A vacuum pump designed to pump air or other gases from any volume is widely used - for storage food products, things, pickling, etc. Buying such a household item is not always profitable, the price of vacuum pumps is quite high. Therefore, you can make a pump yourself.

Converting a cuff pump to a vacuum

To work, you need a conventional cuff pump (bicycle or car). The pump must first be disassembled, that is, unwound. Then you should remove the cuff and turn it in the opposite direction and reassemble the pump.

At the place where the hose is attached (at the inlet to the pump), a check valve is attached (you can buy it in a store or remove it from an aquarium compressor), which will let air out of the volume, but not back. Thus, it turns out the simplest low-power household Vacuum pump.

You can learn more about how to make a vacuum pump from the articles on the ilovekiario.ru website.

Vacuum pump from compressor

It is better to take a compressor powerful enough - from any household appliance but better from a refrigerator or air conditioner. It is necessary to remove the condenser and evaporator from it by cutting the tubes. Attached to the compressor inlet air filter(available at an automotive store) and a hose. The vacuum pump is ready!

The only disadvantage of such a pump will be the impossibility of using it to pump out vapors of liquids, this can lead to a breakdown of the compressor (because the liquid will settle inside the compressor, but this problem is solved by installing a sump), and hence the pump.

You can also make a vacuum pump from an aquarium compressor - just swap the check valves inside the compressor and the compressor, instead of pumping air, will pump it out.

Vacuum pump from a medical syringe

Of course, such a pump will only cope with small volumes of gases, but it will work perfectly for experiment and play. It is necessary to attach identical cuts of a plastic tube to the plastic tee, the same diameter as the inlet of the syringe. H

the syringe shaft is attached to the third outlet of the tee (the other two should be opposite each other), check valves (two pieces from the aquarium compressor) are attached to the remaining outlets of the tee according to the input-output indicator type (one valve looks at the tee, the other from it). The pump is ready!

plastic bottle pump

You need to take two plastic bottles different sizes so that one of them enters the other without resistance, but at the same time there is a minimum amount of free space (then you do not have to seal the inner walls of the bottle).

The top of the larger bottle is cut off, while the smaller one has several holes in the bottom. The smaller bottle is placed in the larger one, into which the hose from the bicycle pump is screwed (in the opposite direction). The simplest pump-pump is ready. The smaller bottle works like a piston.

As you can see, vacuum pumps can be made at home with your own hands, using what is at hand. And it is not difficult to find a use for them in everyday life.

In this story of the TOKARKA channel, they showed an original author's idea of how to make a very simple and useful thing out of a large syringe in a short time - a vacuum pump. With it, you can very conveniently and quickly preserve various products, pump out air from technical mixtures. The power of the vacuum pump allows you to deform plastic bottle so much as if it was opened in space, closed and lowered back to earth. Contactless, you can inflate a balloon or increase the volume of many objects that have air inside.

In order to make a valve, we need an elastic band from a dropper. All plastic inserts must be removed. Now we cut this part into two parts, they will be parts from the valve. The rubber tube, which is smaller, is inserted into the nozzle of the syringe and must be rammed with any convenient rod. Inside the ball from the bearing. A bullet from an air pistol on spray cans is also very good.

The bleed valve is completely ready and air can enter the syringe, but cannot exit it. The last thing left to do is the exhaust valve. The authors heated the needle from the urticaria and sent it to the hole through which air would escape. This piece of rubber tubing was later attached to a drop of superglue. The pump is complete.

For convenience, a thick-walled PVC tube will be used. Not suitable for a dropper, because the vacuum will flatten it. If holes are made in the lid of a container, such as a jar, for the spout of a syringe, a tube is not needed at all.

A great demonstration of how atmospheric pressure works. The air inside the bottle is discharged, or rather a vacuum is formed. Atmosphere pressure flattens her. Absolutely the same thing happened to her if she was lowered to the bottom of the ocean.

If the hole through which the air is evacuated is sealed or sealed with a piece of adhesive tape, such a sandwich can be stored for a very long time. The supermarket products are packaged in this way. If a marshmallow is placed in a vacuum chamber, then it will inflate just like this balloon.

