Wooden fence with gate and gate- a traditional solution that does not lose its relevance. Beautiful and functional buildings adorn many private houses and summer cottages throughout Russia.

- Products are reliable and durable. At correct installation and timely processing protective compounds wooden structures serve for a long time.

- Installation is fast. Professionals will mount almost all elements of fencing in a matter of days. Exceptions are electric wooden sliding gates and automatic swing gates. Their installation will require serious labor costs.

- Wood is an environmentally friendly material. Fences do not allocate hazardous substances and do not harm human and animal health. Modern protective compounds also make safe.

- The tree is easy to process. With a small set of tools and paintwork materials craftsmen create interesting design solutions.

Wooden gates and wickets are integral fencing elements. It is these additional structures that will be discussed in this article. We will talk about the most beautiful and popular types of gates and describe in detail the process of manufacturing and installing standard structures.

Types of wooden gates

We will look at the types of wooden gates below. There are many simple and complex design solutions, however, conditionally, the designs are divided into 4 main groups.

Slatted wooden gates

A slatted wooden gate in the fence is the easiest way to organize the entrance to the site. The design is a frame with shtaketins fixed on it.

Photo No. 1: slatted wooden gate

If you place the boards close together, you get a solid wooden gate. This design will protect your yard from prying eyes.

Photo No. 2: solid gate

Such gates can be installed independently. Manufacturing and installation will not require serious financial costs.

If desired, the design can be made very attractive. For example, carved wooden gates and gates look beautiful and original.

Photo No. 3: carved wooden gate

Wooden gates with a frame frame

Wooden gates with a frame frame are more complex and reliable structures. A wide bar is usually used to make the base.

Photo No. 4: a wooden gate with a frame frame

Frames are made not only rectangular. Often there are interesting curved designs.

Photo No. 5: a wooden gate with a curved frame

To make such a gate, you will have to cut the frame elements from an array of thick and wide boards or timber.

To fill the frames, slats, pickets, plywood, metal structures, forged elements and other materials are used. An interesting option finishes of a wooden gate - "herringbone". The crossbars are attached at an angle to the figured vertical bars.

Photo No. 6: "herringbone"

Wooden gates with awnings

If you want to make an impressive design - install large-sized supporting pillars and build a canopy. The resulting structure will look spectacular and solid.

Photo No. 7: a wooden gate with a canopy

Lattice and solid canopies decorated with green plants are popular. Such structures are called pergolas. With the addition of such a canopy, even simple design turns into a beautiful wooden gate.

Photo No. 7: a wooden gate with a pergola

Wooden gates with arches

Wooden gates with arches do not go out of fashion. Support structures make out various materials. An arched vault made of wood is the easiest to make. It is necessary to supplement the pillars with a semicircular beam.

Photo No. 8: a wooden gate with an arch

Do-it-yourself wooden gate - relevant or not?

DIY wooden gate - The best decision. However, it is relevant when you have time for manufacturing, processing, installation and design. Otherwise, contact a reliable construction company offering wooden fences with the installation of additional structures (gates, gates, arches, etc.).

Professionals will complete all stages of work faster and better. You will receive a guarantee of reliability and durability of the structure.

Production and installation of a wooden gate. Stages of work

Consider in detail the preparation of the opening, the manufacture of a wooden gate, installation and finishing on the example of a simple rack design.

Important! Any gate consists of a framework and the materials filling it. Having studied universal instruction, you can independently implement a more complex project.

Necessary materials:

- timber 10 * 10 cm (for poles);

- timber 4 * 4 cm (for the frame);

- everything you need for sheathing (slats, pickets or other materials);

- sand, cement and crushed stone;

- bituminous impregnation;

- protective and paint compositions.

Of the tools you will need:

- square, pencil and tape measure;

- container for mixing concrete;

- screwdriver or screwdriver;

- drilling rig;

- planer and rasp (if you purchased raw materials)

- hacksaw;

- tamper;

- plumb and level;

- shovel;

- necessary fittings (canopies, hinges and latches);

- screws and galvanized screws.

Stage 1. Concreting of pillars

Drill holes for poles. The optimum depth is 1.2–1.5 m. Fill the bottom of the holes with a mixture of sand and gravel (10 cm) and carefully tamp. Treat the lower part of the pillars with a bituminous impregnation. This will protect the wooden structures from decay.

Place the treated post in the hole, adjust the plumb line and fix the beam with a mixture of sand and gravel.

Photo No. 9: installing a wooden pole

Make sure the support is vertical and fill the empty part of the hole with concrete. Install the second pole in the same way.

Stage 2. Making the frame

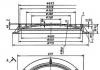

The Z-shaped frame is ideal for attaching pickets and will perfectly resist deformation. The resulting structure will not sag.

Image #1: typical scheme z-frame

For improvement appearance make sure that the brace, horizontal and vertical crossbars are in close contact with each other. The gate will look harmonious.

