Each owner of a building wants his building to be reliable, functional, and not be destroyed not just for years, but for decades. This is a completely natural desire for every person, regardless of what is in his property - modest Vacation home with small area or several huge production buildings of the factory enterprise. In order to fulfill his desire and keep the building in order, its owner regularly checks its condition and carries out the necessary repair work. It is especially important to remember that the state of the building depends not only on its parts, but also on the site on which it stands. Therefore, building owners know that in order to take care of their property, it is necessary surface drainage installation.

Our Company offers you its services for the installation of surface drainage.

Installation of plastic trays.

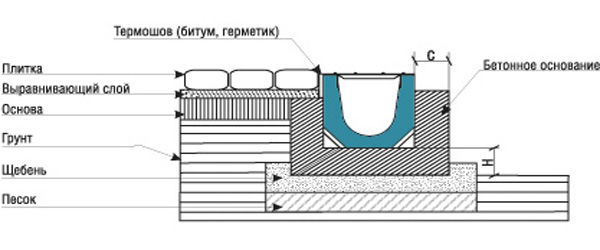

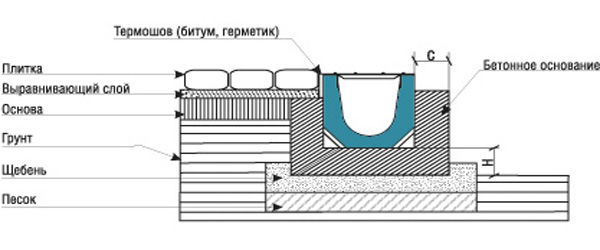

Scheme of installation of plastic trays.

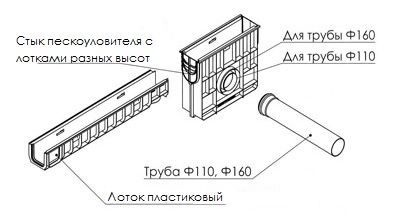

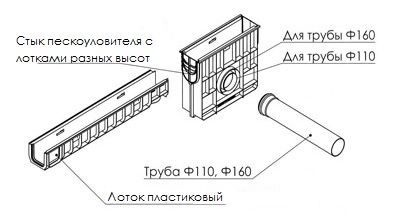

Scheme of docking trays with a sand trap and sewer pipes.

Plastic trays are installed in stages in the following order:

A trench is being prepared in accordance with the diagram in the place where the tray will be installed;

- a concrete step is made by laying concrete in uniform layers along the bottom of the trench;

- plastic trays are located in the trench in the center;

- ramps are concreted to give the system stability.

Plastic drainage trays are interconnected by a butt method. To do this, there is a tongue on one side of the tray, and a groove on the other. To significantly increase the warranty period of plastic trays, the joints are sealed.

To fix the grate to the plastic tray, you must:

Install the main mounting system in the tray by unscrewing the bolt from it;

- thread the bolt through the hole on the grate;

- up to the stop, firmly fasten the bolt, checking the reliability of installation;

- the stamped grating is attached very easily: the locks located at the edges of the grate are bent, the grate is fixed in the tray.

To fulfill lateral connection, you need to make a small hole in the side wall of the tray, connect the trays at a right angle, seal and muffle.

Virtues plastic trays have much more of their shortcomings.

The main advantages are: throughput.

Smooth walls are not covered with growths, for which debris can cling and accumulate over time; durability, which is caused by resistance to stress, chemicals, temperature differences; light weight, which facilitates the transportation and installation of such a system; several holes, which makes it possible to vary when docking with sewer pipe; installation is so primitive that one person can handle it without special education and specific or expensive equipment; extensive application area - from intensive areas to large quantity pedestrians to small courtyard areas.

disadvantages plastic trays are: unreliable at temperatures below freezing.

Plastic may burst when severe frost or because of the weight of passing traffic; possible deformations over time due to different coefficients of expansion of plastic and concrete. In addition, the plastic tray may fall out of the concrete trench over time; due to the lightness of plastic, it must be pressed when connected to concrete, which requires additional effort.

