A stool is an indispensable piece of furniture. It is used in city apartments and country houses. The models presented in furniture stores do not always meet the requirements of customers. Some are not satisfied with the price, others - with the appearance and technical characteristics.

When faced with a similar problem, the best solution would be to make a stool at home. There is practically nothing complicated about this.

Design

The stool has a simple design. Even wood waste, blocks, plywood, etc. are suitable for its creation. The standard and simplest model consists of several parts, well-fitted and securely connected.

Even more photos, as well as step-by-step instructions from the master, are on this website https://masterinterera.ru/mebel

The structural elements are often the same. To make a stool from wood, you will need:

- Lid. It has a round or square shape.

- Dowels. With their help, the parts are securely fixed.

- Wooden legs.

- Additionally, the design contains such details as “crackers”, legs and drawers.

Such names hardly mean anything to home craftsmen. Therefore, we will consider them in detail. All of them are responsible for connecting the stool and giving it maximum strength.

Tsargi are planks or bars that are located under the seat. They connect the legs of the stool (a tenon joint is most often used) and form a reliable support.

“Rusks” are wooden or metal parts in the form of corners that are mounted under the seat on the inner corners.

The legs are located in the center of the legs or in their lower part. They connect them, increase the strength and reliability of the entire structure.

The described details are not mandatory when creating a stool. But it is not recommended to forget about them. They will make the product more reliable and safe.

How to make a simple rectangular stool?

Having dealt with the design, it’s time to start actual manufacturing. Let's look at a few examples. The simplest is the rectangular model. Good for small rooms.

Technical characteristics of this design:

The height of the finished product is from 44 to 50 centimeters;

- Leg section: 3.5 x 3.5 or 5 x 5 centimeters;

- Drawers – 29 x 6 x 2 centimeters;

- Spacers – 29 x 2 x 2 centimeters;

- “Crusks” – 6 x 6 x 2 centimeters.

All details must be prepared in advance. You can make them yourself or order them from a carpentry workshop. If you want to get an original and beautiful product, then you should make curly or turned legs.

Then comes the crucial stage. You need to measure exactly where to make the holes for the fasteners. The dry assembly method is used. Thus, you can even do without glue.

Instructions for creating a stool with spread legs

Let's look at an example of how to make a stool with your own hands, in which the legs will diverge in different directions.

The legs are made from four bars. They should be the same size. It is recommended to use a saw with a miter cutting method. It will help to prevent errors and obtain ideally sized parts.

We cut off the top of the legs evenly and connect the bars. They should be perpendicular to the floor. To avoid confusion, it is recommended to make notes on the inner corners.

We make external struts for the legs from small bars. To securely fasten them, we make holes around the perimeter. Make sure their shape matches the studs of the spacers. During installation we use wood glue. It will increase the reliability of the finished product.

For the legs located on the sides, we prepare blind grooves. The bars that are inserted into them must be properly secured.

We mark holes in the upper base and attach four legs. This will require adhesive and screws. After this, the stool must be left for several hours to allow the glue to dry.

When making a round stool with your own hands, you can take care of additional decoration of the product. For example, the seat is upholstered with foam rubber and leather (a budget option is leatherette). This will make it soft and more comfortable. The foam needs to be cut on the sides.

It is advisable to round the upper edges and cover it with upholstery material. To keep it all securely, you need to use a mounting stapler. We fasten the material to the bottom of the seat with staples.

The seat can also be decorated with braid, fur, fringe, etc. If you lack imagination, then look on the Internet and get inspired by examples of photos of stools made by home craftsmen.

If you do not plan to upholster the seat with leather and foam rubber, then thoroughly clean it with sandpaper, cover it with stain and apply a layer of protective varnish. It is recommended to file the side parts of chipboard.

Photos of DIY stools

“Can you put together a box? Yes? Okay, you’ll make stools for now.” This is from a conversation with a new job seeker in a small furniture company. Indeed, making a simple stool with your own hands is no more difficult than making a box. That one may be more difficult if it is retractable in a nightstand. Therefore, for those interested in carpentry, it is better to master it by starting with a stool. You won’t save a lot of money on this, stools are inexpensive. But the acquired skills will allow you to start working on large cabinet furniture, which will give you significant savings, plus unique items in the interior.

A stool as a starting object in the furniture business has another advantage: it requires little planing and sawing work with the inevitable debris, you can test your carpentry abilities on the balcony or even in the kitchen. Having made sure that things are going well, we will think about a carpentry workshop with a workbench and other things; Without it, you won’t be able to make the furniture more impressive.

The device and something about the terms

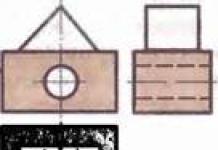

A classic wooden kitchen stool is constructed as shown in Fig. It also shows that its design is a little complicated for a beginner, but we will get to it through simpler samples, but no worse. In this case, the picture is needed for something else.

