, so anyone with basic woodworking skills can handle their assembly. Metal devices are reusable and collapsible, they can be reused on other objects. If you have a tool and knowledge of metal processing, assemble scaffolding it will be very easy to do it yourself.

Types of scaffolding

In addition to the type of material, scaffolding differs in functionality, method of fastening and construction. According to these features, the structures are divided into several main groups.

Wedge

To connect the parts of the structure, a special wedge lock is used. Such devices are very reliable, and, most importantly, durable. Their rigidity withstands big weights and mechanical loads. It is very easy to assemble wedge scaffolding with your own hands, and most importantly, after disassembly, it is also easy to assemble it like the first time. This design significantly speeds up and facilitates the lifting of large loads and materials.

frame

The basis of frame scaffolding is a rigid frame in the form of a frame. Similar devices are used in finishing and painting work. Horizontal and diagonal elements of the scaffolding are connected by nodal fasteners. The advantage of such forests is their low cost, they allow you to create convenient fixture without high costs.

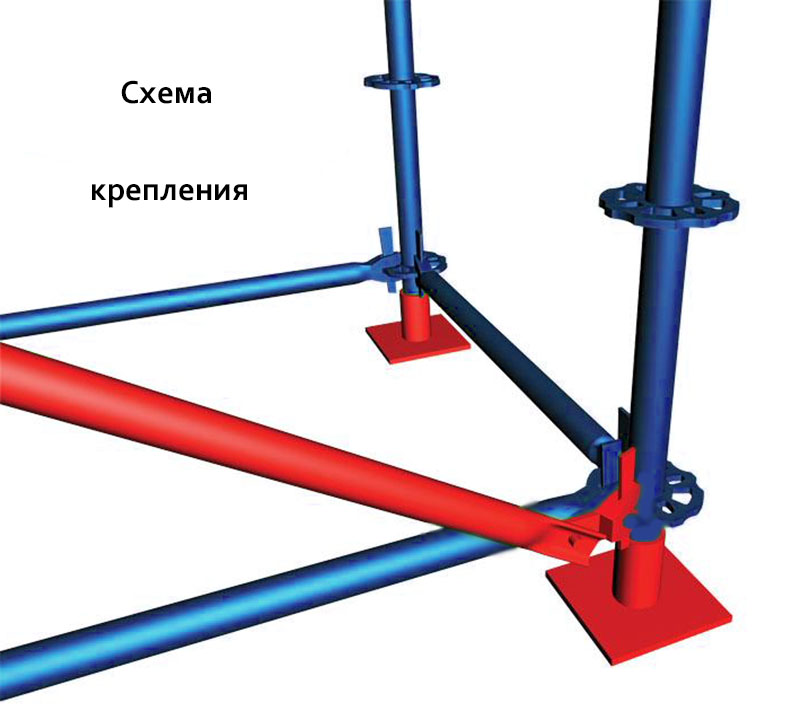

Pin

Details of pin scaffolding are fastened with metal pins. Such designs are most often used in conventional construction work due to the fact that they are more convenient to collect on site. The time for the assembly of pin scaffolding depends on the length of the object, as a rule, the process does not take more than a day.

Clamp

For buildings of the unusual, complex structure clamp scaffolds are used. Parts of the frame are connected in a specific way, which is very popular in professional construction. An important characteristic in the installation and construction of drawings of such scaffolding is the step between the uprights and the crossbars. This distance is chosen depending on the configuration of the building and its dimensions.

General structure of forests

Regardless of the type of connection of parts of the structure and its type, all scaffolding consists of similar elements, such as:

- vertical ribs (racks);

- diagonal stiffeners (make the whole structure strong)

- horizontal crossbars;

- jumpers under the flooring;

- boardwalk for moving workers;

- stops that give the device stability and prevent it from falling back and forth;

- safety fence to protect workers from falling during work;

- ladder for moving between rows.

The number and size of elements varies depending on the scale and complexity of the object. To facilitate the assembly of scaffolding, a schematic drawing can be drawn.

Plank scaffolding

Perhaps, many builders and professionals have their own tricks for assembling and designing scaffolding, there are also a lot of similar instructions on the Internet. Most of the designs do not differ in anything, except for the size of the racks and the thickness of the flooring. To understand such instructions, you should be guided by several dimensions:

- the step between the racks is 2-2.5 meters;

- the average width of the flooring is 1-1.2 meters;

- the structure should not be higher than 6 meters.

Following these rules will create functional and secure forests. To construct scaffolding with your own hands, you will need:

- boards for thrust structures and beams 5-10 cm wide, square and round beams can be used;

- material for spacers and protective structure 3 cm thick;

- jumper boards and wooden flooring- 5 cm thick;

- nails (screws in such structures are not recommended).