Image #2: detailed diagram z-frame gates

Important! What will be the frame - you decide. The main thing is to make sure that the structure is rigid enough. To connect the frame elements, use long screws and tighten them at small angles.

Stage 3. Sheathing

To make a solid gate, fasten the boards closely, and to get a lattice structure - at a certain distance.

Important! To avoid problems, buy the right materials for sheathing only after the manufacture of the frame. Calculate everything carefully and order boards of the correct width. This will save on the purchase of materials, reduce labor costs and create exactly what you need.

If you want to make a gate with carved pickets, process the boards in advance. Already fixed elements should not be subjected to loads.

For fixing rails, boards and other materials, use galvanized self-tapping screws. Their length should be slightly less than the total thickness of the frame and skin.

Stage 4. Installation

Before installing the fittings, treat parts of the poles and gates with protective compounds. This will prevent wear on the wood.

Screw hinged hinges to the wicket frame in the right places. Secure the structure to one of the supporting pillars. At least 5 cm of free space should be left between the ground and the lower edge of the gate.

The final stage of installation is the installation of latches, handles and hinges for locks. Screw the elements in the right places. The locks of wooden gates are usually located at a distance of 90 cm from the ground.

Everything is almost ready.

Stage 5. Finishing and design

Process installed gate protective compounds in at least two layers and proceed to application finish coat. Various paints and enamels will do.

Advice! Purchase only high-quality and proven coatings famous brands. On Russian market the products of Aquatex and Tikkurila have proven themselves well.

Once the topcoat has dried, you can proceed to decorative design wooden gate. The designs are decorated with green plants, carvings, original mailboxes and other interesting items.

As you can see, the manufacture and installation of even a simple wooden gate takes a lot of time and effort. Implementation complex projects will require more high costs. If you want to avoid them - order the desired design and its installation.

Buy a wooden gate

Buy a wooden gate with installation in a reliable construction company means to get convenient service, project implementation in a short time and a guarantee for the work performed.

- A measurer will come to your site, who will do everything necessary calculations. You will be able to conclude an agreement on the spot.

- Specialists will quickly produce a standard or non-standard gate that fits perfectly into the existing opening, does not sag under its own weight and does not warp.

- Professional installers fulfill necessary work quickly and efficiently. You will receive a guarantee for the installed structure.

Want to take advantage of the above benefits - please contact the company "MASTEROVIT".

Wooden gate for a private house, suburban area should not only perform protective functions, but also be practical, simple in construction, aesthetically attractive. These criteria are fully met by a gate made of wood. They can be used to design the entrance to private property, industrial buildings.

The popularity of natural wood for the construction of gates is due to its many advantages:

- accessibility. Wood products are raw materials created by nature. It does not need to be made, only additionally processed (cut, polished), so it costs less than metal products;

- a wide range of products. wood happens different varieties, differing in color, structure, operational qualities. There is a possibility of cutting raw materials into elements of the required dimensions;

- ease of processing, installation. Basic finishing of wood, installation of structures from it can be carried out independently, using a minimum number of tools and equipment;

- presentable appearance. Wooden canvases have a unique natural beauty, but if desired, they can be supplemented with various decorative elements(carved, turned parts, openwork inserts made by laser cutting);

- the possibility of combining with other building materials (metal, stone, brick). Wooden gates with forging elements look very original and beautiful.

Wood is considered a short-lived material, but with the right and regular care it can be used for decades. This natural raw material does not rust like metal, but requires regular treatment with protective special compounds. In addition, with partial damage to the structure, the boards that have become unusable can be easily replaced with new ones.

Structural variety of wooden gates

Registration of the entrance to the site from natural raw materials is possible in several ways:

- double swing system. Gate wooden oar - two cloths closed on the general. When is the entrance to private territory located near the roadway, it is more convenient for the structure doors to open inside the site. So they will not interfere with the movement of cars on the road, provide the driver good review. If a private entrance leads to the territory, the sections can swing open to the outside. Opening the doors requires free space, so this system is not suitable for installation in a limited area;

- retractable sections. These are one or two canvases moving along the fence on rollers along guides. Such gates do not require as much opening space as swing gates, but can only be installed on a flat fence. The disadvantage of the system is that the guides should be regularly cleaned of dirt, leaves, snow accumulated inside;

- lifting mechanism. The basis of such gates is one section of the size corresponding to the width of the entrance opening. Its opening is made by lifting the cords. The canvas is fixed above the opening, fixing it on the beam. IN closed its position is fixed with the help of a rail laid along the ground. This design takes up little space, but is quite heavy (a counterweight must be installed to raise the section).

Please note: the choice of design wooden gate carried out taking into account the area of the site, the location of the entrance to it, design features fencing, owner preferences. The easiest to manufacture is the hinged design, retractable and lifting are more complex, but they can be automated.

