3.3. Limit deviations along the total length of multiple pipes should not exceed:

+ 15 mm - for pipes of I accuracy class;

+100 mm - for pipes of accuracy class II.

3.4. At the request of the consumer, pipes of measured and multiple lengths of accuracy class II must be with chamfered ends on one or both sides.

4. Limit deviations for the outer diameter of the pipe are given in table 3.

Table 3

Note: For diameters controlled by perimeter measurement, the largest and smallest perimeter limits are rounded to the nearest 1 mm.

5. At the request of the consumer, pipes according to GOST 10705 are manufactured with a one-sided or offset tolerance on the outer diameter. One-sided or shifted tolerance should not exceed the sum of the maximum deviations given in table. 3.

6. Limit deviations in wall thickness must correspond to: ± 10% - with pipe diameters up to 152 mm; GOST 19903 - with a pipe diameter of more than 152 mm for a maximum sheet width of normal accuracy.

By agreement between the consumer and the manufacturer, it is allowed to manufacture pipes with one-sided tolerance for wall thickness, while one-sided tolerance should not exceed the sum of maximum deviations for wall thickness.

7. For pipes with a diameter of more than 76 mm, a wall thickening at the burr by 0.15 mm is allowed.

8. Pipes for pipelines with a diameter of 478 mm or more, manufactured in accordance with GOST 10706, are supplied with maximum deviations in the outer diameter of the ends given in Table. 4.

9. The ovality and equivalence of pipes with a diameter of up to 530 mm inclusive, manufactured in accordance with GOST 10705, must be no more than the maximum deviations, respectively, in terms of the outer diameter and wall thickness.

Pipes with a diameter of 478 mm or more, manufactured in accordance with GOST 10706-76, must be of three accuracy classes in terms of ovality. The ovality of the pipe ends must not exceed:

1% of the outer diameter of pipes for the 1st accuracy class;

1.5% of the outer diameter of the pipes for the 2nd accuracy class;

2% of the outer diameter of the pipes for the 3rd accuracy class.

The ovality of the ends of pipes with a wall thickness of less than 0.01 of the outer diameter is established by agreement between the manufacturer and the consumer.

10. The curvature of pipes manufactured in accordance with GOST 10705 should not exceed 1.5 mm per 1 m of length. At the request of the consumer, the curvature of pipes with a diameter of up to 152 mm should be no more than 1 mm per 1 m of length.

The total curvature of pipes manufactured in accordance with GOST 10706 should not exceed 0.2% of the pipe length. The curvature per 1 m of the length of such pipes is not determined.

11. Technical requirements must comply with GOST 10705 and GOST 10706.

Steel electric-welded pipe products are used in the oil and gas industry, energy, engineering and housing and communal services. We deliver throughout Russia and the CIS countries. Our company offers customers products according to the standard that establishes the list of electric welded steel longitudinal products.

The range of pipes in accordance with GOST 10704 91 includes equipment of random length 2-5 m in diameter from 30 to 152 mm and more. We produce products of groups A, B according to state standard 10705 according to the requirements of the client. With a diameter of 152 mm, its length can be at least 10 m. The measured length varies from 5 to 12 m, the multiplicity is from 250 mm.

The assortment of pipes GOST 10704 91 of multiple and measured value can be ordered in two accuracy classes: with cutting and deburring, without deburring and trimming. Please note that the maximum deviations cannot exceed +15 and +100 mm for categories I and II, respectively.

Making an order in our company, customers can be sure that their wishes will be taken into account. So, if necessary, products are manufactured with a one-sided / offset tolerance on the outer diameter.

The main parameters of the GOST 10704 91 pipe assortment:

- a product with a diameter of more than 76 mm can be with thickening of the walls at the burr by 0.15 mm;

- accessories for pipelines with a width of 478 mm or more may have deviations at the ends (outer size) +/- 1.5-4;

- curvature per 1 m does not exceed the allowable 1.5 mm.

There are also three accuracy classes for the ovality parameter; for the first class, it cannot exceed 1% of the outer size, for the second - 1.5%, and for the third - 2%. If the wall thickness is less than 0.01% of the outer diameter, then the ovality will be set by agreement between the manufacturer and the customer of the pipe assortment in accordance with GOST 10704 91. To clarify the price for the product you are interested in, send an e-mail or call the specified numbers.

