It's hard to find someone who doesn't like meat and vegetables cooked over charcoal. That is why the barbecue takes a leading position among other attributes necessary for outdoor recreation. Modern devices have varied design: they can be either portable metal or stationary made of brick or metal, with a canopy, lid, etc. It all depends on the desire and imagination of the owner. And you don’t have to buy a brazier at all, because you can make a metal brazier with your own hands.

Advantages of a metal grill

The simplest, but at the same time very practical barbecue model

The pros and cons of metal barbecues vary depending on which models to consider:

- thin-walled – they are mobile, compact and affordable. They are made by stamping parts from the thinnest sheets of metal, which has an advantageous effect on their weight. The most commonly produced are folding versions. However, they are often used not only as a container for coals from a separate fire, but also for ignition and kindling of the latter. Therefore, the service life of such a barbecue can be significantly reduced. The walls quickly burn out, become deformed and become unusable. In addition, they do not retain heat well, which leads to an unreasonably high consumption of coals;

- thick-walled – wear-resistant and spacious. Such barbecues can last for years. True, they are not so portable, since they are made of thick sheets of metal, and therefore have quite a lot of weight.

Varieties

Before you start making a barbecue, you need to decide on its type.

Portable (folding/collapsible)

A compact, collapsible grill you can take with you even on a hiking trip.

Portable barbecues are easy to assemble and have a simple and compact design, designed for outdoor picnics. They come in two types: folding and collapsible.

- In a portable collapsible barbecue, the elements are connected during the assembly process using bolts, pins and other connecting elements. Such models are mobile and compact, but they have one drawback - poor reliability. Making such a grill with your own hands is quite difficult.

- In a portable folding barbecue, the elements are not completely separated, but moved or folded. The main disadvantage is short term operation. At best, they last for one or two seasons.

- Currently, a model such as a disposable grill, which is designed for one use, is very popular. Its undoubted advantage is low price and light weight.

Stationary

A metal grill with a roof allows you to cook in almost any weather

The stationary grill has large number manufacturing options. Such models can be with or without a roof. The first ones are self-sufficient. The roof will protect not only the cook, but also the firebox itself from direct sun rays, snow or rain, which will extend its service life. The latter are usually installed where there is already a canopy.

With smokehouse

In such a grill you can not only fry, but also smoke meat or fish

A grill with a smokehouse can be used not only for frying meat or fish, but also for smoking them. To do this, it must be equipped with a dense metal lid, and shelves for installing a grill should be provided on the sides on the inside.

The principle of smoking in such a grill is as follows: thin branches are placed on the bottom fruit trees(apple trees, cherries or plums), and on the installed grill - prepared pieces of meat or fish. Cover the grill with a lid and light a fire under it. The branches inside begin to smolder due to high temperatures, but due to lack of oxygen they do not ignite. Thus, meat or fish is simultaneously baked at high temperatures and smoked in the smoke from smoldering fruit branches.

Unlike the rectangular barbecues we are used to, American barbecues are often round

The main difference between a barbecue and a grill is that the meat is fried not on skewers, but on a grill. In this case, not only coals can be used, but also open fire. Thus, the sides must be higher than those of the barbecue, and they require fastenings for the grill.

Table: Pros and cons of different types of barbecues

| TYPE | ADVANTAGES | FLAWS |

| Portable (thin-walled) | Compactness, ease of assembly, light weight, low price, mobility. | Short service life, possible deformation and burning of the main container, poor heat retention. |

| Portable/mobile (thick-walled) | It retains temperature better, is lightweight compared to stationary ones, has a long service life, and is resistant to corrosion. | High price. |

| Disposable | Mobility, light weight, low price. | Cannot be reused. |

| Stationary | Large fryer sizes, low heat transfer, longest service life. | There is no possibility to move. |

| Allows you not only to fry, but also to smoke meat and fish. | Quite difficult to find on sale. Can only be made to order or independently. | |

| Cooking not only over coals, but also over an open fire. | Quite an expensive device. |

Selecting a location

When choosing a location, you need to consider some important points:

- The grill should not be placed under trees or near bushes, as high temperatures can scorch the branches;

- Do not place the device under film or fabric canopies, which may catch fire due to the heat;

- it is advisable to take into account the wind rose so that smoke does not get into the windows of your house or neighbors;

- the best option would be one equipped with a barbecue separate plot, located near the main recreation area.

If the barbecue is on the ground, it is advisable to pave the area under it with fire-resistant material (stones or paving slabs). During the rainy season, this will allow you to approach the barbecue without interference, and the structure itself will not sink into the ground over time.

So, we smoothly approached the main issue of our conversation. How to make a grill with your own hands?

Tools and materials

For making it yourself metal barbecue you will need following tools and materials:

- sheet metal(iron or steel);

- bolts and other fastening materials;

- welding machine;

When making a metal barbecue without welding machine can't do without

- hand drill or electric drill;

- Bulgarian with cutting discs for metal;

- angle grinder;

- pipe or corner (for legs);

- tape measure and square for marking;

For the 'pattern' metal parts barbecue you will need a grinder

- angle grinder;

- hammer or small sledgehammer;

- pipe or corner (for legs);

- tape measure and square for marking.

