By choosing a house project with a basement, you acquire significant additional space.

And, of course, it would be unreasonable to use basements only for technical needs and storing all sorts of belongings. And in order to fully use the rooms in the basement as residential ones, it is necessary to install windows in them.

Both for sunlight and natural ventilation premises. In clear sunny weather, a pair of windows is quite sufficient to provide a normal level of natural light in a medium-sized basement.

And psychologically it is much more comfortable to spend time in a room with windows than in a “concrete cube”, even if well lit by electricity.

Ground floor. Features of window installation - photo gallery

The process of both selecting and installing windows for the basement has some peculiarities.

And it is somewhat different from that for ordinary windows.

The main difficulty is that basement windows are often located either below ground level or at an elevation of ten to twenty centimeters. This means that the windows will bear additional loads, in particular, they will be exposed to excessive humidity.

But, having paid attention to the problem of choice and correct installation enough attention, you will definitely “win this fight.”

Windows in the basement. Which material is preferable

For installation in the basement, you should only choose windows made from modern materials and the latest technologies.

This way you are guaranteed to save your money and time.

Yes, and nerves, since replacing new windows that quickly become unusable, of course, will not make you happy.

Which windows are better to choose? What material?

Plastic windows for the basement

Modern windows made of PVC profiles have a light opening ten to fifteen percent larger than windows of the same size made from other materials. And for a basement, fifteen percent is a very significant plus.

At the same time plastic window will not lose its qualities: neither thermal insulation, nor soundproofing qualities, nor structural strength will be affected.

If the base in your house is high enough, then installation metal-plastic windows will be very profitable in financially. Since if the windows are located above ground level or half recessed, then you will not be able to spend money on ordering special designs, but simply buy ordinary budget windows.

The only condition for selection is that the window must have opening sashes (at least one) and with sufficient good level sound and thermal insulation.

Also take care high-quality waterproofing places of contact of the frame with the walls of the basement. It is best to use polyurethane foam for this purpose. Although it is expensive, it is effective and reliable.

Aluminum windows for basement

Windows made of aluminum profiles are appropriate to use for basements only if you do not plan to equip the basement for housing.

Since such a window is not capable of sufficiently thermally insulating a room, even if we are talking about the so-called “warm” aluminum profile.

If you plan to use the basement as a technical room, for example, for a boiler room or storage rooms, then aluminum profile will suit you just fine. For unheated premises its protective qualities are quite sufficient.

And since aluminum windows cheaper than plastic ones, their installation in technical rooms is completely justified.

Quantity color variations aluminum structures are very extensive and you can always choose the option that suits your interior.

Wooden windows for basement

Wooden windows in basements and semi-basements are installed quite rarely.

Since simple wooden windows made using old technology will not withstand operation in basement conditions for a long time. High humidity and the lack of sun and the “drying” effect of the wind will quickly render such frames completely unusable.

And modern wooden windows, produced using innovative technologies from high-quality wood using various impregnations and varnishes, although durable and “hardy,” are much more expensive than the most expensive and high-quality metal-plastic. This makes their use for basements not entirely financially justifiable.

But, if you still opt for modern wooden windows, you definitely won’t regret it.

No material other than wood will give you such a cozy and “solid” atmosphere. And if your house is built of timber with finishing from natural stone, then the combination with wooden frames it will be just perfect.

Ground floor. Features of window installation

There are several ways to provide high-quality natural lighting in basements and semi-basements.

First of all, this is, of course, the installation of windows.

But it is also possible to use light lanterns and light pits.

The option is selected depending on the design and height of the base and your personal preferences. It is also possible to combine several types of basement glazing.

If the base of your house is high, then the best option would be to install regular windows. As they say, “cheap and cheerful.”

But if the windows are half or completely recessed, then there are three possible options:

Window installation

To be able to install regular window, you will need to dig a pit.

It is usually finished with concrete or brick. The pit can have either a rectangular or semicircular shape and its size should be slightly larger size windows.

Sometimes pits are covered with bars, this option has a double benefit - it will protect children or pets from falling into the pit from intruders and will protect them from falling into the pit.

The bottom of the pit should be deepened approximately fifteen to twenty centimeters below the level of the window sill and must be equipped with a drain grate. Otherwise, after rain or spring floods, you will get an “aquarium” instead of a window.

Water must be drained into the system storm sewer or at least use perforated drainage pipe, deepening it a meter into the ground and covering it with crushed stone around it. This way you will get an absorption well that evenly distributes water throughout the soil.

Installation of skylights

Tunnel lights are corrugated pipe, covered on the inside with reflective material and closed on top with a transparent dome.