Installation of concrete trays.

Scheme of installing a concrete tray in asphalt.

Scheme of installing a concrete tray in concrete.

Scheme of installing a concrete tray in a tile.

Concrete trays are mounted in a ditch on a concrete base in asphalt, concrete or tiles.

The concrete thickness depends on the load class. The base is usually made of B25 concrete.

The sides are fastened in the form of slopes.

The width of the slopes also depends on the load class.

The correct deepening of concrete trays is checked as follows: after installation extreme point on the grate should be 4mm below the road point. Concrete trays are interconnected and sealed. If the drainage is connected at an angle, the concrete tray and grate are sawn.

When installing concrete trays, one should not forget about expansion joints.

The connection of concrete trays is carried out through a sand trap using a pipe 100-160mm or using a vertical branch pipe installed at the bottom of the tray.

Advantages concrete trays are obvious - reliability and simplicity, special wear resistance.

It should be noted that the scope of application of concrete trays is especially effective in Russia due to its special climatic conditions.

Concrete trays withstand strong temperature overloads and retain their functionality. In addition, many concrete gutters and trays are resistant to various mechanical loads. Modern concrete trays are made by a special vibrocompression method, to improve the class of the product, to increase its wear resistance, metal inserts are added. Some products are made of fiber-reinforced concrete, concrete, combined with fiberglass, the characteristics of which include increased impact resistance. An important factor of concrete trays is their correct installation and competent scope. So, there are concrete trays general purpose, class C, section 100, load up to twenty tons.

For the movement of freight transport, more powerful drainage is needed; super-class concrete trays are made for it for maximum load.

The only one flaw of the average concrete tray is its low impact strength, especially this characteristic has great importance during transportation. As mentioned above, for a special type of work, they are made especially durable concrete, trays from which are used on runways, in industry.

Thus, when installing a concrete tray, you need the help of a specialist who will help you understand the class of concrete required for a particular drainage and correctly install it.

Drainage, as its name implies, ensures the removal of excess rainfall from the territory. While from excess ground water, damaging the foundation of buildings, they are saved by drainage systems, surface drainage relieves the site of the occurrence of puddles and dirt, which harm the condition of the territory, make it difficult to move around it, and can also become traumatic, turning into ice in the cold season. Surface drainage installation solves all these possible problems.

Drainage, as its name implies, ensures the removal of excess rainfall from the territory. While from excess ground water, damaging the foundation of buildings, they are saved by drainage systems, surface drainage relieves the site of the occurrence of puddles and dirt, which harm the condition of the territory, make it difficult to move around it, and can also become traumatic, turning into ice in the cold season. Surface drainage installation solves all these possible problems.

Trust such a neat job as plumbing installation, is only for professionals. Turning to a professional company, you can be sure that all work will be carried out in compliance with all sanitary, hygienic and building codes and safety rules. Professionals will tell you in detail about each stage of work, its role in the drainage system, help you choose the right equipment, provide and agree on an installation plan. Our company guarantees you exactly this approach to work.

Our employees have significant experience in working with such equipment, so we provide our customers with order fulfillment as soon as possible. In addition, the opportunity to work with one company from the moment of selection and purchase of equipment to drainage installation will allow you to save the money spent, as we value our customers and offer them the best prices.

Drainage systems, installation which was carried out by our company, are always of high quality and reliable, because we work exclusively with proven equipment from the best suppliers. You can be sure that you have received certified equipment that meets all modern technical standards.

We carry out installation work within Moscow and the Moscow region. However, we always strive to meet the needs of our clients, so it is possible for specialists to travel to the territory of regions located close to the Moscow region.

For effective work drainage system, it is important to comply with all stages of its installation, in particular - professional installation of drainage trays, collecting and directionally draining excess fluid to a certain place. Installation of drainage trays, representing special geometric designs, shaped like a rectangle, square or oval, requires accuracy and skill. Trust such work is worth only experienced professionals.