DIY manufacturing technology

The grill, which we will make ourselves from metal, will be as simple as possible. For not big company 8–10 skewers with meat are enough, and if the need arises, you can prepare another portion.

The skewers should not interfere with each other, but large gaps between them should be avoided so as not to waste heat.

Following these arguments, we calculate the length of the structure. A classic skewer holds 5-7 pieces of meat. The depth of the grill is determined by practical methods. The meat should not be far from the coals, but you should not place it too close, otherwise it will burn. The distance from the top edge of the structure to the ground depends on the height of the cook. Most often it is 75–125 cm.

Drawing

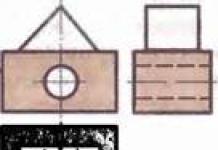

Let's make a drawing of our barbecue. The diagram may look something like the following figure.

Brazier is not space rocket, so the drawing may be the most primitive

We will use sheet metal 2–3 mm thick as the material.

So, we mark the sheet using a square to avoid distortions:

- 70x20 cm – 2 pcs. (back and front walls);

- 70x28 cm – 1 pc. (bottom);

- 28x20 cm - 2 pcs. (side walls).

We cut the elements with a grinder.

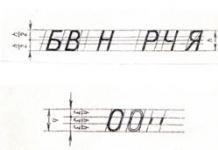

Small slits will help fix the skewer in the desired position

You can make small cuts along the upper long side of the sides to more securely fix the skewer in the chosen position.

To ensure the flow of oxygen, a number of holes are made along the sides of the grill

To ensure air flow inside the drawer base, several holes with a diameter of 10 mm or more should be drilled on the front and back panels at intervals of 10–15 cm from each other. Measure 2 cm from the bottom edge of the structure and draw a straight line, marking the places for cutting.

Welding work

For the legs, you can use a 20x20 cm corner or metal pipes with a diameter of at least 20 mm and a length of 60–100 cm (depending on the height of the cook).

If you use tubes, you can make the structure collapsible. To do this, you will additionally need 4 bolts with nuts. Bolts are welded to each tube. In all four corners of the bottom of the box, you need to drill a hole with a diameter slightly larger than the bolts welded to the support legs. If corners are used, they can simply be welded to the base.

If you want to add a smoking function to your barbecue, then it will be enough to weld two corners to the inside of its long sides at a height of approximately 7-10 centimeters from the bottom. You should also make a metal lid by welding small sides to a metal base slightly larger than the size of the grill. For convenience, it is recommended to weld a bracket on top of the lid, which will be used as a handle.

If desired, you can make a canopy or shelf for firewood or coals, weld it on side walls handles, add a hook for a spatula or poker.

The grill can be not just an ‘iron box’, but a real multifunctional kitchen

How to care for your grill

Yes, the barbecue needs care. Which one?

- You can’t fill a hot barbecue with water yet (temperature changes can cause the metal to become deformed).

- Trapped grease, soot or soot can be easily removed with a rag and sand.

- Grease the grill from time to time vegetable oil, applied to a clean rag - this will add shine and at the same time protect the structure from adverse weather conditions.

Unusual grill design (video)

In conclusion, we bring to your attention a short video that shows how to make a metal grill using the base from an old sewing machine"Singer" (Singer).

Share with your friends!

A real picnic in nature is most often associated with gatherings around the fire and barbecue. It is the process of cooking meat over coals that gives a holiday with friends the sincerity and solemnity of the moment. Most often, men are involved in the action, claiming that “kebab female hands can't stand it." Let's not challenge their right to cook meat, which comes from time immemorial.

Pieces of meat for barbecue, which you plan to cook on the grill with your own hands, should be cubes with sides measuring at least 4-5 cm. This will allow them not to dry out, be juicy and soft.

“The right grill”, made with your own hands. The dimensions of the device must allow the skewers to be placed with sufficient clearances.

As a rule, the length of the barbecue is taken equal to length skewers minus 10-15 cm. The width can be calculated from the condition that one skewer should have at least 80 mm of space. The distance to the coals should be no more than 100 mm, and the depth of the fire should be up to 200-250 mm, with slots for skewers along its long side.

Wall thickness- the more, the better. And there is no need to clean off the soot from their inner surface; this is a source of infrared rays, without which you will simply get meat baked over a fire. In order for the shish kebab to be not only a tasty, but also a healthy dish, the holes for air flow for a self-made barbecue should be in the bottom, as in the numerous photos of devices that are filled with specialized sites.

When air passes through the coals from bottom to top, all the oxygen in it will burn out and harmful oxidation of food enzymes will be avoided. If the blowing holes are located on the side, oxygen will remain in the outgoing flow, which means that the kebab will not be so healthy.

"Aromatic" coals. Analyze the archive home video with eating kebab cooked on the grill with your own hands. You notice that the widest smiles of those present are present precisely during the tasting of dishes cooked on wood from fruit trees? The fairness of this joke is difficult to overestimate - firewood is made from cherry, apricot, apple, pear, etc. will give the dish a unique taste and aroma.

