Cast iron sewer hatch type "L" 1-60 GOST 3634-99

The hatch pig-iron for viewing wells of type "L" (Light hatch). GOST 3634-99. Designed for installation in the area of green spaces and on the carriageway of streets with a permissible maximum load of 3 t/s

Specifications:

GOST GOST 3634-99

Hatch Type Light

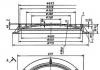

Hatch body diameter, mm 770

Hatch body height, mm 90

Hatch body weight, kg 35

Manhole cover diameter, mm 675

Manhole cover thickness, mm 40

Manhole cover weight, kg 30

Ultimate load, t/s 3

Cast iron grade SCH 20

Purpose K-domestic and industrial sewerage, V-water supply, D-rain sewerage, G-fire hydrant

A sewer hatch is a special structure that provides access to underground utilities, such as sewage, storm, cable or pipeline sewage. It can be made of plastic, polymers, composites, concrete, rubber or metal. The most acceptable option in the opinion of experts is a cast-iron hatch. This material for the manufacture of hatches has been used for more than a dozen years. The cast iron sewer manhole has a number of advantages that make it so popular among buyers. Firstly, the cast-iron hatch can withstand very heavy loads. It will remain in its original form even if a load of 90 tons is applied. This will allow you not to worry about the kids who play in the yard, about the car that hit him. Thus, the manhole will be safe for everyone. Secondly, the cast-iron hatch has a long service life. The durability of cast iron is many times greater than that of other materials, so a cast iron manhole is a great investment. So, you should not look that it is more expensive, for its cost there is excellent reliability and durability. Thirdly, the cast iron hatch is resistant to temperature extremes, which is not uncommon in our climate zone. This hatch will serve you both in winter and summer, and in frost and heat. In addition, such a hatch weighs enough so that children cannot budge it and climb into the sewer.

When buying a sewer manhole, you should pay attention to its cover. It should fit snugly against the body, since its main purpose is to prevent foreign objects from entering the sewer. The safety of the manhole will depend on the density of its fit in the future. In our store, this parameter is monitored very closely, as we are responsible for our product. The safest are round-shaped covers, since they cannot fall into the hatch during installation or dismantling. The round lid is the most economical option, as its shape makes it the most reliable even with a small thickness.

GOST 3634-99

INTERSTATE STANDARD

MANHOLE HATCHES

AND RAIN GEARS

STORM WELLS

Specifications

INTERSTATE SCIENTIFIC AND TECHNICAL COMMISSION

ON STANDARDIZATION, TECHNICAL REGULATION

AND CERTIFICATIONS IN CONSTRUCTION

(MNTKS)

Moscow

Foreword

1 DEVELOPED by JSC "Kirovskiy Zavod" (Kaluga region), SE CNS and a group of specialists

INTRODUCED by Gosstroy of Russia

2 ADOPTED by the Interstate Scientific and Technical Commission for Standardization and Technical Regulation and Certification in Construction (ISTCS) on December 2, 1999

|

State name |

Name of the public administration body for construction |

|

Republic of Armenia |

Ministry for Coordination, Territorial Administration and Urban Development of the Republic of Armenia |

|

Republic of Belarus |

Ministry of Architecture and Construction of the Republic of Belarus (Ministry of Architecture and Construction of the Republic of Belarus) |

|

The Republic of Kazakhstan |

Construction Committee of the Ministry of Energy, Industry and Trade of the Republic of Kazakhstan (Kazstroykomitet) |

|

The Republic of Moldova |

Ministry of Environment and Territory Improvement of the Republic of Moldova |

|

Russian Federation |

Gosstroy of Russia |

|

The Republic of Uzbekistan |

State Committee of the Republic of Uzbekistan for Architecture and Construction (Goskomarchitektstroy of the Republic of Uzbekistan) |

The type of hatch is selected depending on the installation location.

4.2 By execution, hatches are subdivided:

1 - general purpose ();

2 - with a locking device on them (). The design of the locking device is agreed with the consumer;

3 - having a recess in the design of the cover for filling with concrete of a class not lower than B30 ();

4 - with a device for lifting the cover using a standard lifting mechanism. The design of the device must be agreed with the consumer;

5 - with reinforced sealing of the body with anchor bolts or special tides on the body (). The design of anchors, tides and their number (at least two) is agreed with the consumer;

6 - with a cover consisting of two parts ();

7 - with a cover hinged to the body;

8 - with a square or rectangular shape of the cover and (or) hatch body.