The master needs a camera for other purposes. For example, for degassing epoxy resin, that is, the behavior of air bubbles from it. If degassed gypsum mortar, then the cast parts are very good quality. With a smooth surface. The author of the video came up with the design of this wonderful super simple valve for a vacuum pump.

The inhabitants have long appreciated the advantages of the vacuum method of storing food in special containers, now this technology is also used to store seeds and transport clothes.

In addition, vacuum is indispensable in fermentation and distillation installations: it can be used to lower the boiling point of the liquid and rid the fermentation product of an unpleasant odor.

To solve all these problems, you need only one device - a household vacuum pump. Today, such devices are produced by a number of companies, but is it worth giving your hard-earned money if you can easily make a vacuum pump with your own hands? How and from what? This will be our conversation.

A manual vacuum pump is easiest to make with your own hands from a car or bicycle pump, which is sure to be found in any household.

The procedure is extremely simple:

- The pump must be disassembled by unscrewing the threaded cap installed in the upper part of the sleeve.

- After removing the piston, remove the cuff from the rod by unscrewing the screw holding it (it is located in the middle).

- Turning the cuff over, screw it back to the stem and assemble the pump.

The device obtained by such a simple technique can be used to create a slight vacuum in containers of small volume. Of course, in addition to the vacuum pump, this will require a check valve.

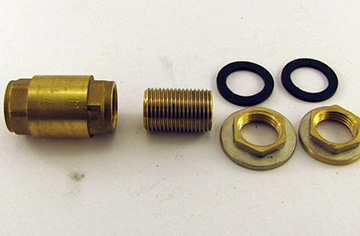

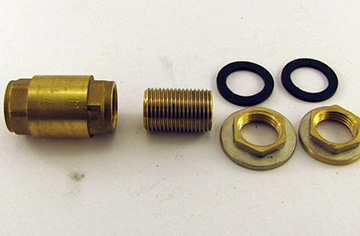

Valve mounting

A check valve for a homemade vacuum pump can be purchased at a store that specializes in selling aquarium equipment.

A check valve for a homemade vacuum pump can be purchased at a store that specializes in selling aquarium equipment.

This inexpensive plastic assembly is used in aquarium compressors.

With luck, such a compressor - in a non-working state - can be found with friends or acquaintances.

The non-return valve will most likely be in order (there is simply nothing to break), so it can be unscrewed and used in our homemade device.

The valve must be fixed in the opening of the pump, and already a tube leading to the tank must be connected to it. Of course, the element must be installed correctly - it must pass air in the direction from the container to the pump. To check the direction of operation of the valve, before installing it, you need to blow into it, like a whistle. If the air does not pass, then you are blowing exactly from the end that should be connected to the pump.

Provided that a quality valve is used and all connections are carefully sealed, a hand vacuum pump is capable of providing a vacuum of up to 200 Mbar (meaning residual pressure).

To pump out very small volumes of air, instead of a car pump, you can use a plastic medical syringe.

How to make a vacuum pump with your own hands from a compressor

Not the whole range of tasks can be solved with a hand pump. To create a higher vacuum or pump out large volumes of air, it is better to use an electrically driven vacuum pump, which can be made from any household compressor.

Almost nothing will have to be redone: it is enough to attach the air suction tube to the inlet of the device, having previously removed the filter from it. After attaching the tube to the evacuated container, the compressor can be turned on.

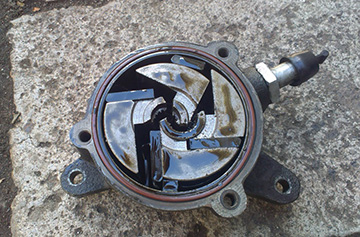

Homemade pump from a refrigerator compressor

If the container is filled with any liquid or moisture containing products, the evacuated air will contain a large number of water vapor. Under such conditions, the compressor will quickly fail. To avoid damage, the system must be supplemented with a dehumidifier, consisting of a receiver and a sump.

Acquisition pumping station— a reliable solution to problems with water supply. It is simple both in the device and during installation. , installation and operation of the unit.