Let's start making the grill. On the Internet you can find the drawings and photos necessary to make your own barbecue of any type - from simple metal to brick or stone. Let's look at all the designs, gradually moving from the simplest - made of sheet metal - to more complex ones, such as a self-made smokehouse grill or a stone grill-stove.

Advantages of metal structures

The most important advantage of barbecues made of metal is their cheapness . Even if you buy metal sheet, angles, rods and pipes necessary for the work, the cost of materials will be significantly lower finished product from the store. And if we take into account that such a design will use unnecessary metal trash in the form of barrels, cylinders, pieces of sheet metal and scraps of corners, then the price of the finished product will approach zero.

The second indisputable advantage is ease of manufacture . Any person who has a little knowledge of welding can repeat the most complex design. Thirdly, such barbecues can easily be installed in a new place or taken with you on a picnic. Fourth - sufficient thickness of the sheet metal will allow the barbecue to serve long time. And fifth - pleasure from the result. Having created a real masterpiece from scrap metal, you can proudly remember it at every opportunity.

Barbecues with insufficient wall thickness suffer from disadvantages - they quickly burn out, they can suffer from overheating, and they can rust from rain and moisture.

DIY sheet metal grill

A brazier made of metal with your own hands will serve you faithfully for many years only if the thickness of the sheet is sufficient and the metal can withstand high temperatures without the risk of burning. In addition, a product 4-5 mm thick will never move, which is often the problem with structures welded from roofing sheets. Most often, a device with a wall thickness of 1-2 mm is needed for outdoor trips. Its weight is much less, and a self-made grill collapsible design, the drawings of which are available online, are also more convenient to transport.

Before starting work, you need to stock up on a sufficient amount of sheet metal 2-4 mm thick, a corner with a shelf width of 40 mm, a welding machine and an angle grinder, an electric drill with drills, a ruler, a marker and a construction square. To make the legs, you need to prepare a pipe or square with a cross-section of 400 mm 2 or more. The work of making a stationary barbecue with your own hands from sheet metal is carried out in the following sequence:

- Transfer the drawing to a metal sheet and use a grinder to cut out the blanks. If a material with a thickness of 2 mm is used, a drawing is applied in the form of a development, and then the workpiece is bent at a right angle along the line where the side walls adjoin the bottom.

We measure, we cut out the required format, we clean the edges of the sheet for the bottom, we measure again, we bend the sheets and grab them

- Using a square, the side walls are welded perpendicular to the bottom, and then the seams are welded along the entire abutment line.

To fix the sheets, welding is required. Take a welding machine. We weld the joints. Welding. Clean the seams.

- Using a drill with a diameter of at least 12 mm, holes are drilled for air flow in the lower part of the side walls or the bottom, depending on what drawings you use when making a barbecue with your own hands. If the air flow will be through the bottom, then an additional lower ash box should be provided.

- Slots should be made in the long walls for skewers. It is best to alternately cut grooves 3-5 cm long and 6-8 cm long. This will allow you to install required height skewers over coals.

Fill with water, add firewood. The water went from 10 degrees to a boil in 20 minutes. Testing a homemade barbecue.

- The next stage will require you to study photos of barbecues on the Internet or design your own frame into which the barbecue, assembled with your own hands, will be installed. Such a frame is mounted from a metal corner and profile, using welded or bolted connections. Its design should include shelves for dishes, firewood and utensils.

- If you plan to make a barbecue with your own hands from thin metal for outdoor trips, the frame drawings can be put aside. You won't need it. It is better to weld short (up to 8 cm) pieces in the corners of the bottom metal pipe with a diameter of up to 25 mm, into which sections of rods or pipes of smaller (up to 20 mm) diameter will be inserted as legs. Their length is selected based on your needs.

- Handles made of a metal rod should be welded to the top of the short walls of the grill for ease of carrying.

- A roof installed over the barbecue can protect the fireplace from snow and rain. It’s not difficult to make it at all, it’s enough to provide side racks and a couple of floors on which roofing iron is laid required size.

- Don't forget to decorate your work with various forged decorative elements that can be purchased at trading network. Next, the product and frame are cleaned with a metal brush and painted with heat-resistant paint. After it has dried, making a metal barbecue with your own hands is considered complete and they begin to test fry the kebab.

In the process of work, you can correct the drawings and make your own barbecue that best meets your technological and aesthetic requirements.

Collapsible metal grill

If you don’t want to transport a large all-metal box, then look at a collapsible structure or a barbecue design for making it yourself. Such products are compact, easy to repeat and quite durable. In addition, you can assemble a portable device in a matter of minutes. We present to your attention drawings and detailed diagrams that will help you assemble a barbecue with your own hands. Step-by-step instructions and photos of the assembly process will help you delve into the smallest details.

To work, you will need the same materials and tools as for the manufacture of a welded one-piece structure. Additionally, you need to stock up on a jigsaw and reinforced scissors for working with metal, as well as a set of dies and fasteners. Are you ready to make a collapsible grill with your own hands? Step-by-step instructions will help you not to miss anything. Determine the required dimensions of the product, taking into account the dimensions of the trunk of your car. We offer best option, suitable in most cases:

- Width - 300 mm;

- Length - 600 mm (calculated for 6 servings, if necessary, can be increased at the rate of 100 mm per skewer);

- The height of the walls is 150 mm, taking into account the distance of 20 mm under the grate;

- The height of the support legs is 600 mm (it is better if the length of the legs matches the width of the barbecue, because we need a compact design).