4.3 Types, basic parameters and dimensions of storm water inlets, their installation location are indicated and. The type of grille is selected depending on the installation location.

Table 1

|

Type (designation according to EN 124) |

Name |

Full opening D, not less, mm |

h, not less, mm |

Weight total, reference, kg |

||

|

LM * (A15) |

Lightweight sunroof |

Green area, pedestrian zone |

||||

|

L (A15) |

Light hatch |

|||||

|

C (B125) |

middle hatch |

car parks , sidewalks and roadways of city parks |

||||

|

T (S250) |

heavy hatch |

City highways with heavy traffic |

||||

|

TM (D400) |

Heavy main hatch |

Trunk roads |

||||

|

ST (E600) |

Super heavy hatch |

|||||

|

Repair insert |

Hatch bodies of types C (B125) and T (C250) during repair work on roads (when increasing the height of the roadway) |

|||||

|

* For underground utilities with a channel depth of up to 600 mm from the outer surface of the manhole cover. |

||||||

4.4 According to the design, storm water inlets are divided into:

1 - with a minimum width of the supporting part of the body along the contour ();

2 - with a minimum width of the longitudinal supporting part of the body adjacent to the road curb ();

3, 4, 5 - with a minimum width of the longitudinal supporting part of the body adjacent to the curb of the road, and one right (version 2) or left (version 3), or both (version 4) short sides;

6.7 - with a minimum width of the short supporting part of the body adjacent to the curb of the road (version 5), or both short sides (version 6);

8 - with a single housing for two gratings ();

9 - with reinforced sealing of the body, for which the latter is equipped with anchor bolts or special tides on the body (). The design of anchors, tides and their number (at least two) are agreed with the consumer;

10 - with a lattice hinged to the body.

table 2

|

Type (designation according to EN 124) |

Name |

Clear area S, not less than, m 2 |

Depth of installation of a cover in the case h, not less, mm |

Weight total, reference, kg |

|||

|

D(A15) |

Rain collector small |

0,05 |

Pedestrian zone |

||||

|

DB1 * |

Large storm water inlet |

0,075 |

Parking lots and roadways of city roads |

||||

|

DB2 ** (B125) |

0,15 |

||||||

|

DM1 |

Main storm water inlet |

0,075 |

High traffic highways |

||||

|

DM2 (S250) |

0,15 |

||||||

|

DC1 |

Heavy duty storm water inlet |

0,075 |

High load areas (airfields, docks) |

||||

|

DS2 (D400) |

0,15 |

||||||

|

On roads (airfields) with longitudinal slopes: |

|||||||

|

* DB1 - i o£ 0,005; |

|||||||

|

** DB2 - i o>0,005. |

|||||||

4.5 The symbol of a hatch or storm water inlet should consist of the word "Hatch" or "A storm water inlet", its type, version or several versions, overall dimensions of the manhole in centimeters and the designation of this standard.

Additionally, the designation of engineering networks for which the hatch is intended is introduced into the symbol of the hatch: B - water supply; G - fire hydrant; K - household and industrial sewerage; D - rainwater drainage, TS - heating network, GS - gas network, GKS - city cable network (including GTS - as agreed with the customer).

Examples of symbols:

light manhole for the water supply network with a square cover and manhole size 60´ 60 cm

Hatch L (A15) - V. 8-60´ 60 GOST 3634-99;

middle manhole for sewerage with a locking locking device and a manhole diameter of 60 cm

Hatch C (B125) - K.2-60 GOST 3634-99;

repair insert for a heavy hatch of any design and names of engineering networks with a manhole diameter of 60 cm

Repair insert R.T-60 GOST 3634-99;

large storm water inlet 2 with a minimum width of the longitudinal supporting part of the body adjacent to the road curb, with a hole size of 30´ 50 cm for roads with a longitudinal slopei o<0,005

Storm water inlet DB1 (V125) - 2-30 ´ 50 GOST 3634-99.

5 Technical requirements

5.1 Manhole hatches, repair inserts and storm water inlets must be manufactured in accordance with the requirements of this standard according to working drawings approved in the prescribed manner.

