Metal tiles are one of the popular roofing materials, which are characterized by reliability, durability and affordability. To perform coating work efficiently, you must follow the instructions below. But first, let's look at what is so remarkable about this material and what disadvantages it has.

Advantages and disadvantages of metal tiles

Among the advantages of this coating are:

- Light weight, which allows you to cover the roof without much effort;

- The work will not cause difficulties and no special training will be required; it is enough to have basic knowledge in this area;

- The service life is very long, which allows you to not think about covering for a long time;

- Affordable price and high wear resistance no less important criterion when choosing roofing material;

- Such material does not burn, but under the influence high temperature does not melt or deform;

- Huge selection and stylish appearance, will allow you to find suitable option everyone without exception.

The only drawback that many buyers cite is its noise. But even this can be dealt with if you take care of sound insulation when covering.

We cover the roof with metal tiles correctly: step-by-step instructions

To do this work yourself correctly, you must follow all the rules outlined in the step-by-step instructions. So, where to start:

- Carry out the necessary calculations to find out the amount of materials, not forgetting about the insulation and fasteners;

- Cover around the chimney;

- Lay the material using one of the options.

Calculation of the amount of metal tiles per roof

Typically, the width of a full sheet is larger than the working area. This difference can range from 80 to 120 mm. therefore, when purchasing material, you need to know the exact dimensions of the working coating.

To perform the calculation correctly, you need to focus on the following formula:

- The greatest length of the material is divided by its width. The resulting figure must be rounded upward.

- First you need to measure the length of the slope, while the overhang of the cornice must also be taken into account;

- The overlap is 0.15 m per row. If it is possible to lay the coating in one row, then the overlap does not need to be taken into account.

Having measured both indicators, they are added together.

If the purchased metal tiles were made to order according to certain sizes, then in order to correctly calculate all the indicators it is better to use the help of specialists.

The sizes of such material range from 70 cm to 12 meters.

But most the best option There will be a covering with dimensions of 4 - 4.5 m.

Apron equipment

Where the chimney passes through the ceiling, care should be taken to take care of the inside of the junction.

Do-it-yourself installation of the apron should be done according to the following scheme:

- The base material must match the color of the strips;

- The groove made in the pipe should be about 15 cm deep, and the slope should be slight;

- Heat-resistant insulation must be installed on the chimney pipe. The place of contact must be glued with tape;

- Where the chimney passes the roof level, it is wrapped with a special film.

A decorative apron can be installed when the sheets of metal tiles are laid on the roof. External connecting strips are placed on the chimney so that they upper part moved into the prepared groove. For more reliable protection, the joints are filled with heat-resistant sealant. And the lower part of the slats needs to be attached with self-tapping screws to the sheathing.

To ensure good ventilation between the chimney and the rafters, it is necessary that the distance between them be large.

And for protection brick chimney to prevent possible cracking, the pipe must be wrapped with polymer-coated steel with your own hands. To ensure good ventilation, it is necessary to leave a small gap, about 20 mm.

A chimney with a circular cross-section must be insulated where the roof surface passes. To do this, you can take a special tape that has the ability to self-expand. It perfectly seals all holes, including the entire diameter.

Installation of metal tiles: sequence of work

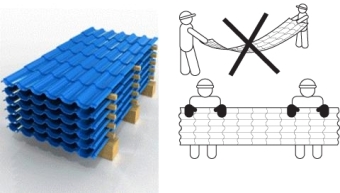

To ensure that installing the roofing yourself does not cause much difficulty, you need to take care of the method of supplying metal tiles to the roof. To do this, it is recommended to make logs.

If the roof large sizes or it is not possible to store all the purchased material near the house, then you can try to make a kind of shelving with your own hands. All materials will need to be transferred there, and then installed. To prevent the sheets from being damaged during storage, they must be arranged with slats during moving.

As soon as the metal tile is in place, the protective film coating should be removed.

If you have to walk on laid material, you need to know how to do it correctly so as not to damage it. The first is caution. Before you step on anything, you need to carefully select a place for it. Secondly, movements should be carried out only along the sheets and step only between the waves of material.

If you need to walk across the surface, then the place where your foot will step should be a fold. Thirdly, you need to wear soft shoes when covering the roof, this will help avoid damage to the material.

If you have to cover it in rainy weather, then water may get into the joints. All moisture is squeezed up under the force of the second sheet. To completely eliminate moisture accumulation, each sheet of material contains a special groove, which helps drain unnecessary water. There are some species that have such a groove on both sides, but mostly it is on one side, on the right. When , make sure that this groove is covered by the subsequent coating.

Having laid the beginning of the row, you can continue to cover in any direction:

- right;

- left.

The direction of installation is chosen for personal reasons regarding convenience. But the beginning of installation should begin from the side on which there are no cuts or bevels. You need to cover, focusing on another roof slope or valley.

If the process begins on the left, then the sheets laid after should lie on the wave of the sheet in front of it. And the groove should be on the left side of the coating.

If the laying principle provides for a direction from the right, then the groove is overlapped using the edge of the next sheet, ending up under the wave of material. The second method of covering is much easier and simpler, since shifting of the laid material is eliminated. But it is also very easy to scratch.

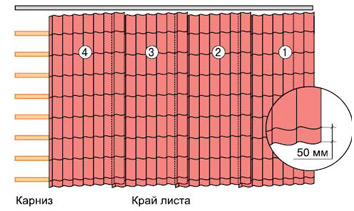

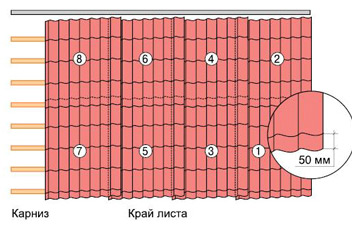

Whatever method of laying this work is carried out, the initial sheets should be placed parallel to the cornice, and the length of the overhang should not be more than 50 mm.

