One of the serious stages interior design two-story private house - construction flight of stairs, designed for lifting to the top. Here the homeowner is faced with a choice: hire for this work experienced craftsmen or start making it yourself. The second option is supported by cost savings and the conscientiousness with which the owner will get down to business in his own home. All that remains is to fill the gap in knowledge and understand how to make a staircase to the second floor with your own hands, having carefully studied our recommendations.

Staircase diagrams for climbing to the second floor

To build an interfloor passage yourself, you need to choose a suitable structure that will fit in the allocated area and at the same time be safe to use. But first you should understand the names of the elements and details of the stairs:

- bowstring (otherwise - stringer) - a longitudinal beam that serves as a support for the steps;

- tread - upper plane steps;

- riser - an opening between two treads;

- support pillar used in some designs for the installation of stringers or steps;

- baluster – vertical support for railings

Straight staircase 1 flight

To organize the ascent to the top floor of a private house, it is customary to build 4 types of stairs:

- Straight marching with or without a transition platform.

- Rotatable 90 or 180° with winder steps.

- Screw.

- Compact goose step ladder.

Reference. For the sake of saving usable area And building materials the listed structures are located along the walls. The exception is a screw structure located in any convenient location, even in the middle of the hallway or hall.

A simple staircase to the second floor consists of one flight with a railing. It is not difficult to make, but with a ceiling height of more than 2.5 m, the building will take up a significant area. To save space, it would be more correct to make the ascent according to a scheme with two flights and a transition platform, as shown above in the photo.

The design of turning (winder) steps allows you to effectively use the entire length of the staircase and thus reduce the size of the span. The assembly of such a structure is somewhat more complicated due to the installation of a support pillar and the manufacture of wedge-shaped shaped steps.

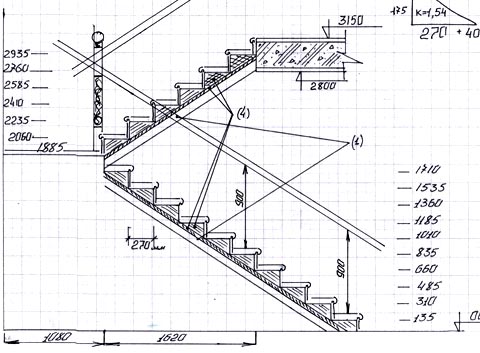

Drawing of a turning staircase

If there is very little space in the house or country house, then it makes sense to build a spiral staircase or a “goose step” type structure shown in the photo. In the first case, all the steps are winders and are attached at one end to the support pillar, and in the second they are cut in width so that you can put your foot on only one side. Make screw design starting from scratch is quite difficult, but the goose step ladder is built using the same technology as conventional marching ascents.

Note. Typically, homeowners purchase metal, wood, and glass spiral staircases as ready-made kits that are installed on site. Nowadays it is not difficult to find beautiful products on sale that harmonize with any interior, but such pleasure cannot be called cheap.

This is what a steep flight of stairs looks like, like a goose step.

To finally select the appropriate staircase design for the second floor, you should calculate the size and number of steps.

Calculation of interfloor stairs

For calculations, you need to know the height difference between the finished floors of the first and second floors, as well as the size of the area that you are ready to allocate for a conditional staircase. The calculation method does not depend on the chosen design and is based on the following requirements to ensure convenience and safety during its operation:

- tread width - at least 26 cm;

- step height – no more than 20 cm;

- the slope of the flight of stairs should be within the range from 27 to 42°;

- railing height – from 900 mm;

- The minimum span width is 90 cm.

Advice. In order to correctly calculate the parameters of a flight of stairs and decide on its design, it is recommended to solve the problem graphically. Make your own mini-project by drawing by hand or on the computer drawings showing the staircase in plan and side view.

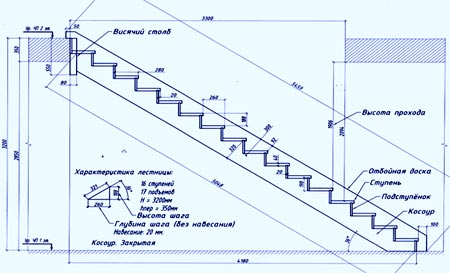

The essence of the calculation is to determine the number of steps and the total length of the climb, taking into account the slope of the homemade ladder. It is proposed to consider the order of calculations using the example country cottage with a height difference of 3 m:

- To prevent the climb from being steep, let’s take the most comfortable height riser - 15 cm. The number of steps is calculated by dividing the total height by this value: 300 cm / 15 cm = 20 pcs.