Also important is the preliminary selection of the trays themselves. Do you need trays made of concrete, or will plastic ones work? Is it possible to install open trays on your site or is it important to have a special grid? What depth and shape of trays best suits your conditions? Answers to all these questions will be given to you by professional consultants from our company. You will definitely select the optimal equipment, and we, in turn, guarantee you a professional installation of drainage trays. The combination of these two factors will give you an excellent result, and installation of drainage trays will be efficient and effective.

Drainage systems, installation which was produced with high quality, will be effectively operated for many years and will not create the slightest problems for the owners of the sites on which they are installed. Provide for yourself the best equipment- contact for installation work to professionals who have proven their effectiveness, please contact our Company!

For drainage of rainwater, drainage plastic, concrete and polymer concrete trays are used. They are installed on roads railways, in the territories various enterprises and other territories.

Varieties of concrete trays

The production of trays from concrete takes place using the process of pressing materials - this makes the product stronger. Sometimes, in order to give the tray extra strength, metal particles are mixed into the concrete. Reinforced concrete trays of water drainage systems, thanks to their more high performance quality compared to conventional concrete products, and have a high cost. Due to the price and increased strength and endurance, they are used for installation in places where more resistant and durable structures for water drainage are required.

Classification of storm sewer trays

Tray classification storm sewer made of concrete, according to the amount of load that they are able to withstand:

For domestic construction, trays are usually used, which are made from polymer concrete. Polymer concrete products, in comparison with concrete, have a more adequate cost. Also in domestic construction, C250 trays made of concrete can be used.

Plumbing advice: Concrete trays are divided not only in terms of strength, but also in terms of parameters. Nowadays, trays are produced that have standard length. It is 1 meter. The internal section of the products ranges from 100 millimeters to 500.

Installation work on the installation of concrete trays

Work on the installation of trays must be carried out in three main stages:

- The choice of installation scheme for the system, based on what coverage will cover the area.

- Preparation for installation work.

- Installation work.

Choice of circuit and installation work

In order for the concrete tray to be installed correctly and efficiently, you need to adhere to specially designed schemes that are intended for different types coatings.

- Installation diagram for asphalt pavement. Trays of the C250 brand are suitable for this scheme. The adjacent seam should be 10 centimeters, and the concrete screed under the tray should be 15 cm or more wide.

- Installation diagram for concrete pavement. Class C250 trays are used. The dimensions of the adjacent seam and the width of the screed are similar to those given in the previous paragraph.

- Installing the tray for tiled flooring. The best option for this scheme is category C250 and D400 trays. The width of the screed under C250 is 10 cm, the size of the adjoining seam is 8 cm. For D400, both values are 10 cm.

- Scheme of installation of extra strong trays for asphalt pavement. The width of the screed should be 15 cm or more, and the width of the adjacent seam should be 20 cm.

Preparatory work

Stages of preparatory work:

- Development project documentation, which contains descriptions of all the main elements of the drainage structure and the places where it is located.

- Breakdown of the terrain using marking marks in accordance with the documentation.

- Preparation of system elements - trays and related materials must be present in sufficient quantity.

- Rental of lifting equipment for installation.

Stages of installation of drainage systems from concrete

After completing all the preparatory work, you can proceed directly to

Drainage trays - plastic, concrete or cast iron - are used in the construction process drainage systems surface type. Moreover, in such systems, the tray "works" as a drainage channel that captures wastewater. Therefore, it is mounted both at the road curb and under sewer, and at the end of the annular blind area.

And in this article we will consider typical varieties of trays, supplementing the review of the assortment with recommendations for the use of such water collectors in linear drainage systems.

A typical tray is designed in the form of a cast U-shaped channel, the open edge of which is covered with a cast-iron grate.

Moreover, according to the European standard EN 1433, there are at least four types of such conduits:

- The waste tray, made in the form of a rectilinear gutter that receives water along the entire length (version I is mounted without lining and foundation, execution M is mounted on a backfill, and is equipped with its own foundation).

- Box-shaped tray - U-shaped chute, top part which is taken away by a removable lattice. This element protects the channel of the tray from large objects washed into the gutter by sewage.