TC "UPSK" supplies the entire range of pipe products (seamless hot-rolled and cold-rolled pipes, electric-welded pipes, large-diameter pipes, shell pipes, shaped pipes), as well as connecting parts of pipelines (branches, tees, transitions, flanges, plugs) in Chelyabinsk.

Constant presence in Chelyabinsk.

Availability of railway tracks, delivery by railway and motor transport to all regions of Russia and the CIS.

Discounts, convenient form of payment, deferred payment.

Longitudinal electric-welded steel pipes are pipes made from a metal strip cut from a sheet, rolled up and welded along the seam.

For this reason, welded metal structures are also called seam or straight-seam, and the method of their manufacture is called by specialists - with cooking bent strip.

State standards (GOSTs) are documents that regulate the conditions for the production of any products. They spelled out the technical characteristics, properties and size range of all types of metal structures acceptable for production.

State standards (GOSTs) are documents that regulate the conditions for the production of any products. They spelled out the technical characteristics, properties and size range of all types of metal structures acceptable for production.

GOST 10704–91 is a state standard that regulates the requirements for steel welded pipes with an outer diameter of a product from 10 to 1420 mm and a wall thickness from 1 to 16.5 mm. The document includes assortment for real products. The range means the sorting of products, presented in the form of a table, which lists all the dimensions and characteristics of this pipe product that are available and acceptable for production.

This state standard was approved for action and put into use by the Committee for Standardization and Metrology back in 1991 (instead of GOST 10704–76) and is still in effect. It also includes the requirements of the following regulatory and technical documents:

This state standard was approved for action and put into use by the Committee for Standardization and Metrology back in 1991 (instead of GOST 10704–76) and is still in effect. It also includes the requirements of the following regulatory and technical documents:

- GOST 19903–74.

- GOST 10706–76.

- GOST 10705–80.

The release of steel electric welded products GOST 10704–91 is carried out on the basis of the requirements of the above technical state standards.

Requirements for the manufacture of pipes

Separate state standards have been developed for each individual type of metal pipes, which are used by both specialists and consumers. Consider the requirements for the manufacture of steel electric-welded structures made in accordance with GOST 10704–91:

1. For the manufacture of metal structures in accordance with GOST 10704–91, use:

- carbon steel, which contains high-quality alloying additives that improve the physical and mechanical properties of the material;

- low carbon steel having a low content of alloying additives;

- stainless steel grades (stainless steel).

2. According to the current GOST, depending on the diameter, welded pipes are made of any length agreed with the customer:

2. According to the current GOST, depending on the diameter, welded pipes are made of any length agreed with the customer:

- measured length;

- unmeasured length;

- multiple measured.

Cut-to-length pipes have the following standards:

Random length pipes:

When ordering random sizes of metal products, weight must be taken into account. It will be important for the transportation and installation of a multi-dimensional product. In this case, it is convenient to use the pipe weight calculator posted on any thematic site. In addition, due to the additional reinforcement of the weld, the weight of the product will increase by about 1%.

Pipes of multiple lengths.

Pipes of multiple lengths.

With a multiple length, pipes are made with a diameter ranging from 250 mm to the lower limit of dimensional structures, that is, up to 426 mm.

They are made according to the regulations corresponding to the product of the measured length. If the production conditions are not individually agreed, then it is customary to make an allowance of each cut with a size of 5 mm, which is included in each allowable multiplicity.

3. When ordering, you need to know that pipe-rolled lengths of measured and multiple lengths can be of two accuracy classes and are produced with the following acceptable standards:

3. When ordering, you need to know that pipe-rolled lengths of measured and multiple lengths can be of two accuracy classes and are produced with the following acceptable standards:

- class I - trimming of the ends is done with chamfering, that is, with deburring;

- class II - designates a product without deburring and is produced by cutting a metal structure on a cutting mill.

All possible and permissible deviations of measured dimensions when cutting products are given in the GOST 10704–91 assortment tables:

- for accuracy class I - this is plus or minus 15 mm;

- for class II - 100 mm.

However, according to the individual order of the consumer, metal products belonging to class II, that is, made according to GOST without deburring, can be chamfered on one or both sides.

4. In the normative GOST 10704–91 for steel welded products, you will find information on all maximum deviations in the dimensions of the outer diameters of metal structures manufactured in an industrial way. In the assortment, these smallest or largest allowable values will be rounded to the nearest 1 mm.