You can cover the roof with sheets using two technologies:

- Place the material in one row;

- Perform multi-layer styling.

How to lay metal tiles in one row

This technology involves installation to the right of the edge. This means that the coating should be leveled, focusing on the ends and cornices. When the first sheet is aligned with them, it needs to be fixed in the middle, not far from the ridge. Subsequent materials are applied with slight overlap. Usually, one wave of sheet is enough for good strength. After aligning the second sheet in relation to the first, it is also fixed, but not in the middle, but together with the previous sheet. Using this method, blocks of 4 sheets are laid out. The resulting block is aligned with respect to the cornice and end and, leaving room for overhang, the entire structure is attached to the sheathing boards. The last sheet in the block must be fastened when the last block has been adjusted. In the figure below, you can take a closer look at this installation method.

Multi-row fastening method

This installation method involves covering the roof according to the following scheme:

- The roof needs to be on the right side. Start sheet must be leveled relative to the end and cornice. Another covering element is mounted on top and attached to the first sheet, after aligning the two sheets. The next sheet must be mounted to the left of the first covering element, and also fastened to it. The fourth element should be laid on top of the third, and this continues until the end of the roof. Having completed two rows of such covering, the block is fixed on a wooden sheathing.

In the figure below you can see the described circuit.

Laying material on the ridge

Before installation begins, markings should be made on the slope and the central axis should be determined. On one sheet of metal tile you should do the same, mark the central axis. Place the surface of the slope and the sheet of material together; the latter must be secured with a self-tapping screw. Subsequent sheets should be laid on both sides of the ridge using one of the above methods.

What points should you pay attention to?

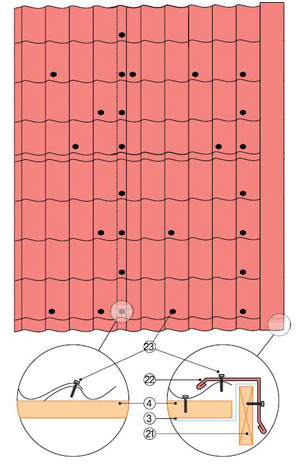

- should occur only at the point where the sheathing boards touch;

- The bottom sheet must be mounted, passing one wave over the step;

- Subsequent rows are fastened at a short distance relative to the steps;

- When attaching the material from the beginning of the end board, it is necessary to use all the waves;

- The laid material must fit tightly to the sheathing boards;

- When covering vertically, the material is secured using self-tapping screws into the recess of the waves.

Having analyzed the process with your own hands, you need to pay attention to the processing of sheets.

- It is prohibited to use a grinder when working with metal tiles, as the coating can be damaged, and this will lead to further corrosion. For these purposes, it is recommended to use cutting electric scissors or a jigsaw. A hacksaw for metal work is also suitable.

- Damaged areas of the material must be treated with paint to avoid further rusting.

In the figure below, you can see how to lay the material yourself.

In the picture shown, number 3 means waterproofing film;

- Number 4 means sheathing;

- Number 21 - end board;

- Number 22 - outer corner;

- Number 23 is a self-tapping screw.

End strip

If it is installed correctly, then it serves not only as a decorative element, but also as a protective one. It allows you to protect fasteners from the harmful influence of factors environment. Preventing moisture from entering is also within her purview.

Endova

It is intended for refining external joints. Removing excess moisture is also within its power. When attaching the upper valley, it is necessary to ensure that the screws do not damage the lower valley; this can lead to damage to the waterproofing.

Roofing fractures

There are two types of fractures on the roof:

If the roof has a slope with a straight bend, then the sheathing boards should be placed fairly close to each other. The coating material must cover the area of the direct fracture, with a small protrusion.

If the roof has a reverse bend, then you need to use wall connection, which will perform the functions of a mating element. Where there is a reverse break, the sheathing boards should be fairly close to each other. And between the metal tile and the junction there should be a layer of sealant.

Selection of roofing material - not an easy task. The roof must be reliable, beautiful, durable, and, preferably, inexpensive. All these requests are met by metal roofing. It should be added to its advantages that installation is not the most difficult, which even a person without roofing experience can handle with his own hands.

Metal roofing is beautiful, reliable, durable and inexpensive

Types of metal tiles

Metal tiles are formed from sheet metal thickness 0.35-0.7 mm, on which protective and decorative compositions. It turns out to be a multi-layer cake. The base of this building material is most often steel, but there are options made of copper and aluminum. Since aluminum and copper are much more expensive than steel, products made from them have a high price. For this reason, copper or aluminum metal tiles are practically not found, but if desired, they can be delivered to order.

Both imported and domestic metal tiles are available for sale. The European version is strictly made of steel 0.5 mm thick - this is stated in the standard. Our GOST allows from 0.45 to 0.5 mm.

In addition to different base materials, different protective coating. First of all, there are two types of steel protection against oxidation - zinc and aluminum-zinc. The second option appeared not so long ago, but it is the one that provides better protection, although such treatment costs a little more.

There are more different compositions for the finishing coating, one that, along with protection from atmospheric influences gives the material one color or another.

Types of protective and decorative external coatings

The outer covering of metal tiles performs two functions simultaneously. It protects the base metal from corrosion and gives the material an attractive appearance. Eat following types of this coating:

- The most common metal roofing has a glossy polyester (PE) coating - about 70% of the total number of roofs are covered with this type of material. All because he has average price and good characteristics. Layer thickness 25-30 microns, service life 5-10 years. This coating is resistant to ultraviolet radiation and corrosion, but is easily damaged mechanically - scratches appear even when removed large quantity snow. Therefore, polyester metal tiles are not recommended for use in regions with heavy snowfall. In other areas, to prevent massive snowfall, it is advisable to install a snow retention system. If you cover the roof with such material, you need to be careful during installation.

