Used for cleaning industrial, surface and Wastewater. In accordance with the rules laid down in the law Russian Federation, before discharging rainwater or city sewer waste and contaminated water, it is necessary to carry out a number of special measures. Their ultimate goal is to bring the quality of the purified liquid to the established indicators.

The equipment depends on the purpose. Usually, when a system is to be used for irrigation only, it goes against the construction of more rudimentary systems, including mainly a reservoir, a coarse filter, and a pump. In these systems, it is good to keep in mind that if the tank is not installed underground at a depth below the freezing point, it is good to empty it in winter. When the system is expected to work all year round and will be used for other purposes such as providing water for hygiene purposes, some additional components need to be included.

Application area

Types and size of systems

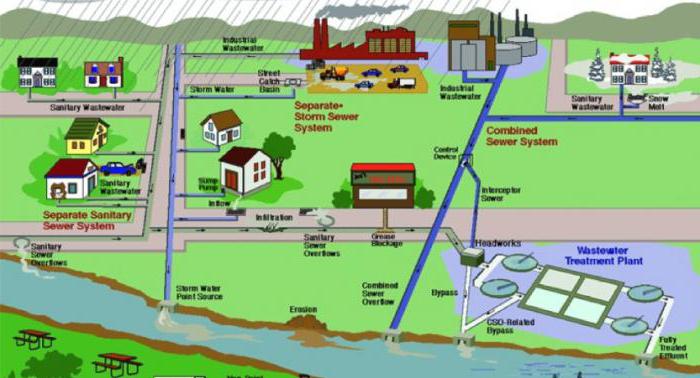

Conditionally treatment facilities Stormwater can be divided into two categories:

- closed systems. This means that water flows through pipes and traps directly into the storm water inlet and is discharged through pipes to places where it is either discharged or stored.

- open systems. In this case, water accumulates and flows down the surface of channels and gutters to the places of its discharge.

Such treatment plant systems are most often produced in the form of horizontal tanks using various materials such as concrete, fiberglass, polyethylene low pressure or metal. As for their size, they directly depend on the area from which runoff flows, as well as on the weather conditions of a particular region, the places where treated water is discharged and the type of the object itself.

For example, it is good to have a siphon for air supply and overflow to provide floating suction with a built-in filter, indoor unit with pump, drinking water inlet and tank, sensors and protections, microprocessor control, overflow.

The presence of sediment at the entrance to the reservoir reduces the presence of shallow water pollution. They usually settle to the bottom of the tank, forming a thin layer of sediment. The caliper prevents mixing of this layer. An important element is also the bypass siphon, which ensures the removal of particles floating on the surface and prevents odors and sewage from entering the sewer. It is also recommended to provide a valve to prevent the return of sewage.

Usually a combination of a gas catcher and a sand trap is installed. Their sizes can be very different and for the convenience of their installation and delivery they are often placed in one housing. If wastewater is discharged into open water bodies, then in addition to sand and oil traps, coal purification units, i.e., sorption filters, are additionally used.

To ensure good year-round operation, underground tanks and filters, as well as water pipes must be set below the freezing point. This is good idea- provide a large viewing hole for underground tanks and filters so that they can be cleaned if necessary.

When constructing systems that will be used to collect rainwater for domestic purposes, floating suction is recommended. Thus, water is sucked out from a clean point. This is usually about 10 cm below the surface of the water. Experts also recommend using a filter return water after the pump uses rain water for washing machines, which also contains dirt in very small sizes.

Systems and their passport

Block-modular storm water treatment facilities are made in the form special installation- sand and oil trap. Through the hatches made in these containers, they are produced Maintenance. Passing through modular cleaners, they get rid of oil products and various kinds mechanical impurities. The first of the above types of pollution includes sediment of conglomerates, film, primary and secondary emulsions, and the second includes hard-to-set particles, silt and sand with a density of more than 1500 kg / m, as well as debris that floats on the surface.