Step-by-step instructions for the construction of wooden gates

Is it possible to arrange an entrance to the site on my own? Exist basic structures, allowing even beginners without carpentry experience to build wooden gates with their own hands.

Drafting

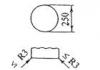

Before you make a wooden gate, you should consider their design, technical aspects. To do this, make measurements of the entrance opening of the site - the gap between the supports - below, above and in the middle. If these indicators differ, choose the smallest value. When installing a double-leaf structure, 25 mm is subtracted from this figure and the resulting number is divided by 2.

According to these parameters, a drawing of the gate is made. Optimal Height products - 1.2-1.8 m. With a distance between the pillars of 3.50 m, the width of the opening will be: 3.50 m - 25 cm = 3.25 m. The width of each section of the double-wing structure is calculated as follows: 3.25 m / 2 \u003d 1.625 m. After determining the dimensions of the structure, it is schematically depicted on paper indicating all dimensions.

Next, proceed to the choice of product design. You can decorate antique wooden gates or create modern design with forging elements, corrugated board inserts, glass. The appearance of the product is selected according to the style of the architectural ensemble of the site, its fence.

Instrument preparation

The manufacture of wooden gates is impossible without the appropriate tools:

- roulettes;

- winkel (square);

- meter level;

- marking pencil;

- drills with various drill bits for working with wood;

- hacksaws;

- screwdriver;

- fittings (hinges, latches, self-tapping screws);

- shovels.

Installation of supports

Before making the gate on adjoining territory or in the country, you need to install a support for them. She may be:

- metal;

- brick;

- concrete;

- wooden.

Advice: poles made from natural raw materials are best suited to wooden gates.

Before installation wooden poles it is necessary to provide protection from insects, the harmful effects of moisture. To do this, they are impregnated with special protective compounds. So that the end of the pillar, which will be buried in the ground, does not absorb moisture from the soil, it must first be tarred. If the gate is light, the supports can be hammered into the ground, if heavy, for example, wooden gates with forging, it is better to concrete.

Attention: on heaving soil, concreting of supports is not performed. In this case, it is better to strengthen the pillars with reinforcement.

The optimal depth of the supports is 1-1.5 m (depending on the severity of the wooden sections). With the help of a shovel, they dig a hole, at the bottom of which a layer of sand is compacted. Then a pillar is inserted, crushed stone is poured around it and poured cement-sand mortar(proportionality 1:2). The evenness of the installation of the supports is checked with a level.

Please note: if the pillars are not located strictly vertically, the installation of the canvases will become more complicated, they will turn out to be crooked.

Formation of the door leaf

Sections for registration of the entrance to the site are made according to the chosen design. First, they build the frame of the future product - the frame rectangular shape. It is formed from pieces of timber, connecting them at the ends. Strengthen the structure with diagonal, horizontal, z-shaped jumpers, fixing them with self-tapping screws.

The basis of the valves is assembled on the ground - it's more convenient. Then it is sheathed with boards, bars, picket fence. Filling the frame is carried out vertically, horizontally, in random order - all wooden details fasten with screws. Gate sections are constructed in the form of:

- solid canvas without gaps;

- decorative lattice.

Tip: in order for the gaps between the boards to be the same with the lattice sheathing of the sashes, you can make a template from fiberboard, slats. Its width should be similar to the clearance.

Section mounting

Hanging the gate leaves is carried out only after the complete hardening of the pouring of the pillars. Before installation, they are fastened in the upper part with a common beam - this will prevent sagging of the canvases, their distortion. Easiest to mount swing structure on loops. At the same time, a small gap will remain between the post and the canvas, which is necessary to maintain the functioning of the gate in case of their possible displacement over time. After curtaining the canvases, the structure is equipped with a valve.

Recommendation: the installation of canvases is a hard physical work that one person cannot handle. It is best to do it with two or three people. Two people will curtain the structure, and the third will check the evenness of its installation with a level.

Ways to improve the performance of wood

In order for wooden gates to serve for many years and not lose their appearance, they must be treated with special teams. To protect against insects and prevent decay, impregnations are used, which are applied in several layers, giving Special attention cuts, end elements, junctions. Lacquer is used as a finishing coat (colorless or with a certain shade, glossy / matte).

Beautiful wooden gates, built with his own hands - protect the site and decorate it at the same time. The material is inexpensive, malleable in work, allows you to create an eco-friendly fence that will emphasize the architectural ensemble of buildings located on the territory, harmoniously complement the surrounding landscape.

If the site is fenced natural wood, then it is better to equip it with wooden gates. This article will discuss how to buildhandmade wooden gate.