As a rule, any dismountable barbecue, created by yourself, a video of the making of which can be found on the Internet, has the following elements:

- Frame made of metal corner;

- Bottom;

- Longitudinal and lateral sides;

- Grate;

- Fasteners

- To make a frame from the corners, weld a rectangle of the required size (if we take our barbecue dimensions as a basis, you should weld a frame 230 mm wide and 570 mm long with your own hands). Weld 50 mm sections at the corners of the structure water pipe with an outer dimension of 17 mm. Later they will be inserted into the support legs.

- Four pipes are needed for the legs internal diameter 18-20 mm. We have already discussed the length of the supports. You can install plugs on the side of the pipes that will be stuck into the ground.

- Cut out the bottom and side structural elements from a metal sheet, cut grooves in them and drill the necessary holes.

- In accordance with the diagram of the barbecue intended for making it yourself, attach the bottom to the frame with bolts. To do this, drill through holes in them, placing a frame of corners on the base of the grill.

- As grates, you can use a grate welded from a rod or reinforcement with a diameter of 8-10 mm. Weld legs 15-20 mm long from the same material along the edges of the grate.

- We fasten the sides on four rods (knitting needles). To do this, we cut threads at their ends for wing nuts and weld the rods to the top and bottom side short walls. If welding is not possible, screw the spokes to the sidewalls with horseshoe bolts.

- Tip: install all bolts from the fireplace side. This will help protect their threads from sintering.

- To assemble such a grill with your own hands, step by step instructions not needed - the process itself is very simple. It is enough to secure the bottom to the legs, and then get the protruding ends of the spokes into the slots on the long sidewalls and tighten them with wing nuts. After attaching the assembled sidewalls to the base and installing it inside the grate, the grill can be considered assembled with your own hands. A photo near this grandiose structure will serve as proof of your prowess on social networks.

DIY barbecue from a barrel or gas cylinder

A metal barrel or propane cylinder are excellent objects for making a stationary barbecue. There can be several options for manufacturing such a design - both with a hinged lid and without it. If you decide to build a barbecue with your own hands from a cylinder or barrel, then we can advise you to start working with a detailed drawing. To help you, we will provide detailed diagram device into which you can make the necessary adjustments.

We won’t write about the tools needed for the job - you already know what you need to stock up on. The materials you will need are the same pipes, rods and angles in quantities that determine the size of the barrel or cylinder and the design you choose.

A grinder will help you start making a barbecue from a cylinder with your own hands. With its help, the container is cut into half its height, length, or a sector is cut off from its side. In the future, it will serve as a lid for the future barbecue.

Cutting a window in the wall of a barrel - Photo 50

Further work is performed in the following sequence:

- A stand is made by bending a pipe in a semicircle and welding legs to it. If it is not possible to bend the pipe, weld two corners at an angle to each other, and weld supports to their edges. The result should be two structures in the shape of the letter M. These elements can be connected to each other by a welded grid made of a metal rod, which will subsequently serve as a shelf for firewood and accessories.

- Half of the barrel is placed on a stand and welded.

- The cut is refined with the help of a metal corner - it will not only carry an aesthetic load, but will also provide additional convenience when laying skewers.

- If the grill that you assemble with your own hands is planned to be used as a grill, then racks for its installation are welded to the sides of the stand or barrel (for a more complete understanding, look at the photos of such devices). For preparing a barbecue inside cylinder (barrel) brackets are welded to install the grille.

Brackets for laying mesh - Photo 53

- In the lower part of the side walls, holes with a diameter of 12 - 15 mm are drilled in a checkerboard pattern for air flow.

- An option is possible when the barrel is mounted on a stand in such a way that its front cut is much lower than the back. In this case, the high back wall will protect the fireplace from the wind. In this case, there is no need to refine the cut with a corner - it will be enough to clean the edges well with a grinder. A horizontal grate installed along the front cut line will serve for barbecuing, and in order to cook shish kebab, you will have to weld a shelf on the high rear wall to accommodate skewers at least 5 cm wide.

Laying metal grating— Photo 55

- Installing the cover is usually not difficult. It is attached to the barrel using a pair of strong loops. The processed edge of the lid will add neatness to the entire structure.

- A barrel with a lid can also work as a smokehouse. To do this, a chimney is attached to its side. You can orient the barrel in advance so that the pipe is connected to the filler neck of the container.

Help to decorate a barbecue from a cylinder decorative elements in the form of curls, flowers and leaves, made with your own hands or purchased at the construction market. The roof and antique metal wheels will give the device a magical look, which can also help with its transportation. In short, you have unlimited scope for creativity.

Advice: if you decide to make a barbecue from a gas cylinder with your own hands, weld a couple of corners with a shelf of 50 - 80 mm along the entire length of its bottom. They will allow the coals to be more evenly distributed over the surface of its bottom, without collecting in too thick a layer in the central part.

