Using all possible space, giving the house originality and significantly reducing heat loss through the roof - these are the tasks that the attic solves. If there is a certain margin of safety at the foundation, in this way you can turn a one-story house into a two-level one. Another attractive thing is that you can build an attic roof with your own hands even without special construction skills. It is important not to make a mistake with the choice of materials and do everything according to the rules.

Windows on a regular floor are located in the walls. In attics there are no or almost no walls. They are replaced by a roof. That’s why windows are made special: they not only must let in sufficient light, but also withstand wind and snow loads, which are much greater on the roof than on the walls.

Dormer windows

When planning an attic, you should take into account the recommendations of SNiP. They recommend making the window area no less than 10% of the floor area. So if the attic is divided into several rooms, each should have a window.

Of all the methods shown in the photo for installing skylights with an attic, inclined installation is the easiest to implement. In this case, it is necessary to ensure the proper degree of waterproofing of the junction, and also to use special models with reinforced frames and reinforced glass - the load on the surface can be significant.

Advantages of a sloping roof window:

- more light, less sharp boundaries of light and shadow;

- the roof surface remains flat, its relief is not complicated;

- relatively easy installation.

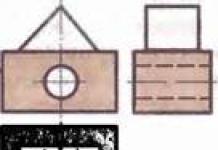

When planning such a window, it is necessary to remember that its area increases with increasing angle of inclination. At what height is it more convenient to install such a window and how its height increases in centimeters depending on the inclination, look at the photo.

The steeper the slope relative to the floor, the smaller the window height should be.

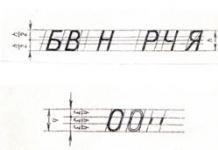

The width of the window frame should be 4-6 cm less than the pitch between the rafters. Then it can be easily installed without disturbing the structure of the frame. If the window is wider, it is necessary to make a reinforced beam above it and calculate the load.

If you need to have a larger window, it is easier to place two narrow ones side by side. They look no worse than one big one, and there will be fewer problems.

When installing a dormer window, the roof geometry becomes more complicated: a valley appears on top and on the sides. Because of this, the rafter system becomes more complex both during planning and during assembly. The complexity of installation also increases roofing. All valleys are the places where leaks are most likely to occur. Therefore, everything needs to be done very carefully. In regions with a lot of snow, it is advisable to install snow guards over such windows so that they are not blown away in the event of a sudden meltdown.

Installation of a vertical dormer window in an attic roof

The advantage of such a window is that you can stand next to it at full height. But they let in less light, the terrain becomes more complex and the roof becomes more problematic.

A recessed window is usually used if there is access to a balcony through it. In other cases, this method of arrangement is not best option: little light gets in, the shadows turn out to be very deep, which is tiring for the eye, the geometry also becomes more complex, although not to the same extent as in the previous version.

The easiest way is to make a window at the end of the attic. In this case, a reinforced frame or reinforced glass is not needed. Just high-quality glass is quite enough. This option is most often seen on country attics: This is the most inexpensive option that can easily be done with your own hands.

Rafter system

When independently building private houses with an attic, they usually choose a broken roof. It allows you to get a room of significant area, larger than under a gable.

With the same width of the base (of the house), the attic space under a sloping roof is larger than under a regular gable roof. The rafter system is becoming more complex, but a gable roof with an attic under a sloping roof is still more popular

The design of the sloping mansard roof is such that the overhangs can be lowered quite low, giving the house interesting view. But the long overhang of the roof serves not only a decorative role. They also cover the upper part of the wall from precipitation and divert the bulk of the water away from the foundation. Although when planning you need to keep in mind that in strong winds they increase windage. Because of this, it is necessary to use more powerful boards and beams. Therefore, the size of the roof overhang is chosen based on several considerations, the main one of which is weather conditions.

Tilt angle

Depends on the roofing material, but most of all - on the region and weather conditions. The classic version is shown in the figure: the lower slopes in relation to the plane of the attic floor are inclined by 60°, the upper slopes by 30°. Based on these data and the parameters of your building, you can calculate all lengths. Just take into account that according to SNiP, the ceiling height in the attic cannot be less than 2 m. Then, by definition, this is an attic. A person will feel comfortable if the ceiling is raised to a height of at least 2.2-2.3 m. Based on this, according to the rules of geometry, calculate the required lengths.

At classic version load from precipitation on side surfaces may not be taken into account. Precipitation can only be retained on the upper part, the angle of inclination of which is less than 45°.

In general, the inclination of the side surfaces usually varies between 45° and up to 80°. The steeper the slope, the greater the windage it has, this must be taken into account: in regions with strong winds It is better to make flatter roofs. Then wind loads will be perceived much better.

Types of rafter systems for sloping roofs

The design of a sloping mansard roof is one of the options for the rafter system (the most common)

To make the frame of a sloping roof with your own hands, they most often use pine lumber, grade no lower than 2. The choice of cross-section of timber and boards depends on the size of the roof, the selected roofing covering (its weight), wind and snow loads in the region, and the pitch of rafter installation. All these parameters are taken into account in the calculation. The methodology is prescribed in SNiP 2.08.01-89 and TKP 45-5.05-146-2009.

One of the options for constructing a frame with hanging rafters

The figure above shows a drawing of a frame with hanging rafters. It can only be implemented if the base of the upper triangle is no more than 4.5 meters (in in this case this is the width of the attic space). If more, you will have to make layered rafters, which should rest on the load-bearing wall in the middle (the attic will be divided into two parts by a row of beams).

Another version of the upper part is shown in the photo below (the picture is clickable). In this case, the side rafters are reinforced with struts. They significantly increase the rigidity of the system.

There is a second way to achieve a similar effect - to establish contractions - in the figure they are only outlined with barely visible lines. The length of the side rafter leg is divided by three, and contractions are established in these places. They will be needed if the roof covering will have a significant weight.

Option for installing a sloping roof truss system - with struts that increase the rigidity of the system

For a small building, the roof frame can be generally simple: at the top there are two hanging rafters, a tie rod, floor beams, racks and side rafters (pictured below).

Construction of a rafter system for a broken mansard roof for small house

How to calculate a sloping roof

The attic sloping roof of a small house (no more than 6-7 meters wide) has been built so many times that, based on experience, we can say what materials should be used. Many parameters are dependent on other materials. For example, the installation step of the rafters is tied to the parameters of the insulation. To ensure that there is as little waste as possible during insulation and installation is simpler, it is necessary that the distance from one rack to another be slightly less than the width of the insulation (by 20-30 mm). So, if you are going to use mineral wool, its width is 60 cm. Then the racks need to be installed so that the gap between two adjacent ones is 57-58 cm and no more.

The width of the board for the rafter leg is again determined based on the insulation. For the central zone of Russia, the required thickness of basalt wool is 200-250 mm. That's not all. In order for the thermal insulation to dry, a ventilation gap of 20-30 mm is required (without it, condensation will gradually rot the wood and render the mineral wool unusable). In total, it turns out that the minimum width of the rafter leg should be 230 mm. The thickness of the board is at least 50 mm. This is in regions with light winds and not very heavy snowfalls. To summarize, for all rafters - ridge and side - a board of 230 * 50 mm is required.

