When planning to replace old windows with new ones, many wonder how difficult it is to install them yourself. The answer is a job of medium complexity. In terms of time, replacing a medium-sized window with dismantling the old one takes about 3.5-4.5 hours. This is for a person with no experience. Company employees who do this all the time spend less than an hour on it. But the installation of plastic windows by the owner of the premises cannot be compared with the hasty work of “professionals”. They simplify the process to the point of indecency, arguing that prices have not been raised for 6 years and they have no time to waste time on trifles. If you are lucky to find truly masters, then you can entrust the installation to them. If not, take a weekend and install it yourself.

Construction of plastic windows

To properly understand the installation process, you need to have an understanding of window design. Let's start with materials and names. Plastic windows are made of polyvinyl chloride, which is abbreviated as PVC. Hence the second name - PVC windows.

The main element of any window is the frame. For plastic windows, the frame is made from a special multi-chamber profile. It is divided by partitions into a number of cells - chambers. The more of these cells, the warmer the window will be. When they talk about how many cameras there will be in a plastic window, they have the number of cells in the profile.

In the middle of the structure, in the largest chamber, a blue insert is visible. This is a reinforcing element of increased rigidity. It gives the profile the required strength. In plastic windows this insert is made of plastic, in metal-plastic windows it is made of metal (usually aluminum). That's the whole difference between them.

There is also a division of profiles into classes: economy, standard and premium. The best choice if you need normal windows is the standard class. In economy class, the partitions are too thin and they begin to freeze almost from the moment they are installed. Premium has a high price due to options that, in fact, are not needed.

If you want to have best profile for plastic windows, take the standard class of any factory. There is no particular difference between products from different companies. They have long been standardized and all managers’ stories about the advantages are fairy tales. If they are made on factory equipment, there is no difference between them: all factory profiles have long been standardized.

Profiles for windows in standard version have white, but they can also be brown - to match the color of any tree, and even pink - to order. Windows made from colored profiles are more expensive than similar white ones.

Window structure

To understand what is being discussed in the description of the installation process, you need to know the name of each component of the structure.

It consists of:

- Frames. This is the base of the window.

- If the window consists of several parts, the frame is divided into parts by an impost - a vertical component. If the window is made of two parts, there is one impost; If there are three parts, there are two, etc.

- The opening part of the window is called the sash, the stationary part is called the capercaillie. A double-glazed window is inserted into them - two, three or more glasses, hermetically sealed together. A foil tape is laid between the glasses to ensure tightness. There are double-glazed windows with special properties: with reinforced glass, tinted and energy efficient, which, according to manufacturers, reduces heat loss through the windows. There are also double-glazed windows with inert gas pumped between the glass panes. It also reduces heat loss.

- Double-glazed windows are pressed to the frame with a cap - a thin plastic strip. The tightness of the connection is ensured by a rubber seal (it is usually black).

- Locking fittings are installed on the sashes. This is a specific set of mechanisms that provide opening and locking. They can be different, as they provide different functionality: opening, opening with ventilation, opening + ventilation + micro-ventilation.

- To ensure tightness, rubber seals are installed on all parts - frame, impost and sashes.

At the bottom of the outer side of the frame (the one facing the street) there are drainage holes that are closed with special caps. Through them, condensation that forms inside due to the difference in temperature outside and indoors is discharged outside.

The window also has a sill - a board on the outside that removes precipitation and a window sill on the inside. Side and top parts from the street and indoors. They can also be made of plastic or made using a different technology.

How to measure a plastic window

When ordering windows, you will be asked for six sizes: the height and width of the window, the length and width of the window sill and slope. To measure everything correctly, you need to determine whether your window opening is made with a quarter or without.

Inspect the opening. If the outer part of the window is narrower, the opening is a quarter. In this case, measurements are taken at the narrowest point: openings rarely have ideal geometry, so you will have to measure at several points. Find the most small value, add 3 cm to it. Transmit the height as it is.

If the opening is smooth, the calculation proceeds differently. Measure the width and height. Subtract 3 cm from the measured width and 5 cm from the height. This will be the height and width of your window. We remove 3 cm in width, since a gap of at least 1.5 cm is required on both sides under polyurethane foam. We subtract 5 cm in height, since the same 1.5 cm is needed on top, and 3.5 cm on the bottom will be used to install the window sill.

The length of the window sill and ebb is taken with a margin - 5-10 cm more than the width of the window opening. During installation, both the ebb and the window sill are “recessed” a little into the adjacent walls, and the excess will go there. The width of the tides is standard, so the nearest larger one is selected. On window sills the situation is different. Its width is chosen arbitrarily - at the request of the owner. Some people like them wide so they can put something, others prefer them flush with the wall. So there are no rules here.

When ordering, you will need to indicate how many and what parts will be in your window: whether there is a capercaillie or not, where it is located, how many sashes, which side they are on, how they should open. You will need to indicate the type of fittings (ventilation, micro-ventilation).

Preparation

If you are replacing windows, installing plastic windows yourself begins with dismantling the old one. Problems usually do not arise: breaking does not build. After dismantling, it is necessary to inspect the opening: remove everything that can fall off. If there are any protruding parts, they must be removed - using a hammer, chisel or power tool. When the plane is leveled, all construction debris must be removed. Ideally, sweep away everything, even the dust, otherwise the foam will not “grab” well with the wall during installation.

If there are too large potholes or cavities, it is better to cover them with cement mortar. The smoother the opening, the easier the installation will be. If the wall material is loose, they can be treated with binding compounds: penetrating adhesive primers.

How to install correctly: choosing an installation method

There are two different methods: with and without unpacking (disassembling) the window. When unpacking, holes are drilled through the frame and anchors are driven through them into the wall. This method is more complicated, but the fastening is more reliable.

This is an anchor bolt installation. There are three of them on each side.

When installing without unpacking, metal plates are attached to the outside of the frame, and then they are attached to the walls. This is naturally faster, but the fastening is very unreliable: under significant wind loads, the frame will warp or it will sag.

If you really don’t want to disassemble the window, you can mount it on a plate, but use not narrow and thin ones, but thick and wide ones, which are often used when installing a rafter system.

In principle, small windows installed on mounting plates, provided there are no significant wind loads, can stand normally. If you live in a region with strong winds, and they blow mainly through your windows, if the apartment is located in a high-rise building, in these cases installation with unpacking is necessary.

Below, watch an emotional and intelligible video that explains why it is better to use anchors.

Do-it-yourself installation of plastic windows: step-by-step instructions

Let's describe both methods: suddenly you need a method with mounting on plates. It is used in buildings made of foam blocks, bearing capacity which are small and the load from the windows has to be distributed over a large surface. This method of installing plastic windows is also necessary if the building is built using “layered” technology. For example, there is concrete in front and behind, and a layer of insulation between them. If the window must stand in the soft layer, then it will need to be secured with plates. Installation of PVC windows in brick, cinder block, panel, etc. the house is desirable on the anchor.

Installation and unpacking

Do-it-yourself installation of plastic windows begins with measurements. Measure the frame and window opening to make sure they are compatible. Afterwards you can start working. The process begins with disassembling (unpacking) the PVC window. Here are the steps:

- Removing the window sash:

- Close the window (the handle is turned down).

- Remove the plastic covers on both hinges. They are pryed off with a screwdriver.