- Matte polyester (MPE) is obtained by adding Teflon. As a result, the film is more durable - its service life is 10-15 years, and can also be used in snowy regions. This composition is applied with a thickness of at least 35 microns. Disadvantage of roofing tiles matte polyester- smaller range of colors (about 20 shades compared to 40 glossy).

- Plastisol (PVC) is a PVC-based composition. Has a beautiful structural surface, is applied in a layer of 200 microns, making the coating resistant to damage. The disadvantage is low UV resistance, which significantly narrows the range of use. In addition, in some countries, due to the presence of polyvinyl chloride in the composition, this coating is prohibited.

- Pural is a polyurethane-based coating with polymer additives. Available in glossy (PUR) and matte (MatPUR) versions. Layer thickness - 50 microns, service life - up to 30 years. This is one of the best options: resistant to mechanical damage(worse than palstizol, but better than all others), tolerates ultraviolet radiation well and aggressive environments, can be used for roofing on the sea coast.

Pural is one of the most durable coatings

- Polydifluoride (PVF or PVDF) is a composition based on polyvinyl fluoride with the addition of acrylic (20%). The main advantage is the high elasticity of the coating, due to which, with a small thickness (30 microns), the film is very resistant to mechanical damage. Other advantages are a wide range of colors, resistance to fading, and long service life - up to 30 years. The disadvantage is the highest price.

The most expensive and durable coating is polydifluoride.

It’s clear that when building a house you don’t want to spend extra money. Probably for this reason, most developers choose the cheapest option - metal tiles coated with polyester. But this is not the most best solution. Let's figure it out. The service life of metal tiles with polyester is no more than 5-10 years, average cost- with a metal thickness of 0.45 mm - about 260 rubles / m 2, with a steel thickness of 0.5 mm - 440 rubles / m 2. Even if the roofing material lasts 10 years, the price per square meter for a year will be 26 rubles and 44 rubles. Now let's take very good option— with pural coating. With a metal thickness of 0.5 mm, the cost is from 510 rubles/m2 to 635 rubles/m2 (depending on the manufacturer). Service life - 30 years. For a year of service it will be 12-17 rubles/m2. The difference is obvious. And this does not take into account the work of re-roofing, which is also time and money.

Profile types

When laying metal tiles, its geometric dimensions and wave parameters are important - the sheathing is calculated and installed for them. Also, the height of the wave determines the degree of rigidity of the sheet - with high wind loads, a material with high wave(more than 50 mm) - the hardest; under normal conditions, metal tiles with a small wave (less than 50 mm) are suitable.

The waveform can be symmetrical or asymmetrical, more rounded or with straight lines. There are quite a large number different profiles. The table shows the geometric dimensions (usable width of the metal tile sheet, amount of overlap, wave parameters), which will be useful when calculating the quantity.

Metal roofing in 70% of cases is made from Monterrey profile. It has a round, slightly asymmetrical wave shape. There are 7 subspecies with different wave parameters.

The next most popular profile is Cascade. About 15% of metal roofing is made from it. It is formed by straight lines and has a clear geometry. Looks very interesting on roofs of complex shapes with a large number broken lines.

This profile is used more in regions with average wind and snow loads— the wave height is small, withstands medium loads.

Another 10% of the market is occupied by Andalusia metal tiles. It is more similar than the others to the classic semicircular tile. The profile is symmetrical, with pronounced differences.

The profile is designed so that the joint is located on the wall of the wave, it is practically invisible. It gives the impression of a monolithic roofing covering.

Sheet sizes and wave parameters of Andalusia metal tiles

If we talk about color, then depending on the type of coating, there are usually from 20 to 40 shades. Choose the one you like best. Service life or other characteristics do not depend on color, although there is an opinion that dark colors burn out faster. In fact, the rate of fading depends on the quality of the coating and pigment, but not on the color.

Calculation of the amount of metal tiles

For calculation required quantity sheets of material, you first need to decide on the type of profile and the manufacturer of the metal tile - you will need the exact dimensions of the material itself, and each profile has its own. Then you need to make accurate measurements of the slopes - length, height, if any, you need to measure all the protrusions or other decorative elements, Which will need to be sheathed with roofing material. If the roof complex shape, it’s better to draw its plan, put down all the dimensions and then sit down to do the calculations.

Number of rows

It is best to look for metal tiles not in stores or markets. It is advisable to contact the manufacturer directly. It's not just the price - it may not differ very much, but the fact that many workshops/factories offer to cut sheets of the required sizes. Minimum height sheet 0.7 m, maximum - 8 m. That is, you can order the required number of sheets covering the roof slope from the ridge to the overhang (taking into account the eaves overhang).

This option is good because a metal tile roof will not have horizontal joints, which means there will be less chance of leaks. The second plus is the minimum amount of waste and less material itself (due to the absence of horizontal overlaps, several square meters are saved). Disadvantages: difficulties with delivery, lifting long sheets to the top, inconvenient installation.

When using sheets standard sizes, the height of the roof slope is divided by the useful length of the sheet. The resulting figure is always rounded up. The useful length is obtained after subtracting the amount of horizontal overlap from the total length - from 100 to 200 mm. The flatter the slope, the greater the overlap of the sheets is necessary so that precipitation cannot get into the under-roof space. On roofs with a slope of up to 12°, one sheet overlaps the other by at least 200 mm; with a slope of 12° to 30°, the overlap is 150-200 mm, more than 30° - 100-150 mm. The specified amount of overlap is subtracted from the total length of the sheet, this will be the “useful length”.