4. In the normative GOST 10704–91 for steel welded products, you will find information on all maximum deviations in the dimensions of the outer diameters of metal structures manufactured in an industrial way. In the assortment, these smallest or largest allowable values will be rounded to the nearest 1 mm.

5. Dimensional deviations along the wall thickness must meet the regulatory requirements. With a pipe diameter of up to 152 mm, the wall thickness should not deviate from GOST in one direction or another by more than 10%. Pipes of larger diameter must meet the thickness requirements for steel sheets from which they are made.

6. Electrowelded structures of large diameters (from 478 mm), used mainly for external pipelines, also have a gradation in terms of the ovality of the ends of the products.

There are three classes of ovality accuracy:

- 1st class - the deviation cannot be more than 1% of the outer diameter;

- 2nd class - 1.5% of the outer diameter;

- 3rd class of accuracy - no more than 2% of the outer diameter.

7. The state standards set the maximum standard for such a parameter of pipes as curvature, which should not be more than 1.5 mm per 1 m of length. The total curvature of the entire finished product of any length should not be more than 0.2%. The curvature of 1 m long products in this case is not determined.

Manufacture of welded pipe

Electrowelded pipes are produced from steel tape (strips) in a rolling mill. By the type of seam, tubular products are produced in two types:

Electrowelded pipes are produced from steel tape (strips) in a rolling mill. By the type of seam, tubular products are produced in two types:

- straight-line-seam - having one seam running straight along the entire metal product;

- spiral-seam - also having one seam, but rotating along the entire length in the form of a spiral around the pipe being welded.

The most common straight-seam steel tubular products. Their main advantage is the minimum length of the weld (compared to spiral seam), which simplifies the quality control required for release. Spiral pipes are often of large diameters and are produced solely for the reason that there is no wide blank (steel sheet or strip) for the manufacture of longitudinally welded pipe.

The technological process of manufacturing electric-welded metal structures is rather laborious, it consists of many complex operations. For the production of high-quality pipes of different diameters, radio frequency welding is most often used, which performs metal joining at high speed. With this method of welding, high-voltage currents are passed through the workpiece, which contribute to the rapid heating of the edges to be joined.

The technological process of manufacturing electric-welded metal structures is rather laborious, it consists of many complex operations. For the production of high-quality pipes of different diameters, radio frequency welding is most often used, which performs metal joining at high speed. With this method of welding, high-voltage currents are passed through the workpiece, which contribute to the rapid heating of the edges to be joined.

In order to form a strong and high-quality weld from the molten billet, or rather, from its edges, they are pressed tightly against each other under pressure. And to obtain a pipe of the required diameter from a steel strip, special machines, swaging mills are used in metallurgical production. This manufacturing technology makes it possible to obtain not only reliable and high-quality products, but also to provide them with an externally attractive appearance. The welded seam on these products looks very neat or even invisible.

The main quality that electric-welded pipes possess and for which they are very much appreciated is their exceptional versatility in use. First of all, this applies to round pipes. Products are successfully used in industry and construction sites:

And also electric-welded pipes of small diameters are used as consumables in the preparation of various products.

The reliable qualities that longitudinally welded pipes have are evidenced by the fact that they are successfully used for the installation of pipelines transporting aggressive chemical liquids and gases heated to very high temperatures.

Electrically welded steel line-weld tubes. Range

GOST 10704-91

OKP 13 7300, 13 8100, 13 8300

Introduction date 01.01.93

1. This standard establishes a range of steel electric-welded longitudinal pipes.

2. The dimensions of the pipes must correspond to the table. 1.

3. The length of the pipe is made: random length:

with a diameter of up to 30 mm - at least 2 m; with a diameter of St. 30 to 70 mm - not less than 3 m; with a diameter of St. 70 to 152 mm - not less than 4 m; with a diameter of St. 152 mm - not less than 5 m.

At the request of the consumer, pipes of groups A and B according to GOST 10705 with a diameter of more than 152 mm are manufactured with a length of at least 10 m; pipes of all groups with a diameter of up to 70 mm - at least 4 m long; measured length:

with a diameter of up to 70 mm - from 5 to 9 m;

with a diameter of St. 70 to 219 mm - from 6 to 9 m;

with a diameter of St. 219 to 426 mm - from 10 to 12 m.