The reader may think that calling the support beam a drawer, and the ties/spacers with legs is a purely furniture-specific feature, sort of like a sailor’s bench is a bank. As for the kings, this is not so. Drawbars can also be found in other branches of technology, and there they are by no means beams, either in appearance or in the nature of the load.

In fact, the drawer is a structural element that distributes multidirectional loads across the components of the power circuit. When distributing the load, it is impossible not to experience it, therefore it is structurally, technologically and economically justified to make the drawers also load-bearing, i.e. make them work.

In furniture production, the frame is most often combined with a support beam in the form of a board or beam placed on the edge. This idea is so ingrained that some experienced carpenters consider any such board to be a tsarga. However, drawers in furniture are very diverse.

For example, at pos. 1 pic. (underneath a stool with legs in sockets) the drawers are still quite drawer-bearing beams, only made of timber. But already at pos. 2 kings are scarves, and their frame does not hold anything and is only decorative; on pos. 3 tsar-kerchiefs can do without it. And at pos. 4 (dressing table) drawer - a jib, which is a beam no more than a gusset.

Table with removable legs, pos. 4, the case is generally interesting. When it is disassembled, the drawer will be a shaped steel brace, because only in this case it keeps the boards of the underframe from breaking out of the tabletop when pushed, or simply from falling apart if the tabletop is also removed. But when the legs are in place, their heads are pressed into the corners and the table is standing, the boards of the underframe will become both beams and drawers, because support both vertical and lateral loads. In this case, it is even legitimate to talk about attaching the legs to the drawers (!), because the product acquires proper strength and rigidity only when the mounting units of the legs are assembled and loaded.

Drawers made from boards can also be vertical posts rather than beams. In this case, they are called combat drawers, pos. 6. In general, with drawers you need to do the same as with beams: first of all, look at how they work in the structure, but how they look is the second to fifth question. It was necessary to immediately be distracted by the drawers, because... in furniture they are found all the time.

What are we going to do?

To make a stool, let's see what you can do. Not everything, there is an endless variety of stools, but for starters, typical examples. Our task is to choose what is simpler and better for a specific purpose.

The classic kitchen stool can be both utilitarian and very artistic, pos. 1 and 2 in Fig. Its design has evolved over centuries and such stools serve for many decades. The strength of the structure allows the stool to be used as a work table, everyone knows this. You can start working on a classic stool from the very beginning, having learned a few woodworking techniques, see below.

In lightweight stools, pos. 3-8, the legs are attached either without drawers at all, in sockets in a thick, durable seat, or in sockets in kerchief drawers. In the first case, both the seat and the legs have to be thickened, so such stools are inferior to others in strength, often in appearance and position. 3.

To make a lightweight stool strong, its legs are tied with tie rods: the lower, the stronger and the thinner the tie bars can be, pos. 4 and 5. But the low frame made of ties interferes with the legs of the person sitting, and cutting into the thin legs of the stool weakens them. Therefore, instead of a simple frame, they often make an H-shaped one, pos. 6, or place ties at different levels, pos. 7.

The greatest strength and convenience is provided by the X-shaped tie system (tie cross), pos. 8. With a certain configuration of the legs, it is possible to do without the lower cross; One example of this kind will be discussed below.

Important subtleties

If you ever decide to make a lightweight stool, keep in mind, firstly, that its legs should be slightly apart, i.e. the axes passing through the centers of the heads and heels of the legs should deviate from the vertical by 7-12 degrees outward relative to the axis of symmetry of the stool. The second option is that the legs should be arched and expand upward, see below. Without one or the other, the legs may break even when slightly rocking on a stool. Moreover, both solutions are valid if the stool is symmetrical about the vertical axis, i.e. not extended in plan. An exception, up to a proportion of 1:1.5, is a stool with ties at different levels; it can be pulled out in the direction of the lower ties.

Second, in order to cut the heels and heads of the legs to the required angle, their blanks need to be collected in a tightly tightened bag and cut in 1 pass. Otherwise, the stool will remain an oblique spread: the vertical legs can then be adjusted to the length along the length, but the accuracy of the angles required for processing the legs one by one is simply impossible to achieve on wood. The angles will already be half a degree or a degree away from the drawing, but this is not so important, as long as all the legs are the same.

Stools-cabinets, pos. 9 and 10, are heavy and material-intensive, but very durable, because consist, from a mechanical point of view, of 3 sides located in mutually perpendicular planes. These same stools are easy to make, and it’s better to start mastering furniture making with them. In such a case - in Fig. drawings of 2 types. At pos. on the right, the details of the cabinet also cut into half the tree, see below; The groove for insertion is not shown. The seat in both cases can be of any centrally symmetrical shape; they place it on dowels, see below. The covers on round pedestal stools make them look indistinguishable from more labor-intensive poufs if you make an upholstered seat, as described below.