If lumber with such characteristics turns out to be too expensive, it will be possible to do the insulation in two directions: partly along the rafters, partly, filling the sheathing, across. You can lay a minimum of 100 mm of basalt wool, therefore you can take a standard board 50 * 150 mm and leave a 50 mm ventilation gap, or order a non-standard 130 * 50 mm. It's up to you to see which is more profitable for the money.

For racks and beams, it is better to take a beam of at least 80 * 80 mm, better - 100 * 100 mm. Especially in areas with difficult weather conditions - heavy snowfalls or strong winds.

Order a more accurate calculation from specialists. This is a long process consisting of collecting loads from the roofing material, the structural elements themselves, wind and snow loads. After which, according to a certain formula, elements are selected. More detailed information For information on how the calculation is carried out, see the following video.

Do-it-yourself mansard roof: installation procedure

The design of the Mauerlat on attic roofs is no different from the standard version. If or logs, you can use the upper crown as a mauerlat. It is only pre-treated with impregnation with high protective properties.

If the wall is made of foam blocks, a reinforced monolithic belt. On a brick wall or made of shell rock or other similar materials, the installation of such a belt is not necessary. Waterproofing is laid in two layers on the wall, and on top is a timber treated with an antiseptic - 150 * 150 mm or a log. It is secured with embedded studs.

When assembling all elements, long nails are used - at least 150 mm long. In the most critical places, it is better to connect three or more elements using bolts or studs with double-sided threads. It is advisable to strengthen all joints with steel plates or corners.

First way

Installation of attic roof rafters is done in two ways. First: they assemble the parts on the ground, then in finished form lift up. There, the outer structures, which will become pediments, are put up first. They are placed vertically and secured. It is often more convenient to secure them with long bars nailed to the wall (temporary). The following are inserted into the prepared recesses in the Mauerlat (they are made with the required step): assembled structures. They are positioned strictly vertically and carefully secured. If necessary, additional temporary spacers are installed to fix them in the desired position. Side beams are installed.

How to build a sloping roof in this way and assemble the nodes, see the video below.

Second way

The second method - the construction of a sloping roof is carried out sequentially by assembling elements directly on site. This method is more convenient if the structure is large and when assembled it can only be lifted using special equipment (crane).

First, the floor beams are laid. Stands and ties are attached to them, and temporary spacers are installed to hold them in the vertical direction. Next, the upper and side rafter legs are assembled, and the tie rods and jibs are installed.

During installation, the following sequence of actions is observed: first, the outermost elements are installed and adjusted to the desired position, and securely fastened. If necessary, use temporary spacers. A fishing line, rope, and cord are stretched between them, which will serve as a guide for the installation of all subsequent elements. This simple move allows you to get the ideal geometry (don’t forget to check the slope angle, verticality or horizontality).

On top of the racks, tie-downs are attached - bars, to which the side rafters are then fixed and onto which the tie-down of the upper triangle is installed. The ties are secured using metal corners. Since the beams are long, they sag. This is later eliminated - after installing the upper rafter legs - with the help of vertical beams of fixed or adjustable height. And temporarily they can be supported with racks (so as not to pull the entire system).

To make it easier to maintain the desired angle when installing the side rafter legs, templates are made according to which cuts are made. But since the geometry of buildings built with your own hands is rarely ideal, adjustments may be necessary. To check the resulting angle of inclination, another template is knocked down from several boards, which is used to check the correct installation.

If the standard length of lumber - 6 meters - is not enough, either order the required length (expensive) or increase it. When building up, two boards measuring at least 0.6 meters (30 cm on each side of the joint) are nailed to the joint. They are nailed on both sides or bolts are used.

A reliable way to build rafters. The length of the “patch” is at least 60 cm

After installing the side rafters, all that remains is to install the top ones. A template is also made for them, pre-cut on the ground, and installed on top.

Upper part can be done in different ways. Its structure depends on the width of the base. How to make it, look at the photo below.

Since the structure of an attic sloping roof does not provide for the presence of a ridge, a beam is placed in the middle to tighten it, to which the slopes are attached, fixing the triangle in the required position.

Nodes and their drawings

When installing a rafter system, questions may arise regarding the assembly of nodes—the intersections and connections of several structural elements. In the photo you see drawings of key connections.

The second option for connecting the side layered rafters and the upper triangle. Bolts are used for more secure fastening.

How to make a do-it-yourself fastening of the upper tee and rafter leg on an attic roof

Methods for attaching rafter legs to the mauerlat or, as in this case, to the side beam are shown in the figure below. To make it easier to mount a heavy element, a thrust board (bar) is nailed to the bottom of the rafter, which limits its movement: the board rests against the edge and does not allow it to sink lower.

If you have made such a decision on how to build an attic, it will be correct. Before building an attic in existing house, first you need to decide on its shape, and whether the roof will be completely converted into an attic floor or not.

After all, the construction of an attic is considered not only more economical, but is also a process that will require much less labor in comparison with the construction of the next floor. It is these facts that make the construction of an attic very popular. Projects country houses with an attic, as a rule, they have a special or, as builders call it, a “broken” roof, since it makes it possible to make maximum use of the usable area.

When deciding how to build an attic, special attention must be paid to the quality of the roof. Since it should not only have an aesthetic appearance, but also have excellent thermal insulation, and also have good waterproofing. The best thermal insulation material roof covering is either slate or ceramic tiles, but under no circumstances use metal tiles, as they tend to get very hot in the sun. In this case, how to build an attic with your own hands? On initial stage During the construction of a building, it is possible to make calculations of the load-bearing structure with maximum accuracy.

It should be taken into account that the rafters must be installed at an angle (from 30 to 60°), since an increase in the degree of inclination leads to a decrease in the usable area of the attic.

To solve the problem, you can insulate the attic from the inside using mineral wool.

A residential attic space requires a large layer of insulation. The material must meet fire safety requirements and be non-toxic. Mineral wool is one of the most suitable options.

Types of material

The main types of mineral wool are basalt wool and glass. Each has its own properties, pros and cons.

Basalt wool

Basalt wool is made from rock gabbro-basalt. Carbonate rocks are specially added to it, which allows you to regulate the acidity module. Material with higher acidity is more resistant to moisture and more durable. Adding to basalt wool binders: bitumen, synthetic, composite, bentonite clays - holds fibers together and helps give the desired shape.

Glass wool

Glass wool is a mineral material, the production of which uses raw materials used in glass production, as well as waste and broken glass.

The properties of glass wool are different from basalt, its thickness is 3–15 microns, and its length is several times greater than basalt. Therefore, glass wool slabs are more elastic, have greater strength, and are resistant to vibrations. Glass wool is fire resistant and can withstand temperatures up to 450 °C.

Despite all the advantages of glass wool, there is one significant drawback that reduces the popularity of its use. When laying this material, many small particles are formed that are harmful to health. Therefore, installation is carried out in special clothing, shoes, and a protective mask. You won’t be able to clean them after work; you’ll have to throw them away.

Nuances of isolation

When insulating a roof, it is better to use cellulose wool; it provides better moisture conductivity and does not allow moist air to accumulate under the roof.

The main difficulties of insulation appear when working on the slopes of a roof that has a truss structure.

Here it is necessary to use dense wool, which can be securely placed between the rafters. It should be light and elastic.

The main advantages of mineral wool remain its non-flammability, soundproofing, good thermal insulation properties, vapor permeability, high environmental friendliness, and relatively affordable price. It is produced in slabs, mats, cylinders, and there are options coated with foil.