An example of calculating the number of rows of metal tiles on a roof. Let the length of the slope be 4.5 m, the useful length of the sheet is 2.3 m. Divide 4.5 by 2.3, we get 1.95, round to the nearest whole number - we get 2 rows. IN in this case Only a small part of one sheet will go to waste, but there are times when more than half is cut off. This is very unprofitable, since this piece cannot be used anywhere else.

Number of sheets in a row

Take the length of the slope and divide it by the usable width of the sheet. This parameter is specified in technical specifications to metal tiles. Most often it is 110 cm (1.1 m). We round the resulting number up to obtain the number of sheets in the row.

An example of calculating metal tile sheets in a row. Let the length of the overhang be 8 m, the useful width of the sheet 1.1 m. When dividing, we get 7.27 pieces, but round up to a larger integer and we get 8 pieces in one row. Moreover, more than 2/3 of one sheet will go to waste.

Features of hip roofs

U hip roofs slopes have a triangular or trapezoidal shape. Here it is necessary to select the length of the sheet in order to minimize the amount of waste.

The height is selected so that no more than half goes to waste. It is quite difficult to do this manually, and there is still a significant error - there will be 20-25% more waste than when calculated using programs. They are usually available from sellers and manufacturers. It is better to provide them with an accurate calculation, and first measure the parameters of the roof at home (or call a measurer), and then try to select the dimensions yourself. Then you can compare the amount of required material calculated by you and proposed.

Determining the number of additional elements

A metal tile roof requires a large number of different additional elements (additions), which form the ridge, the edge of the overhang, the sides of the slope, the passage of the pipe, the valley (the junction of two adjacent roof slopes). The more complex the shape of the roof, the greater the amount of additions required. When idle gable roof ridge elements and plugs, cornices and gable planks. That's all.

What types of additional elements are there for metal roofing and why are they needed?

Despite the wide variety of extras, they are all considered the same. Take the length of the surface on which it needs to be mounted and divide by the useful length of the element. It is usually standard and is 1.9 m (total length 2 m). The result obtained is rounded up.

What and how to attach it to

The metal tiles are secured with special self-tapping screws and rubber washers. Just like the main material, they are made of galvanized steel, and the top is painted to match its coating. When installing, the self-tapping screw must be screwed in strictly perpendicular to the roof surface; tilting it is not allowed.

When fastening metal tiles, you need to monitor how tightly the fasteners adhere to the surface. You cannot tighten it too much, bending the metal, but you also cannot allow a loose fit - the connection will not be airtight.

Lathing for metal tiles

Metal tiles are a fairly rigid material, so a sparse sheathing is made under it, which consists of slats that are located along the roof overhang.

What material?

If the metal tile roof has a simple structure, an inch edged board (24-25 mm thick) 100 mm wide is used for the sheathing. For roofs of complex shapes or in regions with heavy snow loads, it is better to use a 32 mm thick board or 50-50 mm timber. The timber is also used when there is a large distance between the rafters (more than 80 cm).

Lathing step

Installation of metal tiles on the roof has one important feature. There is the strongest place in the profile - under the step of the wave in the hollow. This is where you need to tighten the self-tapping screw. The lathing must be made so that the middle of the plank is located just under this place. This is precisely what causes difficulties: profiles have different sizes Therefore, each of them requires its own installation step for the sheathing strips. This value can be determined by measuring the existing material, but, usually, this parameter is indicated in the instructions for the metal tiles.

There are several important points sheathing devices for metal tiles. Please note that the first plank along the overhang is thicker than all the others - the height of the step for a given profile is added to the selected thickness of the plank. In addition, this strip is made wider than all the others - a drip edge will be attached to it, which covers the cut, protecting the wood from precipitation.

Also note that the second bar is not filled with a standard step, but with a shortened step, otherwise you will not get further into the wave. The step when installing the last plank near the ridge is also different - it is obtained after the fact, as well as the height of the plank. We remind you that there should be sufficient large gaps- both the sheathing and the roofing material should not be joined. This is necessary for normal attic ventilation.

Installation procedure and features

Before covering the roof with metal tiles with your own hands, you need to familiarize yourself with the rules for working with the material:

- First of all, you need to take care of proper storage- in ventilated stacks, laid out with bars.

- When cutting, do not use an angle grinder (grinder), but cut only with a jigsaw or metal scissors. The grinder overheats the metal, which causes the zinc to evaporate, and the material will begin to rust at the cut points.

- Start laying sheets from the lower right corner (the installation diagram for metal tile sheets is in the photo below).

- When installing, wear soft, well-fitting shoes and step only on the lower part of the wave.

Next we will talk about the device. Metal roofing comes in two versions: with a cold or insulated attic. Depending on the type chosen, the order of work changes - during arrangement warm attic, two more layers are added - insulation and a vapor barrier membrane on the room side.

Cold metal roofing

This type of roof is suitable if attic space planned non-residential. Then all the insulation is concentrated in the ceiling, and the function of the roof is only to protect from precipitation and wind. The order of work is as follows:

Warm roof

When installing an insulated roof made of metal tiles, more is added to the roofing pie thermal insulation material, which is attached between the rafters, and vapor barrier film, which is placed on the rafters from the attic side. Further, the entire installation process is similar.

How to attach sheets

When we cover a roof with metal tiles, we need to position the screws correctly. There are several rules that must be followed:

- Self-tapping screws are installed in the lower part of the wave, 2 cm below the step.

- The bottom row, along the overhang, is attached to each wave. Fasteners are also installed in places of horizontal and vertical joints.

- The waves between the horizontal joints are attached through one in a checkerboard pattern.

These rules are clearly shown in the diagram. IN graphic representation some things are easier to understand.

Metal tiles are extremely popular because they have significant advantages over other roofing materials. Using metal tiles when covering the roof, you will provide your home with reliable protection from aggressive environmental influences. Let's considerhow to cover a roof with metal tilesand what it will take.