- Slotted tray - square beam with round through hole along the central axis, in the upper part of which a slot is cut that opens access to the drain. Moreover, the gap can be both continuous and intermittent. Such a tray can replace a box-shaped counterpart with a grate.

- Curb tray - a slotted gutter with an L-shaped protrusion in the upper part, "covering" the slot in the tray body.

|

|

Such trays can be mounted not only under gutters, but also at curbs. garden paths. Well, the most durable products can be installed at airports, on highways and in parking lots of heavy vehicles.

Assortment of drainage trays

Methods for manufacturing concrete trays involve the use of a limited set of inherently plastic or thermoplastic structural materials in the production process of such gutters. So storm trays made from thermoplastic polymers, cast iron and concrete.

This choice is explained by the use of foundry technologies (concrete and cast iron) or thermoplastic extrusion (plastic) in the production process. As a result, the manufacturer produces trays with different strength and performance characteristics.

That is why the classification of the assortment of trays, in most cases, is associated with the type structural material used in the manufacture of such a product. And further in the text we will consider the assortments of polymer, cast iron and concrete trays.

Polymer trays

Structural polymer trays are made from mineral-filled polypropylene. This variety composite materials has high resistance (they are almost impossible to scratch, and they are also inert to most chemicals) and no less noticeable strength (withstands loads up to 60 tons / m2). And the operating temperature range of such material ranges from -50 to 120 degrees Celsius.

Therefore, such trays can be laid both near the house and near the railway track.. Moreover, the weight of one module is only 9-14 kilograms.

Dimensions of a typical polymer tray:

- Length is one meter.

- Width - from 0.14 to 0.5 meters.

- Height - from 0.06 to 0.79 meters.

- Conditional diameter - from 0.1 meters.

Concrete drainage trays with grating

Concrete trays are made from compositions, fiberglass reinforced, polymer threads (polymer concrete) and steel wire (reinforced concrete). Moreover, in the process of manufacturing such products, the technology of vibration casting is used (a mold with a mass that has not yet hardened is immersed on a vibration stand).

As a result, concrete trays are distinguished by high strength, which is unusual for typical reinforced concrete products (reinforced concrete products). Therefore, from such gutters it is possible to assemble both a surface-type home drainage system and its industrial counterpart, mounted on freeways and local roads.

The main dimensions of concrete trays:

- The length of the gutter, which ranges from 500 to 4000 millimeters

- The width and height of the gutter, variable from 140x150 mm to 430x880 mm.

- Dimensions of the passage opening, which cannot be less than the catch diameter DN 100.

Specific dimensions of concrete trays are regulated by industry standards and specifications manufacturer.

Cast iron drainage trays

For the manufacture of trays, two types of cast iron are used: with lamellar graphite grain (ISO 185) and with spherical graphite grain (EN1563). Moreover, not only the “body” (profile) of the tray, but also its grate are produced from such grades of cast iron.

And, of course, due to the tendency of cast iron to corrode, the finished tray (and sometimes the grate) is subjected to a hot-dip galvanizing procedure (according to ISO 4161). However, a cast-iron tray can be supplied to the consumer without a protective coating.

Due to the significant resistance to both longitudinal and transverse loads, cast-iron gutters are mounted only in critical areas (at airports, in parking lots of heavy vehicles, and so on), where the installation of a cast-iron drainage tray is justified from an economic point of view.

The main dimensions of cast iron gratings and trays:

- Maximum length - 500 millimeters

- The largest width is 200 millimeters.

- The thickness of the grating is at least 50 millimeters.

- Through hole - not less than DN100.

Installation of drainage trays: basic rules

Installation of drainage trays is a very responsible operation. After all, the surface drainage system is located in early complex soil, which includes both sandy loam and fertile soil. That is, you can not count on a high supporting ability.

![]()

In addition, such soil freezes 1-1.2 deep almost every winter. Therefore, heaving deformation will also act on the supporting surface of the tray, pushing the product out of the soil.