If the size of the insulation is larger than the distance between the rafters, it is cut into the necessary pieces, adding a few centimeters for a tight fit.

This method is well suited for insulating attics and living spaces located directly under the roof. The disadvantage is the reduction in internal dimensions due to a layer of wool, plasterboard and additional finishing.

Thermal insulation methods

Depending on which structural element of the building is insulated, there are 2 ways to insulate the roof from the inside.

Thermal insulation of the floor

The first option is to insulate the floor. The method is inexpensive and very easy to implement. It consists of laying wool on concrete base slabs or, in the case of a wooden floor, between structural elements. Any type of mineral wool will do, even soft and granular. Installation is simple, there is no need to go around the rafters, as when insulating roof slopes, you can easily fill all the gaps and cracks.

Thermal protection of stingrays

The second option is to insulate the roof slopes. If the attic space is not in use, then this option is not economically viable. The consumption of materials increases significantly; more time is required due to bypassing the rafters and additional fastening of mineral wool.

Insulation of slopes can be done in two ways: on top of open rafters or between them. With the first option, wooden beams remain visible inside the room and have an additional decorative function.

Sequence of work

Regardless of which method of mineral wool insulation is used, the general algorithm of actions is as follows: surface preparation, waterproofing, installation of insulation, laying a vapor barrier, sheathing.

Preparatory activities

Before starting work on thermal insulation, the surface to be insulated must be prepared. The structure is inspected, if necessary, identified defects are eliminated, and cleaned of dirt and debris. TO preparatory work This also includes calculating the amount of material.

The thickness of the insulating layer should be at least 15–20 cm, so if you choose wool of a smaller thickness, it will need to be laid in two layers.

Waterproofing

To protect the roof from moisture, waterproofing is installed on the insulated surface. It is laid overlapping, secured with a stapler and gluing the joints with tape.

It is important to install the waterproofing membrane so that there is a ventilation gap between it and the insulation, and the material completely covers the entire rafter system and extends slightly onto the walls.

Then, over the insulation, a batten of battens is nailed to the rafters, which will secure the material and provide a ventilation gap. It is better to treat all wooden structural elements with a special antiseptic.

Laying insulation

After installing the waterproofing, you can begin installing the insulation. To do this, mineral wool is cut into pieces approximately 5 cm wider than the distance between the rafter beams. Then, after installation, the material will straighten out and better fill the space. Installation of mineral wool should be carried out in such a way that the material fits as tightly as possible to the beams and there are no gaps left.

Arrangement of vapor barrier

After laying the insulation, it is necessary to protect it from water vapor coming from inside the room. If this is not done, the mineral wool will gradually become wet and lose its thermal insulation properties. Therefore, a vapor barrier is installed on top of the insulation. As a vapor barrier, special foil materials, polyethylene films or roofing felt are used.

To ensure tightness, the vapor barrier is laid with overlapping layers, and the seams are taped. It is important to install foil vapor barriers with the metallized side inside the attic. Fix the structure wooden slats, onto which the sheathing (lining or drywall) is subsequently attached.

Insulating the roof with mineral wool is one of the most affordable ways to create a warm and cozy attic. The main thing is to strictly follow the technology. And then everything will work out.

Try to pay attention to insulating the attic roof special attention. If the roof is not insulated, do not expect heat in the attic. A roof is a roofing covering. An attic roof is a “roofing pie” consisting of several layers: a vapor barrier layer on the inside, a waterproofing layer on the outside, insulation between them and an air gap.

Various materials are used as insulation. The characteristics of the materials used depend on several factors: the functional purpose of the room, humidity level, critical temperatures, loads, and so on. Non-flammable basalt materials are the best option.

Various materials are used as insulation for the attic from the inside. The most popular and simplest is mineral wool.

Polystyrene foam is not recommended. It's flammable. Has poor vapor conductivity. Mineral wool is perfect. It is pressed into a slab. WITH inside, a vapor barrier layer is located. WITH outside– waterproofing (special layer).

Nowadays, the use of sprayed polyurethane foam to insulate the attic from the inside has become quite popular. This method is also quite economical and very effective.

If an attic is made from an old attic, then, as a rule, the rafters are retained. The load is minimized by using low-density insulation materials, since they are much lighter. The disadvantage is that they are blown by the wind. Additionally, windproof, vapor-permeable material is laid.

Approach the installation of insulation with due care. Do not forget about the presence of sufficient ventilation space between the roof covering and the insulating layer.

The attic is warm in winter and cool in summer only when all the work on insulating the walls and roof is done correctly. Do not ignore these rules and your budget will have a tangible effect.

Attic - fashionable architectural element. F. Mansara (French architect) three centuries ago was the first to use attic space not only for economic purposes, but also for housing.

Nowadays it is quite widely in demand in civil and industrial construction. IN individual construction the attic is experiencing a real boom. It is equipped both during the construction of a new house and during the repair of attic spaces (roofs).

The house takes on an expressive appearance, and the attic space is used functionally and efficiently. The area occupied by the attic is decent. Additional space for a nice recreation room (billiard room) or a wonderful summer bedroom. Keeping it warm and dry will make it habitable.

A well-insulated and well-made attic can become an excellent relaxation and work room.

How to properly insulate an attic from the inside? A pre-developed project is required. It will allow you to prepare well and provide for all the nuances. A competent approach to attic insulation and the mandatory use of high-quality materials will help to avoid mistakes that can play a very bad role over time.

In a private home, as a rule, there are large heat losses. Basically, this happens through the ceiling and upper floors. The processes of wetting (drying) the insulation occurring under the roof worsen its quality. Microclimate disturbances often cause cold inside the house. This arises mainly due to poor quality construction work related to the attic.

It is recommended to insulate the attic not only from the outside, but also from the inside. Insulation is a technically quite complex process. Impressive area attic floor, its maximum contact with the external environment, the complexity of the design - requires certain knowledge and skills from the one who will be involved in its insulation.

Attic structures are distinguished by the fact that they can be constructed from the most various materials, for example, made of wood, metal, reinforced concrete. There are no restrictions here, you just need to ensure stability and proper insulation. Ceilings in rooms can also be very different: inclined, flat with one inclined wall, formed by two slopes converging under acute angle. All this and much more has made the attic so popular for more than four hundred years.

The main advantages of such a roof are as follows:

1. The possibility of adding an attic, that is, using the infrastructure of an existing building. In this case, there is no need to completely disassemble the entire roof, which allows significant savings during the work. This is an additional floor that can be used for its intended purpose.

2. The living space of the house is increased by reconstructing an unused attic space. This allows you to add a full second floor at relatively low cost.

3. In places with fairly dense buildings, an attic second floor is the best way out.

4. The appearance of the building improves, the structure acquires a finished, holistic appearance.

5. Attics can be built on more than just one level. If necessary and in compliance with all the rules and requirements, it is possible to build a two-tier attic, which will decorate any building by adding additional living space.

6. When constructing an attic, heat loss through the roof of the house is greatly reduced. This also results in lower heating costs during the winter months.

7. Construction of attics is possible even in a residential building without the need to move out residents. To do this, it is not necessary to use heavy construction equipment; all work is carried out directly on the roof of the building in the shortest possible time. A new floor can be erected with virtually no problems or costs.

But the construction of an attic also has its disadvantages, as with any structure. It is worth noting such disadvantages as:

1. When constructing such a room, some of the usable space is lost.

2. Sloping and sloping ceilings greatly reduce the height of the walls; ceilings in attics are usually low, not exceeding 2.4 meters.