- Taking the width of the tread equal to 30 cm, we calculate the length of the span: 30 cm x 20 = 600 cm or 6 m.

- Having drawn a sketch of such a wooden staircase with a side view, we will determine the slope angle - 27°.

Design diagram of a straight march with a slight slope

The 6 m long structure shown in the picture will not fit into every home, so its design will have to be adjusted. Option one: break the climb into 2 flights of equal length and make a transition platform. Taking into account its size, equal to minimum width span, the length of the ladder will be 3.9 m, which is also quite a lot. To some extent, sacrificing amenities, the dimensions of the stairs can be optimized as follows:

- reduce the width of the step to 26 cm;

- increase height to 18 cm;

- move the tread forward 3 cm.

Optimized staircase diagram

Using the instructions given above, we calculate the new parameters of the flight of stairs and get the number of steps 17 pcs., the angle of inclination is 37°, and the total length is 3.7 m. If we organize a 90° turn of the flight with three winder steps instead of a landing, then the length of the rise it will be possible to reduce it to 3 m, and this is quite acceptable. More visual information You will learn about the calculation of flights of stairs by watching the video:

Important point. All home buildings, including interfloor stairs, must be safe for small children. Provide gaps between the balusters according to the child’s age so that he cannot squeeze between them and fall.

Construction materials

The best material for making a staircase with your own hands is wood. It is not only easy to process, but also fits well into any interior. Metal structures are more durable, but at the same time heavier and more difficult to assemble, not to mention the cost of iron elements. Dried wood of the following species is suitable for construction:

- ash;

- aspen;

- coniferous species: spruce, pine, larch.

Advice. For construction inside a house, you should not use birch, as it quickly dries out and loses appearance.

To make stringers, you will need a board with a thickness of 40 mm or more of the required length (splicing a bowstring from pieces is unacceptable). The width of the board should be 25-30% greater than the calculated tread width. Suitable for extreme and intermediate posts for railings wooden beam with a cross section of 10 x 10 cm or more, depending on the length of the supporting part and the weight of the structure.

The appearance of a wooden staircase largely depends on the design of the balusters. In order to beautifully design the railing, it is better to order the production of balusters somewhere in production, where they will be turned on a lathe according to your drawing. If you are skilled in wood carving, then you can design the stands yourself. Also, do not forget to purchase fasteners - self-tapping screws, metal pins or dowels for installing balusters, nails.

Installation Guide

IN lately wooden stairs to the second floor, equipped with turning steps, have gained popularity. They take a little room space and are relatively easy to assemble, so we will give step-by-step instructions for installing such a structure. First of all, prepare the necessary tools and a stepladder or a simple ladder for temporary access to the second floor. Then proceed in this order:

- Mark the blanks according to your drawing. For convenience, you can make a wooden template so that you can draw cutting lines along the stringers using one sample. Cut out the pieces with an electric jigsaw.

- Install the support post and attach it as shown in the picture below. Make grooves in it for attaching winder steps and bowstrings.

- Secure both stringers - screw the first one to the wall, and the second one to the vertical post and the end of the interfloor ceiling.

- To support the winder steps, install horizontal bars on the wall. Mount 2 strings for a short flight - the entrance to the stairs.

- Install all the steps, moving from bottom to top. Mark the attachment points for the balusters on them.

- Secure the balusters to dowels or studs, and install the railings.

Scheme of fixing the central support and assembly flight of stairs

Advice. Do not cut 3 turning steps from one block. It turns out that the fibers of the first of them will be located across the length of the tread, causing the step to break at the slightest load.

It makes sense to make the risers of a homemade staircase closed if you plan to sew up the space under the flight (for example, for a pantry). In other cases, it is not necessary to seal the openings between the steps. To extend the service life, finish the flight of stairs - treat the wood with an antiseptic compound and varnish. How to properly assemble a turning ladder yourself is described in the next video:

Conclusion

When building a wooden staircase, pay special attention preliminary stages– calculation, marking and cutting of parts. If you make a mistake here, it can be difficult to eliminate it during assembly, including redoing the stringers. Think about the design of balusters and railings, study existing options from the photographs and choose the most interesting and suitable for the interior of your home.