After preparing all the materials, you can start assembling. First, 4 racks are fastened at a distance of 2-2.5 meters; diagonal struts are used to connect them on all four sides. Then on required level jumper boards are mounted, and flooring boards are attached to them. For protection, a fence board is installed on the racks. The final stage is the installation of supports and the installation of a ladder to go to the top of the scaffolding.

When assembling scaffolding from boards, the following nuances should be considered:

- racks and supports are mounted in parallel, their location is checked building level;

- horizontal jumpers are used to fasten the racks to each other;

- the protective railing can be stuffed with cross bars for better protection.

To lengthen wooden scaffolding, several sections are used; boards are used to fasten them. Fastener boards are stuffed directly onto the supports.

Advice! Often, when fastening with nails, the wood cracks at the points where the fasteners are immersed. To protect the boards from such damage, it is worth drilling grooves in places where nails will be driven in.

Metal profile scaffolding

Metal products are more convenient if you plan to build several objects. They can be disassembled and reassembled at a new place at any convenient time. To mount the simplest scaffolding with your own hands (150 cm high, 100 cm wide and 165 cm long), the following instructions are suitable:

At the end of the work, it is enough to remove the bolts and disassemble the scaffolding into frames. The service life of such a structure is tens of times greater than the service life of wooden scaffolding. And when proper care they are able to serve long years.

Pros and cons of different designs

Building fixtures are convenient when creating an object, and after the work is completed, the issue of their storage is acute. Even when disassembled, the design takes up a lot of space.

Wooden fixtures can also be collapsible, but this is not easy to do, especially if the boards were fastened with nails. And even plank scaffolding needs to be stored somewhere. In addition, small cracks and crevices remain in the places where the nails are attached after parsing, which will contribute to decay. Often, solvent or paint remains on such structures.

Advice! If you still have collapsible metal scaffolding after construction, you can sell them at a good price or rent them out.

Self-assembled scaffolding is not suitable for working on large objects. As a rule, they are intended for buildings with 1-2 floors. Exploitation of forests at high altitudes is dangerous.

Such structures are used infrequently (for repairing or finishing facades), therefore their installation is not always appropriate. You can perform painting work without scaffolding.

Often, scaffolding is made with a length of 6 meters, which increases their weight and cost. It will be problematic to transfer such a design from place to place, and its disassembly and assembly will take a very long time.

Alternative to scaffolding

The assembly of scaffolding and their design should be considered even before building a house. If you will be hiring for finishing and repair work specialists, then you should not even think about how to make scaffolding. Usually professional teams have the entire list of equipment and tools, including scaffolding.

Often, when disassembling scaffolding and after construction, scaffolding is left idle and thrown away or sold. However, they may still be required for repairs or finishing works Oh. There are plenty of other construction aids that can replace traditional scaffolding.

Before dismantling or renting scaffolding, you should make sure that the facade is in proper shape. Do not save on finishing work, otherwise you will have to restore the decorative layer. One of the most durable and easy to maintain facing materials considered a brick. Today you can find a lot of varieties of this material, differing in colors, size and texture.

Typically, others Decoration Materials(plaster, paint and panels) will need frequent repairs which will result in significant costs. To do this, you will have to hire a brigade or rent scaffolding. If you have your own design profile pipe for finishing work - you can significantly save on cosmetic repairs. To store such a design, you can take separate room or build a simple barn.

How to make scaffolding with your own hands - photo, video. At the stage of construction, repair work and maintenance of a private house, sometimes you have to work at height. With the help of the usual ladder work is not always convenient, and sometimes even impossible.

The way out of this situation will be scaffolding with your own hands.

General information

Scaffolding made of metal will be many times more reliable and durable, but often such structures are made of wood, as it is cheaper. Everyone can work with wood, and all you need is nails or screws, a saw, a screwdriver, or a hammer. As you can see, the set of tools is small and can be found in everyone's house, and if something is not there, at the purchase the right tool won't take a lot of money.

Metal is more difficult in this regard. To make metal scaffolding with your own hands, you will need a certain skill, and so welding machine and at least a basic concept of how to properly weld seams. It is for this reason that in 85% of cases forests are made of wood.

materials

It is clear that the scaffolding (scaffolding) is needed for a short time, but the manufacture requires the use of wood High Quality and with a minimum number of knots. Some builders recommend making scaffolding from spruce wood, since, unlike pine, its knots are located singly and have almost no effect on the final strength of the board. But almost no one has spruce boards, but there are more than enough pine boards.

Scaffolding can also be made from them, but before that you will need to check the material very carefully (at least those boards that go to the flooring and racks). To do this, you need to fold two columns (3-4 bricks on top of each other, 2 building blocks, 2 boulders and more).