3. In many cases, windows can only be located in the ceiling, which is not always convenient.

4. Rafter structures begin to quickly degrade due to lack of ventilation. Typically, their service life is about three times less than with a cold attic.

5. Large amounts of snow often accumulate on roof windows in winter, which reduces the level of already insufficient lighting.

Types of designs

When deciding how to make an attic, you must first decide what type of rafter system will be used. Characteristic feature The attic structure is its broken, rather steep configurations, but we must not forget that this is not an aesthetic function, but a purely practical one. Such broken shapes provide:

· correct transfer of all loads to load-bearing walls;

· allow you to effectively protect the entire structure from precipitation;

· give resistance to such negative phenomena as sudden temperature changes, rainfall, snowfall, formation large quantity ice.

The most simple form a residential attic is a triangle, the most complex one is with a break. It is recommended to make all horizontal logs and vertical posts from thin wooden beams.

Among the rafter systems used for the attic floor, the most commonly used are:

1. Hanging type rafters. They rest on the walls, creating a horizontal load. If you decide to build an attic second floor using this type of rafter system, then you need to take into account the design features. To connect the beams, intermediate supports are not used here, only special ties made of metal or wood.

2. The inclined type of rafter system is recommended for small cottages in which the load-bearing wall is located in the center or there are intermediate supports. The rafters rest on the outer walls, the middle part of the structure rests on the inner wall. Such a simple system can only be used for those houses in which the distance between separate load-bearing walls is no more than six and a half meters.

3. Hanging and inclined rafters can be in the form of right triangles, which have a stop behind the load-bearing wall. In this case, there is no need to erect a mauerlat; ordinary beams are used for rafters. Struts are required, all racks cut into the floor beams, rafters are secured with anchors.

Construction stages

So how to properly assemble an attic structure? The sequence of all work should be strictly observed, which will allow you to build a strong, reliable attic. It is imperative to correctly determine all loads, which only experienced designers can do.

The construction of the attic involves the following work:

1. Dismantling the old roof. In this case, it is not necessary to completely disassemble the ceiling. Unless this is provided for by the project.

2. If necessary, the floor structures are strengthened. This is done so that the second floor (attic) does not place unnecessary loads. If necessary, an additional layer of waterproofing is laid at this stage.

3. Construction of the rafter system, insulation of the attic itself.

4. Installation of windows.

5. Internal and external finishing of the building.

To build an attic, it is recommended to use wooden beams that have a cross-section of fifty by one hundred and fifty centimeters. In this case, the following sequence of work is observed: first, the frame of the future structure is made, after which the support beams and rafters are strengthened. After installing the stepped bevels, waterproofing work and installation of insulation are carried out. Now you can strengthen the sheathing and lay the roofing material. Finishing work is carried out last, after all the windows are installed.

The attic second floor must be insulated to ensure the safety of the structure and comfortable living conditions. For such a process to become effective, it is necessary to observe the construction of a multi-layer “pie”, which includes:

· internal finishing material on the ceiling of the attic room: moisture-resistant plywood, plasterboard, etc.;

· vapor barrier membrane;

· insulation (usually mineral wool in rolls or slabs);

· laying waterproofing;

· installation of roofing covering (tiles, corrugated sheets, etc.).

The insulation layer should be two hundred and fifty to three hundred millimeters; often a special frame is made for its installation, attached perpendicular to the rafter system. During installation, gaps and cavities should not be allowed between the insulation boards, as this will lead to significant heat losses and low thermal insulation efficiency.

The attic is not only beautiful, but also a very functional architectural element that is capable of fulfilling the numerous tasks assigned to it. This is a great place for living space. Here you can arrange a children's room, a playroom or a large gym.

The technology of attic construction consists of high-quality and consistent performance of the following work:

1. Development of a project for the construction of an attic floor or its conversion.

2. Dismantling of old roofing structures.

3. Strengthening wall structures top floor.

4. Installation of waterproofing and thermal insulation of ceilings.

5. Construction end walls attic room.

6. Construction of the attic roof, its insulation and finishing.

7. Installation of attic windows.

8. Arrangement of a new living space.

To work, you will need to purchase materials and tools. It is usually necessary to have wall panels(or other material) for cladding the end walls of the attic, thermal insulation materials for walls and pitched roofs, roofing materials, beams for the roof structure, finishing materials, etc.

After preparing everything that is required for construction and developing the project, you can begin the main work. First you need to make a frame for the roof. The rafters can be made from beams measuring 50x150 cm. The structure must be well secured, install slings, support blocks, erect attic walls and install rafters. The rafter structure must be installed securely and accurately. After this, stepped wall slopes and attic partitions are installed, and work on insulation and waterproofing of the attic is carried out. Next, you should build a sheathing for the attic roof, lay a heat insulator on it, strengthen it and then finish the roof with roofing material. After this, the installation of doors and windows, interior decoration and arrangement of the premises are carried out.

Attic roof

In order to understand how to make a roof in the attic correctly, knowledge about the features of such a room will not be superfluous. Leaks in the roof and other roof defects will have a negative impact on the entire building to a much greater extent than the same defects in a regular roof. attic roof. In this case, water will flow into the living room, which will most likely lead to repairs to the room.

The main feature of the attic roof is that it is exposed to moisture both from the outside and from above (snow, rain, etc.) and from below (the formation of condensation from the moisture in the air of living spaces on the lower floors). To eliminate this problem, the attic construction technology involves installing a special vapor barrier layer that prevents the penetration of moist and warm air from living rooms to the tiles.

It is also necessary to waterproof the roofing material and ensure sufficient ventilation of the roof. attic space. As a roofing covering, you can use soft bitumen shingles or metal tiles.

Insulation and arrangement of the attic

Due to the fact that the attic is usually used as a living space, great importance is attached to its thermal insulation. High-quality insulation of the attic roof ensures the creation of a comfortable microclimate in such a room and other rooms of the house, effective heat retention and a long service life of the entire building. There are several ways to insulate an attic. Insulation from the outside implies general insulation of the entire house.

Optimal and most in an efficient way is additional internal insulation, which involves the use of a multilayer thermal insulation structure consisting of the following layers:

· The first layer (internal) – finishing material, for example, sheets of plasterboard, plywood and other materials that form the ceiling of the attic room

Second layer – vapor barrier film

· The third layer is a porous thermal insulation material (mineral wool, etc.)

· Fourth layer – waterproofing material, laid to form a small gap and allow water to easily drain out

The fifth layer is roofing (metal tiles, soft roof etc.).

Advice from the master!

In addition to insulating the attic roof, it is also necessary to insulate its walls and floor. Arranging a room in the attic includes performing work such as installing attic windows, internal partitions, doors, as well as decorative finishing.

Installation of pitched roof windows – best solution for the attic. Glazing can occupy a significant surface area of the attic, minimally 12.5%. The glass used in such windows is special: it does not break under strong pressure or impact, but crumbles into granules that do not have sharp or cutting surfaces.

Specifics attic premises allows you to arrange them in a special way, decorate them in an unusual and original way. Many designers recommend using translucent plastic partitions or partitions decorated with translucent fabrics to zone these rooms. When choosing a shade for wall decoration, it is recommended to give preference to light colors that will make the interior light and pleasant. It is not recommended to decorate roof windows with curtains, but it is better to choose light-colored blinds.