- On top loop There is a pin that provides a movable connection. It is located in the center and protrudes slightly. They press on it until it sinks (you can take a metal plate, rest it against the pin and lightly tap the plate). The pin will slide out from below. Now you can grab it with side cutters or pliers and pull it down and pull it out.

- Hold the door up and open the lock. To do this, place the handle in a horizontal position. Having tilted the upper part towards you slightly, lift the sash, removing it from the lower pin.

The entire sash has been removed. To make it clearer, watch the video. It describes in detail how to remove and install the sash on a plastic window.

- On the wood grouse, remove the glass unit. It is held in place by glazing beads. They need to be removed, then the glass unit itself will be removed without any problems. Remove the glazing beads like this:

- Something narrow and strong is inserted into the gap between the bead and the frame. If you don't have a special tool, it's best to use a small spatula. Disassembly begins from one of the long sides.

- The spatula is carefully pushed into the crack with a corner and the glazing bead is gradually moved away from the frame.

- Without removing the tool, move along a little, again pushing the glazing bead to the side.

- This goes along the entire length. As a result, the glazing bead is almost separated; it is simply removed.

- With the short side, everything is simpler: you pry up the free edge and, by turning the spatula, remove it from the groove. Grab the free edge with your hand and pull up.

Now you can try to remove the glass unit. Just be careful: it's heavy. If that doesn't work, remove another one of the beads. Just make sure that the window is tilted and the glass unit does not fall out. Now, if necessary, you can replace the double-glazed window yourself. Watch a video on how to remove glazing beads from PVC windows.

- Removing the window sash:

- The freed frame is covered with a special self-adhesive tape along the outer perimeter. Its installation is recommended by GOST. With it the window doesn't get so cold.

- Remove the protective tape with the campaign logo. If you leave it, it will fuse too much with the frame under the influence of the sun and it will be problematic to remove it.

- The prepared frame is inserted into the window opening. Mounting wedges are used to position it. They must be installed in the corners and under the impost. The rest are arranged as needed. By placing them, the window is set strictly level in three planes. The position of the window is pre-fixed. This is what you can use mounting plates for.

- Take a drill and a drill bit that matches the diameter of the anchors. Make holes for fasteners. 150-180 mm retreat from the top edge. This is the first hole. The bottom one is approximately the same distance from the bottom corner. Another anchor is installed between them in a standard window: the maximum distance between two fasteners should not be more than 700 mm.

- Having made a hole, check whether the frame has moved (level in all three planes), then hammer in the anchor and tighten it. You cannot overtighten: the profile should not sag. Repeat this operation required quantity once.

- Install ebb tides outside. To do this, first a vapor-permeable waterproofing is glued to the outer part of the frame (it is self-adhesive). Small grooves are made on the sides of the window opening, into which the edges of the tides are then inserted.

- A layer of foam is applied to the part of the window opening from the outside, where the ebb will rest on the wall. Sometimes, if the height difference is large, a lining profile is installed here. and then an olive is attached to it. The ebb, cut to size, is inserted under the frame lip and secured there to the frame with self-tapping screws.

- Along the lower edge the ebb also foams.

- Next, foam the opening. When installing plastic windows in the summer, the gap between the frame and the window opening is sprayed with water from a spray bottle. This is necessary for better polymerization of the foam.

- A vapor-permeable heat-insulating strip is glued along the contour of the frame - it is also recommended by GOST.

- Take a balloon with foam and fill the existing gaps to 2/3 of the volume. If the gap is large - more than 2-3 cm - foam is applied in several stages. A time interval of 10-15 minutes is required between two layers. When the first layer is partially dry, it is also sprinkled with water and the second is applied. This is repeated until the volume is 2/3 filled.

Foaming PVC windows during DIY installation can be carried out in several stages - depending on the size of the gap

- Without waiting for complete polymerization, the free edge of the heat-insulating tape is glued to the window opening. Just note that when using tape, the slopes will need to be made of plastic: the plaster and mortar will not “stick” to it.

- Assemble all parts of the window. All that remains is the finishing work, and they are not a hindrance.

- It is also installed under the window sill at the bottom vapor barrier tape(also GOST recommendations). The window sill rests on support blocks made of hard wood treated with impregnation. The distance between them is 40-50 cm. They are made in such a way that the window sill is slightly inclined towards the room (about 5°).

How to correctly position a window sill during installation plastic window watch the video. There are many secrets.

The last to be installed or sealed are the slopes. One more video on this matter.

Installation without unpacking

The main details are described above, so this chapter is short. Installation for this option begins with the installation of mounting plates. They are of two types: U-shaped and linear. It is important to choose the most reliable thick metal ones.

They are installed at the same distance as the anchors: 150-250 mm from the edge and no more than 700 mm between the middle ones. They are simply screwed to the profile with self-tapping screws.

Then installing plastic windows with your own hands with mounting plates is identical to that described above, starting from the moment the window is leveled in the opening. Only they attach not the frame, but the plates, and not to anchors, but to dowel-nails. Drill a hole, bend the plate, insert a dowel, put the plate in place and tighten the dowel. Further all actions are identical.

Now it’s clear why installers prefer them: a decent amount of work is spent on disassembly, anchoring, etc.: screws are much easier to tighten. True, if you take powerful plates, they will hold tightly. No worse than an anchor. For example, like in the video.

Installation of windows without a quarter occurs as follows. If your house is new, then the windows are installed in an empty window opening. And in order to order a window, you need to subtract 5 cm from the vertical size of the opening - this will be the height of your window. And subtract 3 cm from the horizontal size of the opening - this will be the width of your window.

Installation of windows without a quarter occurs as follows.

If your house is new, then the windows are installed in an empty window opening.

And in order to order a window, you need to subtract 5 cm from the vertical size of the opening - this will be the height of your window.

And subtract 3 cm from the horizontal size of the opening - this will be the width of your window.

Subsequently, when installing the window yourself, these 3 cm will be filled with mounting foam (1.5 cm on each side of the window). And 5 cm is 1.5 cm from the top of the window to fill with polyurethane foam and 3.5 cm to the window sill under the window. You also need to take measurements of the length and width of the window sill and the external ebb and add at least 5 cm to these dimensions so that the window sill “crashes” a little on the right and left into the wall.

For an inexperienced installer, you can take 20-30 cm as a reserve; the excess is cut off during installation. In general, window sills and sills come in a standardized width (10, 20, 30, 40, 50, 60 cm) and length (up to 6 m), but you, in any case, must provide the minimum dimensions so that they bring you the most suitable window sill and sill from available.

goodlinez.ru

How to install a plastic window with your own hands, how to take measurements

Repair is an undertaking that requires considerable funds, so home owners tend to do some of the work themselves. Let's take, for example, replacing windows. It’s great if you have theoretical knowledge of how to install a plastic window with your own hands. It’s even better if you have practical skills in performing construction and installation work.

You don't need any special tools or equipment to perform this difficult job. The main thing is interest in the result, attentiveness and accuracy. Let's take a closer look at each of the stages of this process.

Installing a plastic window: taking measurements

This task is very important, measurement accuracy means convenient and quick installation and high performance. Measurements are taken individually; even in an apartment building, irregularities in the geometry of the openings are possible, and there may be errors in wall thickness.

Remember what mistakes can result in when measuring.

The results of incorrect measurements are not only difficulties with installation, but after several months or years, cracks and cracks will form around the frame, the window will begin to blow, condensation will appear on the glass, and then mold will appear.