When making a gate, you will need the following tools:

- wrench;

- hammer;

- jigsaw;

- brush;

- electric drill with drills ø3 mm and ø10 mm;

- chisel;

- hacksaw;

- square;

- plane;

- roulette;

- woodworking machine;

- screwdriver

In addition, you will need materials such as:

- self-tapping screws (ordinary and with screw thread);

- sandpaper;

- protective coating for wood;

- acetone;

- bars 7x5 cm;

- two bars 5x5 cm;

- four garage loops;

- board 2.5x10 cm.

Now, after preparing everything you need, you can get to work.

Stage 1. Installation of poles

The gate structure will be attached to the pillars. They need to be installed correctly, with the most rigid and reliable fasteners. Even the slightest sagging is unacceptable.

Important! Attention must also be paid to the perpendicularity of the pillars relative to the ground, otherwise geometric shape the gate is broken. When making calculations, you need to remember that each pillar must be laid in half a brick, and this width should also be taken into account during work.

Step 1. First, the place for installation is cleared and the places for the pits are determined. Can be used for digging bayonet shovel or a small drill. The depth of each pit should be at least 1 m, and the diameter should be made by 10 cm larger diameter pillar (this gap will be filled with concrete mortar).

Step 2. Pipes of the appropriate length are cut with a grinder, which are inserted into the holes made. The gaps are filled with rubble, after which the verticality of each column is checked with a plumb line. If necessary, the position is corrected. The rubble is rammed.

Step 3. A liquid solution of "three hundredth" cement and sand is mixed in a ratio of 1: 3. First, the dry mixture is mixed, then water is gradually added. After the solution has been brought to the desired consistency, crushed stone is poured over it and they are waiting for complete drying.

Important! You can pour a little into the solution washing powder- this will prevent subsidence and, as a result, greatly simplify the laying.

When laying, each seam of the bottom row must overlap with the top one so that the ordering is extremely strong. In this case, do not forget about the correctness of the angles, for which you can use the same plumb line.

To improve the aesthetics and drainage characteristics of the structure, each column should end with a cap. These caps can be purchased from ready-made or cut from a sheet of galvanized steel.

Step 5. After complete drying, the rows of bricks are embroidered.

Stage 2. Making sashes

One of the options for assembling and sheathing the frame of the gate leaves

Show on page View in full size

Step 1. First, the bars are processed. From them you need to make blanks of the required dimensions. So, for a standard double-leaf gate, you will need:

- two horizontal bars (lower and upper)

- two vertical;

- two for the center jumper.

Step 2. After trimming the blanks, their surface is processed with a planer or woodworking machine.

Stage 3. Frame construction

The assembly is carried out with a one-sided spike "on the mustache".

Step 1. A pair of holes is drilled at each joint, into which screws are screwed or dowels from dried wood are inserted. The latter for reliability can be pre-coated with epoxy glue.

The use of dowels / self-tapping screws is necessary to increase the rigidity of the joints.

Step 2. An additional jumper is equipped in the center of the frame, to which the structure's sheathing will be attached.

Step 3. A jib is installed in each corner. For this, bars 30-40 cm long are used, the ends of which are cut at an angle of 45ᵒ. When attaching the jibs to the bars, self-tapping screws are used.

Important! If the gate is, say, 2 m high, then the frame should be calculated in such a way that the boards protrude approximately 20-25 cm. Based on this, you need to make the frame 1.5-1.6 m high.

Stage 4. Structural sheathing

Step 1. Boards are cut to required size, after which they are chipped on both sides until a thickness of 20 cm is reached. The ends are processed in the same way.

Step 2. The boards are fastened with screws to the frame. You can arrange the boards both back to back and with a small step - it all depends on personal preferences.

Important! If it was decided to leave small gaps between the boards, then for this you can use a template - wooden lath, the length of which will be equal to the length of the boards for sheathing. In this case, the thickness of the template will correspond to the step with which it is planned to fasten the boards.

Step 3. After fastening top part boards are cut in a straight line, the cut points are carefully cleaned with sandpaper.

Stage 5. Installing the gate

Step 1. First, hinges are attached to the sashes, in parallel, “grouses” are screwed into the bars with self-tapping screws. The sashes are also attached to the pillars with "grouses".

Important! Before attaching the "capercaillie" you need to drill in the appropriate places a few centimeters deep. The diameter of the holes should be slightly smaller than the capercaillie thread. Such a simple move will greatly facilitate the screwing of the screws.

Step 2. The distance from the bottom edge to the ground should be at least 5 cm. This can be explained by the fact that in the future it is possible to install a new pavement, and with such a gap, no reinstallation will have to be done.

Step 3. To fix the closed doors, a metal pin or padlock is installed. The coating is applied after installation.

Stage 6. Covering the structure

The finished gate must be properly processed, which will require varnish and a primer.

Important! When buying varnish, you need to ensure that it is intended specifically for outdoor use. In addition, you should inquire about the maximum temperature of its operation.