Scaffolding can also be made from them, but before that you will need to check the material very carefully (at least those boards that go to the flooring and racks). To do this, you need to fold two columns (3-4 bricks on top of each other, 2 building blocks, 2 boulders and more).

When checking boards that are 3 meters long, there should be a distance of 2.5 meters between them. A board is laid on the posts, and then they stand in the middle and jump on it. If the board has weak spots it will crack or even break. If it lasts, you can use it.

Now about the thickness. The thickness of the boards for scaffolding should be chosen according to what the structure will be, the distance between the racks and the expected load. The only thing that should be noted is that boards with a thickness of 4-5 cm are most often used for flooring and racks, and boards with a thickness of 2.5-3 cm are most often used for jibs. Such boards can also be used after dismantling scaffolding in construction works, if you can not damage it during disassembly.

Self-tapping screws or nails

Probably, in 100 years there will be disputes about what is better - nails or self-tapping screws, but in this particular case, everything is aggravated by the fact that the work will be carried out at a height and therefore the design must be reliable. In this case, the nails will the best option. The fact is that they are made of soft metal and under load they can bend, but not break.

Unlike them, self-tapping screws are made of hardened steel, which is brittle and will simply break under shock or variable loads. This is critical for scaffolding, because there are cases when they broke. But it was about the "black" screws. There are also yellow-green anodized ones, which are not so fragile and can withstand loads.

If you are seriously concerned about reliability, it is better to use nails to make scaffolding with your own hands. But they are not loved because at the end of the work it is impossible to disassemble the connection without loss and quickly, as the wood will be damaged.

At independent work do this - assemble everything on anodized screws. If the design turns out to be correct and convenient, play it safe by driving a couple of nails into each joint. In order to prevent damage to the wood in the future, trimmings of thin boards can be placed under the nails, and whole boards can be used over a long span, but with a small thickness. When disassembling, you will be able to split them and easily remove the nails.

Design features

For various kinds works will require different types of scaffolding and scaffolding. For work with light weight materials, high load-bearing capacity is not required. In this case, you can make side scaffolds or a structure in the form of an envelope. For finishing the gables or just the exterior of a one-story low house, it is permissible to use construction goats, and flooring is laid on their crossbars. If nothing can be supported on the walls, goats with floorboards laid on the crossbars can be used.

For styling brick walls or building blocks, finishing the facade with stone or brick, full-fledged scaffolding will be required. Wood scaffolding can be made more rigid by using braces and stops.

For styling brick walls or building blocks, finishing the facade with stone or brick, full-fledged scaffolding will be required. Wood scaffolding can be made more rigid by using braces and stops.

As a rule, such structures are not attached to the walls, but are fixed on the stops that will support the racks. Let's talk about each type separately.

Attached scaffolds

The design got its name due to the fact that they are simply leaned against, and not attached. They are held in place by an emphasis. The more you load this scaffolding, the stronger it will stand. There are two types of construction, which are made in the shape of the letter "G", but they are deployed in different directions.

In the first figure, reliable and simple design scaffolding. Their only drawback is that they cannot be adjusted in height. It will be convenient to hem the roof overhang, clean or install a drain, in general, all work that does not have a large variation in height. Some were even able to adapt such scaffolding for building a house from a bar. It will be convenient to lift or roll logs along the edges of the stops. They are quite reliable, as they can withstand a log of 11 meters and three people in addition.

The second drawing shows Armenian scaffolding or envelope scaffolding. This design is also reliable and simple, although at first glance you can’t tell. But still it is verified by thousands of people who used them in construction. It is attractive those that require a minimum amount building materials, and assembly / disassembly / transportation can be done in a few minutes. The main thing is the manufacture of triangles, and installation on desired height does not take much time - raise the triangles, support with a beam, which then needs to be fixed in the ground.

In order to make triangles, a board with a thickness of 4-5 cm and a width of 10-15 cm is used. The vertical part can be long so that it is convenient to lift the scaffold to the required height for it. The crossbar on top should be between 0.8 and 1 meter long, and the floorboards will be laid on it. They will also be 5 cm thick, and wide - the more the better, preferably 15 cm.

When making corners, position the joint so that the horizontal board is on top. To increase reliability, use metal pads in the form of a corner. But if you install the corner with three nailed on both sides, this is not necessary. Installation of triangles is made for each meter. If it works out, they are nailed to, and if not, all hope is for gravity. The main load in this design goes to the thrust board, which is placed at an angle and it rests with one end on the ground and the other on upper part triangle.