If the decision to measure yourself is made, use the advice of the experts:

- decide on the material for finishing the walls and installing slopes

- the frame size should be smaller than the opening in the wall, allowable gaps should be from 2 to 5 cm, they will ensure freedom of construction when exposed to natural expansion

- measurements are taken on the outside and inside of the opening

The width of the opening is determined by three measurements taken at the bottom, middle and top, choosing the smaller of the three values. Similarly, based on three measurements, the height is determined.

Measurement can be done using different methods. Without “quarter”, i.e. From the width indicator obtained as described above, the size of the installation gap is subtracted, i.e. 20-40 mm, while taking into account differences in wall thickness. If the differences are significant, it is better to settle on an installation gap of 40 mm.

When calculating the height, the result obtained by comparing three measurements is used. From it the size of the installation gap is subtracted, from 15 to 20 mm and the height mounting profile– 30 mm.

The dimensions of the window sill and ebb can be obtained by measuring old structures that were previously used for decoration. If they were not installed, you can determine the length by adding 10 mm to the width of the opening.

The width is determined by the depth of the opening from the side of the room. The installation location of the heating radiator should not be blocked by a window sill.

To obtain the length of the ebb, 70-80 mm should be added to the width of the opening measured along the outside. The width of the sills can protrude from the external walls by approximately 50 mm.

“Quarter” refers to the protrusion of the fourth part of the brick along the outer part of the opening. In this case, measuring is more problematic; the quarters themselves may have distortions or be asymmetrical.

Therefore, when taking measurements, adhere to the following rules:

Therefore, when taking measurements, adhere to the following rules:

- frame overhang of the side quarters – from 20 to 40 mm, over the top – 20 mm

- the stand profile should be placed 30 mm above the bottom wall, this will simplify the installation of the drip sill

The dimensions of the ebb and window sill change in the same way as for an opening without quarters.

Ordering a plastic window

The company’s specialist will help you adjust the dimensions and recommend which profile is better, select the optimal configuration, and determine which parts can be made blind and which can be opened. You will need to select accessories.

The choice of fastening system is of particular importance:

- through the frame

- using supporting reinforcement

Ordering new PVC windows

The second option involves installing the elements of the fastening system on the frame itself, during the manufacturing process of the frame in production.

Fastening through the frame is easier, but during installation work it will be necessary to remove double-glazed windows from the blind parts and all swing doors.

When installing the window yourself, the second option will make it easier to cope with the task, but since the design has heavy weight then you will need to hire an assistant.

Getting ready for installation work

Preparatory work begins if the windows have already been delivered; naturally, you will need to move all the furniture away from the window and cover it tightly from dust. The heating radiator should also be covered with foil.

Preparing the window block:

- remove the beads securing the glass unit, first the vertical ones, be sure to mark them

- Having removed the double-glazed window from the grooves, carefully install it against the wall

- dismantling is carried out until only the frame with lintels remains, reinforcing and separating the sashes

- On the inside of the frame, along the perimeter, using a metal drill, holes are made for fastening anchors, the recommended drill diameter is from 8 to 10 mm, corresponding to the diameter of the anchors

If special fastening lugs are used to fasten the window, then dismantling the window will not be necessary; the work will consist of fastening the parts included in the kit to the frame itself, using screws as a fastening element.

To eliminate the possibility of a cold bridge forming in the lower part of the window opening, experts recommend filling the entire internal space of the stand profile with foam. It is advisable to start installing windows when the foam has hardened well.

On the day of installation of windows, the old ones are dismantled.

Removed:

- window frame and frame

- insulation and sealants that are located under the box

- slopes if you plan to install new ones

- window sill and cement backing underneath

- all the debris and dust that formed during work

If windows are being replaced in an old wooden house, then a waterproofing layer is laid around the perimeter of the opening.

How to properly install a plastic window with your own hands: work order

The frame is installed on the substrate. There is no need to remove them after fastening; they will be a good auxiliary device that will reduce the load on the anchors. Pegs are also used to secure the frame to the sides.

After each stage of work, be sure to check that the installation is horizontal; it is recommended to use a more accurate water level rather than a bubble level. To level the structure in a vertical position, a plumb line is used.

After checking correctly, the structure can be secured with anchors.

If the fastening is carried out through the frame, then using a perforator drill, holes are made in the wall, strictly in the places marked for fastening. First fasten the lower edges of the frame, both sides. Anchors are inserted, but not fully secured.

The verticality of the installation is checked, then holes for fastening are made in the middle and top parts. Once all the anchors have been installed, the fastenings can be fully tightened. But there is no need to apply any special effort; excessive tension can lead to deformation of the frame.

The verticality of the installation is checked, then holes for fastening are made in the middle and top parts. Once all the anchors have been installed, the fastenings can be fully tightened. But there is no need to apply any special effort; excessive tension can lead to deformation of the frame.

Fastening with special ear plates is a little easier. The holes for the anchors are already prepared in the ears themselves. You will need to drill holes for anchors in appropriate places. First fasten the lower, then the upper part of the window, observing the horizontal and vertical installation.

After installing the anchors, the structure is assembled. The procedure is performed in the reverse order to that when disassembly took place. Double-glazed windows inserted into the frame are secured first with the lower and upper glazing beads, then with the side ones. Snap the glazing beads until they stop using a rubber mallet.

The assembled window is checked for normal opening and closing of the sashes. When set to position (0 or 45 degrees), the shutter should neither open nor close on its own.

If the check went well, the doors are closed and the gaps between the parts adjacent to the walls and the walls themselves are sealed. Polyurethane foam is usually used. Since foam can deteriorate over time under the influence of the external environment and sunlight, it is recommended to install a water barrier on both sides of the seam.

Ignoring this point over time causes the window to freeze or fog up. On the outside, a special vapor-permeable membrane self-adhesive strip is used.

A foil waterproofing strip is used along the lower inner part; it will be completely hidden by the window sill.

To foam the gaps between the frame and the wall, it is better to use all-season foam. After applying the foam, it can be moistened with a spray bottle. The presence of water accelerates the polymerization process.

How to install a window sill to plastic windows with your own hands

Before installation, the window sill is given the necessary dimensions, i.e. cut it off. Having attached it to the installation profile - using a level, make sure that the slope is correct - a slight slope from the window towards the room is acceptable - it will allow condensation to drain freely. Sagging of the window sill is unacceptable.

Using polyurethane foam, the voids formed under the window sill are filled, then several weights are evenly placed on it, for example, cans of water. The load will prevent deformation of the material from the effects of drying foam.

It will take 12 hours for the foam to dry completely; after this period, the weights are removed and all excess foam formed is removed.

An important point is that a gap should not be allowed to form between the frame and the window sill; if one is found, it will need to be sealed with silicone.

Installation of slopes

Work on installing slopes should begin by attaching the strip along the inner perimeter of the window opening. Screws 95 mm long can be used as fasteners. The bar is installed flush, i.e. It should not go beyond the window opening.

Next, we fix the U-shaped starting profile on the outer frame of the window. Fastening element, namely, the “bug” self-tapping screw is screwed directly into the frame. It is recommended to carefully monitor the accuracy of connecting the outer edges of the profile, because slopes will be inserted into it.

At the next stage, an F-shaped profile is mounted; a stapler is used to fix it. The groove of this profile should be located opposite the groove of the previously installed U-shaped profile; it is these grooves that are intended for installing the slope.