Step 1. The surface is polished sandpaper or Bulgarian special nozzle. All discovered “shells” are sealed with a special putty on wood, and after drying, the structure is re-sanded.

First, coarse-grained sandpaper is used, and after polishing, fine-grained sandpaper.

Step 2. The tree is toned. So the texture and the desired shade will appear. After the tinting has dried, the surface is polished again (with paper with a “hundredth” grain size).

Important! It is imperative to apply a primer, otherwise some sections of the gate will not be painted over, bubbles and waves will form.

Step 3. Following the primer, the first coat of varnish is applied. Drying time should be indicated in the instructions. After this time, a second layer is applied.

Often the gates are decorated with iron forging - so the product has a rich look. If you plan to use such forging, then this should be taken care of even before painting and grinding. At the same time, the tree is covered with thin tin for protection against damage during operation.

For better tightness, after applying the second layer of varnish, the joints between wood and metal are treated with sealant. Indeed, sometimes it is impossible to achieve a snug fit, and such measures prevent moisture from entering through these openings.

Everything, the wooden gates are ready, it remains only to equip them with a wooden gate.

Video - Homemade wooden gates

wooden gate

Before starting work, you need to prepare everything you need, otherwise the lack of one or another material can stop the process, which is highly undesirable.

So, in the work you will need:

- hammer;

- mounting level;

- hacksaw;

- sandpaper;

- pencil;

- rope;

- plane;

- electric drill;

- chisel;

- screwdriver;

- jigsaw;

- boards, picket fence;

- iron corners;

- wood screws;

- fittings - hinges, handle, latch.

Wickets manufacturing technology

Step 1. First, the distance between the supports is determined. If you do it right, the gate will work smoothly. Supports can be wooden poles or metal pipes(as described above).

The distance between the supports is fixed with a piece of wire laid on the ground and fastened with something.

Step 2 Support posts are installed. The technology is no different from that of wooden gates.

Step 3. Next, the door is made. To do this, four boards are connected at an angle of 90ᵒ metal corners. Then hinges are attached to the finished frame, after which it is checked for entry into the opening. If the result is positive, the frame is sewn up with a picket fence. From above, the gate is cut off with a jigsaw in a straight line (it can also be in the form of waves, zigzags, etc.). The lock and the door handle are the last to hit.

Step 4. At the final stage, the gate is hung on hinges, after which it is checked whether the door closes/opens freely. To fix the gate in closed position, you can nail a piece of rubber to the end.

The wooden gate is ready for use.

Video - Beautiful ideas for wooden gates

As a conclusion

As you can see, for the manufacture of wooden gates or gates, certain knowledge and skills in woodworking will still be required. Therefore, if neither one nor the other is available, it is better not to spare money and contact a specialist. The gate is the face of the house.

But with a firm intention to do everything with your own hands, it remains only to wish good luck and the masses creative ideas. With another possible option - sliding gates from wood - you can find out when watching a thematic video.

Video - Wooden sliding gates

If the site is fenced with a natural wood fence, then it is better to equip it with wooden gates. This article will discuss how to build a wooden gate with your own hands.

What will be required in the work

When making a gate, you will need the following tools:

- wrench;

- hammer;

- jigsaw;

- brush;

- electric drill with drills o3 mm and o10 mm;

- chisel;

- hacksaw;

- square;

- plane;

- roulette;

- woodworking machine;

- screwdriver

In addition, you will need materials such as:

- self-tapping screws (ordinary and with screw thread);

- sandpaper;

- protective coating for wood;

- acetone;

- bars 7x5 cm;

- two bars 5x5 cm;

- four garage loops;

- board 2.5x10 cm.

Now, after preparing everything you need, you can get to work.

Stage 1. Installation of poles

The gate structure will be attached to the pillars. They need to be installed correctly, with the most rigid and reliable fasteners. Even the slightest sagging is unacceptable.

Important! Attention must also be paid to the perpendicularity of the pillars relative to the ground, otherwise the geometric shape of the gate will be violated. When making calculations, you need to remember that each pillar must be laid in half a brick, and this width should also be taken into account during work.

Step 1. First, the place for installation is cleared and the places for the pits are determined. For digging, you can use a bayonet shovel or a small drill. The depth of each pit should be at least 1 m, and the diameter should be made 10 cm larger than the diameter of the column (this gap will be filled with concrete mortar).

Step 2. Pipes of the appropriate length are cut with a grinder, which are inserted into the holes made. The gaps are filled with rubble, after which the verticality of each column is checked with a plumb line. If necessary, the position is corrected. The rubble is rammed.

Step 3. A liquid solution of "three hundredth" cement and sand is mixed in a ratio of 1: 3. First, the dry mixture is mixed, then water is gradually added. After the solution has been brought to the desired consistency, crushed stone is poured over it and they are waiting for complete drying.