Acquisition pumping station— a reliable solution to problems with water supply. It is simple both in the device and during installation. , installation and operation of the unit.

How to create a homemade hydrogen generator, read .

Do you know what quality well pump depends not only on the speed and volume of supplied water, but also on the quality of the water itself? Here you will learn how to choose a submersible centrifugal pump for a well.

Do-it-yourself refrigerator pump

If there was no household compressor at hand, you can use a supercharger from any broken refrigeration unit or air conditioner. This vacuum pump is made in several stages:

- Cut with a hacksaw copper tubes connecting the compressor to the condenser and evaporator.

- Remember, or rather take a picture of the connection diagram of the compressor to the mains and relay. It is important to give this Special attention, since if the wires are connected incorrectly, the compressor will not only be inoperative, but may also fail.

- We put a durite hose on the copper piece from the suction side, connect it to the evacuated container and turn on the compressor in the network.

Such a pump, of course, will not be able to provide such a low residual pressure as an installation assembled on the basis of a household compressor, but it will fit perfectly for most household tasks.

Alteration of the aquarium compressor

Very practical option a vacuum pump can be made from the aquarium compressor already mentioned here. The design of this product needs to be modified quite a bit:

- Having carefully examined the compressor, it is necessary to find fasteners, by removing which you can dismantle the check valves.

- After disassembling the product, remove the valves, and then swap them.

- It remains to assemble the compressor, connect it with a tube to the evacuated container and put it into operation.

A small improvement will help to improve the operation of the device: a hole must be made in the housing through which condensate or moisture that has accidentally entered the compressor will be removed.

Vacuum pump repair

In the operation of a do-it-yourself vacuum pump, like any other mechanism, all kinds of failures can occur.

In the operation of a do-it-yourself vacuum pump, like any other mechanism, all kinds of failures can occur.

Even water ring installations, which are considered the most reliable, are not immune from this.

If your pump is running at a slower rate or won't turn on at all, this could be due to one of several reasons.

Motor defective or incorrectly connected

One of the most common mistakes is a violation of the wiring diagram. But first of all, you need to check whether power is being supplied, because the network wire may be broken or interrupted. We check the presence of electricity with a probe-indicator similar to a screwdriver.

If the probe is lit and the wires are connected correctly, the pump must be disconnected from the mains, after which its motor is disconnected from the delivery mechanism. We serve food again. If the motor starts to rotate, then the cause of the accident must be looked for further. If not, the engine is faulty and needs to be carried to the workshop.

Decreased performance or failure of the vacuum pump may be due to poor quality power supply.

Imported equipment is particularly sensitive in this respect. If such problems occur, connect the pump through the stabilizer.

The alignment between the drive and the shaft of the injection mechanism is broken

In most cases, skew is eliminated by installing gaskets under the engine or injection mechanism.

In most cases, skew is eliminated by installing gaskets under the engine or injection mechanism.

Sometimes, even after realignment, the pump does not work.

Inspect the clutch, it may be misaligned or deformed.

The part must be reinstalled or replaced with a new one.

Jammed working element in the discharge mechanism

As a rule, this problem is caused by the presence of contaminants in the pumped medium. To eliminate the malfunction, the pump must be disassembled and thoroughly cleaned.

The bearing failed in one of the support units

This phenomenon is usually accompanied by an unusually loud noise or strong vibration. A worn out bearing should be replaced.

Scale has appeared on the working elements, which prevents the pump from working normally

This problem is typical for liquid ring pumps, which use water as a working (service) medium. To revive the unit, salt deposits must be removed using one of the special formulations("Antinakipin", VD-40, etc.).

The pump was operating in overheating mode, as a result of which some of its parts quickly wore out

This disease affects oil-free rotary vane units.The use of even the most modern anti-friction materials, such as Teflon, is not able to fully compensate for the lack of lubrication, so that when such devices operate for temperature regime must be watched very carefully.

If overheating does occur, the failed parts must be replaced.

Fluid leakage or excess

A decrease in the performance of a liquid ring pump can be caused by a drop in service fluid pressure due to leakage. In this case, it is necessary to replace the seal in the hole (where the shaft passes).