One end of the lantern is inserted into the opening made in the wall, the second is brought out to the surface of the pit. To install the lantern, the pit must be closed at the top.

Lanterns let in less light than windows, but are also cheaper.

The amount of light depends on the diameter of the lantern, which can have a diameter from twenty-five to fifty-five centimeters, and on the orientation of the dome relative to the cardinal points. Also make sure that the lantern is not covered by anything, such as a bush, flower bed or tree.

One light lantern with a diameter of twenty-five centimeters will effectively illuminate no more than four square meters rooms with a diameter of thirty-five centimeters - up to six meters, and fifty-five - “cope” with a room up to twenty-five square meters.

Some models of tunnel lights can be equipped with a frame with a lamp. At night, such a lantern will turn into a type of lamp - a sconce.

What are light pits?

Currently, light pits are universal systems that are used not only to ensure the proper level of lighting in basements, but also for rain and melt water. As a rule, such devices are mostly used in private homes. Light pits characterized by high strength and stability of various types mechanical stress That is why they can be used for a long period of time and do not require repair or restoration work. Thanks to their design, these devices evenly distribute the load over their entire surface and therefore the likelihood of damage even with strong impact is reduced to almost zero. This device can be used in conditions of excessive humidity due to its complete sealing and water resistance. Using extensions, you can adjust the height of the pit at your own discretion.

Light pits for basement windows can be used to collect rain and melt water; even in the event of heavy rainfall, the basement will remain dry and the most favorable humidity level will be maintained. Today the body of this device is made of various options material. White propylene can be used, which is reinforced with fiberglass to provide greater strength. Sawed ordinary and fiberglass reinforced polyester. In many ways, these devices are adapted to the load of pedestrians and vehicles. It should be noted that they are made of galvanized steel with a special anti-vandal mechanism. As a result, they are not afraid of the effects of corrosive processes and mechanical damage.

The standard set of a light pit includes: a housing, a mesh grille, and installation kit, presented in four modifications. For pedestrian movements, for hitting vehicle, for hermetic installation, for installation on thermal insulation. Today, such devices are quite easy to buy and, if you wish and have free time, you can install them yourself without using outside help. These practical and universal devices do not require special knowledge and skills for their use.

Description

More light in the basement The steady increase in prices for land, construction and materials dictates a more rational use of usable space in a country house. This especially applies to basements. Their purpose can be very different - from rooms for engineering equipment to offices and gyms.

Light-transmitting pits ACO Markant® (AKO Markant) are durable and lightweight design, bringing daylight into the basement windows for multifunctional use of basement spaces.

Due to the strength of the material, the optimal location of the fastening bolts and sealing, the pit is suitable for high groundwater Oh. Pits are made with an outlet. Water is discharged from the pit through the outlet into the general sewer system.

Getting into the pit, rainwater flows down its smooth walls to the outlet at the lowest point and is discharged through a siphon into the sewer or wall drainage.

Types of gratings

All pits are equipped with metal gratings for pedestrian or vehicle loads. Thanks to optimal placement dowels for fastening the pit to the basement wall, the impact load is evenly distributed along the perimeter of the structure.

| Grid mesh | Lattice square | Lattice rectangle | ||

|

|

|

Pallet type

Advantages

Technical dimensions

|

|

|

| Pit dimensions (b x h x t) | Height h cm | Depth t cm | Width b cm | b1 cm | b2 cm | t1 cm | f cm |

| 80 x 60 x 40 | 66,6 | 42,9 | 97 | 87 | 87 | 40 | 93 |

| 100 x 60 x 40 | 66,6 | 42,9 | 117 | 106 | 106 | 40 | 113 |

| 100 x 100 x 40 | 107,3 | 42,9 | 117 | 106 | 106 | 40 | 113 |

| 100 x 130 x 40 | 137,3 | 42,9 | 117 | 106 | 101 | 40 | 113 |

| 125 x 130 x 60 | 135 | 62,5 | 142,5 | 132 | 132 | 60 | 138 |

Almost any country house, or just country house can't do without a cellar. Very often it is installed in the basement, and low built-in windows (at ground level) are used to provide it with natural light. And in city buildings such windows are not uncommon. As a rule, a special light or protective pit is installed nearby. This design allows you to protect windows from dirt and moisture, and also allows you to make the most of daylight hours. Manufacturing standards and sizes of pits may vary, depending on the type of building and the size of the basement windows.

Let's take a closer look at their purpose, types and main stages of their installation.

Purpose and characteristics

The main purpose of this element is to restrict access to that part of the walls of the building where the basement windows. The pit device protects the windows themselves and the basement as a whole. This structure will not allow snow, melt water, garbage and animals to enter the basement, and the windows will last much longer thanks to this protection.