Note: in the inset at the bottom left of Fig. variant of a stool-cabinet for a summer residence. It requires 4 parts, but it does not get bogged down in loose soil.

Box-shaped, or panel, stools (items 11 and 12) require 4 parts, but are lighter and less disturbing to the legs. Making them is no more difficult than the previous ones, and all connections are dowel, which makes the work somewhat easier. Box stools can be extended in length until they become benches, and their strength and stability depend very little on height. The well-known utility stool (item 12) is from this breed. In general, stools made from panels are also a rewarding object for a novice carpenter, so we provide drawings for them of several types: a normal room height, on the right in the figure, a utility one lower, on the left there, and below - the construction of a very small children's stool.

Note: in Fig. on the right is a diagram of a reinforced box-shaped stool. Pos. c) there is a way to make it look more attractive by veneering the sides. This stool is well suited for the dacha: it is simple, light, inexpensive, looks good, and is not inferior to the classic one in terms of durability and convenience.

Stools for pos. 13 and 14 only look like box-shaped ones, but in fact they each have 4 wide and flat legs. Therefore, such stools must be made with drawers made of boards or beams, and the legs must be fastened with a leg. True, in this case there is only one and can be located so that it does not interfere with the legs at all.

The next variety available for beginners to make on their own is step stools with X-shaped legs. To give them the required strength, they require either 2 drawers and 2 legs, located mutually perpendicular, pos. 15, or 4 drawer-beams forming the upper frame, and 1 tie between the crosses of the legs. The latter option can be fit into the interior of a living room or bedroom, but most of all the spreaders are made folding. If you suddenly become interested, see Fig. folding country stool, drawings and folding method. You can assemble a country house set from these and a garden folding table. In general, there are many designs of folding stools for different purposes, from a fishing stand to furniture for picnics, and some of them are easy to make with your own hands.

Note: All the described stools are quite plastic and tolerant of the configuration of parts, so their creative executions in different styles and poses are possible. 17-20.

Materials, tools, technology

What to make it from?

The wood is suitable for making any stool. In terms of strength and durability, a wooden stool is second only to a forged metal one, and in terms of convenience and functionality it has no equal among its brethren. Any quality wood will be suitable for a stool, except for very soft and easily rotting species: poplar, willow, aspen, alder.

The quality of wood for any furniture is determined, firstly, by the absence of visible defects: cracks, falling knots, chips, wormholes, traces of rot and mold in the form of spots of a color unusual for this species, see fig. Secondly, the wood for furniture must be room-dry, with a humidity of 8-12%. Kiln-dried wood (humidity up to 8%) is of limited use for furniture, because during the drying process, its structure may be damaged and furniture made from it in the room may shrink or crack over time.

Note: cross-grained and twisted wood for furniture in handicraft production is in many cases acceptable, and sometimes desirable, because allow you to get a beautiful texture. The famous Karelian birch is nothing more than an ordinary warty birch, completely curled due to unfavorable growing conditions.

The wood is air-dry, with 12-20% humidity (this is ordinary timber) must be kept in a dry room at a temperature of 15-30 degrees for 1-6 weeks, stacked on stands that do not dampen. The initial plots (boards, beams) are placed on supports at intervals, and the next belt (layer) of the stack is also placed on supports; Now you can use the same plots as them, laying a pair across.

Note: It is impossible to dry the wood under the influence of heating devices or incandescent light - we will get very poor chamber wood.

They usually use pine or spruce for the seat of the stool, and harder wood for the legs: birch, oak, maple, beech. Of course, the entire stool can be made from hardwood. Of the fairly accessible imported breeds, wenge, hemlock, and mahogany are suitable.

A complete replacement for wild wood will be modified wood - medium and high density MDF. MDF is not impregnated with anything; it is made from industrial wood sawing waste compressed at elevated temperatures, i.e. The material is completely environmentally friendly. MDF is inferior to wild wood in terms of abrasion resistance, so it is advisable to fill the heels of MDF legs with solid wood soles.

From plywood you can make pedestal and box-shaped stools, as well as covered stools with an X-shaped tie of legs (item 8 in the figure at the beginning) and similar ones in the power scheme. Also, plywood will fit on the seat of any stool. As a rule, only box-shaped stools are made entirely from chipboard, because... in the designs of all the others there are points of concentrated loads, which chipboard does not support. But chipboard will also work well on the seat.

Note: It is highly advisable to impregnate plywood for furniture with a water-polymer emulsion on both sides and on the end.

About the glue

Most furniture joints are glued. Traditionally, bone wood glue is used for this. It is inexpensive, does not require touch-drying before joining parts, and gains strength as soon as it hardens. But to prepare it you need a glue maker, which, however, you can make yourself.

Liquid nails wood glue is very strong. It also makes it possible to hide glue seams, because... it is tinted to look like wood with sawdust, or you can buy a ready-made tinted one. Even better is water-based acrylic wood glue.