At the part located above the window, the F-shaped groove is cut using metal scissors or sharp knife. It will definitely need to be removed - it overlaps the top of the window.

After careful preparation of the profiles, you can insert the slopes themselves. If you notice a slight error in the evenness of the seams, it can be eliminated by coating the seam with white silicone.

Low tide installation

If the old casting was made from quality material and was in good condition - its replacement is not necessary. If you decide to install a new one, it is ordered along with the window itself.

The ebb is fastened to the stand profile using several self-tapping screws. To avoid rattling of the ebb and strong noise during rain, the space under the ebb should be filled with polyurethane foam.

When working, do not neglect the rules for its use:

- recommended cylinder temperature – not lower than +20 C

- if it’s cold outside, it is recommended to wear special warm covers on the applicator barrel and on the cylinder

- It is rational to use foam if the gap is 10-60 mm

- if the space intended to be filled is wider, to adjust the dimensions of the window opening (reduce it), it is advisable to use cheaper building materials, possibly polystyrene foam or bricks.

Features of installing PVC windows in a brick, wooden, panel house

Modern house construction involves the use of various wall materials, both natural and artificial. Some of them should be treated with special attention because... during operation they change their parameters and characteristics.

For example, a house made of logs is prone to shrinkage, and the process can take several years, and changes in parameters can be significant. As a result of such changes, windows may become skewed, resulting in problems with closing them.

To avoid such troubles, experts recommend using the so-called casing, or pigtail. Its design will protect window frames from the effects of pressure forces caused by wall shrinkage.

Those who claim that the shrinkage of a wooden house lasts a year are not entirely right; in fact, the drying of wood continues for 5 years. Throughout this time, the casing will protect the frames from loads.

A special feature of panel houses is relatively thin walls. This is not to say that they do not retain heat well, because high-quality thermal insulation materials are used in their manufacture. But the installation of plastic windows in such houses has certain features.

Such walls cannot provide uniform heat distribution; the more surface of the profile is in contact with the wall, the warmer the room will be. For panel houses, it is recommended to use windows with a profile 70 mm wide.

If we consider that 80% of the window opening area is covered by double-glazed windows, then it is not difficult to conclude that in order to maintain heat in the house, a structure capable of providing high heat transfer resistance will be required.

If we consider that 80% of the window opening area is covered by double-glazed windows, then it is not difficult to conclude that in order to maintain heat in the house, a structure capable of providing high heat transfer resistance will be required.

This effect can be achieved by installing energy-saving glass in a double-glazed window. This thermal mirror is capable of reflecting the radiant component of heat and directing it back into the room.

The heat transfer resistance coefficient will be 0.69; according to GOST, this coefficient should have a value of 0.61, and for areas with cold climates.

Those. windows with a 70 mm profile and a double-glazed window with three glasses, one of which will be energy-saving, will be an ideal option for a panel house.

The main problem when replacing windows with plastic ones is brick houses are non-standard sizes of window openings. Projects for such houses usually include double-leaf windows with dimensions of 1.28 -1.40 m (width) by 1.6 m (height). The window slopes are wide, about 30-50 cm; after dismantling the old frames, they become even wider. The depth of the window sills is large, almost always exceeding 40 cm.

The process of installing plastic windows in brick houses is quite labor-intensive; even dismantling an old window is sometimes difficult and takes a lot of time. But the large thickness of the walls of a permanent brick building allows the windows to fully demonstrate their heat-saving qualities; the windows in such a house will last much longer.

Houses of the 600 series (ships) are distinguished by the absence of window slopes and window sills. The windows in them have different sizes and configurations; non-standard configurations of balcony blocks make installation difficult.

With the installation of thinner plastic frames, it becomes possible to install a shallow window sill.

Since external quarters are not provided for in the design of the window opening in 600 series houses, the following are used during installation:

- external flashings

- expansion and additional profiles

In the construction of this type of house, aerated concrete was used - a material whose noise-insulating and heat-saving characteristics are far from ideal. Therefore, when installing windows, experts recommend ordering double-glazed windows with three glasses, one of which is energy-saving.

Having enough information on how to install a plastic window with your own hands, as well as having some skills in performing such work, it is quite possible to cope with the task yourself. When performing work you must be extremely careful and careful.

Noticed a mistake? Select it and press Ctrl+Enter to let us know.

foxremont.com

Window opening - with or without a quarter?

Plastic windows have been ordered and manufactured according to all wishes, and it would seem that only a small matter remains - the installation of the windows is ahead. In fact, high-quality installation windows plays a huge role in the absence of problems in the future. Therefore, you should choose a reliable team and know some of the tricks of installing plastic windows yourself.

Let's take terminology, for example.

Even at the moment of measuring the window, you can hear the phrase “window quarter” or “quarter in the window opening.” What is it, how can the presence or absence of a quarter affect the operation of a PVC window over time, and how is the window installed correctly in both cases?

So let's start with the definition. A window quarter or a quarter of a window opening is a protrusion of a part of the outer wall, about 3-4 cm wide. It got its name because 3 cm is the width of a quarter of a brick, which, in fact, should be a protrusion according to all the canons of construction. Quarters are not provided in doorways.

Rice. a) - window opening with a quarter; b) window opening without a quarter.

A quarter of the window opening is located around the entire perimeter of the window. Its presence is necessary for reliable installation of the window from inside the room.

However, a window opening with a quarter can not always be found. The absence of a window quarter is not very uncommon. For example, in private construction this requirement is often ignored at the stage of building a house, either out of ignorance or because of the laziness of the builders. And houses built in the mid-twentieth century did not have window quarters, since windows were installed in them in a different way.

What do they do in such cases? There are two possible solutions. The first is to treat the space between the frame and the wall with polyurethane foam, and then close the resulting seam with a strip. The second way is to complete or drill a “window quarter”, which will more securely hold the window and maintain a sealed seam, preventing moisture from entering the room.

If you have questions about proper installation metal-plastic windows, company specialists Open windows"We will always be happy to answer them comprehensively. We care about the quality of window installation in your homes.

oknadnepr.com.ua

video and step-by-step instructions from the master

Today, plastic double-glazed windows can be called the best solution for use in any buildings. If you are still using wooden windows, then it’s high time to change them to more modern ones, and forget about the annual problems in winter. You don't have to paint them or plug the cracks, because the plastic frames are perfectly smooth and require little maintenance. We will tell you how plastic windows are installed and show a video of the installation process for clarity.

If you were interested in the services of companies for installing plastic windows, then you probably know that they have regular installation and according to GOST. As a rule, installation of plastic windows according to GOST will cost more, but if all tolerances are met, it will be of better quality than usual. You can learn more about the quality requirements for products and installation work in the following regulatory documents:

- GOST 23166-99 “Window blocks” - general requirements for room lighting, ventilation, weather protection and noise permeability.

- More specific requirements are described in GOST 30673-99 “PVC Profiles” and GOST 30674-99 “Window Blocks from PVC profiles».

- Installation requirements are specified in GOST 30971-02 “Installation seams of junctions of window blocks to wall openings.”

- The standards for heat and sound insulation, ventilation, and light transmission are described in GOST 26602.1-99, GOST 26602.2-99, GOST 26602.3-99, GOST 26602.4-99.

- Those. conditions of glued double-glazed windows construction purposes specified in GOST 24866-99.