5.2 Characteristics

5.2.1 Castings must not have defects that reduce their strength. Castings must comply with the requirements of GOST 26358.

On the surface of the castings, shells with a diameter of not more than 10 mm and a depth of not more than 3 mm are allowed, occupying no more than 5% of the surface of the castings. Cracks are not allowed. Slag inclusions are allowed on the lower supporting surface of the hulls, the inner surface of manhole covers and gratings of storm water inlets, occupying no more than 10% of the total surface area.

5.2.2 Tolerances of castings must correspond to: dimensions - not lower than the 10th accuracy class according to GOST 26645, weight - the 11th accuracy class.

5.2.3 The upper surfaces of hatch covers of all types shall be embossed. Relief height should be for types:

LM (A15), L (A15), C (B125) and T (C250) - from 2 to 6 mm;

TM (D400) and ST (E600) - "3" 8 ".

The surface area of the convex relief must be not less than 10% and not more than 70% of the total surface area.

The configuration of the relief is set by the manufacturer and must be determined taking into account the magnitude of the rated load, as well as the manufacturing technology.

5.2.4 The design of hatches shall provide for at least one depression or opening intended for the possibility of opening the cover.

5.2.5 Manhole covers, repair inserts and gratings of storm water inlets shall freely fit into their respective housings. The gap between them along the perimeter should not exceed 3 mm per side.

5.2.6 Manhole covers (except for water hatches) must have a hole with a diameter of at least 20 mm for sampling the gas contamination of wells.

5.2.7 Manhole covers, repair inserts and gratings of storm water inlets should fit snugly against the corresponding bearing surfaces of their bodies. The flatness tolerance of their supporting surfaces should not exceed 2 mm.

5.2.8 Hatches of types T(S250), TM(D400), ST(E600), the corresponding repair insert and storm water inlets of types DM(S250), DS(D400) must have an elastic gasket between the cover and the body or provide for machining of both mating supporting surfaces. The design, dimensions of the elastic gasket and methods of its fastening are determined by the manufacturer. It is allowed to install several (instead of one solid) elastic gaskets, provided that the lid does not swing. The hardness of the elastic gasket must be at least 40 units. by Shore.

5.2.9 The grooves in the gratings must be evenly distributed over the area of the grating of the storm water inlet. The area of the grooves must be at least 30% of the net area of the grating of the storm water inlet and must be indicated in the accompanying documentation for the storm water inlets.

5.2.10 The grooves of gratings of types D(A15) and DB(V125) shall have the following dimensions, respectively:

width from 8 to 18 mm, length is not limited;

width over 18 to 25 mm, length not over 170 mm.

The dimensions of the grooves of the DM(S250) and DS(D400) gratings depend on the orientation of the longitudinal axes of the grooves in relation to the traffic in accordance with Table 3.

Table 3

|

Orientation |

Type |

Width, mm |

Length, mm |

|

0 to 45° and 135 to 180° |

All types |

16 to 32 |

£ 170 |

|

45 to 135° |

DM(S250) |

16 to 42 |

No limit |

|

DS(D400) |

» 20 » 42 |

5.2.11 The bearing surface of the housing shall be designed in such a way that the pressure on the bearing surface when the rated load is applied does not exceed 7.5 MPa.

5.2.12 The design and dimensions of the locking devices for hatches of manholes, hinged joints of hatch covers and gratings of storm water inlets are determined by the manufacturer in agreement with the consumer.

5.3 Requirements for raw materials, materials, purchased products Hulls, covers, repair inserts of hatches, housings and gratings of storm water inlets are made of gray cast iron of grade not lower than SCH20 according to GOST 1412. It is allowed to change the brand of cast iron, providing a rated load. In addition, it is allowed to manufacture hatch bodies of types LM (A15), L (A15) and storm water inlets of type D (A15) from polymeric materials and cast iron in combination with concrete. Internal locking devices of hatches are made of steel grade not lower than St3 according to GOST 380 with anti-corrosion coating.

5.4 Completeness

Hatches and storm water inlets are supplied as a complete set or as separate parts.