Liquid nails and acrylic are quite expensive, so in many cases they are replaced with almost equally durable PVA, but not the usual office grade for paper, but for wood. The corresponding marking must be looked at on the label, and wood PVA is sold not in office supplies, but in construction and hardware stores. It is necessary to glue parts on PVA only after exposure to tack; glue is applied to both parts to be joined. Allow for at least a day to gain strength, only then can you continue working or load the connection.

Note: All adhesive joints do not hold seam shear well, i.e. they need to be reinforced in this direction in various ways; about some, see below.

What to do?

We will assume that since you are a craftsman, you have simple measuring, marking and working tools, including chisels and chisels. It is also advisable to have a caliper with a depth gauge. But in order to start making stools and furniture in general, you need to stock up on a couple more devices first.

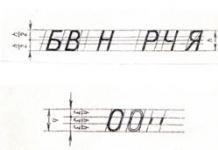

Firstly, a surface gauge (reismus) for marking, see fig. You can do it yourself by using a couple of screws instead of a lever lock. If you wish, you can use a homemade surface planer; amateurs do it.

Secondly, wooden panels for furniture are not assembled just like that; they will come out hunchbacked and cracked. Shields need to be united, i.e. When assembling, do not glue the boards, press them tightly against each other with their edges until the glue dries completely and gains strength. See below how the shields are held together, but for now you need to make devices for this: plazas or weims. The basis in both cases is strong, even and seasoned boards of at least 150x50 for plaza and 120x50 for vaym.

A very convenient plaza made from a screw clamp and a stop with a dead center, pos. 1 in Fig. If there are no components for it, then the simplest plaz, pos. 2. The boards in it are compressed with wedges, pos. 2a, alternately beating with a mallet, and roughly matching the size of the shield, place a spacer from the same board as the base of the plaza.

Large shields, approximately longer than 50 cm, cannot be rallied on the plaza, because its base itself bends. In addition, the extension of the edges of the boards beyond the plaza should not exceed 150 mm, i.e. on a plaza from 250 mm boards you can assemble a shield up to the same 50 cm wide. This is enough for a stool, but for the future it is better to get 3-4 wires, pos. 3. The fastening of the end stop bosses in all cases must be very strong, using M8-M12 through bolts with nuts, because Very large forces act on the work stops.

How to do it?

To make a stool, you first need to master several types of connections of wooden parts:

- Insert into half a tree (half a tree).

- Tongue and tongue connection.

- Tongue-groove connection.

Half a Tree

Half-tree connection shown in Fig. Technologically, it is the simplest and quite reliable if it is additionally fastened, 2-3 points per connection, with dowels, self-tapping screws, bolts, nails and, optionally, glued. When working with a hand tool, the recesses are first sawed along the edges, not reaching 0.5-1 mm to the desired depth, and the excess material is removed with a chisel. Making cuts deeper in order to knock off the excess with one blow is a manufacturing defect!

Half-tree connections are closed, pos. 1, this is how the crosspieces are assembled, open, pos. 2, for assembling corners, and blind (closed) halfway, pos. 3, for insertion on the run. In addition, half a tree can be connected either side by side, pos. 1-3, and along the edge, pos. 4. In the latter case, if the parts are high enough, the connection holds well and only with glue without additional reinforcements; This is how the supports of stools/pedestals are assembled.

Tongue and tongue and groove

For tongue-and-groove joints, pos. 1-3 in the figure, the 1st point of additional fastening or just gluing is enough. The tongue-groove connection can be open single, pos. 1, open double, pos. 2, triple, etc., or closed, pos. 3. The latter can be separated only by pulling the part with the ridge, and open tongue-and-groove joints can also be done by rotating the parts relative to each other, i.e. a closed tongue-and-groove ridge is technologically more complex (the hole must be drilled along the edges with a drilling depth limiter and then carefully hollowed out), but stronger and more reliable.

Mortise-tongue and tongue-and-groove connections are mechanically similar, so they are often confused. For example, connections to pos. 1 and 2 in old Soviet textbooks for vocational schools are called tongue and groove. But in fact, the shoulder of the tenon, unlike the shoulder of the comb, goes around the tenon on all sides, pos. 4. This makes it possible to hide the semicircular edges of the hole selected by the end mill, and makes the connection resistant to breakout in 2 planes, along and across.

The tenon, like the closed tongue-and-groove, can be wedged when assembled with a wedge made of hard wood, also pos. 4. The connection becomes permanent, but very strong and no visible additional fastenings are required; glue will last forever. The connection on a wedged tenon is generally “dead”; it is easier to break the entire product into pieces than to separate it.

Note: There are many types of tenon joints used in furniture; For example, a small part of them is shown in Fig. right. We will get acquainted with the necessary ones along the way when describing the corresponding types of furniture.