Do-it-yourself installation of PVC windows includes the following steps:

- Opening measurements;

- Dismantling works;

- Preparing openings for installation;

- Installation of a plastic window;

However, if you decide to carry out all the actions yourself, then a problem may arise: manufacturers do not provide a guarantee if the measurements and installation were not carried out by their craftsmen. If you make a mistake by a centimeter, then the window unit may simply not fit in, and if you insert plastic windows incorrectly, then in a couple of years they will freeze, leak, etc.

On the other hand, if you approach the work responsibly, having studied all the intricacies before work, then you can do the installation of PVC windows even better than the craftsmen from the company, who often save time and money by not following the technological process.

Let's look at all the stages of installation work in order, and start with measuring the window opening. This is the most difficult stage because it is difficult to determine actual sizes windows when already installed, especially in old houses. The layer of plaster and insulation may fall off after dismantling, and the opening will become larger than you expected, so you should carefully examine the walls when taking measurements.

Measurements and purchase of windows

First, let's look at the process of measuring a window in an opening without a quarter. A window quarter is an internal frame of bricks approximately ¼ brick wide (5-6 cm) that prevents windows from falling out and allows them to be more firmly secured. In addition, a quarter covers the mounting foam from sunlight, which should be done in mandatory even in its absence. If there is no quarter, the frame is attached to anchor plates, and the foam is hidden using a decorative cover. Finding out the presence of a quarter is very simple: you need to compare the width of the frame inside and outside the window; if it differs greatly, you have quarters.

Window measurements are taken as follows:  The width of the window opening is measured. To do this, you need to find out the distance between the internal slopes. At the same time, in old houses it is necessary to take into account the thickness of the plaster; it is advisable to remove it for more accurate measurements.

The width of the window opening is measured. To do this, you need to find out the distance between the internal slopes. At the same time, in old houses it is necessary to take into account the thickness of the plaster; it is advisable to remove it for more accurate measurements.

The height of the window opening is measured from the top slope to the window sill, taking into account the thickness of the window sill. We take at least 3 measurements, from the edge and in the middle, and the minimum result is taken for calculations.

- Width = window opening width – 2*installation gap.

- Height = Height of the opening – 2*installation gap – height of the stand profile.

It is also necessary to check the straightness of the window opening so that they are not skewed. This is done vertically using a plumb line, and horizontally using a hydraulic level. This process will be easier and more accurate if you have a laser level.

If there are irregularities, you must indicate them on the drawing according to which you will order the window. Need to calculate usable space so that it does not happen that during installation the corners of the frame will rest against the wall due to the skew of the opening. In other words, you need to maintain a uniform installation gap around the perimeter.

As for the location of the window unit, if you look from above, it should be installed 2/3 of the width from the inside. If planned external cladding facade, then you can move the window closer to the street.

To measure the width of the drain, it is usually enough to add 5 cm per bend to the width of the already installed drain. Its total width should be the sum of the width from assembly seam to external corner walls + 3-4 cm for the protrusion and + margin for bending. If you plan to finish the façade externally, you need to take into account the thickness of the insulation and finishing, so it is recommended to install the drip lining after finishing the façade, but in any case you need to cover the mounting foam from the sun.

The dimensions of the window sill must be equal to the width from internal corner walls to the mounting seam + inward projection size – window frame width (60, 70, 86 mm). The overhang should be of such a size that it covers about 1/3 of the radiator from above.

It is better to measure the slopes after installing the windows, since it is difficult to determine the exact width. The length will be equal to the height of the window opening with a margin for cutting.

Quarter window measurements

If there is a quarter, you need to take into account its dimensions and measure along the outer part.

If there is a quarter, you need to take into account its dimensions and measure along the outer part.

- Width = distance between quarters + 2*overlap of quarter on frame (2.5-4 cm).

- Height = distance between the ebb and the upper quarter + overlap on the upper quarter (2.5-4 cm).

The installation plane is selected along the inside of the quarter, and from it the dimensions of the window sill and ebb are calculated.

Order a window

After all the measurements, you can contact the manufacturer and decide on the configuration of the plastic window. The fittings, the presence of blind parts and sashes are selected.

Also, when choosing, you should know that there are several window fastening systems:

This means that in the first case, during installation, you remove the double-glazed windows from the frame and fasten it, and then insert it back. The second option means that you install the window immediately with double-glazed windows. Both options have their drawbacks: when removing and installing double-glazed windows, their tightness can be damaged, and if this is not done, the weight of the entire structure will be large, and a heavy window can also be damaged during installation.

Preparatory work

Preparations should only begin once the window is in place. First of all, of course, you need to free workspace and cover the furniture with polyethylene, because there will be a lot of dust.

If necessary, the glass unit is pulled out of the window and the sash is removed from the hinges. To remove the glass unit from the frame, you need to carefully pry the glazing bead with a chisel and pull it out. First we remove the vertical beads, then the horizontal ones. Be sure to number them so as not to mix them up, otherwise gaps may appear later.  After you pull out the bead, you can tilt the frame slightly and pull out the glass, moving it to the side.

After you pull out the bead, you can tilt the frame slightly and pull out the glass, moving it to the side.

To remove the sash from the frame, you need to remove the plugs from the canopies and unscrew the bolts. After this, turn the handle to the center to switch the window to ventilation mode, open it slightly and remove it from the lower canopy.

As a result, you will only have a frame with imposts (lintels for separating the sashes).

Points for anchor fastening are marked, and holes are drilled with inside. We make at least 3 attachment points along the edges and 2 at the top and bottom. For reliable fixation, 8-10 mm anchors and a corresponding metal drill are suitable.

If the walls have a low density (for example, cellular concrete), then the fastening must be done using anchor suspensions. They are screwed to the frame and attached to the wall using hardened self-tapping screws (6-8 pieces for each wall hanger).

Advice! To eliminate the temperature bridge in the place of the stand profile, it is highly advisable to fill its internal cavity with polyurethane foam the day before installation. This way you will protect yourself from freezing.

Removing the old window

It is best to remove the old window on the day the new one is installed. Usually they are thrown into the trash, so there is no need to stand on ceremony: tear them out along with the fasteners, saw the frame for convenience, pry them up with a nail puller, etc.

It is best to remove the old window on the day the new one is installed. Usually they are thrown into the trash, so there is no need to stand on ceremony: tear them out along with the fasteners, saw the frame for convenience, pry them up with a nail puller, etc.

The old seal and insulation are removed, and a layer of plaster is removed from the slopes using a hammer drill with a spatula attachment. The window sill is torn out and the excess cement underneath is removed with a hammer drill so that the base is secure. The slopes are leveled, excess is removed, and dust is removed. Then all adjacent surfaces must be treated with a primer, which installers often forget about. If the opening is wooden, then you need to provide a layer of waterproofing around the perimeter.

Pay attention! If work takes place in the cold season, then it should be warmer outside -15 degrees. In winter, it is necessary to use frost-resistant foam.

Fastening a plastic window

First you need to secure the window with wooden wedges around the perimeter so that you can level it, and then you just need to attach it to the wall. Wooden substrates There is no need to remove them after fixation; they will additionally support the structure.

Plastic windows - installation according to GOST

One more gross violation GOST is the absence of a stand profile. It provides not only stable fastening, but also allows you to attach the window sill and ebb to it. In its absence, they are usually attached directly to the frame, violating its tightness. The diagram shows how to position the window sill profile at the bottom of the frame.