5.5 Marking

5.5.1 On the outer surface of hatch covers of all types and gratings of storm water inlets, a symbol shall be cast, except for the words "hatch", "storm water inlet" and "repair insert" and the trademark of the manufacturer. The designation of the name of the engineering network is located on the center line. The month and year of manufacture are cast on the inner surface of manhole covers and gratings of storm water inlets. The dimensions of the markings are determined by the manufacturer.

5.5.2 Hatches and storm water inlets shipped to the consumer must be accompanied by a passport. The passport contains:

name of the manufacturer or its trademark;

symbolic designation of the product;

the number of products in the lot;

guarantee period;

date of acceptance by technical control;

shipment date.

5.6 Packaging

Hatches and storm water inlets are packaged in bags on pallets. By agreement with the consumer, other types of packaging are allowed to ensure the safety of products during transportation and storage.

6 Acceptance rules

6.1 Acceptance of hatches and storm water inlets of all types, repair inserts (hereinafter referred to as products) is carried out in batches. The batch size is equal to the shift output.

6.2 Products must be subjected to acceptance, periodic and type tests.

6.3 During acceptance tests, the appearance of products, the mechanical strength of covers and gratings should be checked. Each hatch and storm water inlet is subjected to a check in appearance; Manhole covers and gratings of storm water inlets are tested for mechanical strength in the amount of 3% of the batch, but not less than two pieces.

6.4 Upon receipt of unsatisfactory test results for mechanical strength during acceptance tests, a second check is carried out for this indicator of a double number of products. The results of the re-inspection apply to the entire lot and are final.

6.5 During periodic tests, check the dimensions, weight of product parts, deviations from the flatness of hatch covers and gratings of storm water inlets and their bodies on at least three products from a batch that have passed acceptance tests, at least once a year, and also after each replacement of technological equipment.

6.6 Type tests are carried out to verify the effectiveness and feasibility of changes in design or manufacturing technology that may affect the technical characteristics of the product.

Tests are carried out on product samples, the design of which has been amended on the basis of temporary documents.

Types and scope of type tests are determined by the manufacturer.

6.7 The user has the right to conduct a control check of the compliance of all types of hatches, repair inserts and storm water inlets with any requirement of this standard, observing the above sampling procedure and control methods.

7 Control methods

7.1 The dimensions of manhole hatches, storm water inlets and repair inserts are checked with universal or special tools, as well as templates.

7.2 Control of the appearance of hatches, storm water inlets and repair inserts is carried out by external inspection.

7.3 The mass of hatch covers, hulls and other parts is determined by weighing on a scale with an error of not more than 0.5 kg.

7.4 The flatness tolerance of the manhole cover or grating of the storm water inlet is determined on the calibration plate using a set of feelers.

7.5 The mechanical strength test is carried out on a press that provides the required force. The press must be equipped with a steel punch. Punch dimensions are given.

For testing, the hatch or storm water inlet is installed on the press frame, while their supporting surfaces must be adjacent to the frame along the entire supporting surface.

The load on the manhole cover or the grating of the storm water inlet must be applied exactly in the middle through a soft pad with a thickness of at least 3 mm. The press force is uniformly increased at a rate of up to 5 kN/s until the rated load is reached. The test load is maintained for at least 30 s.

A hatch or a storm water inlet is considered to have passed the test if no damage (cracks, spalls) is detected.

8 Transport and storage

8.1 Hatches and storm water inlets are transported by any type of vehicle in accordance with the transportation rules applicable to this type of transport. When transported by road, hatches may not be packaged. In this case, the loading should be uniform and exclude the possibility of moving the load and damaging it.

8.2 Products must have transport markings in accordance with GOST 14192.

8.3 Hatches storage conditions - according to GOST 15150 group Zh 1.

9 Manufacturer's warranties

9.1 The manufacturer guarantees the compliance of hatches, storm water inlets and repair inserts with the requirements of this standard, subject to the conditions of transportation and storage.

300 £ BY £ 1000

200 £ BY £ 300

200 £ BY £ 300

Key words: manholes, manholes, storm water inlets, sewage wells, engineering communications, heat networks, water supply, sewerage

The cast-iron manhole GOST 3634 99 is designed for installation on manholes of underground utilities. The variety of species is associated with operating conditions, resistance to stress and safety. The manufacture of protective products, the requirements for the material are regulated by established international standards.