The stops must be made of timber or boards with a thickness of at least 5 cm, pipes of at least 7.6 cm in diameter or section (for profiled pipes at least 5 * 4 cm). During the installation of the stop, it should be placed exactly in a corner, hammered into the ground, additionally fixed and driven in wedges. To eliminate the risk of lateral shift, the installed stops should be fixed with several jibs that will connect everything into a rigid and strong structure. For mowing can be used unedged board, if it is, the main thing is that the width and thickness parameters should not be less than the minimum limit.

If you want to grow the stubborn boards (so that they are more than 6 meters in length), you should do additional emphasis. It will rest against the middle of the base and thereby remove part of the load. Now about do-it-yourself scaffolding flooring. It must be made from a wide board with a thickness of 4-5 cm. In this case, it is required to fix them to the triangles at least with self-tapping screws. This design does not provide for the installation of railings, and the slightest fluctuations underfoot will cause discomfort, so it is highly desirable to take care of fixation.

Drawings and photos

The described options are good if the use of heavy materials is not expected. It is not always possible to lean the structure on the wall, and then full-fledged scaffolding will be needed. In general, the design is not complicated, but it also requires a sufficient amount of wood.

For the arrangement, you will need boards with a thickness of 4-5 cm, and first we begin to assemble the racks. It will be two thick boards or vertical beams, which are fastened with crossbars. The size of the crossbars should be from 0.8 to 1 meter. Make them proceed from the fact that a more or less convenient flooring width starts from 0.65 meters. But still, you will feel more confident on the flooring 0.8 meters wide. In order to give the structure stability on the sides, you can make racks that will taper upward.

To prevent the scaffolding from falling onto the wall, the crossbars should be made with a release of 25 cm. They will not allow the structure to collapse. Racks are placed at a distance of 150-250 cm from each other. The span depends on the thickness of the boards that you will use to make the flooring so that they do not sag. Installed racks at the right distance should be fastened with slopes between them. So they will not allow the structure to fold to the side. The more you make jibs and crossbars, the more reliable the design will be.

Also, so that self-made scaffolding does not fall, they should be supported with timber or boards, and one end should be nailed to the racks with nails, and the other should be buried in the ground. Cross beams they will not allow the structure to fold to one side, but there is a possibility that without fixing the scaffolding will fall forward. To avoid this, the beams should be supported with jibs.

If the height of the scaffolding is 3 meters, you can not support it, but if the work will be carried out at the level of the second or even third floor, such fixation is necessary. You should also make a railing if the work will be carried out on high altitude. For this, it is permissible to use not very thick boards, but the main condition is that they should not have cracks and knots. Handrails will give confidence during construction.

If the height of the scaffolding is 3 meters, you can not support it, but if the work will be carried out at the level of the second or even third floor, such fixation is necessary. You should also make a railing if the work will be carried out on high altitude. For this, it is permissible to use not very thick boards, but the main condition is that they should not have cracks and knots. Handrails will give confidence during construction.

Standard 6 meters are enough to the floor level of the second floor. But such forests are inconvenient in that they have to be completely disassembled if there is a need to move the structure to another. You can build scaffolding from sturdy old boards. Sometimes pipes or poles are used to make stops and braces - everything that can be found on the farm.

Construction goats

There is another simple way to make mobile light scaffolding with your own hands - to make the same goats, on which the crossbars are stuffed with a certain step, which will be both a ladder and a support for the flooring. Floor boards should be laid on the cross members. This option is good because it is ideal for sheathing a house. The sheathing will take place from the bottom up and it is necessary to change the height all the time, and there is no way to lean or attach the structure to the wall. For this reason, construction goats would be the best option.

Sometimes they make one rack on one side vertical and without tilt. This will make it possible to install them closer to the wall, and then the flooring will be located conveniently for work. it great option when painting, caulking and preventive treatment.

Varieties and knots of metal scaffolding

When building a stone house, or a building made of building blocks, do-it-yourself metal scaffolding is more suitable. They can withstand any load. Their popularity is less than that of wooden structures, as they are more expensive. The second decisive moment is the analysis of the construction wooden scaffolding, since the boards can then be put into action, and the metal parts will gather dust in the shed.

But metal scaffolding also has a lot of advantages. When disassembled, they will not take up much space. From time to time, owners of private houses still need them - to take care of a log house, for example, which means that once every 2-3 years they will definitely be needed. In this regard, a metal structure will be more practical than a wooden one, as it is easier to assemble and stronger.

All metal scaffolding have the same shape vertical layers, which are connected by slopes and crossbars.

Only the method of fastening between them will differ:

All you have to do is choose one of the types, and the type of work that you are going to carry out will help you decide. When making metal scaffolding with your own hands, pin ones are most often used. They are the easiest to implement, but not good only for

All high-rise works are different increased complexity, and in this case it is definitely impossible to do without special devices. One of them is scaffolding. Their price is calculated in rubles / m², and even in relation to the cheapest set (frame) is about 140 - 145. Besides, where to put it then? Rent can also be expensive (from 55) if the repair or construction drags on for a long time, which usually happens in practice.