When choosing a water ring type vacuum pump, opt for models with an end seal over stuffing box packing, which is considered obsolete.

If the condition of the seal is still satisfactory, then the leakage occurs through the flange connections - it is necessary to replace the gaskets present there.

If the condition of the seal is still satisfactory, then the leakage occurs through the flange connections - it is necessary to replace the gaskets present there.

Also, too intense flow of the working fluid may be associated with excessive wear of parts.

This usually means that the pump has already served its due date and it is time to change it. But do not rush into this, because the unit may still be maintainable.

In this case, only the most worn parts will need to be replaced.

The high pressure of the service medium, due to its excess or overheating, also adversely affects the performance of the device. If you return its parameters to optimal values, the pump will work with the same force. If the temperature is normal, then you need to reduce the water supply or eliminate opposition from pressure pipeline– the valve may not be fully open or there may be extremely high friction losses.

In conditions country life the pump is a necessary and demanded equipment. Today, there are many types of pumps, and each of them performs its own functions. we'll figure it out in the next article. And also we will comparative characteristic with centrifugal pump.

In conditions country life the pump is a necessary and demanded equipment. Today, there are many types of pumps, and each of them performs its own functions. we'll figure it out in the next article. And also we will comparative characteristic with centrifugal pump.

How to connect a hydraulic accumulator in an autonomous and centralized water supply, read in the material.

Related video

Vacuum car pump (mixer) is designed to facilitate braking. It is mainly used in buses, trucks and other large cars, where the driver has to make an effort to brake.

The mechanism of action of the presented device is to use the vacuum in the intake manifold. The mixer can also be used to inflate wheels.

Work is carried out by connecting the pump to the battery. Making a vacuum pump with your own hands will be easy.

Such equipment is equipped with a special sensor that indicates pressure, which can be controlled and used in solving problems. various tasks. If you do not need a serious device, you can create a small vacuum mixer using a medical syringe.

The most common mixer is made with a medical syringe and check valve taken from the compressor from the aquarium.

Interesting! The principle of operation is simple - after several cycles of using the syringe, air will be pumped out of a small volume.

If you need to work with large volumes, then you will have to use more serious elements, for example, a compressor.

You can make a mixer using a simple cuff car pump or a regular bicycle pump.

The assembly of the conventional mixer is completed.

Vodokoltsevaya

Such a device belongs to the class of low-vacuum pumps. Inside the structure are special plates that are attached to the rotor. When they are immersed in water, the volume changes.

Important! The main advantage of the presented hand mixer is a high motor resource, which is achieved due to the absence of seals.

Among the shortcomings, it should be noted the following:

- You will have to periodically replenish the liquid in the structure.

- You will have to organize the cooling of the fluid used.

How to do:

- Find a body right size and cylinder shapes.

- Inside, install a shaft with a wheel, which should have small blades.

- Now take care of the water supply to the body. Make sure that the fluid supply causes the blades to spin. The centrifugal force will create a vacuum in the center of the mixer.

If you want to do hand device having high level rarefaction, then use a membrane household compressor taken from the refrigerator and which can heat the air without problems.

This method can be used if you find it difficult to use a manual vacuum pump. How to make an electric version:

This method can be used if you find it difficult to use a manual vacuum pump. How to make an electric version:

- First, cut the copper tubes that come out of the refrigeration compressor housing.

- Remember that the presented device will carry out its work only due to electricity. Before you begin to disassemble the refrigerator pump, remember the placement of all the conants. And only then proceed to disassemble the pump.

- Attach a diorite hose to the end of the suction tube to help in the further operation of the device.

Important! If you are not sure that you can remember the placement of all contacts, then take a photo. Otherwise, the vacuum car pump will not work. We have considered several options self-creation presented device. You can save enough money.

Vacuum pumps can be used in various fields and are used for pumping air and various materials. Previously, such devices were used only in industry, but now they are also used in everyday life. Almost everyone can make a vacuum pump with their own hands. To do this, you need to learn about how the products are arranged, from which you can make a similar unit.

general description

Vacuum devices are selected according to the following characteristics:

- nominal air pumping speed;

- pressure;

- device performance;

- the amount of energy consumed by the product.