Having learned how to build an attic yourself, arrange it, create a comfortable, cozy and unusual room, you can try to build an upper floor at home. This is a great way to make your home unique and individual, increase its usable area and equip additional living space.

You should also take into account that the attic must be at least 3 meters wide, and the height in the center of the room is at least 2.2 m. But in this case, how to build an attic that was not originally planned? Additional questions always arise, such as, for example, the arrangement of stairs. You can place a ladder in the area attic hatch, which will simplify construction, and the spiral staircase will also make it possible to save space. In order to prevent the wood from rotting and being damaged by pest beetles, all wooden elements of the roof must be treated with an antiseptic.

To increase fire resistance, it is necessary to impregnate with fire retardants (special wood fire retardants). Also, when deciding how to build an attic, it is necessary to take into account that the attic and the attic differ primarily in climatic conditions. The attic is a less ventilated room, which causes condensation to form on the insulation. Therefore, it is necessary to leave a space between the insulation and the roof (at least 50 mm), and another layer of vapor barrier should be laid on the inside of the insulation. When carrying out thermal insulation work, you should also not forget about insulating the walls, which are thinner in attic structures. Their thermal insulation layer must have a thickness of at least (250-300 mm). Self-construction an attic floor is possible, but for this it is necessary to carefully plan the execution of all work and thoroughly follow the existing technology.

Of course, it would be much easier not to disassemble it, but to reinforce the ceiling above the premises of the house. As load-bearing structures You can use bars or a channel.

After the ceiling has been strengthened, you need to decide on the size of the attic rooms; their height at the walls should not be lower than 1.5 m, and in the middle part it should be a standard height of 2.5 m, or even more. After this, a guide profile (PN) is attached to the floor for drywall, and above it, the same profile is attached to the rafters. Markings are made using a plumb line, tape measure, or strong cord. Then the profile of the racks (PS) is installed in the guide profiles, the pitch of which should be 600 mm. On sloping ceiling surfaces metal profile Can be mounted horizontally. After this, when the location of the rooms is clearly visible, several skylights can be installed on the roof so that the rooms are well illuminated with natural light. In addition, it will be necessary to make an opening in the ceiling to install a staircase to the attic. The least amount of space on the ground floor will be occupied by a single-flight staircase with goose-step steps.

After this, with outside the frame of the attic partitions can be sheathed with waterproof plasterboard, and then electrical wiring can be laid inside the frame to connect switches and sockets. Next, mineral wool slabs with a thickness of 100, or, in extreme cases, 50 mm are placed in the frame. On the inside they are closed with a vapor barrier, and attached interior lining made of waterproof plasterboard, holes are made in it for the installation of sockets and switches, and wires are brought out into them for connection. Then the ceiling and inclined surfaces are hemmed, which are also insulated with a mineral wool board.

Modern people try to make the most of the space in their home. Therefore, the proposal to arrange extra space under the roof is always met with enthusiasm. It is much easier to plan the construction of an attic at the stage of building a house, but you can make an additional superstructure over an old building.

How to make an attic on an old house

The presence of an attic not only increases the living space, but also gives the building a colorful look.

The attic turns a country house into a fabulous building

An old house can be updated by building an extension in accordance with existing codes.

The attic superstructure begins with calculating the strength of the old house

First you need to decide whether the existing foundation and walls can withstand the load of the attic floor and the new roof. If they have a sufficient margin of safety, then you can begin to remodel the house. Otherwise, they should be strengthened.

Old brick walls sometimes they seem durable, but with additional load over time, cracks may appear in the solution. Therefore, it is necessary to immediately examine their condition, and, if necessary, tie them with a rigid belt. This is done as follows:

- metal pillars with a cross section of 10x10 cm are inserted into the foundation with their lower edge, and connected with the armored belt of the first floor with their upper edge. Installed around the perimeter of the house every 2 meters;

- metal reinforcement with a cross-section of 12 mm is laid in grooves and tied around the walls of the house: from the bottom of the window every 2 meters upward;

- spreads over the reinforcement metal mesh with a cell size of 2x2 cm, which after completion of all work is covered with plaster.

The foundation is strengthened by tying it with a reinforcing belt on all sides.

If old foundation may not withstand the attic, then it must be sheathed with reinforcement

Having decided on the strengthening of the building, you can proceed to choosing a project for the future superstructure. It should look harmonious against the background of other buildings and match the style of the entire house.

The calculation of the dimensions of the internal upper room and the necessary materials for construction will depend on the type of attic roof

There are several types of attics:

- single-level with a gable roof - low ceilings with a small living area;

A single-level attic with a gable roof is the simplest type of superstructure for small buildings

- single-level with a sloping gable roof - increased internal space, but serious costs of money and time for construction;

A one-level attic with a sloping gable roof is usually built on a brick house

- single-level with cantilever extensions - complex design, allowing you to get even more space, since the attic frame extends beyond the building, and the windows are installed vertically;

A one-level attic with cantilevered extensions allows you to get a lot internal space by increasing the upper structure

- multi-level with mixed roof support - used in the construction of a new house, built only by specialists.

A multi-level attic with mixed roof support is usually not installed on old houses due to the complexity and large volume of work

Video: converting half of an old roof into an attic - an easy way

Remodeling the roof into an attic - comparatively cheap way increasing living space. A private house usually has a pitched roof, so you can make an additional spacious and bright room with your own hands.

Internal wood lining makes the attic warm and bright

And if the house is large enough in length, then the attic can turn into a real floor: with several rooms and even a balcony.

A large attic allows you to divide the area into different living areas

Advantages of creating an attic:

- the possibility of installing one or more new living rooms;

It is most convenient to furnish an attic with low ceilings under a gable roof with low sun loungers

- low costs compared to the construction of a full floor or side extension to the house;

- update appearance buildings;

A house with an attic under construction always attracts the attention of passers-by and makes them interested in the final result.

- opportunity to observe beautiful view from the attic window.

A lot passes through the windows in the attic sunlight, illuminating the room all day

However, this solution also has certain disadvantages that must also be taken into account:

- the need for insulation and soundproofing of the ceiling and a new roof, installation of several double-glazed windows;

- difficulty of carrying out additional heating and lighting in the upper part of the old house - you will have to combine it with home wiring or use a stand-alone connection;

To heat the attic with access to the balcony, you can use a stove-stove

- planning part of the home space for a staircase leading to the attic;

The staircase leading to the attic must be fenced for safety

- the need to purchase special furniture for a sloping roof or purchase squat models: low cabinets, sofas and tables.

Low furniture is best suited for attic interiors

The presence of sloping walls makes the room unusual and romantic, but with this decision you will have to take a more responsible approach to design development. You can make furniture for the inclined superstructure yourself or assemble a single set from existing multi-level models, painting everything in the same color.

You can make furniture that follows the slope of the attic yourself

So, the main disadvantage of converting an attic space into a loft is that it requires an investment, but it is worth it.

Building an attic will cost much less than creating an additional floor, regardless of what materials are used to build the walls. After all, to create them you will need basic material, insulation and finishing, while for an attic superstructure you only need roofing insulation and a new rafter system.

The superstructure is made of symmetrical or asymmetrical shape. Internal walls are designed both inclined and vertical.