Finishing of metal products

After finishing work, the metal grill must be cleaned of rust using metal brush, which is mounted on a drill or grinder. Welded joints Clean with an emery wheel of an angle grinder.

Next, the outer surfaces of the grill are degreased and painted with heat-resistant paints and varnishes. Decorations in the form of leaves and curls can be enhanced with a patina, giving them the appearance of antique pieces. Inner part There is no need to paint the products. There is also no need to clean this side of carbon deposits that appear during operation of the device. It is believed that it has a positive effect on the quality of cooked products.

DIY brick barbecues

A stationary brick grill, built with your own hands, is good for its solidity - its thick walls retain heat for a long time and allow you to cook a wonderful shish kebab or barbecue with your own hands without the risk of burning tender meat. The structures of brick barbecues sometimes form a single whole with a gazebo and patio, being, in fact, a whole complex that complements general style garden plot. By building such a barbecue out of brick with your own hands, you can cook not only barbecue, but also cook fish soup, shurpa, pilaf, and also smoke poultry or fish.

The solidity of brick barbecues results in their only drawback - they take up permanent place. They cannot be moved or hidden in a far corner. That is why you need to be very careful when choosing a secluded place if you decide to install an outdoor grill with your own hands.

Let's get started

Like any capital structure, garden grill requires a foundation. The best choice for building a brick barbecue with your own hands is a strip-type foundation with a pit depth of up to 0.6 m. The pit is backfilled with large crushed stone or stone and filled sand-cement mortar. A foundation of rubble stone, up to 0.3 m high, is laid above the ground surface. The best material for such a fireplace is natural stone or red stove brick. Stone masonry is quite labor-intensive and requires great experience. It is quite possible to build a brick grill with your own hands, the main thing is to do the work carefully and without haste.

Before starting construction, consider the design of such a barbecue. As a rule, they all have a firebox with a low chimney. A grate is installed inside the firebox, under which there is an ash pan chamber (one or more), closed with an ash pit. Under the ash pans there is a niche designed for storing firewood.

Are you interested in barbecues built from brick with your own hands? Step-by-step instructions will help you fully understand all the nuances of such structures.

To build a small brick barbecue you will need: 400-450 pcs. bricks, clay, river sand, a pair of grates, a copper hood for the hood, a corner 30x40 mm and 40x40 mm, valves or ash pan doors.

- Choose a place for the stove - in an open space or under the canopy of a gazebo. The composition of the solution depends on this. For the first option, heat-resistant cement will be needed, and for the second, a clay solution will do.

- Build the foundation.

- Lay out a niche measuring 0.75 x 0.5 x 0.5 m. Lay a row of bricks above this niche (spoon masonry). Here, use the support from the stored metal corners. Equal corner install in the rear part of the row (in the 8th row of masonry), and 30x40 in the front part, making slots in the face brick of the 9th row under the corner flange.

The second row is needed to eliminate overheating of the roofing material. We form the volume of the oven on the 3rd row

- The tenth and eleventh rows are formed into ash pans measuring 0.12 x 0.25 m. Doors or valves are also installed here to regulate the air flow. To install the grate in the 11th row of bricks, a quarter is cut off.

In the original, this type of oven door was used. Attaching the oven door. We fix the wire to secure the door.

- In the twelfth-thirteenth row we arrange a ledge for skewers.

- Laying the firebox continues until the 21st row. Next, it is covered in the same way as a niche under the ash pan, only the laying is carried out in half of the brick - interlocking.

An area for laying the firebox We lay out the bottom part of the firebox We put a grate We erect the walls of the firebox We cover the firewood with a sheet of metal

- From the 24th row, the masonry begins to be narrowed with ledges. On the sides, each row is reduced by 35 mm, and in the front by 17 mm. Rear wall The smoke collector is laid out perpendicular to the base.

- The last row of the brick grill will be the 33rd, with a copper exhaust hood installed by yourself. A photo of this design will help you figure out how to do this.

We form 6 smoke outlets from the firebox. Then we close the firebox. We will lay the flooring on top. We will lay thermal insulation and cooking flooring on top of the firebox. Masonry chimney. The grill is ready!

The presented drawings of brick barbecues will help you build the most suitable structure with your own hands. Photos of such buildings will help you appreciate their design and splendor.

However, building a brick grill with your own hands is not enough. We still need to install a chimney.

Requirements for chimneys and hoods

To ensure that a self-built barbecue oven does not smoke the gazebo, hot gases are vented through a chimney. A special smoke hood is designed to collect smoke, which must exceed the dimensions of the metal grill by at least 30 cm in each direction. There should be at least 80 cm from the lower section of the hood to the upper section of the chimney. If you make a hood with an adjustable suspension, you can adjust the thickness of the smoke cover above the skewers. This kebab will be much more flavorful.

Do-it-yourself brick barbecues should not have any smoke circulation or smoke teeth. It is necessary to arrange only straight lines smoke channels with built-in view for traction adjustment. Otherwise, carelessness in handling the stove may result in waste.