Plus - some problems with the transportation of forests, since personal transport is not suitable for these purposes. In the field of low-rise buildings (for the private sector) optimal solution- make them by hand.

There are opinions that it is better (and cheaper) to rent metal and wood scaffolding than to assemble it yourself. The main argument is that buying pipes will cost more. And such judgments are supported by economic calculations. Apparently, the authors of such comments live in city apartments and have a rather vague idea of what it is like to maintain their home in proper condition (both the front part and the premises, the height of which, as a rule, exceeds the typical one). But the owner has to do this regularly.

Moreover, the combination of materials such as metal (skeleton) and boards (flooring at each level) is considered optimal. One of the advantages of wooden scaffolding is (the second is the low final cost) that the structure is easily disassembled after construction (repair) is completed, and the material is used for other economic purposes. But there is also a significant disadvantage - the limitation in carrying capacity.

That is, on such a device, only such work as facade design (painting, siding), ceiling treatment, plastering and a number of others can be carried out. When erecting brickwork or simultaneous stay at the height of several people wooden scaffolding unsuitable. But the assembly of pipes and boards is universal in use.

The only difficulty is in right choice options for scaffolding and a method of fastening all structural elements. The cost of manufacturing such multi-level scaffolds is justified only if they can be disassembled and stored in a barn (on site or elsewhere) until the next use. But spending money on a non-separable model, welded, is irrational, and it is unlikely that anyone will do this. It is impossible not to take into account such factors as the complexity of manufacturing, the strength of the structure and its stability.

Brief description of the types of scaffolding

Clamp. Plus - the ability to change the geometry of the skeleton along any of the axes. Minus - the complexity of the installation / dismantling of the structure. In addition, if necessary, increase bearing capacity you have to buy fasteners. Only one wire, especially a rope, in this case is not enough.

Wedge. Differ from all similar models in application in the increased reliability and durability. But the manufacturing costs are immeasurably higher (primarily for holders). For the private sector - not the best option.

Pin. plus is not big weight with the ability to withstand a significant load; ease of assembly (albeit relative). Minus - high cost; high blood pressure on the ground. To ensure sustainability, it is necessary to adopt a number of additional measures. As a rule, such forests are not used in the private sector. The main reason is the complexity of manufacturing. Needed here accurate calculations and welding machine.

Frame. Plus - the weight of the structure is small, but with proper drawing up and assembly, such scaffolding is able to "carry" a load of up to 200 kg / m². The height limit of 50 m for a private building of great importance does not have. It is this model in the field of individual development that is considered the best.

What you need

It is pointless to designate the exact linear values of structural elements - they simply cannot be. The dimensions of scaffolding are selected based on the specifics of the work being carried out, the availability of space for their installation, the number of craftsmen who are simultaneously at the height, and a number of other parameters.

All numerical values are in mm.

By material:

- Duralumin. It costs less than steel, but such scaffolding is suitable only for low structures used for finishing work. When erecting masonry, they will not work because of the low bearing capacity.

- Steel. Such scaffolding for the private sector is versatile in use. The explanation is quite understandable - the high strength and reliability of the frame.

By section:

- Vertical racks. Profile pipe 30 x 30.

- Spacers (diagonal, horizontal). The pipe is round at 15.

- Inserts (supports for fencing and decking). Profile 25 x 25.

To ensure sufficient strength of scaffolding flooring - not lower than "magpie".

- Length - from 1600 to 2000.

- Width - within 1000.

- Height - 1550.

Those home craftsmen who are not satisfied with the given dimensions for some reason can take the following drawings as a basis.

Fasteners

- Bolts + nuts + washers + Grover - for fastening metal elements.

- Self-tapping screws (for metal) - for fixing the boards at the place of laying.

The main stages of manufacture

Preparing details. Pipes are cut first. Even if a drawing has been drawn up, there is no need to rush with the boards. After assembling the skeleton of scaffolding, their dimensions will still have to be specified. This will save you from unnecessary work if you need to fit pre-prepared flooring elements in place. ends round pipes(about 80) are flattened so that you can then drill holes for fasteners. To facilitate such a “pressing”, it is worth making an axial cut (metal cut) to the specified length.

- Preparation of "horizontals". Before using them in the assembly of the frame, inserts from the profile should be welded to each pipe in the places indicated on the drawing.

- Preparation of "verticals". To ensure greater stability of the racks, a so-called mounting heel is welded at one end of each. Although it can be made removable - plate + profile section.

- Drilling holes in structural elements. Special attention- vertical and horizontal (racks, lintels). Mismatches will lead to distortions. Therefore, the part will have to be definitely changed, and this is an irrational waste of materials.