Related posts:

When building a house with at least 2 floors, you definitely need to think about the stairs in it. And if the house is built with your own hands, it is logical to build the stairs as well.

Various photos of stairs help you make a preliminary choice and clearly understand what type of lift you need. But before you start doing the work, do the math carefully. future design on strength and size, this will save time and money, because incorrect calculations (or lack thereof) will lead to numerous alterations of the original project.

Types of stairs

Exists large number different options flights of stairs. They differ in the material of manufacture (wood, concrete or metal), the type of rise (sloping staircase, spiral staircase, with a turn at a certain degree).

The most common is a wooden staircase. Staircases are also often constructed with a 90-degree turn. It is not uncommon for these two types of lifting devices to be combined into one.

In case of limited space, make a spiral staircase from metal. Screw view lifting allows you to save space, and making it from metal increases the strength of the structure. Concrete is used for stairs in massive buildings (for example, mansions).

What to pay attention to

In a low-rise building, without construction experience, it is better to order modular staircase, a kind of construction set where all the parts are cut out and numbered, and all you have to do is assemble them using the instructions. This is how wooden stairs are usually made.

When building a concrete staircase, in addition to pouring the frame, you will need to external finishing (beautiful stone or wood materials). It turns out to be a double waste of time and money. However, for cottages with 3 or more floors, they are mandatory according to fire safety requirements.

When making a ladder for the first time, you don’t need to swing at it right away. complex design. The simpler the model, the more likely it is that you will be able to successfully build this lifting device on the first try.

Pay attention to the angle of inclination of the stairs: if it is more than 45 degrees, the ladder will be considered an extension, and you can only go down it backwards. The optimal elevation angle is considered to be 37 degrees.

Wood is preferable as a material for construction, since, thanks to its properties, it allows you to correct minor construction flaws that arose due to inaccurate calculations and inexperience of the work performer.

Also, after construction, the building may settle due to loose soil, as a result the staircase can become several centimeters higher or lower than the floor, and it is easier to correct this in a wooden structure.

When constructing a lift with a turn towards, the distance between spans must be at least 100 mm.

Construction stages

Answering the question of how to make a staircase to the second floor with your own hands, there are several stages of construction.

The first stage of any structure, be it a staircase into a house or an interfloor staircase, is the creation of a project. Special attention it is necessary to pay attention to the safety of the building and its ease of use.

The structure must withstand average weight ordinary person with a fair amount of reserve. Be sure to use railings!

If they are not there, another fence must be designed to ensure the safety of descent and ascent.

Consider creating a wooden staircase with stringers

After you have designed your building, you need to prepare the materials. In our case, choose boards of suitable thickness and length, prepare balusters with railings and prepare stringers. This will be the second stage of construction.

A 4 cm thick pine board is suitable as a material for stringers. On it, mark the steps according to the pattern and cut them out with a jigsaw.

Pay attention!

We use the resulting product as a sample for the second (and if the width of the staircase is more than a meter, then the third) stringer. Cut to size required quantity steps.

Third stage assembly will begin all the details together. First of all, the stringers are installed in their permanent locations. Then, using self-tapping screws, the steps are attached to the stringers.

Then, using pins, balusters are placed on the steps, and handrails are attached to them. The staircase is ready!

DIY staircase photo

Pay attention!

In any building with a height greater than a floor, a staircase is installed. This design requires a detailed calculation of all its components, the ability to work with plumbing and carpentry tools, and some design skills. After studying this instruction, you will learn how to design and make a wooden staircase with your own hands.

A wooden staircase for a private house most often consists of one or several flights (flights), which are located between floors or intermediate platforms.

The design of a flight of stairs is a combination of various components with different functional purposes:

- Kosour. It is a load-bearing beam made of wood with a sawn comb. Risers with steps are fixed to it, so the part must be durable.

- Bowstring. In some cases, it becomes an alternative to a stringer, performing load-bearing functions (especially if one side of the structure is adjacent to the wall). Before installation, the string must be marked in detail so that the steps are located at a horizontal level.