Having studied the diagrams of single-level attics with different types of roof, it is easier to make a choice when planning

Converting an attic into an attic does not require dismantling all existing structures. But you need to make sure that the ceiling is reliable: check its condition, reinforce it with wooden or metal beams, cover with new boards. Then it will be able to withstand the weight of furniture and people.

For frequent ascent to the attic, you will need to make a convenient staircase, provide for the installation of ventilation, natural and artificial lighting, carry out interior decoration - all this will create a cozy and comfortable room.

Add-on with sloping roof, issued in light colors, visually increases the space, and color spots add brightness to the interior

When constructing an attic floor, the following conditions must be met:

- the rafters are made of laminated veneer lumber with a thickness of at least 250 mm, so that the required amount of insulation can be laid;

- Foamed polystyrene is used for insulation due to its low weight and high thermal insulation characteristics;

- a gap is left between the thermal insulation and the roofing material to ensure natural ventilation;

- A hydro- and sound-proofing layer must be laid.

Converting the roof into an attic with your own hands

During the construction of a house there is usually a lack of funds, so many people refuse to build a second floor. Or another situation may arise when an old one-story small house is purchased along with the plot. In both cases, there is an affordable option for increasing living space - rebuilding the attic space into an attic with your own hands.

Creating a Project

Before starting work, you need to draw up a plan and develop a project with accurate drawings. Correct calculation will allow you to get a cozy, durable and secure premises. You can perform all the calculations yourself or entrust it to specialists.

You can draw a plan and develop a preliminary design yourself by studying different options on the Internet

Strengthening the walls and foundation may be necessary if complete replacement rafters If the roof is partially redone, then reinforcement may be necessary only for the ceiling. You also need to immediately decide what types of windows will be used in the attic: the reinforcement in the rafter system will depend on this.

The location of all windows in the attic roof must be thought out in advance and this data must be included in the project plan

Rafter system

Rafters can be layered or hanging. The former rest on the internal walls of the house or additional supports, and the latter on the external walls.

In attics, layered and hanging rafters are used

Hanging rafters are best suited for the attic.

An attic with hanging rafters looks more beautiful and benefits in the size of the internal area

The attic usually occupies the entire space of the attic, and its walls are combined with external ones.

The best option for creating an attic is a layered rafter system

The rafter system consists of different load-bearing bars. To understand the structure of the entire structure and build it correctly, you need to understand the purpose and operation of its individual elements.

Image individual elements rafter system helps to understand the structure of the entire structure

Refurbishment of premises

If the attic height is sufficient, there is no need to alter the rafter system. It is enough to inspect the old rafters, identify possible flaws and eliminate them.

If the rafter system is in good condition, you can begin arranging the floor. Insulation is first laid between the joists, after which the surface is sheathed with ordinary boards or sheets of OSB or chipboard.

The floor in the attic is insulated and covered with boards

Before laying the insulation, all necessary communications are installed between the rafters, and places are cut in the roof for installing windows. carried out before insulation.

All wires and pipes of communications must be placed in special corrugations

Care must be taken to create natural ventilation of the under-roof space through vents so that moisture does not accumulate inside the room.

Roof insulation

The roof must be insulated correctly and efficiently - the microclimate under the roof will depend on this. Typically, mineral wool, polystyrene foam or sprayed polyurethane foam are used as insulation.

A thick layer of heat insulation is tightly laid and fixed between the rafters so that there are no cracks or gaps left anywhere. Waterproofing is installed along the upper part of the roof - between the roof and the insulation - and then thermal insulation material is laid on the side of the room. Then the inside of the insulation is covered with a vapor barrier film.

For better ventilation, a small distance is left between the roofing material and the insulation: this way air circulates through the holes in the eaves and ridge. If the roof is covered with corrugated sheets, then the gap thickness should be 25 mm, but if flat material, then you need to bring it to 50 mm.

When creating thermal insulation for an attic, the sequence of layers must be strictly observed.

When planning to climb to the attic, you need to take care of the convenience and safety of movement. Therefore, the staircase is usually installed inside the house. It is constructed from wood or metal: it can be either a screw or a marching structure.

The staircase to the attic may be different types and designs, which allows it to fit into any interior

An opening is cut in the ceiling of the first floor, which is reinforced around the perimeter with metal or wooden strapping.

The design of the stairs to the attic must be strong, reliable, safe and beautiful

Interior decoration

In most cases, plasterboard slabs are used for wall cladding, and the seams between them are plastered. Wallpaper is pasted on top or decorative plaster is applied. An alternative option is lining or natural wood.

If some rafters protrude through the walls into the attic, then they can be decorated as decorative elements and even used in the form of a horizontal bar for hanging a hammock, swing, chandelier and other devices.

Decorating the visible parts of the rafters in the interior of the attic is an interesting and creative matter.

It is not recommended to use heavy finishing materials in the attic, as they increase the load on the walls, ceiling and foundation of the building.

There are many options for interior decoration of the attic, but it is advisable to use only lightweight materials

To cover the floor, you can use laminate or linoleum, but it is better to avoid tiles or porcelain stoneware.

Installation of the roof of the attic floor

The roof of a residential superstructure must consist of the following layers (the order of arrangement is from the street to the internal space):

Video: why and how to properly lay layers on the attic roof

Calculations of an attic roof for a house

Determining the total weight of the roof

To calculate total weight roofing materials, the specific gravity of one square meter of covering must be multiplied by total area mansard roof. To obtain the weight of one square meter, you need to add up the specific gravity of all the materials that make up the roofing pie and multiply it by the safety factor (1.1).

If the thickness of the lathing is 25 mm, then its specific weight is 15 kg/m2, insulation 10 cm thick has a specific weight of 10 kg/m2, and the roofing material ondulin has a weight of 3 kg/m2. It turns out: (15+10+3)x1.1= 30.8 kg/m2.

According to existing standards, the floor load in a residential building should not exceed 50 kg/m2.

Determining the roof area

To calculate the surface of a sloping roof, you need to break it down into simple shapes (square, rectangle, trapezoid, etc.) and determine their area, and then add everything up. To define a surface gable roof you need to multiply the length by the width, multiply the resulting value by two.

Table: determining the area of the attic roof

When calculating the angle of inclination, the climatic zone in which the house is located is taken into account, and that it is convenient to move in the attic at full height

It is also necessary to calculate the roof slope. Usually the angle is 45–60 degrees, but when determining it, it is necessary to take into account the climatic zone in which the house is located, the type of attic construction, snow and wind loads, and the architectural design of the house.

The greater the angle of inclination of the roof, the less will be the load on the rafter system, but the consumption of materials will increase.

Calculation of the rafter system

When choosing a rafter system, you can choose the following options:

- hanging rafters;

- inclined type;

- ridge run;

- combined design.

If the roof length is more than 4.5 m, then they can be used for reinforcement. support purlins and struts. If the length is more than 7 meters, a ridge beam is installed.

For wooden rafters timber with a thickness of at least 70 mm is used. Their installation step should be 50 cm.

Over a large area, it is better to attach a metal rafter system: due to the increase in the distance between the rafters, the absence of spacers and struts, the weight of such a structure will be less than that of a wooden one, and the strength will increase significantly.

If the attic area is large, then it is better to install metal rafters

Calculation of the required amount of materials

To carry out the calculation you need to know the following parameters:

- width, thickness and pitch of rafters;

- distance from the edge of the roof to the rafters;

- the size of the sheathing boards and the spacing between them;

- size, type of roofing material and overlap between its sheets;

- type of steam, hydro and heat insulating material.