Rainwater systems designed for year-round use can be equipped with automatic control to make work easier. For example, during long dry periods when there is not enough water in the tank and cannot cover the demand, the water supply is prevented. In the same time drinking water only supplied when it is not possible to provide sufficient rainwater.

Some manufacturers of drainage system components also offer specially designed rainwater collection systems, such as gratings to retain leaves and large contaminants and keep them out. drainage system other.

It should be noted that factory-made systems always have a passport for storm water treatment plants, certificates of conformity and sanitary and epidemiological conclusions. In addition, the manufacturer must give a guarantee for the tightness of the case. Usually it is 10 years.

Petroleum products and oils are present in most wastewater. They must be removed due to the extremely negative impact on flora and fauna. Their removal to early stage wastewater treatment is necessary due to their negative impact on processes biological treatment. Wastewater from garages, car washes and parking lots contains mineral oils that are not biologically degradable. Their disposal into the sewer is undesirable, not only because sewer system can be blocked, but also because they are not biodegradable in wastewater treatment.

What is an oil sand trap and how does it work

This product is a cylinder, often made of this gives it extraordinary strength, resistance to adverse external conditions and the ability to easily endure the influence of various aggressive environments.

The operation of the sand and oil trap consists of five stages of wastewater treatment:

The removal of this type of contaminant uses oil separators or so-called oil traps or calorie traps. They are divided into: gravity separators and combined filter separators. SPECIFICATIONS FOR GRAVITY OILS Static oil separators are designed for a retention time of at least 15 minutes at maximum flow. The oil traps are designed according to the nominal flow, i.e. the maximum flow for cleaning according to the design specifications.

These values are determined in such a way as to provide sufficient storage time for treated wastewater and characterization studies carried out with a mixture of water and diesel fuel. For the calibration of oil traps, the flow rate and composition of the treatment waste water must be taken into account, as well as possible consumption rainwater, the volume of light liquids and the presence of substances, the presence of ingredients that may interfere with the separation process, detergents.

- Sump. At this stage, the primary rejection of large particles occurs, which, under the influence of gravity, fall to the bottom.

- thin layer module. It separates suspended solids, as well as their oil conglomerates into sediment, and the primary emulsion floats to the surface, merging into drops and collecting on hydrophobic plates.

- Sorption filter. Its task is to capture particles of oil products that did not fall on hydrophobic plates located on a thin-layer module. Sorption fibrous filler, which is located in the filter housing, is placed in a high capacity and has a significant selectivity for heavy, medium and light oil products.

- coalescent module. It contributes to the separation of particles of oil products that float to the surface, the size of which is greater than 0.2 mm.

- Coal filter aftertreatment. It is filled with a special sorbent, selective to all oil products.

Design

As you know, in the territories of enterprises and stand-alone gas stations, there is a constant accumulation of rain and melt water, which must be removed and discharged outside onto the ground or into any body of water.  To determine which treatment facilities are needed, you need to know the following data:

To determine which treatment facilities are needed, you need to know the following data:

USE AND MAINTENANCE Accumulation more floating materials leads to a decrease in volume for separation. The separation process is aggravated by the presence of a significant amount of sediment. In order to avoid the passage of inert particles and oil products, which worsens the initial parameters, it is recommended to periodically check and clean the separation chamber at least once every 6 months. Inspection and cleaning should be carried out much more frequently when wastewater is from car washes, workshops, oil shops, etc.

REFRIGERATOR FINISHING FILTERS. TECHNICAL SPECIFICATIONS Oil separators with coalescent filter improve the removal of light solids. Thanks to the polyurethane filter, which purifies and retains oil products and sand particles, high level cleaning. This type of cleaning is recommended if a higher degree of purification from mineral oils, petroleum products and hydrocarbons is required. To prevent clogging of the filter, it is recommended to install a sandbox in front of the oil separator.

- uniformity and volume of wastewater;

- composition of impurities and effluents;

- options ground water and earth.