That is why, when installing drainage trays, you should be guided by the following set of rules:

Firstly, you select a tray according to its throughput, based on the average monthly rainfall rate, increased by 25 percent.

- Second, choose best option the design of the tray and the material from which the product will be made, at the location of the gutter. After all, the curb tray is not suitable at the airport (based on strength characteristics). In turn, the airfield tray will not fit the home storm system(based on economic considerations).

- Thirdly, minimum slope linear meter of the tray - 10 millimeters.

- Fourthly, do not skimp on the substrate - mount the tray on at least a 10-centimeter sand and gravel bed, or better, on a 10-centimeter gravel bed. Such a “cushion” will improve the strength characteristics of the soil and partially level out the heaving deformation.

- Fifth, stainless steel gratings are easier to install (they weigh less cast iron version). In addition, they will last longer than their counterparts made of gray or ductile iron.

- Sixthly, a sand trap must be present in the system - the only protection of the drainage system from silting.

- Seventh, the grill must be fixed using a special mechanism with a screw lock.

The process of assembling a drainage system based on drainage trays is implemented as follows:

![]()

- Along the curb or in another place chosen by the designer, the center line of the future drainage system is marked. To do this, it is enough to use pegs and twine.

- After that, the data of meteorological observations are requested, and on the basis of this information, the average daily volume of effluents is determined, according to which the throughput diameter of the gutter is selected.

- The model and external dimensions of the conduit are determined by the throughput diameter.

- Based on these dimensions, increased by 30-40 centimeters, the volume of excavation (the dimensions of the trench) is determined. Moreover, the depth of the trench will be 10-15 centimeters lower than the height of the tray. After all, its edge, after installation, should be at least 5 millimeters below the zero level.

- At the next stage, a trench is dug, the selected soil is utilized and a backfill is formed, with the help of which the slope is outlined and the bottom of the “pit” is strengthened.

- Further, drainage trays and sand traps are laid in the trench. Moreover, the extreme trap is connected with a DN100 pipe to the main (deep) drainage system.

- After that, concrete is poured into the space between the trench wall and the tray, fixing the drainage system at the selected location.

Such a drainage system is mounted along the central paths in the area laid between the gate and the entrance to the dwelling. In addition, the ring conduit is “circled” around the blind area, which protects the soil from rain runoff. Moreover, the wall drainage can be assembled from plastic, and the road one is “folded” only from concrete blocks.

Any building built in our middle lane, inevitably faces the vagaries and unpredictability of Russian weather. It is equally important for the owner of a private house or industrial facility to consider possible consequences those often unpleasant surprises that a sudden change in weather conditions will certainly bring to him and his structure, which in last years often does not depend on the season of the year and can be truly unexpected. It is not difficult for each of us to imagine prolonged rains in January, sharp cold snaps in May, or unexpected rainfall in mid-July. If you want to keep your building in order and extend its service life to the maximum possible, you know that it is necessary to take care of all the nuances proper construction and care of the territory on which the building is erected. One of the highlights of this activity is installation of surface drainage, including installation of drainage trays.

H Our Company offers you its services for the installation of surface drainage.

Installation of plastic trays.

Scheme of installation of plastic trays.

Scheme of docking plastic trays with a sand trap and sewer pipes.

Plastic trays are installed in stages in the following order:

A trench is being prepared in accordance with the scheme, in the place where the tray will be installed;

- a concrete "cushion" is made by laying concrete in uniform layers along the bottom of the trench;

- plastic trays are located in the trench in the center;

- ramps are concreted to give the system stability.

Plastic drainage trays are interconnected by the "father-mother" junction method. To do this, there is a tongue on one side of the tray, and a groove on the other. To significantly increase the warranty period of plastic trays, the joints are sealed.

To fix the grate to the plastic tray, you must:

Install the fasteners of the tray with the grate into the tray by unscrewing the bolt from it;

- thread the bolt through the hole on the grate;

- up to the stop, firmly fasten the bolt, checking the reliability of installation;

- the stamped grating is fastened with tension: the locks located at the edges of the grate are bent, the grate is fixed in the tray.