Pipes with a diameter of more than 426 mm are made only in random lengths. By agreement between the manufacturer and the consumer, pipes with a diameter of more than 70 to 219 mm are allowed to be manufactured from 6 to 12 m;

multiple length with a multiplicity of at least 250 mm and not exceeding the lower limit established for measured pipes. The allowance for each cut is set at 5 mm (if no other allowance is specified) and is included in each multiplicity.

Table 1

Continuation of the table. 1

Continuation of the table. 1

Continuation of the table. 1

Continuation of the table. 1

Continuation of the table. 1

Continuation of the table. 1

Continuation of the table. 1

Continuation of the table. 1

N o t e s:

1. In the manufacture of pipes in accordance with GOST 10706, the theoretical mass increases by 1% due to the strengthening of the seam.

2. By agreement between the manufacturer and the consumer, pipes are manufactured with dimensions of 41.51.5-3.0; 43 1.0; 1.5-3.0; 43.51.5 - 3.0; 52 2.5; 69.61.8; 111.8 2.3; 146.15.3; 6.5; 7.0; 7.7; 8.5; 9.5; 10.7; 152.41.9; 2.65;1682.65; 177.31.9; 1982.8; 203 2.65; 299 4.0; 530 7.5; 720 7.5; 820 8.5; 1020 9.5; 15.5; 1220 13.5; 14.6; 15.2 mm, as well as with an intermediate wall thickness and diameters within the table. 1.

3. Pipe dimensions enclosed in brackets are not recommended for new design.

3.1. Pipes of fixed and multiple lengths are manufactured in two length accuracy classes:

I - with cutting ends and deburring;

II - without chamfering and deburring (with cutting in the mill line).

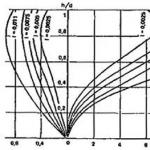

3.2. Limit deviations along the length of measuring pipes are given in table. 2.

Table 2

3.3. Limit deviations along the total length of multiple pipes should not exceed:

15 mm - for pipes of the I class of accuracy;

100 mm - for pipes of accuracy class II.

3.4. At the request of the consumer, pipes of measured and multiple lengths of accuracy class II must be with chamfered ends on one or both sides.

4. Limit deviations for the outer diameter of the pipe are given in table. 3.

Table 3

Note. For diameters controlled by perimeter measurement, the largest and smallest perimeter limits are rounded to the nearest 1 mm.

5. At the request of the consumer, pipes according to GOST 10705 are manufactured with a one-sided or offset tolerance on the outer diameter. One-sided or shifted tolerance should not exceed the sum of the maximum deviations given in table. 3.

6. Limit deviations in wall thickness must correspond to:

±10% - for pipe diameters up to 152 mm;

GOST 19903 - with a pipe diameter of more than 152 mm for the maximum sheet width of normal accuracy.

By agreement between the consumer and the manufacturer, it is allowed to manufacture pipes with one-sided tolerance for wall thickness, while one-sided tolerance should not exceed the sum of maximum deviations for wall thickness.

7. For pipes with a diameter of more than 76 mm, a wall thickening at the burr by 0.15 mm is allowed.

8. Pipes for pipelines with a diameter of 478 mm or more, manufactured in accordance with GOST 10706, are supplied with maximum deviations in the outer diameter of the ends given in Table. 4.

9. The ovality and evenness of pipes with a diameter of up to 530 mm inclusive, manufactured in accordance with GOST 10705, should not exceed the maximum deviations, respectively, in terms of the outer diameter and wall thickness.

Pipes with a diameter of 478 mm or more, manufactured in accordance with GOST 10706, must be of three accuracy classes in terms of ovality. The ovality of the pipe ends must not exceed:

1% of the outer diameter of pipes for the 1st accuracy class;

1.5% of the outer diameter of the pipes for the 2nd accuracy class;

2% of the outer diameter of the pipes for the 3rd accuracy class.

The ovality of the ends of pipes with a wall thickness of less than 0.01 of the outer diameter is established by agreement between the manufacturer and the consumer.

10. The curvature of pipes manufactured in accordance with GOST 10705 should not exceed 1.5 mm per 1 m of length. At the request of the consumer, the curvature of pipes with a diameter of up to 152 mm should be no more than 1 mm per 1 m of length.

The total curvature of pipes manufactured in accordance with GOST 10706 should not exceed 0.2% of the pipe length. The curvature per 1 m of the length of such pipes is not determined.