The grille protects the windows from mechanical damage and practically does not prevent light from entering.

An important purpose of a basement window is access daylight into the room. Light pits must be designed in such a way that maximum quantity sun rays got into the basement through the windows. The presence of windows in the basement or cellar allows you to reduce energy costs for lighting, as it makes it possible to use natural daylight.

If the basement is well-equipped, daylighting greatly increases the comfort of people staying inside for a long time. Thus, the light pit is not just a protective structure, but an important functional element.

And if you apply maximum imagination, you can make a spectacular one out of this design. decorative element facade of your house.

The dimensions of the pits are calculated depending on the size of the windows themselves and how deep into the ground they are planted. As a rule, the length of the pit (the part that runs parallel to the wall) should be one and a half times the width of the window. And the second side ( perpendicular to the wall) should not protrude more than 1 m. The best option– 70–80 cm. The depth of the pit is determined based on the location of the lower edge window frame: its bottom should be approximately 20 cm below the window. It is also advisable to plan a slight slope of the well bottom (about 3–5 degrees).

The shape of this structure can be very different: semicircle, trapezoid, square. But still, the rectangular shape is the most convenient and practical.

There are also special SNiPs - these are building codes and the rules that designs must comply with. When designing, be sure to check what these standards are for your building.

How to organize a drainage system

To prevent dampness in the basement, the pits should be equipped with a drainage system, which will allow water to be drained away from the building. Additional waterproofing of the well walls and connecting seam may also be required.

Scheme of pit arrangement with drainage system.

If the building is located on a waterproof pad, you can get by with a simple drainage system. To do this, you will need to leave a pipe with a diameter of 6–8 cm and a length of about 1 meter under the bottom of the pit. The hole in the pipe that goes into the basement pit should be closed with a special drainage grate. To drain water more efficiently, the floor must be laid with a slight slope away from the building (towards the drain hole). The bottom of the well should be covered with a layer of gravel about 3–4 cm deep. simple procedure will prevent the earth from falling off and debris will not clog the pipe.

In cases where the groundwater level is close to the surface, a more serious drainage system will be required. It is best to organize circular drainage around the entire perimeter of the building (at a distance of about 50 cm from the foundation). And from the pits, drain water into the general waste system.

Additionally, waterproofing of walls and expansion joint between the pit well and the building. Well walls can be treated bitumen mastic. The seam is sealed with geotextile or roofing felt. Waterproofing in combination with a drainage system will reliably protect the building from moisture ingress from the wells of the basement windows.

Installation of ready-made structures

Modern construction companies they offer quite a lot today wide choice ready-made structures for arranging pits. By purchasing such a product, you can easily equip pits in the basement: the only thing you will have to work on is digging a pit to fit the dimensions of the purchased structure.

Installation of the finished structure.

Today, finished pits are made from different materials. It can be galvanized steel, propylene, plastic or polyester. The latter option, reinforced with fiberglass, has such strength that structures made from it can easily support not only the weight of an adult, but even a car. Therefore, such designs are the most popular.

Replacing old elements with new ones.

Metal, in particular steel structures, also have their advantages. Thanks to the galvanized surface, they are not exposed to moisture. In addition, most are equipped with anti-vandal devices. This option is perfect for country houses, in which there are no permanently residing owners. Iron bars for pits will protect not only windows from mechanical damage, but also the home itself from thieves.

Typically, ready-made pits on the market include the following required elements:

- Well body.

- Grills on the windows.

- Set of fastening devices.

The design and manufacture of pits involves certain technological subtleties, but installing ready-made pits is not difficult. Any man (familiar with construction) can cope with this work without the involvement of specialists.

First, you should study in detail the installation instructions for the product. It probably contains all the dimensions of the product that you need to know in order to dig pits for pits. Don't forget about the water drainage system, which has already been mentioned.

The well body is installed in the finished pit, all communications are connected (drainage, discharge, grate on the drain pipe). After all the above work, all that remains is to install a fence or grate for the pit, and the structure is ready. All structural elements are attached to each other and to the wall with special dowels, which are included in the product package.

The finished pit is also good because it does not need additional insulation. The only drawback of ready-made structures is their price. This pleasure is not cheap. Therefore, if you are not ready for high costs, you can try to make a pit with your own hands.

Arranging a pit with your own hands

When performing such a construction yourself, you can choose one of the following options:

The well is rectangular in shape.

- Monolithic well (cast from concrete).

- Only the bottom of the pit is filled with concrete, and the walls are lined with bricks or blocks.

In both cases better than walls shape into a rectangle. The thickness of the walls should be about 15 cm. It is desirable that the upper edge of the pit rises 25–35 cm above the ground. Sometimes pits in basements are made level with the ground, but in this case its functional qualities will be lower. The well should not be too deep. Its bottom should be approximately 15–20 cm below the window frame.