The design of storm water treatment facilities for production sites requires, first of all, to determine which group this object belongs to. There is a specially developed classification of NII VODGEO, dividing them into two groups. The first includes surfaces and enterprises, the effluents from which are similar in composition to the waters of residential areas. This means that they contain toxic and other specific elements.

MAINTENANCE With respect to maintenance of the coalescent filter, it is recommended that it be cleaned by washing in addition to standard procedures. Dissolved With coalescence filter Separation and surface treatment of streams containing contaminants such as hydrocarbons, mineral oils and heavy sediments from parking lots, garages, gas stations, warehouses for oil industry, stations, car washes and the like.

One of the world's problems today is the protection environment and water purity, so the requirements for wastewater treatment are becoming increasingly stringent. Wastewater treatment plants provide a high level of wastewater treatment in a completely biological species with affordable delivery and installation costs and low operating costs. Unlike other wastewater treatment plants, there is no need to place moving mechanical and electrical parts in the container. This eliminates the potential hazard of an unwanted and costly problem that must be solved in already buried underground equipment.

The second group includes those territories of enterprises from which surface runoff with similar harmful impurities. After that, the type itself is chosen, and at the end, calculations are made and suitable stormwater treatment plants are determined.

Necessary Calculations

Calculations differ from each other depending on the specific selection of components. When using a flow circuit without the use of an equalizer, the structure is selected by determining the flow rate of storm drains. For this you need to know statistical characteristic rain in a certain locality, as well as the coefficient SNiP, which determines the surface of the waters. When the calculation of stormwater treatment plants is ready, they finally choose suitable model systems.

The actual equipment is located in a special external cabinet, easily accessible for viewing and maintenance. In this way, an excellent wastewater treatment result is achieved with the advantages quality assembly, long service life, easy and convenient maintenance and low production cost.

A significant advantage of this technology is that the processes run in accordance with the laws of nature without the need for additional supplies. The wastewater stream enters the buffer tank. There they are temporarily stored before entering the second chamber with subsequent cycles of complete biological treatment performed during a certain cycle. In this way, optimum utilization of the equipment and a constant and uniform quality process are achieved.

Performance

It should be noted that the efficiency of the facilities is very important, since untreated melt and storm water can be extremely dangerous both for buildings and structures, and for the entire territory of the enterprise. Harmful chemical impurities contained in wastewater can damage waterproofing, and this is fraught with the destruction of foundations and engineering underground utilities. Moisture, accumulating on structural elements, contributes to the appearance of fungus, which in turn can cause irreparable harm to them. Therefore, the efficiency and performance of stormwater treatment plants is very important, not only because of the fact that it is required by environmental authorities, but also, by and large, based on practical considerations.

All processes operate simply and without significant equipment damping, compressed air made from high quality synthetic material on the principle of a mammoth pump. The special design ensures a minimum water level in the facility without the need to interfere with the floating electrical elements or other sensors. Aeration of the installation is carried out by thin air supply through the membranes at the bottom of the tank. In this way seamless and efficient mixing with oxygen is achieved.

There are no rotating elements to cause an accident. High quality steel elements are used in air ducts. Used tanks are made of monolithic reinforced concrete or duralumin. Because of this, they are easy to install and close, as they do not leak water. The tanks are designed for serial production and are guaranteed to be extended and extended. They can easily adapt to the terrain. One tank can be used for 20 equivalent villagers.

Systems installation

There is a certain order in which the installation of treatment facilities. First of all, with the help of equipment or manually they dig several trenches and pits required size. Sometimes, if necessary, their bottom is concreted. After that, all the cleaning components are installed on the places previously prepared in an appropriate way, and then the structural elements are insulated and waterproofed. Final stage work is backfill soil.

Equipment of existing trenches. The technologist can also be used in existing trenches and reservoirs. Due to the simplicity of the building elements, the equipment does not present a problem. The direction of flow in an existing trench does not need to be changed. Here, all building elements are pre-assembled on one carrier and only need to be installed on the separating wall of the cleaning tank.