11. Technical requirements must comply with GOST 10705 and GOST 10706.

EXAMPLES OF CONVENTIONS

A pipe with an outer diameter of 76 mm, a wall thickness of 3 mm, a measured length, an accuracy class II in length, made of steel grade St3sp, manufactured according to group B GOST 10705-80:

The same, increased accuracy in outer diameter, length, multiple of 2000 mm, accuracy class I in length, from steel grade 20, manufactured according to group B GOST 10705-80:

A pipe with an outer diameter of 25 mm, a wall thickness of 2 mm, a length that is a multiple of 2000 mm, an accuracy class II in length, manufactured according to group D GOST 10705-80:

Pipe with an outer diameter of 1020 mm, increased manufacturing accuracy, a wall thickness of 12 mm, increased accuracy in the outer diameter of the ends, 2nd accuracy class in ovality, random length, made of StZsp grade steel, manufactured according to group B GOST 10706-76:

Note. In the symbols of pipes that have undergone heat treatment throughout the volume, the letter T is added after the words "pipe"; pipes that have undergone local heat treatment of the weld, the letter L is added.

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the Ministry of Metallurgy of the USSR DEVELOPERS

V. P. Sokurenko, Ph.D. tech. sciences; V. M. Vorona, Ph.D. tech. sciences; P. N. Ivshin, Ph.D. tech. sciences; N. F. Kuzenko, V. F. Ganzina

Longitudinally welded pipes (GOST 10704-91 and 10705-80) can be produced in several different groups with or without additional heat treatment.

1 Longitudinal electric-welded steel pipes - GOST 10705-80

The specified State Standard provides information on the assortment and manufacturing technology of longitudinally welded pipe products that have a diameter of 10 to 530 millimeters. They are produced from low-alloyed materials and for operation as part of a variety of building and other structures, as elements of pipelines and products of various purposes.

Note that GOST 10705-80 "does not obey" pipes used for the production of electric thermal heaters. According to the quality characteristics, the straight-seam steel pipe (GOST 10704-91 and 10705-80) is assigned to one of four groups. Products of group "A" are produced according to State Standard 380 from semi-quiet, calm and boiling steel 1, 2, 3 and 4. Finished products are produced with standardization of mechanical parameters. Products of group "B" are made by:

- according to the State standard 9045 from steel 08Yu;

- according to standard 380 from St1–St4;

- according to standard 19281 from steels with a low level of alloying, in which carbon should be no more than 0.46 percent (thus making pipes with a cross section of more than 114 mm);

- according to State Standard 1050 from St10, 08, 20 and 15 (sp, kp, ps).

Also, products of group "B" (all of which are mandatory normalized according to their chemical composition) are made of steel 22GU, which has the following chemical composition (in percent):

- from 1.2 to 1.4 - manganese;

- from 0.15 to 0.22 - carbon;

- 0.03 - titanium;

- from 0.15 to 0.3 - silicon;

- from 0.02 to 0.05 - aluminum;

- up to 0.02 - phosphorus and calcium;

- up to 0.4 - chromium;

- up to 0.01 - sulfur;

- up to 0.012 - nitrogen.

Pipes of group "C" are already normalized both in terms of chemical composition and mechanical characteristics. At the same time, their production is carried out from steels that are used to manufacture products of group "B". In addition, straight-seam pipe structures can also be of group "D". In this case, they are normalized in terms of hydraulic test pressure.

GOST says that:

- pipes made of steels with a small amount of alloying elements can be produced both without additional heat treatment and with it (for example, with), and the processing is carried out over the entire welded joint or over the volume of the structure);

- also processed at elevated temperatures and products made of steels of carbon composition, but they can also be reduced by hot technology, but products from St1 never undergo heat treatment;

- a plant that produces electric-welded structures has the right to independently choose a specific option for heat treatment, it is allowed to carry it out even in a protective environment, but under a preliminary agreement with the buyer of the finished product.

2 Special requirements for welded pipes with a straight seam in accordance with GOST 10705

Finished tubular products are subject to the following requirements of the State Standard:

- On their surfaces there should be no sunsets, cracks, flaws and captivity. If the pipes are processed at high temperatures, the presence of an oxide film on the products is allowed. In this case, the presence of scale is not allowed.