The presented gallery of barbecues, equipped in summer cottages, will allow you to fully experience the beauty of technical and design solutions, feel the aroma of cooking barbecue, plunge into an atmosphere of warmth and harmony, and imagine yourself in the circle of your closest and beloved people. And, perhaps, you will become so interested in how to make a barbecue that you will stock up on tools and begin to create magic with your own hands.

Reading time ≈ 10 minutes

What is a suburban area or dacha without a metal barbecue. It is in great demand when relaxing and preparing hot dishes. The design of forged barbecues and barbecues allows you to quickly cook food over coals with an exquisite taste. At the same time, the structure is simple, and even a beginner can handle the manufacture.

Features of barbecues

Purchasing a finished product in a store is quite an expensive pleasure, but it does not always live up to expectations. A metal brazier, made by yourself according to drawings and photos with step-by-step instructions, can serve you for a long time, as it is designed specifically for your needs.

Of course, the best option for suburban area There would be a brick oven, but it is quite bulky and takes up a lot of space. as a rule, it is used seasonally, so it can lie for a long time unnecessarily. You can place it anywhere: in a gazebo or in the open air.

Types by configuration:

Technical characteristics and structural features:

Important points

Depending on the type of design, during manufacturing there may be controversial issues. What is important for all users to know:

What makes these cooking devices so attractive:

Where to put

Metal devices for frying and smoking cannot be placed in all places; there are safety requirements and recommendations for better use. Professionals recommend:

What types of braziers are there:

How to choose a size

Dimensions metal device very important for a beginning master. It is important to take into account the number of people in a company or family to calculate the number of barbecues and the size of the structure itself. Standard size recommendations:

Welding a homemade grill

Using a welding machine, you can create a strong and reliable structure that is resistant to sudden changes temperatures and can last you a long time. At the end of the welding process, all seams between parts are carefully checked and ground.

What materials can you use to make a home grill:

- Steel barrel.

- Cuttings of a wide metal pipe.

- Empty cylinder.

- Tank from a washing machine.

- Massive sewing machine.

- Forged countertops or metal shelves.

Non-demountable design

To make a stationary grill we will need:

- Durable metal sheet (steel).

- Welding installation.

- Powerful drill.

- Corners for racks or pieces of reinforcement.

- Well working grinder.

Before you start assembling the structure, you need to draw up a drawing with the dimensions and distance between the parts. For example, there should be 7 to 8 centimeters between the ventilation holes in the lower part of the case. The photo shows the use of an additional stand.

We determine the number of skewers; we will have no more than 8 pieces in one tab. Procedure:

Using the video master class, you can make an excellent barbecue for evening gatherings with friends.

Folding suitcase

You can make a folding barbecue with your own hands from metal according to drawings with photos. You will get an easy-to-use diplomat installation, it is transportable and mobile. The design folds inward, thereby hiding all dirty surfaces and parts. You can place skewers in such a suitcase and transport it to any place simply by holding the handle.

How to make:

Barbecue-barrel

We will need a barrel with thick walls and good drawing. There are 2 methods for cutting a barrel: only cutting upper part(creating a lid) or the barrel is cut exactly in half (the most common). We'll look at both.

1 way

Let's look at the process of assembling a barbecue with your own hands from metal with a barrel roof:

2 way

Manufacturing proceeds as in the first case. The only difference will be cutting the barrel into two equal parts. The second piece can be left and used as a lid.  Then it should be scalded, the handle and holder fasteners should be mounted in it. Step-by-step instructions in the video master class.

Then it should be scalded, the handle and holder fasteners should be mounted in it. Step-by-step instructions in the video master class.

Your home grill needs to be carefully looked after to increase its service life. Remove dirt with soft cloths and lubricate the unit from time to time with special oil. And also don't forget about final painting and decor, because the grill should be not only functional, but also beautiful.

A metal grill is the easiest to make. Therefore, it is the most common, especially among those people who like to do something with their own hands and constantly relax in the country or in nature.

Species

Barbecues made of metal are:

Portable ones can be fully or partially collapsible.

Folding products

The first type is single design, which can be folded into portable case. These metal barbecues are designed for tourists. Therefore, their features are:

- small sizes;

- relatively light weight.

Most of the drawings of such barbecues include a brazier with dimensions of 45x26x16 cm (LxWxH). It is not very suitable for a large company, because it will take a very long time to cook the kebab.

Another feature of the right folding barbecues is the special material. For their production they are used thin fire-resistant stainless steel. At the same time, all the loops are also made from it with your own hands. Thanks to this, the grill turns out to be quite light in weight.

Stainless steel is very easy to clean from soot. Just wipe it with a cloth and it returns to its mirror-like appearance. Therefore, you can put a folding barbecue in your backpack and not worry that something inside will become dirty.

Folding barbecues are also made from sheet metal. They can have the above dimensions, or they can also be larger. The products are a little heavy and therefore suitable for short trips. Such designs are good option in cases where there is very little space in the car.

Collapsible and stationary models

Portable, fully collapsible barbecues can also be folded compactly. However, the compactness will be worse than that of folding ones. After all, the scheme provides for large-sized parts. At the same time, the creators use racks with a height of 1 m. They are much larger than similar elements of a folding barbecue. Thanks to large sizes and height collapsible portable barbecues create great comfort while preparing barbecue.