The advantages of this material include:

- low cost;

- pleasant appearance;

- reliability;

- light weight;

- long service life.

What will be required at work

Before starting work, you need not only to carefully study the instructions, but also take care of all the necessary materials and tools. First of all this:

- metal scissors;

- roulette;

- hammer;

- hacksaw;

- marker;

- stapler with galvanized staples;

- wooden slats of suitable length;

- screwdriver;

- drill.

Pay attention! It will be quite difficult to cut metal tiles with hand scissors. complex profile, so it is better to use a power tool for this (if possible).

It is also worth noting that the material is coated with a special polymer coating, which must not be damaged under any circumstances - it performs an anti-corrosion function. For this reason, you should exclude all cutting options that involve heating the area being cut. The optimal tool for cutting may be a grinder, but onlywith abrasive wheel.

Regarding necessary materials, then for work you will need:

- metal tiles;

- board for constructing sheathing, 2.5x10cm;

- wooden beam, 2.5x5 cm;

- mineral wool for insulation;

- waterproofing (any except bitumen).

Let us immediately make a reservation that this material is not suitable for all types of roofing. The fact is that the roof must meet certain requirements, namely:

- to be pitched;

- have a slope of more than 14°;

- have simple geometry.

If the roof has complex design, albeit straight, then during installation it will be necessary to make more than a dozen trimmings, which will increase material consumption(after all, most of it will simply go to waste). Consequently, this will greatly increase the cost of building materials and installation itself.

Preliminary roof measurement

You need to start work with a competent measurement of the roof, its length and width - this will allow you to calculate the required amount of materials. If the width of the slope is no more than six meters, the length of one sheet should be equal to this width (with a small margin for the cornice). But if the width of the building exceeds six meters, then the sheet is divided into two parts, which are installed with an overlap of approximately 10 cm.

The sheet of tile itself must be at least 4 cm longer than the slope. The fact is that the sheet is attached to the slope, slightly overlapping the cornice. This allows us to ensure good ventilation under the ridge of the roof.

After this, the roof needs to be measured diagonally. It is also worth making sure that the roof has the correct geometric shape. Moreover, at this stage all defects and distortions will be revealed that need to be corrected immediately.

Before you begin installing the sheathing and laying the tiles, you need to ensure that the roof good waterproofing. This will prevent condensation on the inside of the roof, and even after leakage, moisture will be retained by a special substance - absorber

Vapor barrier film is considered the most affordable and therefore popular insulating material. Treated with a special absorbent substance, it is installed directly above the room.

The insulation must be laid on the rafter system so that the initial overhang layer does not exceed 2 cm. The following layers are overlapped by approximately 15 cm. A small sag can be left between the rafters, but not more than 2 cm. To fix the film, galvanized nails or a mounting stapler are used.

In parallel with waterproofing, the roof should also be insulated. Insulation boards are placed between the rafters. If the material is made in the form of mats, then it must be secured with the same mounting stapler (in this case, everything depends on the selected material; this issue has already been discussed in one of the previous articles).

Assembling the sheathing

To assemble the sheathing, it is necessary to secure wooden beams along the slope to the waterproofing layer. Then boards 2.5 cm thick and 10 cm wide are attached to the beams.

Pay attention! Installation of boards must begin from the bottom! The first board should be approximately 1–2 cm thicker than the others, because it is on it that the edges of the metal tile sheets will be installed.

The pitch between the boards can be different, from 30 to 45 cm, depending on the transverse profile of the roofing material. It is typical that the step between the first and second boards should be approximately 4 cm smaller than between other battens. Before starting work everything wooden elements should be treated with an antiseptic and (if possible) a fire retardant.

When installing the sheathing, you should special attention devote to auxiliary elements.

- On both sides of the roof you need to install additional bars on the rafters - this will increase the reliability of fixing the ridge.

- When installing waterproofing, you need to extend it a couple of centimeters onto the chimney pipe and seal it with reinforced tape - this will help hide the gaps that have formed. On the chimney itself, it is necessary to make grooves (small grooves) 2 cm deep. Upon completion installation work You need to install adjacent strips into these grooves and insulate the joints with silicone sealant.

- Valleys should be installed in the gaps formed between the slopes. For this purpose, it is mounted from boards continuous lathing with an additional layer of waterproofing. Each of the valleys should be installed above the cornice strip and secured with self-tapping screws every 25 cm.

- You need to install a cornice strip on the frontal board with self-tapping screws and secure it every 25 cm. Such a strip must withstand strong winds, so it is installed with an overlap of 12 cm.

Work on laying tiles is carried out in the following order.

First stage. Actually, we have already discussed it above - it consists of installing a cornice strip to the frontal board of the sheathing. We remind you once again about the mandatory 12-centimeter overlap.

- In case gable roofyou need to start work from the end of the ramp. If it was decided to cover from the right slope, then each subsequent sheet is installed on the extreme wave of the previous one. But if the material lies on the left end, then the new sheet is installed under the extreme wave of the one in front of it.

- Hip roof you need to cover from the highest point, gradually lowering (here it’s all about the peculiarities of the geometric shape of the hipped roof).

All sheets must be laid parallel to the cornice, with a mandatory 4-centimeter plumb line.

Third stage . If the sheets are installed in one row , then the first of them needs to be aligned with the cornice and temporarily fixed with a self-tapping screw in the ridge area. The second sheet needs to be aligned with the first and temporarily connected. So it is necessary to install two more sheets, then align the formed block along the cornice and secure it to the sheathing with self-tapping screws.

In case multi-row layingmetal tiles, the first sheet must be installed at the bottom, secured with a self-tapping screw and aligned with the end and cornice. A second sheet of tile is installed on top, and a third one on the side. All of them are temporarily attached with self-tapping screws. Then you need to level the formed block and finally fix it on the sheathing.