- In those cases when traces of stripping, small risks, nicks, scale, ripples, dents do not lead the section of the pipe structure and its wall thickness beyond the permissible deviations, they may be present on the products.

- The welding zone must be cleaned, and seam lack of penetration is also welded.

- The edges can be offset relative to the wall thickness (nominal) by no more than 10 percent. For pipes with a cross section of 159 mm or more, the allowable displacement indicator increases to 20 percent.

The mechanical parameters of the base steel for hot-reduced and heat-treated products vary depending on its grade:

- elongation: from 20 (steel 26KhMA, 17G1S, 09G2S, 20F, 13KhFA) to 30 (08Yu) percent;

- yield strength: from 174 (08Yu and 08kp) to 343 (26XMA, 17G1S, etc.) N / mm 2;

- resistance (temporary) to rupture: from 255 to 490 kgf / mm 2.

The mechanical characteristics of low-alloy alloys and 22GU steel may differ from the standard ones upon agreement with consumers.

Other important provisions of the document describing the production process of longitudinally welded pipes include the following requirements:

- one seam in the transverse direction is allowed on products with a cross section of 57 mm or more;

- if heat-treated pipes are repaired by welding, they must be re-treated by seam or by volume using a similar technique;

- be sure to remove the outer burr on the products;

- burrs are removed from the ends of the structures (by stripping), pipes are cut at right angles.

3 Longitudinally welded pipes - GOST 10704-91

This official document establishes the dimensions of tubular products made from steels according to GOST 10705, as well as their maximum deviations from standard values and the assortment of electric-welded pipes. From it you can find out that the finished product is manufactured according to the following parameters:

- diameter (outer): 10–1420 mm;

- length: unmeasured - 2–5 m, depending on the pipe section, measured - 5–12 m; multiple (the multiplicity should not be higher than the lower limit of the measured length and at the same time have a multiplicity of 25 cm or more);

- wall thickness: 1–32 mm;

- mass (theoretical) of one kilogram of finished product: varies from 0.222 kg for a pipe with a wall of 1 mm and a cross section of 10 mm to 779 kg for products with a wall of 32 mm and a cross section of 1020 mm.

It is important to know that in the case when products are manufactured according to State Standard 10706, the weight of pipes is large for all products, which is due to the need to strengthen the weld.

The length (dimensional) deviations of pipe structures can be as follows:

- +5 cm for products of the 2nd class and +1 cm of the 1st class (pipes less than 6 meters long);

- +7 and +1.5 cm for pipes longer than 6 meters.

According to the multiple length, the deviations that the standard allows are +10 cm for products of the 2nd class and +1.5 cm for the 1st, regardless of the length of the structure. Under the pipes of the 1st class, they mean products with deburred and cut ends, the 2nd class - without deburring and trimming.

The manufacturing accuracy of a longitudinally welded pipe according to GOST 10704–91 can be:

- elevated;

- ordinary.

The accuracy of production is taken into account when describing the permissible deviations of finished products from their diameter (outer):

- pipes over 1020 mm: ±6.0 mm (high accuracy) and ±0.6% (normal);

- 426-1020: ±0.65% and ±0.7%;

- 193.7-426: ±0.65% and ±0.75%;

- 51-193.7: ±0.7% and ±0.8%;

- 30–51: ±0.35 mm and ±0.4 mm;

- 10–30: ±0.25 mm and ±0.3 mm.

Pipes with a cross section of less than 10 mm of normal accuracy may have deviations of up to ± 0.2 mm; for high-precision products, deviations are not provided.

The difference in wall thickness and the ovality value of electric-welded products with a cross section of not more than 530 mm is possible no higher than the permitted deviations in wall thickness and outer section, respectively. But the curvature of the pipes cannot be higher than 1.5 mm per meter of their length. For products that are planned to be used in critical structures as constituent elements, the curvature must be even less - up to 1 mm.

INTERSTATE STANDARD

ASSORTMENT

Official edition

Standartinform

UDC 669.14-462.2:621.791:006.354

INTERSTATE

Group B62 STANDARD

ELECTRIC WELDED STEEL PIPES

Assortment

Electrically welded steel line-weld tubes. Range

ISS 23.040.10

OKU 13 7300, 13 8100, 13 8300

Introduction date 01.01.93

1. This standard specifies a range of steel longitudinally welded

2. The dimensions of the pipes must correspond to the table. 1.

3. The length of the pipe is made: random length:

with a diameter of up to 30 mm - at least 2 m; with a diameter of St. 30 to 70 mm - not less than 3 m; with a diameter of St. 70 to 152 mm - not less than 4 m; with a diameter of St. 152 mm - not less than 5 m.