The roof is divided into simple shapes and the required amount of each material is determined. Simple mathematical formulas are used for this.

The results obtained are converted into standard values: for wood - in cubic meters, for roofing materials, steam, hydro and thermal insulation - in square meters. And you can go to the store.

Common mistakes

Most often, when calculating independently, errors are obtained during the determination required quantity insulation. If climatic conditions severe, then its volume will have to be increased, otherwise it will not be possible to create it in the attic comfortable conditions accommodation. The insulation is installed on the floor of the house, gable walls and roof slopes. But the thickness of the insulation can be different everywhere.

Video: calculation of a mansard roof with diagrams and load

The attic floor allows for additional living space and gives a private home a modern, attractive appearance. It’s not difficult to create an attic with your own hands, you just need to correctly draw up a project, perform calculations and carry out high-quality installation of all materials. And the result will please the owners for a long time.

A do-it-yourself mansard roof built over a house allows you to increase the total living space with minimal financial investments. The most popular options include gable sloping roof, the installation technology of which is not complicated.

Project development

By “breaking” the roof slopes at different angles, you can increase the volume of space under the attic roof. The broken structure, like other types of attic roofing, is more massive and heavier than a standard gable roof, which should be taken into account when equipping the attic floor during the process of reconstructing a house. It is first necessary to examine the condition of the foundation and walls of the structure to determine whether they can withstand increased loads. If the construction of a massive attic structure is planned at the stage of preparation for DIY construction, this should be taken into account when developing the design of the foundation and walls of the house.

You should be careful when creating a mansard roof project, since errors in calculations or incorrectly selected parameters of the elements of the rafter system can lead to damage to the roof itself, and in some cases, to the walls of the house during operation.

It is recommended to entrust the development of a mansard roof project to professionals. It is also possible to use special computer programs that perform calculations optimal angle roof slope and other parameters. All calculations are performed in accordance with the SNiP document “Loads and Impacts”.

When choosing an attic project, the construction of which can be done with your own hands, you first need to pay attention to the dependence of the room parameters on the angle of inclination of the roof. The living space must have a height of more than 2.2 meters. If the roof slopes are straight, then their angle of inclination seriously affects the width of the room.

A broken attic roof allows you to maximize the expansion of the room, providing required height ceilings along its entire width. In this case, the side (lower) rafters are located at an angle of about 60 degrees, and the angle of inclination of the upper ones can be chosen at your discretion, based on aesthetic preferences, as well as snow and wind loads characteristic of the construction area.

Roofing pie and other elements

If you are planning to make an attic roof with your own hands, it is necessary to include in the project the use of certain materials for installing the roofing pie. They include:

- waterproofing;

- vapor barrier;

- insulation;

- roofing material.

The choice of insulation affects such a parameter as the pitch of the rafters - in order to save thermal insulation material, it is recommended to position the rafters in such a way that the slab or mat fits tightly between them. The type of lathing (solid or sparse) and the spacing of the sparse lathing depend on the choice of roofing covering. It is worth noting that the installation of the roof of the attic floor provides for the creation of not only high-quality insulation, but also effective ventilation roofing system.

The choice of insulation affects such a parameter as the pitch of the rafters - in order to save thermal insulation material, it is recommended to position the rafters in such a way that the slab or mat fits tightly between them. The type of lathing (solid or sparse) and the spacing of the sparse lathing depend on the choice of roofing covering. It is worth noting that the installation of the roof of the attic floor provides for the creation of not only high-quality insulation, but also effective ventilation roofing system.

Materials and tools

To ensure safety, the construction of the rafter system and roof should be carried out using fireproof, environmentally friendly materials. Wood materials are treated with fire and bioprotection agents.

To build a rafter system for a private house with your own hands you will need:

- wooden beam with a cross section of 50×100 mm;

- board 150×50 mm;

- unedged board;

- 80 nails, self-tapping screws and other fasteners;

- annealed wire (diameter 3-4 mm);

- level;

- plumb line;

- roulette;

- hacksaws;

- axes;

- hammers;

- sharp knives carpentry

Usage quality instrument simplifies and speeds up installation wooden structures with your own hands. Step-by-step instructions for carrying out the work can be found in the video.

Mauerlat device

The base of the rafter system of the attic roof is a mauerlat made of timber or strong boards. A gable roof requires laying a mauerlat on the long walls of the house. The Mauerlat not only allows you to securely fasten the lower part of the rafters, but also helps to distribute the load evenly when it is transferred to the walls and foundation of the building.

To secure the Mauerlat board or beam, metal pins are used, fixed in a monolithic concrete beam made in the upper part of the wall, or annealed wire embedded in brickwork. When attaching the Mauerlat to the upper rim wooden wall wooden dowels are used. The Mauerlat device requires high-quality waterproofing wooden beam. For this purpose, roofing felt or other durable materials with water-repellent properties can be used.

Installation of the Mauerlat is necessary if you intend to build a roof frame with your own hands, the rafters of which rest against the upper part of the wall with a beveled end or a special cutout. If an attic is designed, the width of which actually corresponds to the width of the house, the rafters rest with their lower end against the outer supports. The supports are powerful beams laid across the long walls. The number of supports must correspond to the number rafter pairs. The beams are attached to the walls in the same way as a Mauerlat, and waterproofing is also used.

The Mauerlat or support beams must be securely fastened to the walls, as these elements prevent the roof from moving under strong wind loads.

Construction of the supporting structure

The construction of the frame of a sloping attic roof begins with laying supports under the racks, which must be positioned strictly symmetrically relative to the axis of the building. The distance between the supports is equal to the width of the future attic. First of all, U-shaped arches are installed on the gables of the structure. Each arch consists of two support posts connected by a lintel. To make racks, a beam is used, the cross-section of which must be no less than the cross-section of the support underneath.

The racks are installed plumb, strictly vertically. A jumper is attached to them, the horizontalness of which should be checked during installation. Based on the dimensions of the first arch, a second one is made on the other front. It is important to level the structure. A cord is stretched between the U-shaped arches, which must be positioned strictly horizontally. If necessary, one of the arches is dismantled and adjusted exactly to size. Focusing on the stretched cord, you should install the remaining arches. Their number and pitch depend on the designed pitch of the rafters, since the upper end of each rafter is attached to the corresponding rack. This provides the necessary rigidity of the attic roof frame.

The uprights of U-shaped arches can be attached to the support with metal brackets, nails or tenon joints. You can learn about the main methods of connecting rafter structure elements from the video instructions. To ensure the verticality of the racks under the load that the roof will experience during operation, it is recommended to additionally install braces. The arches in the upper part are connected to each other by lintels parallel to the long walls of the house.

Installation of rafter legs

DIY construction sloping roof involves the use of two types of rafter legs. The lower rafters are located at a very acute angle, connecting the racks to the Mauerlat or the ends of the outer transverse supports. The upper gable rafter structure is mounted on an arched system.

Before installing the lower rafter legs, you must carefully mark the location of their installation on the Mauerlat. The rafters closest to the gable are installed first. Trimming the rafter legs is carried out in such a way that the cut of the upper edge of the board fits at the required angle to the rack, and the lower cut rests against the mauerlat or remote support. If, according to the project, the attic roof is made with overhangs, a specially shaped cutout is made in the lower part of the rafter leg: with the horizontal part of the cutout, the rafter rests on a support. The rafter is secured with nails or staples. It is recommended to additionally strengthen the connections of the legs with the Mauerlat or external support with burnt wire with a diameter of 3-4 mm. All lower rafters are installed according to a similar scheme.