- Display racks. The main thing at this stage is to maintain their compliance. vertical plane. The slightest distortion will significantly complicate the further assembly of scaffolding and drastically reduce their bearing capacity. Yes, and the convenience of working on them is unlikely to add. That is why all horizontal ties must be extremely identical (in length).

- Structural reinforcement. Diagonal spacers are used for this. The peculiarity of their fastening is in symmetry. If this condition is met, then the entire load on scaffolding will be distributed more evenly over the entire area.

- Making stairs. The practice of using homemade scaffolding shows that portable models are preferable to stationary ones. For effective work(in relation to the private sector) one removable ladder is enough. It is small in size, easy to remove and install in another place if necessary. The material is the same - a pipe.

- Arrangement of scaffolding flooring. The boards are laid last, after the final adjustment to size. They are attached to the welded inserts with self-tapping screws.

To ensure maximum stability of scaffolding, it is necessary:

- prepare "shoes" with which the structure is leveled at the installation site. It is easy to make them from boards with your own hands; preferably a few different thickness. In the future, this will simplify the process of adjusting the position of forests relative to the ground;

- to process the soil in the area where they are planned to be used. It is leveled (if necessary) and compacted. This ensures that during operation there will be no shrinkage of the soil (under load) and distortion of the scaffolding.

- Most often, one section is not enough. In this case, more is done - two, three. To connect them to single assembly adapters need to be prepared. The same profile (30 x 30) will do, which is cut into pieces of 100 and welded to the racks. U-shaped metal earrings can be used to fix the sections. In order for the fastening to be as reliable as possible, a pipe should also be taken for them, but with a slightly smaller section (25 x 25) or diameter.

If you carefully understand the manufacturing process, it turns out that there is nothing complicated in assembling scaffolding. The main thing is the correct calculation and accuracy.

When building walls or exterior finish buildings use scaffolding. This design makes it possible to work safely at height and keep at hand necessary tools and inventory of materials used.

Types of scaffolding

Despite the fact that scaffolding is presented in many forms, their structures contain identical parts that carry the same purpose:

- vertical supports.

- Ties connecting supports horizontally and vertically.

- Crossbars.

- Flooring.

- Support slopes.

- Handrails.

- Stairs.

Material for manufacturing

In the manufacture of forests use:

- lumber;

- metal.

A wood structure is much cheaper than a metal one, but it can only be used with two, three assemblies. In the future, it is suitable only for "ejection".

Woods made from metal pipes, although much more expensive than wooden ones, they are not limited in use. They are easy to dismantle and carry as needed. In addition, pipe scaffolding can be increased in height, complementing the tiers.

Making wood scaffolding

To make scaffolding from wood and pallets with your own hands, it is necessary, first of all, to develop drawings and determine the dimensions.

There is no need to invent anything in this regard. Many years of practice has itself determined and established sizes that are convenient for work:

- the maximum height of the structure is 6 meters;

- the distance between the supports can vary from 2.0 to 2.5 meters;

- the width of the working platform is 1 meter.

Scaffolding

DIY step-by-step scaffolding:

- On the flat surface the soil is laid out in two supports, preferably from a bar, but it is also possible from a fiftieth board, parallel to each other, of the same height.

- The supports are fastened horizontally with crossbars, on which a work platform will subsequently be laid.

- The resulting two fastened structures are installed vertically against each other and connected diagonally and horizontally by crossbars.

- Boards are covered and fixed on the horizontal crossbars, which will subsequently serve as flooring.

- To fix the scaffolding, side stops are installed.

- A cranial bar is nailed to the supports, which will play the role of a railing.

- On the last step a climbing ladder is installed and fixed.

If you need to install two or more sections, then they are connected to each other with a wide board, which is stuffed onto adjacent supports. To prevent splitting from nails, you must first drill holes for them.

The specifics of the manufacture of scaffolding from pipes

When starting to manufacture collapsible scaffolding from pipes with your own hands, you need to know that in terms of their design data they are identical with wooden scaffolding. The difference among them is the adapters that are used to increase the height of the structure.

Detailing for the assembly of one metal section

To assemble one section, you will need:

- Profiled pipe for supports 40x40 mm - 4 pcs. 1.5 m.

- Profiled pipe for crossbars - 4 pcs. 1 m.

- Thin-walled pipe with a diameter of 20 mm - 4 pcs. 2 meters for diagonal screed.

- Profiled pipe 35x35 mm - 8 pcs. 10 cm each, which will play the role of adapters.

- Profiled pipe 35x35 for railings - 1pc 2 - m.

- Steel plate for thrust bearings 10x10 cm 3 mm thick - 4 pieces.

- To connect the cross bars diagonally to the frame, you will need 10 bolts with nuts and washers.