Dowels

The dowel connection is the most important thing in carpentry, because... it is quite strong and invisible, i.e. completely closed. Actually, a dowel is a round or octagonal tenon made of hard wood, made separately from the parts being connected. How the connection is made with dowels is shown in the figure; for marking, you can’t do without a surface planer.

The dowels can be wedged during assembly, see fig. on the right, then they are called dowels; The wedges must be placed across the grain of the wood of the parts being joined. The dowel connection is permanent, but very strong and reliable. The connections on the dowels are usually glued.

The attentive reader probably already has a question: where can I get them, these dowels? Random twigs and slivers will not be reliable. It’s true, dowel sticks are available for sale, but you can also make them yourself. In general, the main dowel connection in furniture has a lot of other subtleties, so we give a selection of videos:

Video: dowel connection

Video: making round sticks for dowels and arrows

Video: a device for making dowels with your own hands

Video: homemade jig for drilling holes for dowels

Rally

Boards are assembled into furniture panels in different ways. On a tongue and groove connection (a type of tongue-and-groove connection), pos. 1 in Fig., it is easiest to consolidate if you use tongue-and-groove boards. Due to the large contact area of the surfaces being connected, glued tongue and groove is very reliable and is often used. However, only boards of sufficient thickness can be tongue-tied, because the tongue crest should, on the one hand, be no wider than 1/4-1/3 of the thickness of the board, and on the other hand, it should not be narrower than 10-12 mm. It is believed that the minimum thickness of wild wood boards for joining onto tongue and groove is 30 mm, but it is not recommended to join boards less than 40 mm onto tongue and groove; The dimensions of the tongue for a forty board are shown in Fig. higher. MDF and laminate panels can be tongue-and-groove with board thicknesses of 16 mm or more.

Joining in rebate, pos. 2, secure only if the fold has a lock. A lockless rebate is just a quarter, and a shield made from quarter boards will not be reliable, just like a shield assembled into a batten, i.e. just the ends of edged boards. It is difficult to make a locking rebate at home, so they, like the locking tongue and groove, are used to join panels made of MDF or laminate, see fig. right. In this case, the thickness of the boards can be from 12 mm.

Rallying on dowels, pos. 3, perhaps solid wood boards from 20 mm and MDF/laminate from 12 mm, but it is labor-intensive and difficult. It is best to join thin boards using a smooth reveal, pos. 4. The grooves for the fugue will have to be selected using a manual wood router with a disk cutter, but the fugue itself can be made from plywood from 3 mm, which makes it possible to join together “wild” boards from 12 mm.

About the seat

Sitting on a hard stool for a long time is uncomfortable, so something softer will do just fine. How the soft seat of the stool is arranged is shown in pos. 1 pic. You should immediately note that it is better to make the external upholstery from burlap, and sew capes for the stools from decorative furniture fabric. The stool is used intensively, often carelessly, and expensive jacquard, etc. It will soon get oily. And the cape can be washed, and sewing it is much easier than a cover for a chair or armchair.

The inner lining is installed on glue with a wing turn of 60 mm, pos. 2. Glue is applied only to the base and the wings are applied, drying it until it sticks. Foam rubber is chosen “by snap”: compressed to the limit with your fingers and suddenly released, it should straighten sharply, and not pull up smoothly.

The outer skin is also installed with glue, with the inner wings overlapping by at least 30-40 mm. To prevent it from creeping, its edges are tied lengthwise and crosswise with harsh threads, and the threads are sealed with thick paper, thin cardboard or just tape, so as not to accidentally break. Upholstery nails, if necessary, are imitated with pushpins, pos. 3. The seat is attached to the base when it is completely ready.

The wicker seat pos. does not irritate the “fifth point” at all. 4, but it requires a reliable frame, like a classic stool. Lightweight stools and stools without a tightly attached seat are not strong enough. Modifying cabinets and box stools by replacing the top board with a frame is not worth it for the same reason.

Note: the dimensions of ordinary, not for a bar, stools are 420-450 mm in height; the seat is from 350x350 to 400x400 mm square and with a diameter of 300-450 mm round.

Examples and samples

The most reliable and functional, as we see, is still the classic stool; No wonder she became one of the classics. Therefore, we also provide its drawings, see Fig. Pos. A – general view and structure; B – method of fastening the seat; B – detailing; D – scheme of joining the seat on the dowels; D – base assembly; E – checking for evenness by measuring pairs.

However, established canons do not exclude evolution up to revolutionary changes. Revolutions are generally not necessary for society because they are ruinous, but in technology they are almost always fruitful. An example is a lightweight stool for the kitchen based on a classic one, see next. rice. The use of plywood (top frame), laminate for the seat and, most importantly, the extension of the drawers outside the load-bearing belt, gave rise to a very simple, light, cheap and convenient design - there are no protrusions. And in terms of strength, it will not be inferior to the classics, but you can’t make a wicker seat.