If we are building a house whose length exceeds 8 meters, it is recommended to install a rafter system with ridge beams. This device allows you to evenly distribute the load over the entire frame. In this case, racks are installed in the center of the gables, the verticality of which is checked with a plumb line, and a ridge beam is mounted strictly horizontally on them. It is important to correctly determine the height of the ridge, since the angle of inclination of the upper rafters directly depends on this. The rafter legs rest against the ridge beam with their upper cut ends, and with their lower ends against the supporting arched structure.

The upper rafters of the attic roof can be an L-shaped structure. Rafter legs can be connected end-to-end using a wooden or metal fastening plate, or by cutting into half a tree, using bolted connection. It is recommended to fit the first pair of rafters locally, which are then dismantled and used as a template. The prepared trusses are installed in the standard order - first the outer ones, then the rest with constant leveling.

On last stage To create a roof structure with your own hands, installation of sheathing, laying of waterproofing, creation of a ventilation gap, and installation of roofing are carried out. Thermal insulation and vapor barrier are attached from the inside, and the sheathing is attached. In the video you can get acquainted with the technology of work in detail.

In an effort to effectively use all available area In a country house, many owners equip the attic. When doing this, you need to be prepared to arrange the roof in a certain way. At its core, the attic is a converted attic and requires certain constructive solutions and some alterations in thermal insulation and roofing. In general, the construction of an attic roof for a country house is not much different from the construction of other types of roofs. But due to the operational characteristics of the attic roof and the requirements placed on it, it is necessary to have knowledge and understanding of the specifics of the arrangement of this type of roof.

Types of mansard roofs

Like any construction work, the construction of an attic roof begins with the design stage and selection of the most suitable attic roof for the structure, its type and type. For the attic, shed roofs or regular and sloping gable roofs are used. In addition, the appearance of the roof is influenced by the materials used and design features the roof itself.

Depending on the structural features of the building itself, several standard solutions for the roof. Mansard roofs: photos and description

- Gable roof for a one-level attic. This option is the usual gable roof, under which the attic is located. During design and construction, no major difficulties arise due to the simplicity of calculations and the ease of construction of the truss structure. The main disadvantage of this roof design is the small interior of the attic with rather low ceilings.

- Broken gable roof for a one-level attic. Unlike a conventional gable roof for an attic, in broken structure 4 pitched planes are used, located at different angles. This type of roof structure is somewhat more complex to design and construct, but it an undeniable advantage is a full-size interior room.

- Single-level mansard roof with remote consoles. The design of this type of roof is more complex compared to the previous ones. But a spacious room and full vertical windows compensate for shortcomings in the complexity of design and construction. The design feature of an attic with such a roof is its displacement and extension beyond one of the sides of the house, and the roof is more like a pitched one.

- Two-level mansard roof with mixed type of support. Roofs of this type are the most difficult to design and construct. Such roofs are designed in conjunction with the house, as one whole, due to the multi-level placement of rooms.

Various designs of mansard roofs are not much different in design from conventional ones pitched roofs. Of course, there are certain design features, but in general they are the same as gable or single-pitch, and consist of the following main elements:

. Roof. The outer part of the roof, which serves as protection against various atmospheric phenomena.

. Lathing. Most often, wooden boards to which the roof is attached, as well as insulating materials.

. Ridge run. The upper part of the entire truss structure.

. Rafters. These are the stiffening ribs of the entire roof structure; they can be layered or hanging. Layered rafters are used for the attic roof.

. Mauerlat. This structural element consists of beams laid along the perimeter of the external walls and connected to the walls using special fasteners. The entire rafter structure is attached to the Mauerlat.

.Diagonal connections. To ensure the reliability and strength of the entire rafter structure, the rafters are connected to longitudinal beams and vertical posts using diagonal connections or bevels.

. Internal supports. To give the roof stability, the rafters and/or ridge girder are supported by vertical beams.

. Insulation layer. Due to the fact that the attic roof and the interior premises are practically one whole, to maintain temperature and humidity conditions, a multi-layer insulation cake is laid between the roof and the walls of the room. The insulation consists of hydro- and vapor barrier, sound and noise insulation, as well as a thick layer of thermal insulation. In addition, proper insulation of the attic roof is important for the safety of the roof itself.

Mansard roof construction technology

When designing and constructing an attic roof, many builders and designers, either out of ignorance or doing their work poorly, make serious mistakes in insulation, ventilation and truss structure. The result is an attic roof, which literally after a couple of seasons becomes unusable, fungus and mold appear, and the roof begins to leak or completely collapse. This happens due to a violation of the mansard roof construction technology.

Due to the fact that the attic roof is maximally drawn to the walls of the interior, and in this case it is quite difficult to obtain excellent heat transfer performance, the entire attic roof structure must have excellent thermal insulation, ventilation and a properly constructed rafter structure using wood treated with fire-bioprotective agents.

To make your attic roof reliable and durable, you need to know the following:

- The thickness of the rafters must be more than 250 mm. For such rafters you can use laminated veneer lumber;

- Use materials as thermal insulation that will not lose their properties in the event of increased humidity. For example, extruded polystyrene foam or foam glass;

- between the roof and the thermal insulation layer we make full ventilation with vents and hoods, through which air will circulate under the entire surface of the roof;

- on the inside, along the entire surface of the thermal insulation, it is necessary to install a vapor barrier layer;

- On the outside of the rafters, a layer of waterproofing and, if necessary, a layer of sound insulation are laid under the roof.

Such requirements are determined by certain natural and physical phenomena. But first things first:

A large thickness of the rafters is required to be able to lay a 20 cm thick layer of thermal insulation between them, and this in turn entails an increase in the mass of the entire roof structure, which is supported by the rafters.

The wood for the entire structure is processed by special means for protection against fire and microorganisms, which is a strict requirement of SNiP. This will protect it from damage by fungi and increase its service life.

If you use such popular materials as mineral and glass wool for thermal insulation, you can only gain in ease of installation and lightening of the entire structure as a whole. But cotton wool, no matter what it is, is cotton wool that absorbs water like a sponge, cakes and loses its insulating qualities. If you choose a material other than polystyrene and foam glass, you should focus on complete resistance to moisture, low heat transfer coefficient and relatively low weight.

A thermal insulation thickness of 20 cm is necessary because in our latitudes it is very cold in winter and very hot in summer. A feature of the attic design is large heat losses in winter and rapid heating of the room in summer. A large layer of thermal insulation will prevent heat loss and penetration inside. But this is only one of the reasons, the second is the safety of the roof. The fact is that the heat that escapes from their premises in winter warms up the roof, on which there is a layer of snow and partially causes it to thaw, and snow is a natural insulation. Melted snow at sub-zero temperatures turns into ice, which has no thermal insulation properties, it weighs down the roof and ultimately destroys the roof itself. And since up to 100 cycles of thawing and freezing can occur in one day, the roofing material will fail in just one season. In the summer, the room becomes incredibly hot and stuffy, and you need to install an air conditioner, or even two. But these inconveniences can be avoided by installing a thick layer of proper thermal insulation.