Assembly of metal scaffolding of one level

To assemble the structure, you must follow the instructions: how to properly make scaffolding.

The assembly of scaffolding from pipes includes the following operations:

- To the shield from OSB sheet, with the help of clamps, the supports of the scaffolding are fixed.

- To the supports, by welding, the crossbars are welded horizontally.

- Adapters measuring 5 cm are welded to the upper end of the racks.

- Having lifted the racks with crossbars from the shield, they must be rotated 90 degrees, laid again on the shield and secured to the shield with clamps.

- The edges and the middle of the pipe, intended for diagonal stretching, are flattened and a slot for the bolts is drilled.

- Two diagonal crossbars are tightened in the center with a bolt, applied to the uprights and a place for drilling is determined.

- The crossbars are fixed on the racks with bolts and tightened with nuts.

- Holes are drilled on the supports and handrails and they are bolted together.

- Thrust bearings are welded to the base of the pipes.

- The finished structure is installed vertically.

- Boards are laid on the side rails, which serve as the basis of the working platform.

A photo of how to make scaffolding can be seen below.

It is important to remember that the diagonal crossbars must be fixed on one side of the structure, and the horizontal ones on opposite side. Then when assembling, they will not interfere with each other.

DIY scaffolding photo

Note!

Note!

Many works in the construction, maintenance and repair of private houses have to be carried out at height. To facilitate and make the process of performing such activities safer, scaffolding, which is easy to purchase in ready-made or assemble by hand. Independently, such structures are made from profile pipes or from wooden elements according to fairly simple schemes.

The main elements of scaffolding made of wood and metal

Scaffolding (SL) is an auxiliary supporting structure. They are used for mounting wall siding and roofing, filing gables, installing gutters, decorating the facades of private houses, and performing other events. Do-it-yourself scaffolding is made of wood or metal. Regardless of the material used, they consist of the following main elements:

- Vertical racks. These parts take the load from the structure and transfer it to the ground.

- Jumpers. Parts of the structure that serve for the installation of the flooring. Jumpers are installed on the sides of the scaffolding.

- Ties. They are horizontal and diagonal. They are necessary to give the SL frame maximum spatial rigidity.

- Railing. They are the simplest fence that protects a person performing construction work from falling from a height.

- Flooring. The structure is made of boards knocked together. The flooring serves as a working platform.

- Stairs. Allow builders to climb up and down scaffolding.

- Stubborn cuts. An important element of the structure, protecting it from overturning.

Wood scaffolding is easier to assemble. They are light in weight. Their parts are attached to each other with screws or nails. But wooden structures not suitable for heavy loads. The dismantling of such scaffolding takes a long time. They are allowed to subsequently collect a few more times to perform high-altitude work. But the strength of re-mounted structures is reduced, since holes from hardware remain in the beams and boards.

SL from a profile pipe is much more reliable. They are quickly dismantled and then promptly assembled, retaining their initially high strength characteristics. If necessary, they are allowed to increase additional elements.

Types of structures and their performance characteristics

All scaffolding is divided into several types depending on the design and the fasteners used to assemble them. Exist the following types structures described:

- Frame.

- Pin.

- Wedge.

- Suspended.

- Clamp.

Frame structures are strong and durable in operation. They are made from metal parts with low weight (for example, from aluminum pipes). Such scaffolding has several vertical frames, which are reinforced with spacers. Often they are equipped with wheels to quickly move the structure along the surface to be treated (walls of the house, gable).

Pin scaffolding is clumsy and heavy. They are considered the most stable and durable. They are assembled from metal pipes connected in single structure socket locking elements and welding (with its help, curved pieces of reinforcing bars are welded to the structure). Pin SLs are recommended for brick (stone) masonry, as they can easily withstand the heavy weight of the materials used.

Wedge scaffolds are mobile and strong enough. They combine the advantages of pin and frame structures. This is achieved through the use of special fasteners-holders, which are special slotted flanges. Wedge SL are optimal for the installation of complex facades and their maintenance.

Suspended structures, called cradles by home craftsmen, are used when decorating walls with tiles and other types of facing materials, for washing facade windows. They are not very functional, which cannot be said about clamp structures. The latter are recognized by experts as universal structures. Making clamp scaffolding is not at all easy. But with their help it will be possible to process (decorate, repair) buildings of the most complex and unusual configuration. Such structures, if necessary, easily change their shape vertically and horizontally.

Reliable wooden construction - how to do it yourself?

Frame wooden scaffolding is assembled from boards with a section of 10x5, 3-5 cm thick and a beam of 10x10 cm. The tool is required Circular Saw, drill and hammer. Nails (self-tapping screws) are used to fasten structural parts. Marking work is carried out with a tape measure and a building level. Boards with a thickness of 3 cm are designed to create stiffeners, 5 cm - for the construction of flooring. The scaffold drawing is developed taking into account the following requirements:

- The maximum height of the structure is 600 cm, length - 400.