Finally, if the slope hastriangular shape, then first you need to determine and mark the center line on it. The same line should be drawn on a sheet of tiles. Then both lines are combined, the sheet is fixed with self-tapping screws. Subsequent installation is carried out on both sides of the first sheet.

Fourth stage . Self-tapping screws should be screwed into the recesses of the sheetsin one wave. Each new row of screws should be staggered relative to the previous one. For each square meter 7–8 screws should come out of the material.

Overlaps need to be strengthened in each wave.

When covering a roof with metal tiles, special attention should be paid to the reliability of fastening the sheets and the accuracy of their joining.

As a conclusion

All work must be carried out in accordance with the instructions given, ensuring that the wooden elements are thoroughly dried and there are no signs of rotting on them. This is the only way to achieve durability and reliability of the structure, as well as an attractive appearance of the roof.

Video - Installation instructions for metal tiles

Metal tiles are becoming more and more popular every day. This is an excellent roofing material with an optimal ratio performance characteristics and cost. Metal tiles are suitable for finishing roofs of almost any complexity. At the same time, you can cope with the tasks of installing the material yourself.

Metal tiles are produced in the form of galvanized sheet material made from steel. The sheet consists of several layers that perform important protective or decorative functions.

- Zinc layer. It is the basis for applying subsequent layers. Additionally prevents the development of corrosion.

- Passivating layer. Prevents the accumulation of static electricity.

- Primer layer. Provides the highest quality adhesion of previous and subsequent layers of metal tile sheets.

- Polymer layer. Protects the material from adverse external influences and gives it the required appearance. The coating can be matte or glossy. Many available color variations, which allows you to select roofing material that fully satisfies the owner’s needs.

Metal tiles have many advantages over other popular roofing materials, namely:

- light weight. There are many excellent roofing materials available on the market today, but the use of many of them is limited due to their heavy weight. Modern houses are increasingly being built from “light” building materials and they absolutely do not need the additional burden. Metal tiles weigh little, so they can be safely used even for roofing houses built on weak foundations;

- many color variations. It is unlikely that you will find another roofing material presented in such a variety color solutions, like metal tiles;

- good technical characteristics. Metal tiles are resistant to atmospheric and other adverse influences. Installation of sheets can be carried out at any time of the year;

- relatively affordable price. Metal tiles are noticeably more expensive than other coatings with similar parameters. Natural tiles it costs much more, although its properties are practically no different from those of modern high-quality steel sheets.

Metal tiles look great on the roofs of almost any building. It is best suited for large and solid houses and cottages, but if desired, you can develop great project roofs even for a small country house.

Video - DIY metal tile installation instructions

Before you begin arranging the sheathing and directly fastening the sheets of metal tiles, you must definitely think about reliable and high-quality waterproofing. Thanks to the moisture-proofing material, the possibility of condensation on the internal surfaces of the elements will be excluded roofing system, which will contribute to a significant increase in their service life.

The most popular waterproofing option is polyethylene film. This affordable material flawlessly copes with all the tasks assigned to it.

Waterproofing should be laid on the rafters under the counterbeam. Individual pieces of film are laid with an overlap of about 15-17 cm. The sag of the film between the rafters can be no more than 1.5-2 cm. To fix the film, use galvanized nails or construction stapler with metal brackets. Cover the waterproofing joints with adhesive tape. It is desirable that it be metallized.

The technology for installing a metal roof requires mandatory installation of insulation. It is most convenient to use slabs mineral wool. The material is placed between rafter legs. The construction stapler you already know is perfect for fixing the slabs.

Sheathing device

Metal tiles will be laid on load-bearing structure, known as sheathing. The system frame is assembled from wooden planks about 100 mm wide and 25-30 mm thick. All wooden elements must be treated antiseptic. Otherwise, the wood will rot in a fairly short time.

The lathing is attached in the interval between laying the waterproofing and installing the insulation. The task comes down to attaching wooden boards or bars to the rafters. Start fastening from the ridge roofing structure, gradually moving vertically down to the cornice. Fix the sheathing elements in a horizontal position. Use nails of the appropriate length. As a rule, boards are mounted as a continuous sheet.

Laying roofing material

Laying metal tiles should begin from the bottom corner of the roof slope. It is best to start working from the lower left corner. In this case, each subsequent sheet will overlap the previous one. If you start installing the covering from the right corner, the next sheet of metal tiles will have to be placed under the already laid material. It is not advisable to do this, because... With such installation there is a high probability of damage to the roofing.

Laying of metal tiles should be carried out parallel to the cornice. Do not forget to leave an overhang behind the eaves of about 4 cm. There is a technology according to which sheets of metal tiles can be laid vertically. But in the absence of proper experience in roofing work, it is better to abandon this method, opting for a more traditional and simpler horizontal installation.

When laying, you will need to turn the corners slightly clockwise. This is done so that the right corners of the elements laid in one row are located in a single straight line.

To secure adjacent sheets, 1 self-tapping screw is used. This preliminary fastening is placed at the top of the sheet. After this, you need to align the elements of the system and perform their final fixation.

Place the longest sheets of metal tiles in the bottom row. With this option, installation is greatly facilitated, and the finished coating takes on a more solid and attractive appearance.

Approximately 7-8 screws are required for 1 m2 of coating. The sheets need to be fastened in transverse waves, screwing in the screws in increments of 35 cm. You can also install screws in longitudinal waves. With this method, it is necessary to fasten through the wave, placing self-tapping screws in the upper ridges.

An electric screwdriver is best suited for tightening screws. An electric drill will also work. The main thing is that it has the function of slow and smooth rotation of the cartridge. To achieve greater fastening accuracy, it is recommended to core the hole in advance.