- Step. The main element of any staircase, which is attached to one of the load-bearing beams. In addition to the usual ones, there are winder and radius steps. The winder elements have a non-standard shape and are mounted at the starting point of the march. Radius steps distinguished by a curved leading edge, they can be semicircular, wavy or with rounded corners.

- Riser. The part is optional, but it provides the staircase with high strength by supporting the step in the center. A spacer bushing is used to secure the riser. A radius type is installed under semicircular steps, and a curved version is mounted under the corresponding steps or under the landing between flights of stairs.

- Pillars for support. They are placed at the starting and ending points of the stairs, as well as along the edges of the inter-flight platforms. The elements increase the strength of the fence and serve as support for the handrails.

- Balusters. These are supporting posts for handrails, from which side railings are formed, and can have different configurations.

- Handrails. They are a required part. They rest on balusters and support posts. The main requirement for the element is a smooth surface.

- Distance sleeve. Such a stand is required for any structure with several flights (even when using stringers).

When choosing staircase design The main factor is the size of the area required for its construction. In second place is the convenience and comfort of ascent and descent. Here you need to take into account the frequency of use, the presence of children and elderly people in the house.

Aesthetics is also an important criterion. The staircase should be combined with the interior of the room. In addition, you need to take into account material possibilities: manufacturing wooden stairs with complex configuration requires a lot of time and financial costs than options that are simpler in form and execution.

Marching

Are the most popular. They got their name thanks to marches (flights) - a group of united steps. The staircase may have one or more flights.

There are straight structures (single-flight and double-flight, with a rest area). They can be free-standing or placed near the wall. But straight models require a lot of space, so to save usable space, two-flight options are provided with a turn at an angle from 90 to 180 degrees.

The march has a curvilinear shape with optimal angle lifting, then turning steps are used, which are also available in structures with two and three flights without platforms.

The most popular types of wooden stairs for a country residential building are:

- Ordinary one-march ones. Have simple design with a span in the center of the room or near the wall - the most durable with reliable support.

- Curvilinear single-flight. Installed in large rooms to emphasize spaciousness. They are distinguished by smooth rotation and extended outside steps.

- Marching with lower turning steps. Sometimes this option is provided for by the layout of the room and can support the chosen architectural style.

- A simple 2-flight system. A staircase with two flights and an interfloor turning platform can be mounted above the door and save space.

- 2-flight L-shaped design. It is located in a rectangular opening along perpendicular walls and saves space.

- 2 march U-shaped staircase With upper platform and turning steps. The structure is mounted in luxury mansions with a large hall.

- 3-flight system with two platforms. This type of staircase saves space, but requires a significant ceiling height.

To select a specific configuration, you must correctly calculate and measure the free area for installation and draw up a drawing. Detailed Guide How to do this will be described below.

Screw

Screw-type structures are used less frequently, as a rule, when limited area or for aesthetic reasons of the owner of a private house. They are not as convenient as marching ones, and it is difficult to transport furniture on them. To install the ladder, you will need to perform complex calculations, since with a small error it may lose its functionality.

Spiral staircases are sometimes simple decorative function, especially with fencing made by artistic forging. The installation of such options is possible in almost any room, because they occupy less space than designs with a turn. The following types are distinguished:

- with cantilever pinching of steps on the internal pillar;

- with steps supported on the internal pillar and perimeter walls;

- with cantilever support of steps on the casing pipe;

- with support on the fence and bent bowstrings.

Spiral staircases save space

Spiral staircases save space Types of structures

Before you do wooden stairs, should be selected best option designs for your premises.

There are the following popular types designs:

The simplest is a straight staircase, which ensures linear movement along the flight.

Making a wooden staircase with your own hands with a visual step by step instructions Let's look at it in more detail. The process includes two main stages: design and installation.

Calculations of staircase dimensions

Before you start designing, you need to do accurate calculations, draw a diagram and put all the data on it. If you are not sure of the correctness of the calculations, then it is better to entrust the work to professionals who will make a competent drawing, which will allow you to carry out the installation step by step without errors.