Types of protective hatches and their purpose

Access to view underground utilities, such as sewage, cable, pipeline systems, is provided by a manhole in the manhole.

The main purpose of the covers is to ensure the safety of pedestrians, cars, as well as protection against damage and clogging of underground networks.

The standard for cast iron manhole covers is based on worldwide requirements for product marking, design, testing and quality control. Hatches are produced in accordance with the requirements of GOST 3634 99 "Hatches for manholes and storm water inlets".

Depending on the installation conditions, loads, different types of hatches are distinguished. They are associated not only with ease of installation and operation, but also with the aesthetic filling of the structure, the preservation of technical parameters, regardless of the conditions of use.

Super-heavy protective structures with a diameter of 550 mm and a weight of 155 kg, a rated load of 600 kN, are installed in docks and airfields.

Super-heavy protective structures with a diameter of 550 mm and a weight of 155 kg, a rated load of 600 kN, are installed in docks and airfields.

Heavy main hatches weighing about 140 kg are mounted on highways, withstand loads up to 400 kN. On urban roads with heavy traffic, products with a mass of 120 kg and a rated load parameter of 250 kN are installed.

Medium products that can withstand loads up to 125 kN are installed in residential areas and roads with a limited traffic load. Installation of light sewer hatches, weighing 65 kg, is carried out on sidewalks, pedestrian areas, lawns.

Hatches for wells are manufactured in accordance with the requirements of the established standard according to approved drawings. Castings must not contain defects that affect the strength of the product.

The design provides for the presence of at least one hole, providing the possibility of opening the cover. It must simultaneously fly tightly to the supporting surface and freely enter the housing.

If we characterize the cast-iron hatches of round manholes, then for them there are 2 main parameters - the outer and inner diameter of the hole.

All overall parameters of the product are prescribed in GOST 3634 99, but in practice you can find cast-iron manhole covers with a diameter of 380-810 mm. Full opening size is 450-550 mm.

The cover of the protective structure can also be square. The minimum side length can be 300 mm and can be increased by 50 mm with each step. The optimal dimensions of this design are 800 mm.

Technical specifications

Cast iron hatches must be equipped with an elastic gasket between the upper and lower parts of the structure. The material from which protective products for manholes are made must meet the requirements of the state standard.

Cast iron hatches must be equipped with an elastic gasket between the upper and lower parts of the structure. The material from which protective products for manholes are made must meet the requirements of the state standard.

Manhole covers, bodies are made of gray cast iron grade SCh20. If necessary, it is allowed to replace the material with another brand, provided that the maximum load is ensured.

The manufacturer puts a marking on the outer part of the hatch design, and the date of manufacture on the inner part. Each product has a passport, which indicates the data on the product, the warranty period of operation, the date of acceptance by the technical control department.

Each batch is tested for strength and tested for mechanical stress.

The service life of cast-iron hatches is at least 80 years, and the withstand load is up to 90 tons. They are resistant to temperature changes. The only drawback of cast iron structures is their high cost.

The service life of cast-iron hatches is at least 80 years, and the withstand load is up to 90 tons. They are resistant to temperature changes. The only drawback of cast iron structures is their high cost.

The arrangement of a technological well is associated with the need for constant maintenance and current repair of various types of highways. Therefore, such structures are reliable and provide conditions for access to underground utilities.

Installation and operation

Tightly closed manhole covers do not guarantee complete safety and protection against various objects falling into the hole. The main purpose for which heavy material is used in the manufacture is to prevent accidental falls.

Tightly closed manhole covers do not guarantee complete safety and protection against various objects falling into the hole. The main purpose for which heavy material is used in the manufacture is to prevent accidental falls.

The cast iron cover is quite heavy, so a certain force must be applied to overbalance and shift it. Cast iron is resistant to atmospheric conditions, corrosion, durable, does not crack under the influence of loads.

The manhole cover provides limited access to the manhole, in which the nodes of distribution and shut-off equipment, as well as the mechanisms for monitoring and controlling the systems, are provided.

Well openings must always be closed so that they cannot be opened by random one-sided loads or curious passers-by.

If the installation of the hatch must be done on a personal plot, then the main efforts must be made when installing the supporting part of the structure. The support ring has technological holes necessary for high-quality armoring of the structure.