Sheets of covering must be secured in the lower crest of the wave, where the material is pressed against the sheathing. This will allow you to create the maximum reliable fastening and do not deform the material.

The bottom sheets of metal tiles must be attached to the first lathing in each wave, without gaps. This area will be subject to the most powerful wind loads, so the fastening must be as reliable as possible so that the sheets do not blow off at the first strong gust of wind.

Attach to other battens at a minimum distance from below to the step. This is where the sheet material has the highest rigidity. In addition, with this arrangement the screws will be almost invisible.

In places where they overlap, sheets of metal tiles must be secured through the wave. If you wish, you can record each wave. This will ensure the highest quality fit of the upper sheet elements.

For fastening roofing materials, galvanized self-tapping screws made of alloy steel are best suited. Stainless steel self-tapping screws with a seal have also proven themselves to be excellent. Such fasteners can have a wide variety of colors, which will allow you to create the optimal color combination self-tapping screws and base coating.

Self-tapping screws are screwed strictly perpendicular to the sheathing elements. Deviations are not allowed. Sheets of metal tiles should be pulled as tightly as possible to the sheathing. Any distortion of the screws can lead to the appearance of through holes in the sheets. If the roof will be exposed to prolonged exposure to an acidic or alkaline environment, self-tapping screws with plastic caps should be used to fix the metal tiles.

Check the screws 3-4 months after completion of the roofing work. Under the influence of wind loads, fastenings usually weaken. Tighten any loose screws.

Thus, in self-installation There is nothing complicated about metal tiles. Follow the instructions, adhere to the recommendations received and everything will work out.

Happy work!

Video - DIY metal tile installation instructions

Metal tiles are one of the popular roofing materials. This is due to its good performance properties, accessibility and the ability to install it yourself.

Pros and cons of metal roofing

Most often, metal tiles are used for the roof of a private house, since this roofing material has many advantages:

Metal tiles are a durable and attractive roofing material

Metal tiles are a durable and attractive roofing material But metal tiles also have one significant drawback - noise during rain and hail. Therefore, a layer of sound insulation (for example, polystyrene) must be included in the roofing pie of a residential building. This role can also be played by a double layer of insulation or metal tiles with a special soundproofing coating.

Layers of insulation under metal tiles do a good job of suppressing external noise

Layers of insulation under metal tiles do a good job of suppressing external noise Installation of insulated and non-insulated roofs

Metal tiles can be used to cover a private home and any outbuilding. The roof residential buildings They always make it insulated. The roofing pie of an insulated residential attic has the largest number of layers:

- metal tiles - performs the protective function of the structure;

- sound insulation - dampens vibration and noise due to external influences on metal sheets;

- sheathing - the place where the roof is attached;

- counter-lattice - provides ventilation gap, prevents condensation from forming;

- waterproofing - protects the insulation from moisture;

- thermal insulation - retains heat inside the living space;

- rafter system;

- vapor barrier - prevents the penetration of moisture from inside the room;

- internal lining.

When settling in roofing pie It’s better not to skimp on metal tiles so that the roof turns out to be of high quality and lasts a long time

When settling in roofing pie It’s better not to skimp on metal tiles so that the roof turns out to be of high quality and lasts a long time On an outbuilding or summer unheated garden house The design of a roofing pie for metal tiles is much simpler:

- metal tiles;

- sheathing;

- counter-lattice;

- waterproofing;

- rafter system.

Metal tiles are good for roofing outbuildings, sheds from sun rays, garage and bathhouse

Metal tiles are good for roofing outbuildings, sheds from sun rays, garage and bathhouse Installation of metal roofing

You can cover the roof with metal tiles yourself, if you study the instructions in advance, calculate the material and prepare necessary tools.

Before work, it is important to remember the basic rules for installing metal tiles on the roof

Before work, it is important to remember the basic rules for installing metal tiles on the roof Required Tools

To lay metal tiles on the roof you will need:

You will also need a sturdy ladder. For installation work on low outbuildings, it is better to use a stepladder. And to move on the roof of a building you need to secure it wooden stairs on the ridge bar.

For safety and ease of installation of metal tiles, ladders attached to the top of the roof are used.

For safety and ease of installation of metal tiles, ladders attached to the top of the roof are used. Calculation of materials

The metal tile sheet has two widths:

- total (1180 mm);

- useful (1100 mm) - the edges are not counted, since the sheets overlap each other.

When making calculations, the value of the usable width is used.

If desired, you can order material from the manufacturer according to own sizes so as not to cut the sheets later

If desired, you can order material from the manufacturer according to own sizes so as not to cut the sheets later To determine the required amount of material, you need to measure the roof and calculate:

- How many rows will there be? To do this, divide the width of the slope (along the eaves or ridge) by the usable width of the metal tile sheet. For example, 5 m: 1.1 m = 4.5. Round the resulting number to 5 rows.

- How many sheets are there in a row? To do this, the height of the slope must be divided by the length of the metal tile sheet ( standard sheet 2.5 m). For example, 3.5 m: 2.5 m = 1.4. Round up to 2 pieces. If desired, you can order the length of the sheets equal to the height of the slope.

- Quantity of material. It turns out: for one slope you need 5 * 2 = 10 sheets, and for two - 20 sheets.

The color of the screw head for attaching metal tiles to the sheathing can be matched to the color of the roofing material

The color of the screw head for attaching metal tiles to the sheathing can be matched to the color of the roofing material When choosing self-tapping screws, you need to pay attention to:

- distance between turns - self-tapping screws with a large distance between turns are suitable for attaching metal tiles to wooden beam;

- tip - self-tapping screws with a sharp tip attach the metal tiles to metal base;

- length - long screws suitable for fixing additional elements, short ones - for connecting sheets and attaching metal tiles to the sheathing (2.8 cm);

- hat shape.