Total height of the stairs

The height can be determined by measuring the distance from the floor of the first to the second floor, taking into account the thickness of the ceiling. For example, if on the 1st floor the ceiling height is 2700 mm, and the thickness interfloor ceilings– 300 mm. As a result, the total height will be equal to 3000 mm.

If there is no finished floor, then its dimensions need to be approximate.

Number of steps

If the height of the staircase and riser are known, the number of steps in the structure can be determined. To do this, you need to divide one indicator by the second. For example, when overall height stairs are 3000 mm, and the riser height is 175 mm, the calculation will be as follows: 3000: 175 = 171 mm.

After this, you need to round the value, the result will be 170 mm. The table shows an example of a calculation:

Dependence of the height of the steps on their number at a given floor height

Dependence of the height of the steps on their number at a given floor height Riser height

On the recommendation of experts optimal height the riser should be 150–180 mm, which is actually the size of a human step. This height can be 150–200 mm. Usually average value according to the standard it is 160-170 mm.

The optimal slope range of the stairs is highlighted green

The optimal slope range of the stairs is highlighted green Step width

To avoid injuries as a result of incorrectly selected width of steps, you need to calculate it correctly. Based on many years of practice, the width of the part should be in the range of 220 – 400 mm.

To determine more exact value you can use a certain formula. You need to take the average width of a human step (600 - 640 mm) and subtract from it the height of the riser, multiplied by 2, i.e. 640 – 2x175 = 290 mm. This indicator will be optimal for moving.

March width

According to safety rules, for convenient movement of people, the span should be at least 80 cm wide, but it is better to take at least 90 cm. For convenient transportation of furniture, this figure for a private residential building should be 100 - 120 cm.

Plan length of the staircase

To calculate this parameter, you need to multiply the number of steps and the width of the tread. In our example, it will be 29x17 = 493 cm. That is, the staircase is quite long and when constructing one flight, a room of at least 6 meters will be required. In a small log house or village house you will need to do 2 marches with a 90 or 180 degree turn.

A platform is installed between the flights or turning steps are installed. If you can’t perform the calculation yourself, you can use the special program presented below, which will clearly reflect the localization of the staircase parts.

Ceiling opening size

When constructing a staircase from solid wood You need to remember to calculate the ceiling opening so that you don’t have to bend over when going up. This indicator will depend on the slope, which affects the ease of movement and is selected individually.

A slope of 23-36 degrees is considered optimal, but often it is not possible to maintain the required angle due to the small area of the room (the steeper the slope, the less area it will occupy).

The size of the opening in the ceiling area will depend on the angle of the flight of stairs. So, for a folding structure, a small opening will be required, and for a larger slope, a more significant one will be required (up to 2 m).

The size of the opening in the ceiling is determined based on the minimum permissible value for human passage

The size of the opening in the ceiling is determined based on the minimum permissible value for human passage Stringer length

To determine the length of the stringer, the Pythagorean formula is used: (length of the staircase in plan)²+ (height of the staircase)²= (length of the stringer)².

That is, with a length of 493 cm and a height of 300 cm, we get the following: L = √ (4932 + 3002) = 577 cm (the indicator is taken with a margin of 580 cm).

Online calculator for calculation

For your convenience, you can use the convenient and visual one.

Material selection

After all the calculations have been completed, you need to purchase materials. This will require boards of different lengths and densities: for steps the thickness is 3-4 cm; for risers – 2-2.5 cm; for a bowstring or stringer, the thickness is 5 cm and the height is 150-250 mm. It is better to buy ready-made handrails and balusters, since their production will require lathe and timber measuring 10x10, 15x15 cm. To fix the components you will need screws and nails, as well as metal corners for strengthening.

Manufacturing of parts and installation of stairs

The installation technology includes the manufacture and installation of all elements of the staircase structure in accordance with the drawing.

Assembling bowstrings or stringers

On the prepared boards you need to mark the length and saw off the excess. On the block, using a square, mark the height of the riser and the width of the tread with a decrease of 2-4 cm.

Marking a solid stringer

Marking a solid stringer

Assembling a bowstring with stiffeners

Assembling a bowstring with stiffeners The notches for the steps are cut out with a jigsaw or saw. Next, place the workpiece at the installation site so that the lower edge rests against the floor, and the upper edge against the ceiling. The cuts under the steps should be horizontal, without “blockages”. After this, it is recommended to sand the surface of the block and perform milling, rounding the outer edges.