And finally, a version of the base of a lightweight stool without legs. See fig. for assembly method. Material – wood or plywood. The seat can be anything. Thanks to the correctly chosen configuration of the legs, the stool is quite reliable, and in appearance, especially with a soft seat, it will fit into any living room.

In conclusion

Making furniture with your own hands is not only economical, but also exciting. And therefore - good morning! From a simple stool to a wardrobe or bed that will make the seasoned designer gasp in admiration.

And site guests. Today I want to show off another of my homemade products - a pouffe stool with a soft seat and a place to store small items inside.

To make this thing we need old shelves from cabinets or a piece of thick plywood, at least one centimeter thick. Tools needed:

drill and drill bit with a diameter of 6 mm

grinder with grinding disc

circular saw

roulette

measuring corner

furniture bolts and a key for them

two small loops for the saddle

glue gun, several small nails with a wide head

Now let's begin the process of assembling the stool.

step 1.

we take the source material. in my case, these are shelves from old Soviet cabinets.

Now we need to mark the blanks. The height of each part is 35 centimeters. I made two parts, the sides, 30 centimeters wide. the remaining two are 27 centimeters each.

we cut it out. the following blanks are obtained for the future stool

step 2.

Now we mark on the side of the workpiece the places for the holes for fastening the furniture bolts. We apply one side panel to the edge of the other, mark the width with a marker and, in any order, make holes in any place convenient for you.

Now that we have drilled holes on the side panel, which is 30 centimeters wide, we apply another side panel, which is 27 centimeters wide. and with a pencil we mark the markings for drilling at its end so that they coincide with the holes on the first sidewall.

drilling one hole in the end of the part 27 centimeters

we drill out others.

Step 3. For this, I no longer marked each hole, but simply tightened one furniture bolt and aligned all the edges of the part, and began to drill along the holes of the first part. it turns out much faster and more convenient.

tighten all the bolts. you will need three of them on each side

Step 4. We carry out similar actions with all the details. As a result, we get a rectangle that is the basis of our stool.

Step 5. The next stage of work was sawing out the bottom and lid of the stool. I got two blanks with the dimensions indicated in the photo

the dimensions of the upper part, which will be the seat, are indicated in smaller sizes, since the foam rubber will be attached to it and if the dimensions are left as on the lower part (the bottom of the stool), then the lid will close very poorly.

Step 6. Next, I took a grinder with a petal disc and sanded all the ends and sides of the rectangle.

Step 7. The next step is to attach the bottom part (bottom) to the rectangle. take 4 furniture bolts and screw them in. they will be quite sufficient. The part holds tightly.

step 8. Now that our stool is assembled, let's get down to what, in my opinion, is the most tedious task. we need to cover it with fabric to give it a finished look. take a piece of fabric whichever you like best. spread it on a flat surface and place a pouf on it.

Next, we attach the fabric to the edge of the stool with a stapler.

We stretch the fabric around the entire perimeter of the part so that it is wrinkle-free. when we approach the already stapled edge, we bend the fabric and also fasten it to the staples.

Since the wooden base is quite strong and staples cannot always penetrate it, we knock it down with a hammer.

Step 9. After covering, unnecessary fabric remains at the ends. we trim it.

We leave a few centimeters at the bottom and top so that we can bend and hide the ends.

We fasten the fabric at the ends of the stool with staples.

this is what it should look like. folded and covers the corners.

step 10. take another piece of fabric, but more dense. We will attach it to the very bottom of the stool, covering part of the trim and the open space.

We fasten with staples, then we knock them out with a hammer. it turns out like this:

We do the same with the upper part. We fasten the fabric to the edges of the stool.

Step 11. For the next steps we will need 2 pieces of foam rubber and a glue gun.

We put a smaller piece of foam on the seat and glue it.

Step 12. We attach the remaining piece of foam rubber, larger in size, on top of the first. we turn the corners and from the inside

We attach the sides of the seat.

It turns out this is the detail.

When purchasing furniture, you can notice a clear discrepancy between the prices of materials for their manufacture and the final price of the product. This is especially noticeable when purchasing fairly simple pieces of furniture, such as stools.

Stools are most often made from chipboard.

Stools are most often made from chipboard. It is a fairly cheap material, easy to work with, durable and perfect for indoor use. Taking one look at a chipboard stool, it’s easy to understand that making one with your own hands is quite easy. We invite you to familiarize yourself with detailed instructions for making various configurations of stools at home.

Taking one look at a chipboard stool, it’s easy to understand that making one with your own hands is quite easy.

You can make a stool with your own hands, having professional and non-professional elements and devices at hand.

Required tools include:

- electric jigsaw, complete with a fine file;

- screwdriver

To decorate the seat of the stool, you can also prepare foam rubber and upholstery materials.