After this, you need to make sure that the window is perfectly level in all 3 planes. This can best be determined by a plumb line, water or laser level. Popular bubble levels have low accuracy for such measurements.

Once you have positioned the window unit exactly without distortions or slope, you can fix it with anchors to the wall.

Installation of a plastic window

Using a hammer drill, carefully so as not to damage the profile, we drill the wall 60-120 mm through the holes prepared in advance in the window. First we fasten the lower anchors, but not completely, then we check the evenness again and fasten the remaining points. The anchors can only be finally tightened after a final check. There is no need to overdo it, otherwise the frame will warp. Fastening to anchor plates occurs in the same way.

Drainage installation

On the outside of the window, the ebb is attached to the stand profile with a self-tapping screw or in a special groove on the bottom of the frame. All joints must be sealed with sealant to prevent moisture from penetrating inside. Additionally, you can deepen the ends of the ebb into the wall a few centimeters by making a recess with a hammer drill. Before laying, the bottom gap is sealed from the outside to prevent freezing. To reduce the sound from rain, we glue a strip of Linotherm sound insulation to the lower part of the ebb, or we make a foam pillow.

On the outside of the window, the ebb is attached to the stand profile with a self-tapping screw or in a special groove on the bottom of the frame. All joints must be sealed with sealant to prevent moisture from penetrating inside. Additionally, you can deepen the ends of the ebb into the wall a few centimeters by making a recess with a hammer drill. Before laying, the bottom gap is sealed from the outside to prevent freezing. To reduce the sound from rain, we glue a strip of Linotherm sound insulation to the lower part of the ebb, or we make a foam pillow.

Window assembly

When all the anchors are secured, you can reinsert the double-glazed windows and put on the sashes. We insert the glass into the frame and fasten the glazing beads back, they should snap into place; to do this, carefully tap them with a rubber hammer.

Elements of plastic windows

After this, you need to check that the doors open freely and fit tightly when closed. The window level is finally checked. An open sash should not open or close arbitrarily if the window is level.

Once you have ensured that the installation is correct, you can begin sealing the installation seam. We seal it with polyurethane foam and provide reliable waterproofing on both sides to avoid freezing and fogged glass.

Before applying foam, you need to moisten the cracks with water. When the gap is filled, you need to spray it again to improve the polymerization process.

Advice! Be especially careful when sealing seams! It is important to apply correct amount foam (70-95% of the seam space), if there is too little of it, freezing is possible, and if there is too much, the window may fail. After drying, it should protrude a few centimeters from the seams. Also be careful not to get on the front of the plastic profiles. Fill wide seams over 8 cm in several stages.

Inside we glue a water vapor barrier tape for plastic windows around the perimeter, except the bottom. Along the bottom of the window you need to glue waterproofing with a foil surface, which will be hidden by the window sill. You need to stick a vapor-permeable membrane on the outside so that moisture escapes from the inside, but does not penetrate inside.

Window sill installation

We cut the window sill so that it rests on the lining profile and fits into the opening. Along the edges it should extend onto the walls by 5-10 cm. Don’t forget to leave a temperature gap of 0.5-1 cm, which will be hidden by plastic slopes.  The window sill is installed on wooden pads, level, slightly inclined into the room. The empty space underneath is filled with foam and plastic plugs are glued to the ends. After this, you need to place a heavy object on it until the foam dries. You can also attach it to anchor plates by screwing it to the wall from below.

The window sill is installed on wooden pads, level, slightly inclined into the room. The empty space underneath is filled with foam and plastic plugs are glued to the ends. After this, you need to place a heavy object on it until the foam dries. You can also attach it to anchor plates by screwing it to the wall from below.

Video on how to correctly measure and install plastic windows:

Conclusion

Now you know how to install a plastic window correctly, and you can probably do it yourself. It is recommended to finally check the operation of the fittings one day after installation, so that the foam has time to set. It is necessary to adjust the fittings to ensure a tight fit of the window on all sides.

These instructions for installing PVC windows also apply to balcony glazing, but there are some subtleties there. In particular, it is usually necessary to strengthen the parapet by additionally creating a partition from foam blocks.

Installing PVC windows is not a difficult task if you have at least once held construction tools in your hands and have at least a little understanding of materials. Installation of such windows will take a little time: half an hour to an hour to dismantle old windows and 2 hours to install new ones.

Installation of PVC windows. Installation according to GOST

GOST for PVC installations Windows, unfortunately, in most cases is only a recommendation, but some rules should be followed when installing windows. First of all, this concerns preliminary measurements. We determine the type of window opening - with or without a quarter. Below is a visual example of a schematic view of an opening with a quarter (A), without a quarter (B).

Scheme 1 - Window opening with and without a quarter

Measurement of windows without a quarter

Installation of windows without a quarter occurs by installing windows into a cleaned window opening. To order a window:

- subtract 5 cm from the vertical size of the window opening - an indicator of the window height;

- subtract 3 cm from the horizontal size of the window opening - an indicator of the width of the window.

These gaps will subsequently be filled with polyurethane foam: i.e. 1.5 cm on each vertical side of the window, as well as 1.5 cm for the top horizontal and 3.5 cm for the bottom (for mounting a window sill).

We measure the length and width of the window sill, the external ebb and flow and add at least 5 cm to the resulting numbers - the window sill should crash into the wall on both sides of the window.

Measuring quarter windows

We measure the window opening horizontally at the narrowest point. To the resulting number we add 3 cm (1.5 cm on the sides of the window) - this is the required window width. We measure the length vertically from the bottom of the window opening to the top quarter - this is the required vertical size of the window.

The window sill and ebb are measured similarly to the option without a quarter.

As a result, you should have:

- window height indicator;

- window width;

- window sill length;

- window sill width;

- ebb length;

- low tide width.

Scheme 2 - Window measurements

Installation technology

The technology for installing new windows in old houses is similar. The only amendment is that measurements of the new window are made based on the outer dimensions of the dismantled window frame.

When ordering windows, please also check whether the following are included in the package:

- windowsill;

- plugs;

- installation profile (mounting profile);

- anchor plates for fastening the window;

- instructions for PVC installation windows (some manufacturers include it in the kit).

When ordering a window, you should also know the answers to the following questions:

- What type of window profile do you want to order - 3, 4 or 5 chamber?

- What type of double-glazed window did you choose - 1-chamber, 2-chamber, 3-chamber?

- The method of opening your window is a fixed window, a window with opening, a tilt-and-turn window with ventilation, or a combined window (a tilt-and-turn window with ventilation and micro-ventilation).

By the way, if you want to get a quality product for reasonable price, you should choose from mainly German and, not surprisingly, domestic manufacturers of window systems: REHAU, Veka, KBE, Schuko, Aluplast, Kemmerling, Brugmann or Trocal.

The installation technology provides two methods: installing PVC windows with unpacking and installing windows without unpacking.

Scheme 3 - Construction of a metal-plastic window

The first method involves preliminary disassembly of the window: removing the glazing beads, removing the double-glazed windows from the frame, fastening the frame to the wall with dowels, and then installing the double-glazed windows and glazing beads.

The second technology does not require the removal of double-glazed windows: the frame is fastened using fasteners fixed to the outer surface of the wall, and not through dowels.

The installation method with unpacking can sometimes lead to fogging of the windows; also, with a lack of experience, glazing beads and double-glazed windows can be damaged, and the installation process itself will take much longer. Of course, correct installation will not lead to any negative consequences. However, be extremely careful!