For optimal rigidity, sometimes 2, 3 or 4 stringers may be required, the number of which is selected depending on the width of the stairs. Sometimes it’s easier to order a ready-made supporting frame, which will include all the elements with cutouts, designated by numbers for joining in accordance with the diagram.

Installation of steps and risers

The risers are mounted in the prepared cuts of the stringer, leveled and sanded. Fastening is done using self-tapping screws, which can then be puttied or closed. finishing material.

Options for attaching steps to the string

Options for attaching steps to the string After fixing the risers, pre-milled steps are installed, the length of which should exceed the distance between the pair of outer stringers by 1-2 cm. The width of the elements should be 2-3 cm larger than the comb protrusion. The steps are fastened to the risers and stringers using self-tapping screws, the heads of which must be recessed into the wood.

Attaching the stringer to the upper ceiling. Methods of connecting staircase elements.

Attaching the stringer to the upper ceiling. Methods of connecting staircase elements.  Attaching the stringer to the floor

Attaching the stringer to the floor Installation of fences

You can give the structure a complete look with the help of auxiliary parts. For this purpose, carved, straight, figured wooden and metal fencing.

Installation of posts with balusters is considered challenging task, where required precise marking with adjustment. In the step, the hole for the dowel is marked at a distance from the edge equal to ½ the width of the base of the baluster. Then holes are made on the steps and dowels are glued into them (they should protrude 1-1.5 cm from the surface).

After this, you need to make holes in the base of the posts and balusters according to the diameter of the dowel and coat them with glue. All elements are mounted on dowels with adjustment according to vertical level. Next, prepare the handrails by cutting the edges under the right angle and milling them with bottom side. To connect to the supports, holes are drilled at the edge of the element. The handrail is installed on a dowel glued into the support post.

After the glue has dried, the stairs must be coated with an antiseptic primer, then the surface is treated with transparent or paint. You can put decorative plinth. IN spiral staircase You can design it with an axial support in the form of a log or beam, or install a bent string to support the steps. The price of such a design will be high, since viscous flexible wood is used in production, but the final effect is worth it.

Very often country house they are built in such a way that there is a lot of space in it, so the second floor is a common occurrence. Therefore, to get to the top, a ladder is required. In this article we will look at diagrams on how to make a staircase to the second floor.

There are companies that manufacture ready-made staircases on a turnkey basis; all you have to do is come to them, agree on the construction of such a product, buy it and assemble it yourself in your home. There are many catalogs that offer a wide range of ready-made stairs, among which you can always choose something for yourself.

However, for many reasons, you can not buy a ready-made structure, but make the stairs yourself, but you will have to make accurate calculations, draw detailed diagram, stock up on quality materials and start building.

Remember that all of the above points are mandatory, since if the ladder that a person is climbing is broken, it can result in dangerous injuries.

The staircase can be built in such a way that it is barely noticeable, in in this case it will play a more functional role, and if you build such a creation in the middle of the room, and even aim for grace, then the staircase will become almost the epicenter of attention. Take a look at the photo of the stairs to the second floor and you will understand what we are talking about now.

Calculations

Before buying materials for manufacturing, you need to do detailed plan future product, to do this, sketch out several options that you like best, and only then select the necessary components.

Stair elements

The entire staircase structure is divided into two groups - necessary and secondary. The second subgroup is considered more decorative than functional, so you can do without it. Thus, it turns out that the ladder consists of a support and steps, which are the main components of reliability.

A step is a fusion of two parts - vertical and horizontal planes. However, there are steps from just one step.

Supports are also divided into several types: a bowstring, the role of which is played by a beam supporting the steps on the sides, and a stringer - from below.

In addition to these elements, metal and wooden stairs, built with your own hands, consist of railings and balusters. With a spiral staircase, it is supported by a stand - a rod axis around which the product is located.

There are stairs whose steps seem to float in the air, in which case they are supported by bolts - rods that come out of the wall and support the steps.

Types of stairs

Let's consider options for DIY stairs.

Marching

Most popular look stairs It has several sections made in the same style, running strictly straight. Very convenient to use, but takes up quite a lot of space.