Technology of stuffing lathing under metal sheets

The weight of metal tiles is light, so a special base for it is not required. You only need to rafter system nail the sheathing.

You need to fill the sheathing under the metal tiles exactly according to the markings

You need to fill the sheathing under the metal tiles exactly according to the markings It is important to correctly determine the step of laying the boards. The distance between the first and second boards should be 25–35 cm (depending on the distance between the bends of the sheet of a particular model of metal tile), then the step increases by 5 cm and is kept constant.

The sheathing pitch must correspond to the wave pitch of the metal tiles

The sheathing pitch must correspond to the wave pitch of the metal tiles In problem areas (placement of valleys, junction of metal tiles to pipes and near windows), the sheathing is made continuous.

Technology of laying metal tiles on the roof

Typically, metal sheets begin to be laid from the right edge of the rectangular roof slope. Then each subsequent sheet is laid on the previous one. If you move in the opposite direction, then each subsequent sheet is placed under the previous one. If the slope is triangular in shape, then the first sheet is placed in the center of the slope (where its height is greatest). And the rest are already attached to it on both sides. The installation itself is performed in the following sequence:

- The first row of metal tiles is laid. At the same time, you should not immediately securely fix the sheets. It’s better to grab a little in one place, align them relative to each other and the edge of the slope. The first row should hang 5 cm from the eaves.

You can start work either from the left side or from the right

You can start work either from the left side or from the right - Fix the metal tiles. It is recommended to use only high quality fasteners, since the service life of the roof directly depends on this. You need to place the screws through the wave.

The fasteners must be placed through the wave, screwed tightly, but do not pinch the O-ring

The fasteners must be placed through the wave, screwed tightly, but do not pinch the O-ring - At the joint, part of the corner is cut off to remove the seal. It is possible to straighten the capillary ditch, which is located under the stamping line.

If you need to move on metal tiles, then you can only step on the lower part of the wave

If you need to move on metal tiles, then you can only step on the lower part of the wave - Repeat the process for the second and subsequent rows.

Eat different options laying metal tiles in two rows, so after studying the installation principle, you can choose more convenient way for a specific roof

Eat different options laying metal tiles in two rows, so after studying the installation principle, you can choose more convenient way for a specific roof - Fix the end strips. Lay them with an overlap of 2 cm.

When working with metal sheets, you need to follow some rules:

- move along the roof carefully, in comfortable shoes, step only on the lower part of the wave;

- Immediately paint the cut area with special paint. It is prohibited to cut metal tiles with a grinder, as the protective coating is damaged;

- After installation, remove the protective film from the surface of the material: it will not look aesthetically pleasing if it crumbles under the influence of sunlight.

Video: installation of metal tiles with step-by-step instructions

Installation of roof ridge

The ridge is made of the same material as the roofing. Its installation is carried out as follows:

If the slope angle is 45°, before installing the ridge, you need to check its compatibility with a roof of a similar design. Otherwise, there is a risk of moisture penetrating into the under-roof space, which will entail a complete replacement of the roof.

Video: how to install a skate yourself

Installation of the valley

If the roof has a complex shape, then a valley is placed at the junction of two slopes.

First, the lower valley is attached, then the roofing covering is installed, after which the joint is closed with the upper valley

First, the lower valley is attached, then the roofing covering is installed, after which the joint is closed with the upper valley Its installation must be carried out in accordance with the technology:

Video: internal structure of the valley

Pipe finishing

Special aprons are used to finish the exit points of heating or ventilation pipes. Installation is carried out as follows:

Video: how to properly bypass a pipe

Grounding

When using metal sheets as roofing material, it is worth thinking about arranging grounding. To do this, you can use a pin electrode or metal pipes(natural grounding). But not pipes with flammable liquids, sewer and central heating.

metal roof must be grounded to avoid problems during thunderstorms

metal roof must be grounded to avoid problems during thunderstorms The cross section of the electrode pin should be 50 mm 2 or more, and the thickness of the steel strips should be from 4 mm. A lightning rod is mounted on the roof: a steel rod 12 mm thick and 200–1500 mm long. You can use a pipe with a sealed end for it. The pin is buried in the ground and connected with galvanized steel wire with a cross-section of 6 mm or more to this lightning rod.

During a thunderstorm, the lightning rod takes over electrical discharge and transfers it to the ground

During a thunderstorm, the lightning rod takes over electrical discharge and transfers it to the ground Video: budget version of a lightning rod with your own hands

Installation of snow guards

On last stage After installation, snow guards are attached to the roof. This element is mandatory if polyester-coated metal tiles were used.

The greater the roof slope, the more snow guards will be required.

The greater the roof slope, the more snow guards will be required. The snow guard strips should be placed in one or two rows in a checkerboard pattern. The greater the slope angle, the more planks you need to use. They can be attached to the metal tiles using the same self-tapping screws that were used to install the roof.

Snow guards are installed for the safety of people below when the frozen mass of snow begins to fall off the roof.

Snow guards are installed for the safety of people below when the frozen mass of snow begins to fall off the roof. Video: why and how snow guards work, rules for their installation

The service life of metal tiles depends on correct installation and compliance with maintenance rules. First of all, this concerns regular cleaning. But you need to clean metal tiles correctly so as not to damage the protective polymer layer. The main stages of caring for a metal tile roof:

- to remove dirt and leaves you need to use a fluffy brush;

- in the presence of more serious contamination, you can choose special products designed for polymer coatings;

- drainage system clean only with water under pressure;

- remove snow with special tools that are not capable of damaging the material (plastic scraper).

Proper care can extend the life of metal tiles up to 50 years.

Metal tiles can be an excellent protection for a building from weather conditions. And it will last for decades, but provided that installation technology is followed, high-quality additional elements and fasteners are selected, as well as timely cleaning and repair.