To make a side connection, you need to make a small hole in the side wall of the tray, according to the designated docking station, connect the trays at a right angle, seal and plug.

Virtues plastic trays have much more than disadvantages.

Virtues plastic trays have much more than disadvantages.

The main advantages are: throughput.

-smooth walls are not covered with growths, for which debris can cling and accumulate over time;

- durability, which is caused by resistance to stress, chemicals, temperature extremes;

- light weight, which facilitates the transportation and installation of such a system;

- the presence of docking nodes makes it possible to vary when docking with a sewer pipe;

- installation is so primitive that one person can handle it without special education and specific or expensive equipment; extensive area of application - from intensive areas with a large number of pedestrians to small courtyard areas.

disadvantages plastic trays is: unreliability at temperatures below zero.

- plastic can burst in severe frost or due to the weight of passing vehicles;

- possible deformations over time due to the different coefficient of expansion of plastic and concrete.

In addition, the plastic tray may fall out of the concrete trench over time;

Due to the lightness of plastic, it must be pressed when connected to concrete, which requires additional effort.

Installation of concrete trays.

Scheme of installation of concrete trays in asphalt.

Scheme of installation of concrete trays in concrete.

Scheme of installation of concrete trays in tiles.

Concrete trays are mounted in a ditch on a concrete base in asphalt, concrete or tiles.

The concrete thickness depends on the load class. The base is usually made of B25 concrete.

The sides are fastened in the form of slopes.

The width of the slopes also depends on the load class.

The correct deepening of the concrete trays is checked as follows: after installation is completed, the extreme point on the grate must be 4 mm below the road point. Concrete trays are interconnected and sealed. If the drainage is connected at an angle, the concrete tray and grate are sawn.

When installing concrete trays, one should not forget about expansion joints.

The connection of concrete trays is carried out through a sand trap using a pipe 100-160mm or using a vertical branch pipe installed at the bottom of the tray.

Advantages concrete trays are obvious - reliability and simplicity, special wear resistance.

It should be noted that the scope of application of concrete trays is especially effective in Russia due to its special climatic conditions.

Concrete trays withstand strong temperature overloads and retain their functionality. In addition, many concrete gutters and trays are resistant to various mechanical loads. Modern concrete trays are made by a special vibrocompression method, to improve the class of the product, to increase its wear resistance, metal inserts are added. Some products are made of fiber-reinforced concrete, concrete, combined with fiberglass, the characteristics of which include increased impact resistance. An important factor of concrete trays is their correct installation and competent scope. So, there are general-purpose concrete trays, class C, section 100, load up to twenty tons.

For the movement of freight transport, more powerful drainage is needed; super-class concrete trays are made for it for maximum load.

The only one flaw of the average concrete tray is its low impact strength, especially this characteristic is of great importance during transportation. As mentioned above, for a special type of work, especially durable concrete is made, trays from which are used on runways, in industry.

Thus, when installing a concrete tray, you need the help of a specialist who will help you understand the class of concrete required for a particular drainage and correctly install it.

Surface drainage is a system of equipment designed to collect liquid that remains on the surface of the earth after precipitation and further divert it into the sewerage and drainage system. Surface drainage installation is a functional addition to traditional deep drainage systems. Ordinary drainage pipes solve the problem with water and precipitation that has already fallen into the ground, and surface drainage relieves your site of puddles and streams of precipitation that linger on the surface of the earth. Such a system is necessary for every modern building. It is equally important for residents of private houses who protect their site from dirt and for owners industrial areas who strive to ensure a neat and sustainable look for their businesses.

Our Company offers you its services in the selection, sale of equipment and organization drainage installation within your area. We work with both corporate and private clients. A wide range of equipment, professional staff and significant experience allow our company to equally successfully implement orders of any size - from equipment surface drainage territory country house, until the provision of functional water disposal for the territory of a large enterprise. We are interested in each of our customers. Therefore, we always guarantee our customers high-quality plumbing, installation which will be completed as soon as possible. At the same time, we strive to keep attractive prices for their customers. Quality work on affordable price is the profile of our company.