The unpacking method is rightfully considered more reliable, especially if the frame was attached to large, long anchors. If we are talking about fixing a window on the floor above the 15th, or about installing large windows (2x2 m), the right choice is to fix the frame through, disassembling the window.

Necessary tool

To install windows you will need:

- screwdriver;

- level;

- gun (for a container of polyurethane foam and sealant);

- polyurethane foam (1-3 cylinders per 1 standard window);

- PSUL for external waterproofing;

- Primer;

- perforator;

- set of hexagons;

- jigsaw;

- stationery knife;

- pencil;

- paint brush;

- roulette.

We install windows. Work progress

During the installation process, you should be guided by a previously outlined plan: the window installation diagram (whether you drew it yourself or it was provided as an example in the instructions from the window system manufacturer) will help you avoid mistakes and strictly follow the plan. If you doubt whether your calculations or ideas about the window installation process are correct, a technological map for window installation can help - a universal set of installation norms and rules, guided by which you will be confident in the correctness of your actions.

We dismantle the old window and prepare the surface for installation of the new window system.

We prepare the tool for work.

To improve the adhesion of waterproofing tapes to the surface of the opening, we treat it with a primer. Apply the primer with a paint brush.

Having removed the cellophane packaging of the windows, we glue the internal vapor barrier tape to the frame along the semi-perimeter.

Figure 1 — Gluing the window frame with vapor barrier tape along the semi-perimeter

We cover the frame with an external vapor barrier; we fasten the PSUL along the outer surface of the frame. When gluing, do not allow gaps between the joints of the tape. PSUL - a vapor-permeable tape will not allow the polyurethane foam to escape when processing gaps to the outside, protecting not only the appearance of the structure, but also the polyurethane foam from environmental influences - precipitation, ultraviolet radiation and wind, which destroy the foam.

We install the frame in the opening, align and fix it, focusing on the installation rules:

- On the frame prepared for installation, we mark the places for subsequent fastening;

- We fasten the frames on 4 sides in increments of 70 cm, while the distance from the corner of the window frame to the first fastener should be no more than 15 cm;

- fasteners are attached to the window frame (the self-tapping screw must be fixed in the metal inside the frame, therefore the correct installation technology involves the use of metal self-tapping screws with a diameter of 4-5 mm; for large window sizes, the diameter of the self-tapping screw should be 12 mm);

- use anchor plates as fastening elements;

- in places for mounting fasteners, we make recesses in the window opening (fasteners are recessed by 2-4 cm for ease of working with slopes after completing the window installation work);

- the window must be level (to slightly level the horizontalness of the window, you can use wooden wedges, placing them under the frame at the right points);

- to fix the frame in the opening, we install wedges - first the bottom two, thanks to which you can align the lower and upper edges of the frame to the horizon (so that the window does not dangle; it is appropriate to secure the upper anchor), then fasten the wedges along the vertical of the window;

- We attach the window to the window opening.

We attach a diffuse tape under the tide to the outside of the window opening.

After adjusting the fittings (it is not recommended to buy fittings from a manufacturer other than the manufacturer of the window system, however, if necessary, pay attention to offers from Winkhaus, Siegenia, G-U, Aubi, Schuko (Germany), Maco (Austria)), you can foam the window (apply mounting foam along the entire perimeter of the window frame, taking into account that this installation material increases its volume up to 3 times) and 15-20 minutes after processing all the gaps, it is necessary to bend the protective film previously applied around the perimeter of the window frame so that it completely covers the installation gaps ( see picture).

Figure 2 - Processing of assembly seams

We fix the ebb. It is advisable to install it under the window - this way you can avoid water seepage at the connecting seam of the ebb and the window frame.

Do-it-yourself PVC window installation in winter

Many people are concerned about the question: “Is it possible to install PVC windows in winter?”

Of course it is possible! And the installation technology remains unchanged. The only thing worth paying attention to is the temperature indicators for the materials used during installation. In particular - indicators of the use of polyurethane foam.

Special winter options have been developed, thanks to which you can work even at -10°C!

When choosing polyurethane foam for winter work, focus on products from the brands Macroflex Profi (Finland), Illbruck (USA) and Moment (Russia).

Installation of PVC window sill

The installation of a PVC window sill completes the installation of new window blocks.

The length and width of most window sills are standard. In any case, you need to take a window sill with a margin in length and width. The excess can be easily trimmed with a grinder.

Work progress:

Place the window sill under the window and level it using wooden wedges or any other durable material at hand.

The window sill should extend into the wall at least 1.5 cm.

Before final installation, make sure that the window sill does not sag by pressing in several places.

The slope of the window sill relative to the window should not exceed 3°.

We fill the cavity under the window sill with construction foam.

The surface of the window sill must be evenly loaded for at least 12 hours so that the expanding foam does not affect the installation angle of the window sill.

A day later, the remaining foam is removed with a utility knife, and the joint between the window and the sill is treated with sealant.

Scheme 4 - Window sill installation

All that remains is to install the slopes on the PVC windows - and you're done!

According to GOST! Installation of PVC windows: VIDEO

Installation of PVC windows: VIDEO

$ Installation of PVC windows: price issue

The cost of the work will depend on how much your window costs: companies that provide a full package of services often derive window installation prices from the cost of the window - starting from 10%. Thus, when doing the work yourself, savings on window installation can range from $40 to $60 (for one window).

Installation of PVC windows. Price:

- Kyiv - from 100-130 UAH. per m²;

- Moscow - from 1,000 – 1,200 rubles. per m².

Cost of plastic windows with installation:

The cost of plastic windows with installation averages from $80-90 (a fixed window 1 m by 1.5 m) and up to $2,200 (glazing an area of 3.4 m by 1.5 m with a sliding two-chamber window system). As you can see, the range of prices is amazing. Window installation - price not always included in total amount. Therefore, when signing an order for the manufacture of a window and the corresponding contract, make sure what is included in final price, and what you still have to spend money on.

The estimate is an extremely important document: when you receive it, ask for a full price list of work and materials - a check is never superfluous.

The cost of installation, paid separately, varies: prices range from $30-70.

If the client is not able to pay the entire amount at once, some companies provide the goods and services of their team of craftsmen in installments.

The window business, by the way, is a profitable business: for example, winning a tender for glazing high-rise buildings or a residential area under construction is the same as hitting the jackpot in a casino. The company's profits can be in the hundreds of thousands of dollars.

Not so long ago, metal-plastic windows were considered a kind of “elite” element of a house or apartment, accessible to very few wealthy owners. Today the situation has changed - these window systems are no longer so expensive and have become widely used used by almost all average families. They significantly outperform wooden ones in terms of insulation, sound insulation, and By by matching all the elements, which becomes a reliable barrier to drafts and street dust. And just in appearance, such windows are very nice and easily fit into any design of the house and its premises.

In a word, both during the construction of new housing and during renovations, the issue is almost always clearly resolved in favor of installing just such. There are a great many companies, large and small, currently engaged in their assembly in almost all regions of the country. Large companies immediately include their installation in the price of their windows - with large production volumes they can afford it. But you can often find small private enterprises that require a separate fee for installation - and in today’s times this is about 2.5 ÷ 3.0 thousand rubles. It is clear that the thought immediately arises - is it so difficult to install a plastic window with your own hands? Is it possible to save on this by doing the installation yourself?