At the request of the consumer, pipes of groups A and B according to GOST 10705 with a diameter of more than 152 mm are manufactured with a length of at least 10 m; pipes of all groups with a diameter of up to 70 mm - at least 4 m long; measured length:

with a diameter of up to 70 mm - from 5 to 9 m;

with a diameter of St. 70 to 219 mm - from 6 to 9 m;

with a diameter of St. 219 to 426 mm - from 10 to 12 m.

Pipes with a diameter of more than 426 mm are made only in random lengths. By agreement between the manufacturer and the consumer, pipes with a diameter of more than 70 to 219 mm are allowed to be manufactured from 6 to 12 m;

multiple length with a multiplicity of at least 250 mm and not exceeding the lower limit established for measured pipes. The allowance for each cut is set at 5 mm (if no other allowance is specified) and is included in each multiplicity.

Official publication Reprint prohibited

© Standards Publishing House, 1991 © Standartinform, 2007

Table 1

|

Outer diameter, mm |

Theoretical mass 1 iv |

with wall thickness, mm | |||||||||

Continuation of the table. 1

|

Outer | ||||||||||

Continuation of the table. 1

|

Outer |

Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||

Continuation of the table. 1

|

Outer |

Theoretical weight of 1 m of pipes, kg, with wall thickness | |||||||||||

|

diameter, mm | ||||||||||||

Continuation of the table. 1

|

Outer |

Theoretical mass |

1 m of pipes, kg, with wall thickness, mm | ||||||||||

|

diameter, mm | ||||||||||||

Continuation of the table. 1

|

Outer |

Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||

Continuation of the table. 1

|

Outer |

Theoretical weight of 1 m of pipes, kg, |

with wall thickness, mm | |||||||||

|

diameter, mm | |||||||||||

Continuation of the table. 1

|

Outer |

Theoretical weight of 1 m of pipes, kg, with wall thickness, mm |

|||||||||||

|

diameter, mm | ||||||||||||

Notes:

1. In the manufacture of pipes in accordance with GOST 10706, the theoretical mass increases by 1% due to the strengthening of the seam.

2. By agreement between the manufacturer and the consumer, pipes are manufactured with dimensions of 41.5x1.5-3.0; 43x1.0; 1.5-3.0; 43.5x1.5-3.0; 52x2.5; 69.6x1.8; 111.8x2.3; 146.1x5.3; 6.5; 7.0; 7.7; 8.5; 9.5; 10.7; 152.4x1.9; 2.65; 168x2.65; 177.3x1.9; 198x2.8; 203x2.65; 299x4.0; 530x7.5; 720x7.5; 820x8.5; 1020x9.5; 15.5; 1220x13.5; 14.6; 15.2 mm, as well as with an intermediate wall thickness and diameters within the table. 1.

3. Pipe dimensions enclosed in brackets are not recommended for new design.

3.1. Pipes of measured and multiple lengths are manufactured in two accuracy classes along the length;

I - with cutting ends and deburring;

II - without chamfering and deburring (with cutting in the mill line).

3.2. Limit deviations along the length of measuring pipes are given in table. 2.

table 2

3.3. Limit deviations along the total length of multiple pipes should not exceed;

15 mm - for pipes of the I class of accuracy;

100 mm - for pipes of accuracy class II.

3.4. At the request of the consumer, pipes of measured and multiple lengths of accuracy class II must be with chamfered ends on one or both sides.

4. Limit deviations for the outer diameter of the pipe are given in table. 3.

Table 3

Note. For diameters controlled by perimeter measurement, the largest and smallest perimeter limits are rounded to the nearest 1 mm.

5. At the request of the consumer, pipes according to GOST 10705 are manufactured with a one-sided or offset tolerance on the outer diameter. One-sided or shifted tolerance should not exceed the sum of the maximum deviations given in table. 3.

6. Limit deviations in wall thickness must correspond to:

±10% - with pipe diameter up to 152 mm;

GOST 19903 - with a pipe diameter of more than 152 mm for a maximum sheet width of normal accuracy.