After installation, the device begins to reliably and reliably fulfill its intended purpose. Modern microprocessor equipment can be adapted to individual requirements. A simplified built-in menu is divided into a user and a service, which is protected by a code. A random error in the system is reflected by a restart, an optical and audible signal. The control engine keeps a log of logs that reflects system failures as well as hours of operation. The magazine can be easily controlled through the opening. The employee diary is missing.

It should be noted that the successful design of treatment facilities largely depends on the correctness of the necessary analyzes, research and calculations, since even a small error can contribute to the flooding of the site and the breakdown of the treatment system itself.

general description

All equipment is standard and equipped with a low or low warning system electrical voltage. In addition, remote radio monitoring is possible. All items in the cabinet are made with junction boxes to eliminate repair and maintenance by an electronics specialist.

New: recognition of the degree of loading. The latest generation is equipped with a system that automatically detects the load level to save energy. The normal cleaning and energy saving cycle starts with the need. To avoid manual sampling by a specialist, small cleaning systems are also available with an integrated sampling part.

Wastewater treatment plants made of fiberglass of the Veksa type are designed to treat storm sewage generated during rains, snow melt, watering roads from oil products and suspended solids.

They are used in stormwater systems for industrial sites, shopping centers and gas stations, as well as from residential areas, from warehouses, bridges and highways. They are also used in the disposal of industrial effluents, the purification process of which involves sedimentation and filtration on sorbent materials such as activated carbon.

Safety for people and the environment. Cleaning station with intelligent technology meets all scientific requirements and has permission to different requirements to cleaning. Therefore, it can be used in sensitive areas. Modular building for more flexibility. Modular design fully biological treatment plant allows you to adjust the special requirements of the place and terrain.

Nitrogen reduction. This option is planned to further eliminate the nitrogen contained in the treated water. The decomposition of nitrogen also occurs organically with certain types of microorganisms. Additional funds nitrification, supplemented by a particularly intense injection of oxygen, creates optimal conditions for the life of nitrifying bacteria that degrade ammonia and nitrates. In installations that are additionally designed for further denitrification, a radical change in water and the excitation of denitrifying bacteria is achieved by briefly introducing oxygen into the initial phase, which degrades nitrates to elemental nitrogen.

Video - the manufacturing process of Vexa equipment

The technology for treating more complex wastewater, such as mine, quarry, commercial, etc., will include additional treatment methods, such as preliminary reagent treatment of wastewater with coagulants and flocculants.

Treated effluents that have passed through stormwater treatment plants are discharged (by gravity or in a pressure mode) into the city sewer, as well as onto the terrain or into a reservoir.

In terms of cleaning performance, Veksa equipment meets all the requirements and norms of MPC, which are imposed by the owners of sewerage networks, water utilities and environmental organizations.

VOC design

Based on project requirements, contaminant concentrations and required cleaning performance surface water, the composition of the complex of water treatment facilities contains the following blocks and elements: 01 Sand trap Responsible for the sedimentation of coarse mineral and organic pollution, debris, as well as the emergence of film oil products. 02 Thin-layer block Divides the water flow over numerous inclined plates, in the tiers of which oil droplets enlarge and rise, as well as sliding and removal of suspended solids in the form of sediment in a countercurrent pattern. A thin-layer block occupies an area 8 times smaller than with traditional settling. 03 Coalescent filter When surface water passes through it, further coarsening of drop oil products occurs, accelerating their ascent. The use of a kaolescent filter increases the operating time of the sorption unit by reducing the load on it. 04 Sorption filter The cassette filter used here is multi-layer and consists of polymer sorbents and activated carbons. In the loading layer, water is purified due to the sorption of emulsified and dissolved oil products to the required values for discharge into a reservoir for fishery purposes of the first category of water use.