Partially collapsible models and their sketches provide for the possibility of removing the legs. The roaster is a one-piece structure.

Stationary ones are heavy and can only be carried around the courtyard. They are distinguished by a large number of beautiful decorative elements. Many of them are . Such barbecues have a brazier almost identical to that of collapsible structures. All other elements are beautifully designed and depend on the imagination of the creator. Often such barbecues resemble fairy tale characters, trains, cars and any other objects. Many stationary barbecues built into a frame with a roof.

Ideal model

Its features depend on the shape of the roaster. Each shape has its own optimal size.

The drawing of an ideal classic rectangular metal barbecue has the following features:

- Width – 250 mm. This is enough to accommodate 6-8 pieces of meat. With this value, heat from the longitudinal side walls is received by all pieces, including those in the middle. This heat is necessary to form a golden brown crust. If you make the width larger, then the middle pieces will be without crust.

- Length – about 1 m. It is taken into account that there should be 8-12 cm per skewer. A margin of 5 cm on both sides is also taken into account. It turns out that in a meter-long grill you can place 8 skewers. This is quite enough for an average company. You should not make it longer, because the cook will have to run from one end to the other. It is more convenient to stand in one place.

- Height – 200 mm. Optimal height is 150 mm. However, firewood is different and produces its own amount of heat.

- Vertical cutouts in the longitudinal side walls. Their length should be 50 mm. This value will allow you to select the height of the skewers depending on the type of firewood. The meat should be 30-70 mm from the coals.

- Holes in the bottom. There should be a lot of them. The diameter of each hole should be 10-15 mm. The distance between holes and rows of holes should reach 20-30 mm. Drawings of an ideal barbecue may include a mesh bottom. This option is better because the air flow to the coals increases. The mesh should be made of wire with a diameter greater than 4 mm.

- Thickness metal walls - 2 mm, and even better 4-6 mm. This will ensure long term services and creation required heat for cooking barbecue.

- The height of the entire structure depends on the height of the cook. In most cases - 1 m.

Read also: Brazier from improvised means

How to make the perfect model

First you need draw your own drawing. In this case, the above rules are observed. The drawing will allow you to determine the dimensions of each side wall. While drawing it, the implementation of the possibility of disassembling the grill is determined. If this is possible, then the length of the side walls should be increased by 2 cm. These additional centimeters will be curved edges. That is, 1 cm of each side that will be adjacent to the posts will need to be bent at an angle of 90°. 1 cm of the lower edge of the sides of any roasting pan also needs to be folded. They do this inside the structure.

According to the drawn up drawing cutting prepared sheet metal And profile pipe or corners. Holes are drilled in the bottom. Slots are made in the longitudinal side walls. In the case of creating a completely collapsible structure, two long openings are made in the racks. Their length should be equal to the height of the roasting pan. The imaginary lines that will pass through the openings should form a right angle.

If you create a non-separable barbecue with your own hands, then first weld the sides. Next, the racks are welded to them. You don't have to weld it. This will improve the portability of the design. In this case, each pair of racks must be made in the form of the letter “H”. In this case, the ends of the racks should be 1-2 cm higher than the horizontal partition. For reliable fixation 4 protruding metal squares with dimensions of 2x2 cm can be welded to the sides of the roaster at the level of the top of the racks. These squares and racks will need to be fastened with hooks in the shape of the letter “P”.

For additional stability, you can make the ends of the posts sharp to drive them into the ground.

Model with a throat

This grill resembles a large bottle. The design consists of three parts:

- Wide cylinder. Its height is 180-200 mm.

- A cut cone. Height – 100-150 mm.

- Narrow cylinder. It has a height of 100-150 mm.

The lower part has many holes in it. They are not only in the bottom, but also in the side walls. The upper ones are made at a height of 130 mm. The presence of side holes is very interesting feature. Proper grills should not have such holes, since a lot of oxygen reaches the meat through them. He changes chemical processes in the meat, and the dish turns out not as it should be.

However, in the case of cooking meat on this grill, this is not the case because so much wood is burned in the brazier that the side holes are blocked by coals. With the gradual smoldering of the coals, the holes will become free, but until this moment the process of cooking the meat is completed. As a result, some of the wood is wasted.

Barbecue in the country - distinguishing feature Have a pleasant holiday outside the city with barbecue in good company. Perhaps that is why most summer residents are happy to install on their summer cottage barbecue or grill.

Yes, you can just buy a ready-made barbecue for your dacha, but there is something attractive in plans to build such a barbecue with your own hands. A country barbecue is not only a gathering place for the whole family and interesting element country house design,

but also a very effective thing when you need to feed quite a lot of people, for example, for a holiday; because The surface size of a homemade barbecue is usually much larger than a standard store-bought one. In addition, a barbecue made by yourself is more durable, less demanding to use, and has a more “warm, individual” appearance than a purchased one.

The task of making a barbecue with your own hands can be solved by a pair of skillful hands over the weekend. There is nothing complicated in the construction of a country barbecue; you can see this for yourself in the drawing.