Important! You can pour a little washing powder into the solution - this will prevent settling and, as a result, will greatly simplify laying.

When laying, each seam of the bottom row must overlap with the top one so that the ordering is extremely strong. In this case, do not forget about the correctness of the angles, for which you can use the same plumb line.

To improve the aesthetics and drainage characteristics of the structure, each column should end with a cap. Such caps can be bought ready-made or cut from a sheet of galvanized steel.

Step 5. After complete drying, the rows of bricks are embroidered.

Stage 2. Making sashes

One of the options for assembling and sheathing the frame of the gate leaves

Show on page View in full size

Step 1. First, the bars are processed. From them you need to make blanks of the required dimensions. So, for a standard double-leaf gate, you will need:

- two horizontal bars (lower and upper)

- two vertical;

- two for the center jumper.

Step 2. After trimming the blanks, their surface is processed with a planer or woodworking machine.

Stage 3. Frame construction

The assembly is carried out with a one-sided spike "on the mustache".

Step 1. A pair of holes is drilled at each joint, into which screws are screwed or dowels from dried wood are inserted. The latter for reliability can be pre-coated with epoxy glue.

The use of dowels / self-tapping screws is necessary to increase the rigidity of the joints.

Step 2. An additional jumper is equipped in the center of the frame, to which the structure's sheathing will be attached.

Step 3. A jib is installed in each corner. For this, bars 30-40 cm long are used, the ends of which are cut at an angle of 45?. When attaching the jibs to the bars, self-tapping screws are used.

Important! If the gate is, say, 2 m high, then the frame should be calculated in such a way that the boards protrude approximately 20-25 cm. Based on this, you need to make the frame 1.5-1.6 m high.

Stage 4. Structural sheathing

Step 1. The boards are cut to the required size, after which they are chipped on both sides until a thickness of 20 cm is reached. The ends are processed in the same way.

Step 2. The boards are fastened with screws to the frame. You can arrange the boards both back to back and with a small step - it all depends on personal preferences.

Important! If it was decided to leave small gaps between the boards, then for this you can use a template - a wooden lath, the length of which will be equal to the length of the boards for sheathing. In this case, the thickness of the template will correspond to the step with which it is planned to fasten the boards.

Step 3. After fastening, the upper part of the boards is cut in a straight line, the cut points are carefully cleaned with sandpaper.

Stage 5. Installing the gate

Step 1. First, hinges are attached to the sashes, in parallel, “grouses” are screwed into the bars with self-tapping screws. The sashes are also attached to the pillars with "grouses".

Important! Before attaching the "capercaillie" you need to drill in the appropriate places a few centimeters deep. The diameter of the holes should be slightly smaller than the capercaillie thread. Such a simple move will greatly facilitate the screwing of the screws.

Step 2. The distance from the bottom edge to the ground should be at least 5 cm. This can be explained by the fact that in the future it is possible to install a new pavement, and with such a gap no reinstallation will have to be done.

Step 3. To fix the closed doors, a metal pin or padlock is installed. The coating is applied after installation.

Stage 6. Covering the structure

The finished gate must be properly processed, which will require varnish and a primer.

Important! When buying varnish, you need to ensure that it is intended specifically for outdoor use. In addition, you should inquire about the maximum temperature of its operation.

Step 1. The surface is polished with sandpaper or a grinder with a special nozzle. All discovered “shells” are sealed with a special putty on wood, and after drying, the structure is re-sanded.

First, coarse-grained sandpaper is used, and after polishing, fine-grained sandpaper.

Step 2. The tree is toned. So the texture and the desired shade will appear. After the tinting has dried, the surface is polished again (with paper with a “hundredth” grain size).

Important! It is imperative to apply a primer, otherwise some sections of the gate will not be painted over, bubbles and waves will form.

Step 3. Following the primer, the first coat of varnish is applied. Drying time should be indicated in the instructions. After this time, a second layer is applied.

Often the gates are decorated with iron forging - so the product has a rich look. If you plan to use such forging, then this should be taken care of even before painting and grinding. At the same time, the tree is covered with thin tin for protection against damage during operation.

For better tightness, after applying the second layer of varnish, the joints between wood and metal are treated with sealant. Indeed, sometimes it is impossible to achieve a snug fit, and such measures will prevent the penetration of moisture through these holes.

Everything, the wooden gates are ready, it remains only to equip them with a wooden gate.

Video - Homemade wooden gates

wooden gate

Before starting work, you need to prepare everything you need, otherwise the lack of one or another material can stop the process, which is highly undesirable.

So, in the work you will need:

- hammer;

- mounting level;

- hacksaw;

- sandpaper;

- pencil;

- rope;

- plane;

- electric drill;

- chisel;

- screwdriver;

- jigsaw;

- boards, picket fence;

- iron corners;

- wood screws;

- fittings - hinges, handle, latch.