After connecting the pump to the network, the volume of the working chamber changes, as a result of which the pressure increases significantly. The principle of operation of many vacuum devices is similar to the principle of operation of a syringe during water collection, when the liquid fills it

Types of pumps

There are many models of devices on the market that can be used at home. To commit right choice It is worth considering several types of such products:

Choosing a specific type of device is based on the purpose of its use.

Where pumps are used

Vacuum pumps are often used in the textile, food and pharmaceutical industries. For example, with the help of such devices, air is pumped out of their glass containers during a liquid spill.

In metallurgy, for example, the described devices are used to eliminate gaseous impurities. Vacuum products are also used in the following industries:

- Agriculture;

- production building materials;

- Oil and gas industry;

- the medicine.

Vacuum devices are also often used in everyday life. Several situations can be cited as an example:

- Vacuum pumps contribute to a significant reduction in the load on the driver, as they are installed in the brake system.

- The described devices are used in air conditioning systems.

- Vacuum devices are often used in Food Industry to increase the shelf life of products.

- Removal of air to reduce the volume of various things. An example is the removal of air from a bag of things. This allows you to increase the amount of free space in the cabinets with things.

Car compressor pump

To do this, you need to do the following:

- unscrew the cover located on the pump sleeve and remove the stem with the cuff;

- after that it is necessary to disconnect the cuff;

- then you need to screw the part back, but with the reverse side;

- after that, you can return the stock to its place;

- at the next stage, a plastic check valve should be attached to the tube through which air was previously injected.

Such products have a fairly low cost. In order to avoid mistakes and check in which direction the air will flow, it is enough to blow into the hole.

Do-it-yourself vacuum pump can be made from a bicycle compressor.

Using a Diaphragm Compressor

As a vacuum pump, you can use a compressor from an aquarium, which is characterized by low productivity. For use as a pump, it is enough to change the part of the device in which the valves are located. It is also necessary to insert a tube to drain the condensate.

During revision, it is necessary to swap the valves. Thereby membrane device will not start to pump air, but to pump it out. Membrane products may have different design, but they are modified in the same way.

If the performance of such a device is not enough, it is worth using a larger compressor. Thus, it is possible to make a vacuum pump with my own hands from inexpensive materials.

Water ring pump

If you are willing to take the time to build your own pump, you can make a design with a liquid piston. Such a mechanism consists of a pipe in which an impeller with blades is installed. The wheel shaft in the described devices is driven by an electric motor.

A cavity is formed between the liquid ring and the rotor, which is working chamber devices. The blades contribute to its division into several parts, the volume of which constantly changes with the rotation of the wheel. First, the pumped gas is sucked in, and at the end of the cycle, it is injected. As a result of compression, heat is released, which subsequently goes into the water. Due to the fact that the fluid is constantly heated, it must be constantly replaced.

Water enters the vacuum device through a hydraulic seal. After that, it is discharged through the injection holes. For the manufacture of the described device, the following materials are used:

- pipes needed to create the hull;

- a sheet of steel needed to create a wheel, tank and blades.

It is worth remembering that the impeller must be installed so that it does not interact with the casing. Thanks to this, there is no friction between the parts of the pump, so no part wears out during long-term operation.

Refrigeration compressor pump

Often a vacuum pump is made from a compressor located in a refrigerator. Such products are practically finished vacuum pumps. To convert the device into a pump, you must perform the following steps:

- First, with a hacksaw, you need to cut off the top of the compressor.

- After that, you need to remove the motor suspended on springs, and then connect the suction and discharge lines using tubes with scraps copper pipes on the hull.

- Then you need to make a cover for the case. It is not worth using a cut top, as this will lead to the oil draining and seeping out.

To control the oil level in the device, it is worth installing a level gauge. This part of the pump can be made from a transparent ballpoint pen placed in a vertical position.

The cap of the hand pump must be unscrewed in such a way that a small amount of air passes through it. For ease of use of the level gauge, marks must be scratched on it corresponding to a certain amount of oil. All elements of the pump should be installed in the frame.