- The minimum deck width is 100 cm.

- The distance between the supporting posts of the structure is 200–250 cm.

For the construction of scaffolding, well-dried wood is taken. It is not allowed to have cracks and other defects. All wooden elements are treated with solutions that prevent the development of mold and decay. Work begins with the manufacture of frames. According to the planned height of the SL, four beams are cut. The resulting blanks are placed on a flat piece of land. Two beams 360 and 400 cm long are attached to the support beams (from the inside). The second are fixed along the lower edge of the supports, the first - along the top. The result is two trapezoidal frames. They are reinforced with struts. The installation of the latter is carried out diagonally.

Frames are lifted from the ground, placed vertically, connected (temporarily) by sidewalls. The distance between the upper edges of the support posts is taken as 100 cm, between the lower ones - 115 cm. The level checks the accuracy of the horizontal mounting of the sidewalls. The made frame is connected into one piece with self-tapping screws or nails. It is preferable to use nails as fasteners. They are made of soft metal, which does not break under heavy load, but bends. Self-tapping screws are made from hardened steel, which is characterized by increased fragility. If variable or tangible shock loads act on the scaffolding, such fasteners break. This causes the SLs to fall apart.

The flooring is made from boards. They are attached to the transverse upper bars. The boards are mounted without gaps - the denser they lie, the more reliable the construction will be. On the sides of the structure, additional crossbars are being installed. These jumpers give the structure additional rigidity and serve as stairs.

Metal scaffolding - how many years are they designed for?

Profile pipe structures consist of 2–4 sections 160–200 long, 100 wide and 150 cm high. The specific number of the latter depends on the height and length of the house. Sections are made with aluminum or steel racks. In cases where scaffolding will take on serious loads, it is better to build them from steel. For Assembly metal structure you need a welding unit, an electric drill, a level, a grinder, fasteners (bolts and self-tapping screws). Scaffold decking is made from edged board(recommended thickness - 4 cm). Supports, crossbars, adapters and other parts of the structure are made of round and shaped pipes with a section of 1.5, 3x3 and 2.5x2.5 cm.

Spacers are cut from 1.5 cm diameter products. Diagonal parts are made 200 cm long, horizontal - 96 cm. Cuts are made at the ends of the pipes (two meters). Their length is 6 cm. After that, the tubular products are flattened at the points of cuts. The operation is performed to facilitate the connection of the bearing supports-racks and struts.

Pipes with a section of 3x3 and 2.5x2.5 cm are cut into segments 8 and 30 cm long, respectively. Adapters are made from the obtained blanks - special elements for increasing the height of the SL. Segments of shorter length are put on longer ones and welded together.

With the help of spacers and uprights two frames are created. It is not difficult to make them - you should weld the spacers to the racks every 0.3 m of the length of the latter. The result is products that visually resemble stairs.

Plates measuring 7x7 cm are welded to the lower ends of the supports. They are cut from sheet steel. The plates won't let massive construction fall under its own weight and the weight of people working on it into the ground. If necessary, wooden bars are additionally placed under these plates during the use of scaffolding.

Welded frames are placed vertically. The fixing points of the diagonal braces are determined. Holes are made in the marked places with an electric drill. Bolts are screwed into them. All parts of the scaffolding are connected. After that, the horizontalness of the crossbars must be checked using a level. In the presence of a skew, parts of the SL are adjusted. exploit homemade design with non-horizontal crossbars is prohibited due to its low stability.

Fabrication of flooring and painting of pipe structures

Flooring metal scaffolding made from boards. They are laid across or along the section. In the first case, wooden blanks are fixed to pipes that are installed on the sides of the scaffolding (fastening is done with bolts). AT longitudinal direction it is allowed to lay boards with a length of more than 200 cm. They are knocked into one flooring (without gaps) and reinforced from deflection by transverse bars. The latter are mounted below the boards.

At the ends of the flooring, a U-shaped metal profile is mounted. Its width is 1.7–2 cm. The profile is cut to the size of the flooring and fixed to last self-tapping screws. This design eliminates the possibility of shifting the boards.

Scaffolding from a profile pipe is used repeatedly. They are easily disassembled and assembled as needed. To prolong their service life, it is recommended to paint SL. Painting is carried out according to a simple scheme:

- all elements of scaffolding are carefully sanded;

- metal surfaces are dedusted;

- pipes are primed.

After the soil dries, painting is carried out. It is advisable to apply a layer of paint on the flooring from the boards, having previously treated the wood with an antiseptic composition.