Wickets manufacturing technology

Step 1. First, the distance between the supports is determined. If you do it right, the gate will work smoothly. Supports can be wooden poles or metal pipes (as described above).

The distance between the supports is fixed with a piece of wire laid on the ground and fastened with something.

Step 2 Support posts are installed. The technology is no different from that of wooden gates.

Step 3. Next, the door is made. To do this, four boards are connected at an angle of 90? metal corners. Then hinges are attached to the finished frame, after which it is checked for entry into the opening. If the result is positive, the frame is sewn up with a picket fence. From above, the gate is cut off with a jigsaw in a straight line (it can also be in the form of waves, zigzags, etc.). The lock and the door handle are the last to hit.

Step 4. At the final stage, the gate is hung on hinges, after which it is checked whether the door closes/opens freely. To fix the gate in the closed position, a piece of rubber can be nailed to the end.

The wooden gate is ready for use.

Video - Beautiful ideas for wooden gates

As a conclusion

As you can see, for the manufacture of wooden gates or gates, certain knowledge and skills in woodworking will still be required. Therefore, if neither one nor the other is available, it is better not to spare money and contact a specialist. The gate is the face of the house.

But with a firm intention to do everything with your own hands, it remains only to wish good luck and a lot of creative ideas. With another possible option - sliding gates made of wood - you can see when watching a thematic video.

Video - Wooden sliding gates

Do-it-yourself wooden gates are made by many people. After all, this material is quite attractive in many respects. How to make a wooden gate with our own hands, we will consider today. Also on the video in this article and the photo you can choose and not just desired view gate, but also decide on the design.

Such gates have their undeniable advantages, which allow you to make a choice in this direction of the material:

| Price | Prevalence and democratic value. Shops and markets of building materials offer customers a wide range of wooden planks and a bar. Their cost, in comparison with metal products, will pleasantly amaze any person. |

| Easy processing | Easy processing. You can easily prepare your own material for the gate. The difference between wooden products and metal ones (see) is that they can be processed using hand tools from the home collection. Commonly used tools such as an electric hacksaw and grinder. |

| Durability | If you properly care for the gate, then they will definitely serve you for a solid number of years. Unlike metal wooden products rusting is not typical, but gradually they become worn out. That is why it is recommended to treat the wood with strengthening agents and apply paint to places that require it. And if you notice damage to the canvas, then do not worry, it will not take you long to put other boards in this place. |

According to your needs, you can build varieties yourself. For example, retractable or with a mechanical lift are suitable.

But most popular view are hinged. Their mechanism is so simple that every person, even not connected with construction in any way, will be able to install them.

Choose a view

Wooden, with your own hands, you should start doing after choosing desired option of this design. The photo shows possible options and you can choose what you need. Or take advantage separate elements design.

Swing

This type has enough low price: 1 m2 on average costs from 3 thousand rubles. Optimal Width- 4 meters, but in extreme cases, you can make 3.5: there will be enough space for the car to enter.

Swing wooden

So:

- You should be attentive to the supports that serve to fasten the gate. It is necessary that their length be 20 cm longer. It is advisable to use a canopy over the gate, as it is aimed at preventing moisture at the ends of the leaves.

- Before installing a visor, you need to think carefully. In the event of an overlap, cars from building materials or you will have to plant trees. Install the canopy at a height of poles from 3.5 to 4 m.

- The valves are sometimes disproportionate in size. For example, the gate (see) may be smaller than other parts.

- The advantage of swing in their simple installation- mainly only hinged hinges are used (with a sash size of not more than 200 kg). If your sashes have larger size(starting from 200 kg), then it is pointless to use loops: most likely, they will become oblique. To avoid this, use bearing loops that completely disperse the load.

Swings have their disadvantages:

- They need free place so that they can be opened. At the same time, it is necessary to ensure that there are no elevations on the ground that may interfere with the opening.

- Another drawback is that in snowy weather, residents of the house will not be able to get into it until they clear the snow in front of the gate. Lastly, the weight of the sashes only require strong supporting posts.

In order to make your swing doors more modern and convenient, you can install automation that will allow you to open with a button. The price is not high, but the comfort is a pleasant thing.

Sliding

Sliding or retractable - this is modern type. To date, all large quantity people prefer automatic.

Wooden sliding

The advantages of these are:

- No need to clear the area from snow to enter the yard

- Passage width limit - 11 m, which is much more than that of swing gates

- Width directly depends on relative position carriages

But sliding also have disadvantages:

- The main disadvantage with automation is their cost, the lower bar of which is 14 thousand rubles, and the upper bar is 30 thousand rubles.

- This type needs a significant space along the fence (about 40-50% more than the width of the passage)

- It is better to install such a specialist immediately, since the process itself is quite complicated.