You may also need a drill with a drill and a stapler for construction purposes.

The upholstery can be fabric, oilcloth, leatherette.

To simplify the assembly task, you can first glue the parts together and then secure them with self-tapping screws.

Materials for production:

- chipboard sheets, new, substandard or remaining spare parts from old furniture;

- self-tapping screws, no longer than the thickness of the chipboard;

- confirmations 4 pieces. Dimensions 6.4 mm by 50 mm;

- metal corners 4 pieces;

- adhesive tape for processing sheet edges;

- thrust bearings made of any acceptable materials;

- sandpaper for sanding.

Creating a stool from chipboard with your own hands allows the master not to limit himself to standard models.

Non-professional tools that can be found in any home:

- pencil or marker;

- cardboard for making templates;

- ruler or tape measure;

- knife of any configuration, most importantly sharp.

The seemingly simple design of a stool has several dozen different models.

The parts of the stool are assembled using confirmations and self-tapping screws.

To decorate the seat of the stool, you can also prepare foam rubber and upholstery materials. The upholstery can be fabric, oilcloth, leatherette.

You can look at visual examples in furniture stores, from neighbors or on the Internet.

Create a project

Creating a stool from chipboard with your own hands allows the master not to limit himself to standard models. The seemingly simple design of a stool has several dozen different models. You can look at visual examples in furniture stores, from neighbors or on the Internet.

Usually several stools are needed at once, so it is extremely important to choose one shape you like and make identical objects according to the chosen drawing.

When starting the final assembly of parts, it is necessary to pre-treat all cut edges with a special tape.

Usually several stools are needed at once, so it is extremely important to choose one shape you like and make identical objects according to the chosen drawing. When making a drawing, it is important to remember that the design of a stool requires a strict balance between its lower and upper parts. A discrepancy between the dimensions of the seat and the width of the legs can lead to an imbalance, as a result of which the object will be very unstable and therefore dangerous.

When making a drawing, it is important to remember that the design of a stool requires a strict balance between its lower and upper parts.

Choosing material for manufacturing

Stools can be made from different materials. Chipboard, multi-layer plywood, wooden blocks and boards are suitable. The cheapest and easiest to use material is chipboard. Sheets can be purchased in a store, at furniture factories, or you can buy scraps from small companies that make custom-made furniture. Sheets of old chipboard that were previously parts of other furniture are also suitable.

A discrepancy between the dimensions of the seat and the width of the legs can lead to an imbalance, as a result of which the object will be very unstable and therefore dangerous.

The final step in preparation before assembly will be drilling the necessary holes.

We apply graphic markings

Stools can be made from different materials.

Having decided on the model of the future stool, you need to mark a sheet of chipboard, thereby preparing it for further work. If you plan to make several identical stools, then it is better to make a pattern for all parts of the furniture. It is convenient to make the template from thick cardboard.

For further ease of use of the manufactured furniture, the corners of the parts should be rounded. It is better to make even curves using a compass. The absence of this item can be compensated for, for example, with a plate of suitable diameter.

The cheapest and easiest to use material is chipboard.

High speed will ensure cutting of sheets without chips or nicks.

After trimming, you need to sand all the edges of the stool with sandpaper.

Depending on the selected shape and model, the dimensions of the elements may be as follows.

No. Stool model Seat dimensions Leg dimensions Crossbar dimensions

- 1 30x30 30x40 20x12

- 2 30x40 30x40 30x15

- (3 pieces)

- 3 40x40 20x35 (8 pieces) 30x20

- (4 pieces)

Sheets of old chipboard that were previously parts of other furniture are also suitable.

Cutting out elements for the future stool

The main thing is to decide in advance on the number of pieces of finished products and calculate the required volumes of materials.

Cutting out elements from existing pieces of chipboard is done using an electric jigsaw.

Cutting out elements from existing pieces of chipboard is done using an electric jigsaw. You can make a good edge cut using a fine file and high speed jigsaw. High speed will ensure cutting of sheets without chips or nicks.

After trimming, you need to sand all the edges of the stool with sandpaper. This processing will ensure a good fit of one part to another and simplify assembly.

The final step in preparation before assembly will be drilling the necessary holes. Make sure the holes are drilled at the same level.

Having decided on the model of the future stool, you need to mark a sheet of chipboard, thereby preparing it for further work.

Assembling the stool

When starting the final assembly of parts, it is necessary to pre-treat all cut edges with a special tape. The tape must be chosen to match the color of the sheet or, conversely, contrasting shades.

The tape is applied to the cut of the legs and seat and glued with a hot iron. The iron must be applied with quick and short movements. The warm tape should be pressed down with a clean cloth. The glue, which is on the back of the tape, sets very quickly and does not require long heating or cooling.

The parts of the stool are assembled using confirmations and self-tapping screws. To simplify the assembly task, you can first glue the parts together and then secure them with self-tapping screws.