By agreement between the consumer and the manufacturer, it is allowed to manufacture pipes with one-sided tolerance for wall thickness, while one-sided tolerance should not exceed the sum of maximum deviations for wall thickness.

7. For pipes with a diameter of more than 76 mm, a wall thickening at the burr by 0.15 mm is allowed.

8. Pipes for pipelines with a diameter of 478 mm or more, manufactured in accordance with GOST 10706, are supplied with maximum deviations in the outer diameter of the ends given in Table. 4.

Table 4

9. The ovality and evenness of pipes with a diameter of up to 530 mm inclusive, manufactured in accordance with GOST 10705, should not exceed the maximum deviations, respectively, in terms of the outer diameter and wall thickness.

Pipes with a diameter of 478 mm or more, manufactured in accordance with GOST 10706, must be of three accuracy classes in terms of ovality. The ovality of the pipe ends must not exceed:

1% of the outer diameter of pipes for the 1st accuracy class;

1.5% of the outer diameter of the pipes for the 2nd accuracy class;

2% of the outer diameter of the pipes for the 3rd accuracy class.

The ovality of the ends of pipes with a wall thickness of less than 0.01 of the outer diameter is established by agreement between the manufacturer and the consumer.

10. The curvature of pipes manufactured in accordance with GOST 10705 should not exceed 1.5 mm per 1 m of length. At the request of the consumer, the curvature of pipes with a diameter of up to 152 mm should be no more than 1 mm per 1 m of length.

The total curvature of pipes manufactured in accordance with GOST 10706 should not exceed 0.2% of the pipe length. The curvature per 1 m of the length of such pipes is not determined.

11. Technical requirements must comply with GOST 10705 and GOST 10706.

Legend Examples

A pipe with an outer diameter of 76 mm, a wall thickness of 3 mm, a measured length, an accuracy class II in length, made of StZsp grade steel, manufactured according to GOST 10705-80 group B:

76x3x5000 II GOST 10704-91 V-StZsp GOST 10705-80

The same, increased accuracy in outer diameter, length, multiple of 2000 mm, accuracy class I in length, from steel grade 20, manufactured according to group B GOST 10705-80:

t ba 76pkhZh2000 kr. I GOST 10704-91 B-20 GOST 10705-80

A pipe with an outer diameter of 25 mm, a wall thickness of 2 mm, a length that is a multiple of 2000 mm, an accuracy class II in length, manufactured according to group D GOST 10705-80:

25x2x2000 cr. II GOST 10704-91 D GOST 10705-80

A pipe with an outer diameter of 1020 mm, increased manufacturing accuracy, a wall thickness of 12 mm, increased accuracy in the outer diameter of the ends, 2nd class accuracy in ovality, random length, made of StZsp grade steel, manufactured according to GOST 10706-76 group B:

„ - 1020pkh12-PT-02kl GOST 10704-91

Pipe -

V-StZsp TOST 10706-76

Note. In the symbols of pipes that have undergone heat treatment throughout the volume, the letter T is added after the words "pipe"; pipes that have undergone local heat treatment of the weld, the letter L is added.

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the Ministry of Metallurgy of the USSR DEVELOPERS

V.P. Sokurenko, Ph.D. tech. sciences; V.M. Crow, Ph.D. tech. sciences; P.N. Ivshin, Ph.D. tech. sciences; N. F. Kuzenko, V. F. Ganzina

2. APPROVED AND INTRODUCED BY Decree of the Committee for Standardization and Metrology of the USSR dated 11/15/91 No. 1743

3. REPLACE GOST 10704-76

4. REFERENCE REGULATIONS AND TECHNICAL DOCUMENTS

5. REPUBLICATION. February 2007

Editor L.I. Nakhimova Technical editor L.A. Guseva Proofreader A. S. Chernousova Computer layout V.I. Grishchenko

Signed for publication on 14.03.2007. Format 60x84 "D. Offset paper. Headset Times. Offset printing. Conditions for printing l. 0.93.

Uch.-ed.l. 0.90. Circulation 53 copies. Zach. 210. From 3790.

FSUE "Standartinform", 123995 Moscow, Granatny per., 4. Typed in FSUE "Standartinform" on a PC.

Printed in the branch of the Federal State Unitary Enterprise "Standartinform" - type. "Moscow printer", 105062 Moscow, Lyalin per., 6.