The task of making a barbecue with your own hands can be solved by a pair of skillful hands over the weekend. There is nothing complicated in the construction of a country barbecue; you can see this for yourself in the drawing.

The device of a simple barbecue.

Firebox: The inner wall of the barbecue can be lined fire brick. It is better to move the wall forward a little for more convenient access to the grill grate.

Grill grate: Choose cast iron or stainless steel. Supported by corner ledges.

Foundation: a concrete platform (8-10 cm) on a bed of compacted crushed stone (8-10 cm) ensures the stability of the grill structure.

Brick walls: They form a closed grill frame, reducing wood consumption by 65% and protecting against hot sparks.

Ash pan: metal sheet for fuel. Placed at a distance of 20-35 cm below the grill grate.

Make a grill yourself or buy it?

If you have bricklaying skills, no back problems, and a couple of friends willing to help you, then you can make a barbecue yourself in a weekend.

Where to place a barbecue on a summer cottage?

Determine the prevailing wind direction and install the grill so that smoke does not fly into the house or recreation area.

What to make a grill from?

Concrete foundation blocks – the cheapest building material for the barbecue. Inside the firebox it can be lined with refractory bricks for greater heat retention. The outside of the grill can be lined with natural stone.

Natural stone– natural stone retains heat well. Allow enough time to select and fit the stone. In addition, it is good to have some excess stone in reserve, because... It is difficult to predict the exact consumption of material for the construction of a barbecue made of natural stone.

Red ceramic brick - almost optimal choice for the construction of a barbecue. Externally attractive, retains heat well, and is not afraid of interaction with open fire. For a brick grill you will need a little more skill in brickwork than for a barbecue made of concrete blocks.

How to heat the grill?

Use dry logs of fruit species, which add an unforgettable aroma to all dishes cooked on the grill. Provide a place in the grill design where you can place in advance suitable logs that you received when pruning fruit trees.

Barbecue tools.

Forceps– the longer the better for your safety.

Brush made of metal for cleaning the grill grate.

Gloves for barbecues that can withstand high temperatures.

Additional barbecue options.

Barbecue with spit, which will make it possible to evenly fry a large piece of meat.

Brazier with chimney– will allow the smoke to be collected and diverted upward away from summer kitchen or a gazebo next to which a barbecue is installed.

Fireplace with barbecue– Do you want to build something grandiose at your dacha? Building a fireplace for a patio or summerhouse, into the walls of which we build in corners to support the barbecue grill.

The grill grate should be hot. Preheat the grill for about 15 minutes before placing the meat on the grill.

Create different temperature zones for the grill grate by moving some of the coals to one side. Fry meat on the hotter side, vegetables or fish on the cooler side.

Do not turn the food on the grill every minute; in order for the meat to fry, it is enough to turn it once, frying for 5-6 minutes on one side.

Add flavor. Whatever the type of firewood in your barbecue, you can always enhance the aroma of the food you cook by soaking a couple of branches of fruit species in water for a few minutes and then placing them on hot coals.

Give it a rest. Leave the cooked meat to cool for a couple of minutes, so the juices will be better distributed in it.

The correct coals for cooking on the grill are red with light touch gray ash.

Barbecue and safety.

Food poisoning. Wash your hands, buy meat from safe places. This best advice to avoid food poisoning in the midst of your picnic at the dacha.

Charred meat. Do you like well-done meat? Don't char the kebab until it turns black! Charred food particles double your risk of cancer. So you can raise a toast to health and to meat with a slight redness inside.

Carbon monoxide poisoning. Everything is good in its place. If you're grilling in bad weather and the crazy thought “why don't I do this in the garage” comes to your mind, chase it away with a filthy broom. Concentration carbon monoxide indoors can become dramatic for you.

Fire. At least 3 m from buildings, wooden fences, sheds, etc. will give you the opportunity to avoid colossal fire damage and serious injury.

Heatstroke.“It’s so hot in here I’m going to have a stroke.” This may not be just a joke. Overheating can cause serious illness for people with cardiovascular disease.

Loose clothing. Do not wear loose clothing with loose sleeves or flaps when working on the grill. A spark that hits it may not produce the fireworks you planned.

Deep frying. Working with deep fat is best left to professional chefs. Spattering particles of fat, open fire - it’s better not to overestimate yourself, we are smart enough to understand that “the game is not worth the candle.”

Be careful, wasp. Wasp stings are extremely painful and very dangerous for people with allergic reactions. Therefore, it is better to have anti-allergenic drugs in your first aid kit and wear a long-sleeve shirt.

Coals and fire safety. Wait 48 hours before disposing of the ash from the grill.

How to care for your grill?

Clean the grill grates with a steel brush to prevent ash and food debris from accumulating there. Spray the cooled grill grate sunflower oil to prevent the formation of rust on it. Remove ashes after each use of the grill to avoid the accumulation of foreign odors for the next cooking.

Whether you make a barbecue yourself or buy a ready-made one, it will bring you many pleasant moments when, with a barbecue in your hand, admiring the open fire in a pleasant company, you will get a much-needed respite from the busy daily rhythm.

Tags: ,