We carry out work on drainage installation on the territory of Moscow and the Moscow region. By additional agreement with the client, our employees will also carry out field work on the territory of other regions located close to the Moscow region. We guarantee you prompt work. From our company you will receive a full range of services - from the selection of equipment to its installation. At the same time, working with one organization will help you significantly save time spent on organizing preliminary activities that precede the actual installation of equipment.

We work only with high-quality equipment that has passed certification. Drainage systems, installation which our company offers to its customers, meet all quality standards. Drainage trays, which form the basis of the surface drainage system, are made of high quality modern materials providing these products with high reliability and special durability.

Tray installation drainage largely depends on the quality of the equipment itself. The trays used by our company are guaranteed to withstand sharp drops temperatures, large volumes of water and other loads. At the same time, the service life of the drainage trays remains invariably long.

Installation of drainage trays produced by highly qualified professionals great experience work, so the turnaround time is always as fast as possible. At the same time, the quality installation of drainage trays guaranteed to be preserved.

Choose, order, install - these are three saving steps to comfort on personal plot! The construction of a house cannot be completed without ennoblement of the adjacent territory, and the installation of a drainage system around the house occupies one of the leading places among the measures for arranging a homestead plot. Drainage consists of a whole set of equipment, which has its own characteristics. For the proper functioning of the drainage system, it is necessary to properly install the drainage trays yourself or entrust the work to specialists.

The low cost of installing drainage trays, when the price saves the site from flooding!

Manufacturers are improving technology and are already offering customers new models of lightweight and durable equipment for drainage systems. Despite the simplicity of the design of drainage trays, installation, the price of which is reduced on our website, can take a lot of time. This is because the surface drainage system is often installed around the perimeter of the entire site and requires careful positioning of the equipment and careful connection of the elements. Before planning the installation of drainage trays with your own hands or with the help of a team, it is worth studying the types of products and their characteristics.

How much water has flowed, or the capacity of the drainage tray!

The determining factor when choosing trays, in addition to the material, are installation parameters and throughput. Plastic drainage trays, which are often installed on private estates, fully cope with the task and remove excess water from a large area, the main thing is to choose the right size. Keep in mind that surface drainage- one of important factors landscaping.

Plastic and reinforced concrete drainage tray, the installation of which directly depends on the design parameters, incorporate such basic elements as gutters and grid-like covers different shapes to give an aesthetic look. So the throughput of the tray depends on the size of this very gutter, along which water flows rush to wells or other collection points.

In civil engineering, concrete and plastic products. When ordering the installation of a drainage tray, remember that the price of such a service is considerable, but it is carried out taking into account long term service life of the system, that is, for decades. Therefore, serious requirements are set for trays.

Nice prices for the installation of drainage trays!

If there is no desire to put up with puddles on the site, it's time to order the installation of drainage and installation of drainage trays. The price for the work will pleasantly surprise you, especially if the materials and trays are purchased on our website. This is because buyers are given an object discount.

Our specialists will perform all turnkey drainage work, and you will only have to forget about flooding, humidity and dampness, as nightmare. The estimate for the installation of drainage trays is drawn up clearly and understandably, it prescribes all types of work related to the installation.

- The cost of works on installation of drainage trays includes preparatory work on the ground, digging channels and trenches under the drawn up scheme.

When digging trenches for the installation of drainage trays, it is important to observe a slope of 10 mm for each running meter tray.

- Construction of a concrete base for trays, sand trap and pipes with sufficient strength to keep the equipment from tilting. On the basis of the master, a pillow is made of gravel or sand, which in the future will protect against discrepancies at the junctions of the trays and their deformation.

- Fixing trays to concrete base using bolts and connecting all elements of the system with gluing with sealants in the right places.

- Arrangement outside: installation of a grate or other measures to design a water intake channel.

We offer you an integrated approach, when the installation of a drainage tray, the cost of which is reduced on our website, includes full project support from the idea and scheme to the implementation and maintenance of the system. Don't miss your chance to solve "wet" problems now!