Preparatory process before starting work

Before collecting the necessary tools and materials, you need to make a drawing of your future gate and accurately measure the places for their subsequent installation. Only after passing these two steps, you will understand how to build a wooden gate with your own hands without the intervention of professionals.

Making a drawing

To build a gate with your own hands, you need to accurately view the opening, and in the context of the yard, you need to measure the length between the fence ends.

After that, you can start doing. To simplify and make your work as convenient as possible, we advise you to use ready-made example. All you need from the finished drawing is to replace the old numerical data with your own. Such a detailed sketch will allow you to accurately select the desired components.

Cooking tool

To build yourself, you should use the tools:

- Wooden bars, the diameter of which will be at least 5x5 cm. Or metal pipes, whose profiles will be approximately 5 cm;

- boards;

- hinges;

- Electric jigsaw or hacksaw;

- Meter, tape measure, corner, level;

- Drill with drills;

- Plane;

- Chisel;

- Screwdriver;

- Self-tapping screws and pins;

- Sandpaper;

- ground liquid;

- Welding tool (if necessary);

- Rods or anchor bolts;

- Paint or varnish for outdoor use;

- Tassels.

If you are engaged in the creation of wooden gates for their installation in the yard, then you need to prepare in advance the pillars that serve as a support. If they are not available, you can create them yourself. All you need is 2 oak beams or metal pipes with an approximate diameter of 15 cm.

Completing of the work

Do-it-yourself wooden gates are made in the following order:

- Poles are being installed.

- Then you need to give them the desired length. After that, make 2 holes at the distance indicated earlier. The depth of such holes should be approximately 1 meter. Proceed from the following principle: the stability and durability of the entire installation depends on the depth of the installed supports.

- To avoid problems with the stability of the installation, you can fill the recesses with rubble and trample the bottom.

- If you want to avoid subsequent decay, you can use wooden beams. To do this, carefully process the part of the beam that goes into the ground with such means as bituminous mastic or epoxy resin. After processing, you can begin to install support pillars, fixing the vertical with a level and filling the pits with rubble.

Attention: Useful action will be if you concrete them with cement. And in order to achieve absolute durability and excellent appearance, you can do brick lining of supports.

gate manufacturing process

After you have prepared and made sure that all the components are available, you can safely begin the production of the gate.

If you are planning to make Garage Doors, then the frame is assembled by hand. To do this, you need to cut the wooden bars, based on the measurements of the opening. After that, lay them on the surface in a square or rectangular shape.

After that, make sure the diagonals are even and use metal corners along with self-tapping screws to strengthen the corners.

So:

- For the manufacture of the frame, you may well use metal pipes or angular profiles. But in order to firmly fix them, you need to use welding machine. After that, you can safely fix the frame in the opening with dowels or anchors.

- After that, you need to start creating the frame of the valves. Initial work they begin with an incision of wooden beams to the required length, followed by processing the upper part with a planer and placing them on a flat plane, as shown in the sketch. Remember that the front of the gate must be 15 cm larger than the frame. In order to protect the gate from external influence, we advise you to cover wooden materials liquid to be handled.

- Make sure all diagonals are same size, install self-tapping screws at the docking points or create a recess with a drill to insert the pins there, which are responsible for the stability of the part. After all the structures are ready, fix them in the middle cross beams. At the ends of the bars, make slopes of 45 degrees. And in conclusion, reinforce the products with self-tapping screws.

- You can mount metal sashes on the frame. To do this, you must follow the same principles as when installing wooden beams. But as fasteners, we advise you to use welding.

- Next, you need to do the preparation and processing of products in order to sheathe the front parts of the wings. Select required number boards and, using an electronic jigsaw, give them the required length.

- Then connect the boards together, and with the help of self-tapping screws, fix the point of contact. After that, take care of trimming uneven places and sanding with sandpaper.

- Now that your gate is almost done, it's time to install the metal hinges. For gates designed for a garage, the hinges must be welded to special places in the frame, and if you have it in the yard, then fix it to the supports.

Attaching hinges to poles

- In the final stages, prime the surface of the gate with a special liquid, then open it with paint. If you do not want to use paint, you can turn to stain, which will provide an attractive shade. After that, varnish the gate and, based on own desire, you can put metal products on the front of the gate.

- It remains only to install handles, locks and bolts on the gate. To install the bolts, you can resort to the use of rods fixed on the sashes. To achieve their absolute fixation, make grooves in the soil.

- Thus, wood can be easily made with your own hands and at home. Important Rule which must always be followed is to measure accurately, pay attention to the sequence of actions, use only proven products.

- Since they are made of wood, caring for them is doubly important. Therefore, do not be afraid to use paint and paint over old places, and in case of creaking loops, use grease.

It is not difficult to make it with your own hands from wood, you just need to follow the instructions. And if you do everything with your own hands, this will be the key to the quality of the work.