The seat of the resulting chair can be made soft using foam rubber and upholstery material.

For further ease of use of the manufactured furniture, the corners of the parts should be rounded.

It is better to make even curves using a compass.

VIDEO: Do-it-yourself stools made from chipboard scraps.

50 photo ideas on how to make a stool with your own hands from chipboard

There is always some kind of furniture in any home. In the kitchen, a table, various types of wall and floor cabinets, and simple stools are most often used. These seats have a fairly simple design, are not particularly beautiful and the materials are expensive, but their cost is quite considerable. But you can make a decent stool with your own hands from the simplest materials. The product will turn out to be very cheap, but it will look no worse than from a furniture store. How to make a stool with your own hands?

Image 1. To make a stool, you can use new sheets of chipboard, or you can use the remains of old furniture.

Preparing for work

To make a stool (image No. 1), you need to find a couple of pieces of chipboard. These can be new sheets, or you can use separate parts from disassembled old furniture. For a test copy, just prepare:

- Chipboard 40x30 cm - 2 pieces;

- Chipboard 30x30 cm - 1 piece;

- Chipboard 20x12 cm - 1 piece;

- pencil;

- ruler;

- drill;

- drill with a diameter of 5 mm;

- electric jigsaw;

- screwdriver;

- confirmations 6.4x50 mm - 4 pieces;

- furniture thrust bearing of any shape;

- furniture corners - 4 pieces;

- several small screws;

- sanding paper;

- edge processing tape;

- electric iron;

- sharp knife;

- foam rubber and a piece of fabric or leatherette 41x41 cm;

- furniture stapler.

Making a stool

Image 2. Drawing of a stool with dimensions.

To make a stool, you need to complete several stages of work:

- On chipboard blanks you need to draw life-size side posts, a lintel and a stool seat (image No. 2).

- Cut out the parts and round the corners.

- Drill the necessary holes in the parts.

- Process the edges of the parts.

- Assemble the stool.

- Install upholstery (optional).

If you plan to make several stools, then it is better to make templates for each part out of cardboard. Place the finished template on the chipboard and trace it with a pencil. This will speed up the work process, and all details will be completed with high quality. Curvature lines on parts or on a template can be drawn by hand, but it is better to use a compass or a round object of suitable diameter.

Cut out the marked parts with an electric jigsaw (image No. 3). The file should have fine teeth. You need to choose the maximum speed. In this case, the edges will be smooth and clean. Small irregularities are processed with sandpaper.

A special finishing tape is glued to the edges of the parts. It must be selected by color and width. A layer of special glue is applied to the tape.

Image 3. The marked parts of the stool need to be cut out with an electric jigsaw.

This layer of tape is applied to the edge and smoothed with a hot iron, then with a soft, clean cloth. This needs to be done quite quickly. The heated adhesive mass cools down and firmly connects the tape to the wood in just a few tens of seconds. The excess is cut off with a knife.

The seat is screwed to the structure, consisting of side posts and a jumper between them. This is done using corners and screws. The DIY stool is ready.

The seat can be made soft if desired. To do this, using “Moment” glue, foam rubber is glued to its blank, the excess of which is carefully trimmed with a sharp knife. This entire structure is covered with leatherette or fabric. It is better to fasten the fabric using a construction stapler.

The assembly ends with the installation of thrust bearings of any type, so as not to scratch the flooring with the stool. If desired, you can use slightly different sizes of the stool (image No. 4). You just need to remember that its lower part should not be narrower than the seat. Otherwise the product will be very unstable.

In the same way, you can make a stool from multi-layer plywood 18-20 mm thick. Only the finished product will have to be additionally sanded, primed, painted, and varnished. In all other respects, the manufacturing technology does not differ from working with chipboard. If you wish, you can come up with your own models. You can make more than just a stool with your own hands from chipboard and plywood. If you add a backrest to it, you get a chair.

Notes from experienced craftsmen

Image 4. Diagrams of various sizes of stools.

- When upholstering a seat, remember that leatherette is a fairly dense material. If you get up from a stool, it will take a long time to take its original shape. To avoid this, you need to drill 4-5 through holes at the base of the seat for free passage of air. They can be drilled both before assembly and after assembly of the product.

- To make leatherette look more aesthetically pleasing at the corners of the seat, the folded material must be heated with a hot iron through a damp cloth. In this state it fits much better and after cooling retains its given shape.

- Furniture of this kind is very practical and durable. It can serve not only for its intended purpose, but also as a stand for various objects, as a replacement for a stepladder.

You can make a kitchen stool from chipboard at home from ordinary scraps.

This material can be found in many garages and sheds after dismantling old home furniture. You can purchase substandard material in stores at woodworking enterprises. It will make excellent furniture that will suit your needs. Very often, after making a simple stool, there is a desire to make a chair, a cabinet and more complex things.