Staircase on rails

Bolz comes from the word bolt in German. Thus, the ladder is attached to rods that are threaded. There are no risers in the design of this staircase and it looks light and relaxed.

Screw

This staircase has a complex structure, so when building it you must carefully follow the instructions on how to properly make a spiral staircase.

Its main advantage is the minimum usable area of the room, since it is a pipe going to the second floor. It has a rich aesthetic and can become the centerpiece of a room.

Design Aspects

Before building a staircase, it is necessary to calculate its requirements. It must have a number of requirements, namely:

- Safety

- Calculation of all parameters such as length, height, width, angle of inclination

- Presence of guardrails if the ladder is not against the wall

- Frequency of balusters if children use the stairs

- Non-slip surface of steps

- Quality of materials used

Calculation of staircase dimensions and drawings for its manufacture

The standard slope for a staircase is 45 degrees, it can be less, but you should not make the staircase too steep. Carefully calculate the depth of the steps and the height of the risers. A reliable layout of steps will allow you not to make mistakes when building it.

Stair elements

When you build a staircase step by step with your own hands, do not forget that correctly executed parts of the staircase are the key to successful construction.

The main thing is to choose quality materials, dried wood and reliable fastenings. It is better to double-check the parameters of the manufactured components several times before starting installation.

Installation

This point is the most difficult and most important, because the quality of construction will depend on it. Show maximum responsibility at this step. You shouldn’t do everything at once; assemble the stairs in order, as you may have to redo something, but it would be better to do everything right the first time.

DIY photo of the stairs to the second floor

Sooner or later, they think about the issue of expanding the space and organizing the second floor in the building, be it or completing the construction of a full-fledged additional tier. In this case, you will definitely need steps leading to the upper floor; this will help to install this necessary item efficiently and safely.

Details and names of elements of a wooden staircase to the second floor of the house

Become the choice of many. It is not surprising, because they have an aesthetically attractive appearance and are favorable in terms of pricing.

What are the advantages

Such designs have a number of advantages that open up ample opportunities to owners of private houses.

What are the disadvantages

It is worth considering the shortcomings of the material, which can be encountered due to negligence and insufficient preparation.

These are the most popular negative aspects of wood products. Nevertheless, knowing them, you can warn yourself and receive only benefits from the implementation of your plans.

How to draw a diagram of a staircase for your home yourself

If you want to draw a diagram with your own hands, you should know some features that you should definitely pay attention to. You need to have on hand:

- Roulette;

- A felt-tip pen or chalk, which will be used to make marks on the surface of the wall or floor;

- Pen or pencil;

- Sheet of paper;

- Ruler;

- Compass.

These accessories will be quite enough to make the necessary drawings for a wooden staircase in the house.

Step-by-step steps for drawing a drawing

When you get your hands on it and a person begins to draw drawings of wooden stairs to the second floor on a sheet of paper, you should proceed step by step:

Carrying out the steps step by step, adhering to the order, making a drawing of a wooden staircase will not be difficult.

What to pay attention to

When taking measurements, be sure to pay attention to the following factors:

Taking into account these details, there is a possibility of drawing up the most accurate drawing of the staircase leading to the upper floor.

Wooden outdoor stairs

Of course, for climbing upper tier buildings can be used ladders, fixed on the base of the house. But this is unsafe and inconvenient. Therefore, if the entrance to the second floor level is planned to be organized not inside the space, but outside, then you should choose the design that best suits your preferences street stairs made of wood.

In this case, you need to adhere to some rules, since being in an open space, a wooden staircase is very susceptible to the influence of natural factors. This is why:

Advantages

Those who have decided to place a wooden staircase outdoors can note a number of advantages:

In this case, small errors are allowed, because the fact that the staircase is a little wider or longer plays a role in the house, and not outside it. Therefore, it is, of course, worth taking measurements, but in some indicators there is no need. For example, for the street there is no need to measure the space from the step to the ceiling, which must be done in the house.

This is not a complete list of advantages; each home owner will note his own. However, along with positive aspects There are also negative sides.

Project of a street staircase to the second floor

Project of a street staircase to the second floor Flaws

- Exposure to natural factors;

- A wooden staircase outdoors requires careful maintenance.

Knowing the pros and cons, each home owner will be able to independently determine for himself whether to rely on installing stairs on the street or not.