The cover of the sewer well should rise above the surface if it is placed on the lawn. When installing on a roadway, ensure that there is a minimum slope in the area where the cover will be installed to allow water to drain.

Ease of installation is closely related to strict compliance with the rules of operation. The well cover must be opened with extreme care, especially if it is made of cast iron. The heavy weight of the product may cause injury.

An open well must be ventilated, and all work is allowed to be carried out only with personal protective equipment.

The middle Hatch L (A15) is a hatch body and a cover installed on the opening of manholes. Hatch C is made of lightweight and durable polymer-sand material. The middle hatch is used to protect manholes of sewerage, water supply and other engineering networks in streets with low traffic intensity and in industrial zones. The norms and standards for the production of hatches are enshrined in GOST 3634-99. The mass (cover and body) depends on the material - a polymer hatch is much lighter than a cast iron hatch, its weight is 40 kg. But, this mass is enough to guarantee stability during operation. And the absence of metal in the composition of the polymer hatch makes it unattractive for theft and subsequent scrapping.

Medium Hatch L (A15) is available with a diameter of 770 mm. The cover of the middle hatch type C shall withstand a force of 125 kN. has a round shape, the body is flat, and the lid is flat or convex with "ears" for easy installation in the body. The upper surface of the cover of the middle hatch C has a relief from 2 to 6 mm high, often the relief takes the form of various patterns. Also, the cover of the middle hatch has a hole for sampling gas contamination (except for water hatches).

The polymer-sand manhole has an extended color range (red, green, etc.), which helps the manhole to fit more harmoniously into any infrastructure.

Product marking

On the surface of the hatch cover, parallel to the center line, bounded by an annular rib, the symbol of the hatch, the year of its manufacture and the manufacturer's trademark are cast.

The marking of the hatch of the middle type depends on the version, where the design differences of the products are indicated by numbers. The number 1 denotes hatches for general purposes, 2 - the presence of a locking locking device, 3 - the presence of a recess in the structure of the cover for filling with concrete, 4 - the presence of a device for lifting the cover using a standard lifting mechanism, 5 - hatches with reinforced body sealing, 6 - hatches with a two-piece lid, 7 - with a lid hinged to the body, 8 - square or rectangular hatches.

Also on the manhole cover indicate the designation of the engineering network, the well of which the hatch will cover. Name of engineering networks for which the hatch is intended:

- B - plumbing;

- G - fire hydrant;

- K - household and industrial sewerage;

- D - rain sewer.

- TS - heating networks

- GS - gas network

- GTS - urban telephone network.

The symbol of the hatch should consist of the hatch type, version or several versions, the overall dimensions of the manhole in centimeters and the designation of this standard. You can also find markings with other letter designations. This is nothing more than the compliance of domestically produced hatches with European standards. So hatch L corresponds to class A15; hatch C - class B125, etc.

As an example of a middle hatch symbol, consider:

Luke L (A15) – K 8-60 GOST 3634-99 ( 770X 770X 120mm), Where:

- L-type hatch (medium);

- B125 - compliance with the European standard B125;

- K - name of the engineering network - sewerage;

- the first digit is execution;

- the second digit is the diameter of the manhole in decimeters;

- GOST 3634-99 - an indication of the state standard.

Product quality control

The casting of the middle hatch should not have significant defects and cracks that could affect the strength of the product. Shells with a diameter of more than 10 mm and a depth of more than 3 mm are not allowed. The lid should fit snugly against the supporting surface of the housing - the gap between the lid and the housing is not more than 3 mm. The flatness tolerance of the bearing surface must not exceed 2 mm.

On acceptance tests hatches C, the appearance of all covers and hatch bodies, as well as the mechanical strength of the covers (at least 2 hatches from a batch) are controlled.

Technical certificate, which must necessarily accompany a batch of cast-iron hatches, must indicate:

- name or trademark of the manufacturer;

- product marking;

- lot number;

- the number of hatches in the party;

- warranty period of operation;

- stamp and date of acceptance by technical control;

- designation of the state standard.

Transportation and storage.

Light hatches are transported by various vehicles packed in bags tied with wire. Luke L (A15) is covered by the manufacturer's warranty. The warranty period is 3 years from the date of putting the hatches into operation, but not more than 5 years from the date of shipment of products to the customer.