It turns out that this is quite doable. The main thing is to have a good understanding of the process technology and immediately prepare the necessary consumables. And, of course, be extremely careful when installing and strictly follow the installation instructions.

The main stages of installing a plastic window

Must be carried out in a clear sequence. This technology has already stood the test of time, and it would be inappropriate to make adjustments to it at your own discretion.

- First of all, the necessary measurements are taken and an order is placed for the window structure.

- After the window is manufactured and delivered, the old frames are dismantled, the opening is cleaned, and it is adjusted - if necessary.

- The next stage is preparing the new window for installation. It may vary depending on the chosen method of window installation, which will be discussed below.

- The most important stage is the correct installation of the window in the opening, its alignment vertically and horizontally, leaving the required gaps, and fastening it to the walls.

- Next, the seams between the frame and the opening are sealed, and water and vapor barriers are provided.

- The next step is to install the ebb sill outside and the window sill inside the room.

- The final adjustment of the window mechanisms and installation of the necessary fittings are carried out.

- When finishing is done in the room, window slopes are installed.

Now about the main stages - with all the details.

Two main methods of fastening plastic windows

Before you take on independent work, you need to understand a little theory.

- Firstly, someone who does not accurately understand its structure should not undertake window installation. First, let's look at the window from the outside:

1 – Window frame assembled from PVC profile.

2 – Opening window sash, also made of a special profile. It can open in several planes, for example, it can be tilt-and-turn. Suspended from the frame using special fittings that allow fine adjustment sash position.

3 – The central post is an impost that divides the common plane of the entire window into two or more parts. The material used is the same frame profile.

4 – Installed in the opening sash or directly in the frame profile (with a “blind” part of the window) glass unit It can be single-chamber (two glasses) or double-chamber (3 glasses).

5 – Fitting elements. In this case, the handle of the opening sash is shown.

6 – PVC window sill, which is usually ordered, purchased and installed simultaneously with the window itself.

Now let's look at the same window in section (for convenience, continuous numbering is used, that is, if positions coincide with the top picture, their numbers are saved):

— The frame profile (item 1) has several air chambers (usually from 3 to 5 ÷ 6) - the more there are, the higher the thermal insulation qualities of the window system. Profiles are counted along a horizontal line in the direction from the street to the room. In this case, the figure shows a three-chamber profile.

— Inside the profile there is a reinforcing metal profile(pos. 7). This item pr I guess T t the required rigidity of the frame structure.

— The structure of the sash profile (item 2) is approximately the same. The number of chambers is usually the same as on the frame; a reinforcing metal element is also placed inside (item 8)

— The glass unit in the frame or sash of the window is held in place by glazing beads (item 9).

— The diagram additionally shows the installation of a window slope made of PVC panels. Pos. 10 – starting profile, pos. 11 – PVC panel, pos. 12 - also made of PVC.

Of course, by the windows various manufacturers may have its own characteristic features, the cross-sectional shape of the profiles and reinforcement, the number of air chambers, the design of the double-glazed window may differ, but still typical diagram remains the same.

More details about this, and how to correctly approach the choice of its optimal model, are described in a special publication on our portal.

- Secondly, you need to decide on the method of fastening the window in the opening. In practice, two main approaches are used - installation directly through the frame using dowels or anchors, or installation using brackets (anchor plates) pre-attached to the window.

A. In the first case (in the figure on the left), the frame is drilled through, and a hole is made in the wall coaxially with the hole in it. The fastening element is inserted through the frame, tightened, and its head will then be hidden by the installed double-glazed window or covered sash.

Advantages of this method:

- The window in the opening is installed much more accurately.

- The fastening strength of the entire window system is higher, so this approach is the only possible for large window sizes (2000 mm or more on any side), or where high external loads are expected (especially windy places, high number of storeys, etc.)

Flaws:

- The window requires mandatory disassembly - removal of beads and double-glazed windows, opening sashes. For an inexperienced master This - unnecessary problem , since when dismantling the glazing beads can easily be scratched or even bent, and the removed double-glazed window requires especially careful handling. Due to the need for disassembly, this method is often called installation with unpacking the window.

- Violating the integrity of the profile (drilling through it) reduces its thermal insulation qualities, and in certain conditions can provoke.

- This type of installation takes more time.

B. Installation on anchor plates or other brackets mounted on the end part PVC window frame. After placing the window in the desired position in the opening, these plates are attached with dowels or anchors to the wall (shown schematically in the top figure on the right). The window sill and further finishing of the slopes will hide them from view.

Advantages:

- Such installation is easier and faster, especially if standard anchor plates are used, which fit tightly into the grooves intended for them on the end part of the profile.

- The integrity of the profile is not compromised - there is no need to drill through it.

- There is no mandatory need to disassemble the window - it can be installed assembled. (Because of this, this method is sometimes called “no decompression”). True, this advantage can be called very conditional, for several reasons. Firstly, most often windows are delivered from the manufacturer in disassembled form. Secondly, installing an assembled window with double-glazed windows installed, especially on a high floor, is very difficult and dangerous due to its large mass. And thirdly, it is still more convenient to fill the remaining cracks from the outside, provide external waterproofing and install the drip lining with completely removed double-glazed windows.

Flaw, in principle, one, which has already been mentioned - in terms of installation strength, in terms of the resistance of a large window to weight and wind loads, this method is significantly inferior.

Taking measurements

It is immediately appropriate to do one very important note. Apartment owners, one way or another, will have to contact a company that manufactures windows to place an order. The optimal situation would be for a manufacturer’s representative to come and independently carry out all the necessary measurements. Firstly, a specialist in this matter has much more experience, and the likelihood of an error will be minimal. Measurers, as a rule, are already familiar with all typical buildings, and it is much easier for them to understand the nuances of window openings. And secondly, if it suddenly happens that the manufactured window, for some reason, suddenly does not correspond to the opening, then all responsibility will fall on the company’s employees, and the customer will have the right to demand the production of the correct window structure.

Measurements are most often a free service.

Measurements are most often a free service. Very often, in serious companies, measuring the opening is included in the cost of the order and is not paid additionally, so there is no need to fool yourself.

If you decide to take the measurements yourself, you should first understand the configuration of the window opening.

- IN panel high-rise buildings most often there are openings with a quarter - a monolithic side on both sides and on top of the opening, forming such way external slope of the window (in the figure - on the left).

- In brick houses there is usually no quarter - the opening is formed by straight planes perpendicular to the wall (in the picture on the right).

Measurements of different openings have their own characteristics.

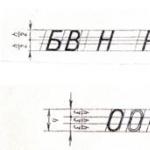

Measuring a window opening with a quarter

When measuring a window with a quarter, it is taken into account that on both vertical sides and on top the window frame should be quartered by 15 ÷ 25 mm, and there should still be a gap left for filling it with polyurethane foam.

This means that the measurement is carried out as follows:

- Outside, in several places (top, center, bottom), the distance is measured strictly horizontally A between opposite slopes. Considering that the window should overlap them by 15 ÷ 25 mm, add 30 ÷ 50 mm to the resulting distance. This way the required window width is obtained in advance.

Now measurements are taken inside. The width of the opening is determined WITH at its widest point, at the level of the wall (also horizontally in several places - for control). Not to be confused with size IN, which shows the distance between the slopes near the frame itself - this indicator in this case has no determining value.