Let's take a closer look at the design features of each option.

Monolithic well

The well is semicircular in shape.

For such a pit you will need following materials and tools:

- cement;

- gravel;

- boards and wedges (for formwork);

- iron fittings;

- shovel;

- concrete mixer (or large container for diluting the solution);

- roofing felt or geotextiles;

- lath (for compacting the solution);

- container with water.

First of all, you need to dig a pit, determining its dimensions in advance. Then formwork is installed from boards and pegs for concrete walls. If you are planning to construct a pit of any shaped shape (for example, a semicircle), then you can use fiberboard or pieces of old PVC panels for formwork. Reinforcement is used to strengthen the future pit. You can use steel rods or a grate as it. Although this procedure is not mandatory.

Remember that the walls are formed first, and only then the bottom of the pit is filled.

The seam between the wall of the house and the walls of the pit is filled with geotextiles. You can replace it with a couple of layers of roofing felt. Waterproofing will help protect the basement from excess moisture.

When the formwork is ready, you can take on the mortar. Use high-quality cement so that the pit does not have to be redone in a couple of years. If you have a concrete mixer, the work will be greatly simplified and time-saving. When pouring the solution into the formwork, do not forget to tamp it periodically with a lath so that there are no voids left in the walls. After the concrete has completely dried, its surface should be treated with bitumen mastic. This is good waterproofing.

If the basement is heated, you should consider insulating the pit, because heat will be lost through it.

It is better to buy a ready-made window grille or weld it yourself from pieces of reinforcement. The canopy over the pit can be made from a profiled sheet or a piece of cellular polycarbonate.

Brick or block construction

The walls can be made of brick, stone or blocks.

For this option, you will need all the tools and materials from the previous paragraph, with the exception of formwork boards, and you will also need less cement and gravel. But you will have to fork out for bricks or foam blocks.

The work also begins with a foundation pit, the walls of which are lined with the selected material. The rest of the pit structure does not differ from the previous version.

The second option is more labor-intensive, since not every person has the ability to lay bricks and blocks. In addition, this option will cost you more.

Decorative finishing of the pit

If you want your structure to not only protect the basement windows, but also decorate the facade of the house, you can think about its decorative finishing.

wonderful and functional material for this it is considered ceramic tiles or artificial stone. Some craftsmen line the walls of the pit with wild stone, which also looks very original. More simple options: cover the walls with clapboard or simply paint.

If the basement windows face a street with heavy pedestrian traffic, it is better to provide a fence for the pit. A good option will metal grill. Steel structures will reliably protect windows from debris, dirt and vandals.

Design option.

If one of the purposes of the pit is, then it is better that its walls are light colors. As you know, light surfaces reflect light better, therefore, more sunlight will penetrate into the basement. Light pits significantly increase the comfort of being in basements. In addition, by equipping windows with such structures, you can make the most of natural daylight, significantly reducing energy costs for lighting.

When choosing fences and bars for windows, do not forget that you will need to periodically clean the pits from debris and snow. Therefore, these elements must be removable.

By arranging a light (aka protective) pit according to all the rules, you can not only improve the lighting of the interior of the room, but also protect your windows and the basement as a whole.

In addition to underground, buildings can have ground, basement and underground floors.

Tsokolny- floor when the floor mark is placed below the planning mark of the ground to a height of no more than half the height of the premises.

Basement– floor when the floor level of the premises is below the planning level of the ground by more than half the height of the premises.

Underground- a floor with the floor level of the room below the planning ground level for the entire height of the room.

Elements of the arrangement of the underground part of the building are entrances to the basement, pits, and blind areas.

Entrances to the basement are usually arranged in the form of single-flight stairs open to the outside, located in special pits adjacent to external wall building and enclosed by a retaining wall.

To protect against atmospheric precipitation such a pit is covered with a roof (sometimes translucent).

The entrance walls are made of 250 mm thick brick, slag concrete stones (190 mm), monolithic reinforced concrete (200 mm), prefabricated reinforced concrete blocks (300 mm).

IN multi-storey buildings The entrance to the basement is usually made from a staircase inside the building, and in manor residential buildings, most often from the first floor under the flight of interfloor stairs. In this case, it is advisable to isolate the entrance from the first floor by installing a fence on all sides and a door on the first floor.

Slope external staircase, as a rule, 1:2 (150x300 mm), internal 35-45°, width - at least 900 mm.

Blind areas. One of the ways to isolate the underground part of buildings from surface water is to install a blind area made of asphalt, asphalt concrete, cobblestone, flat stones, concrete, and figured paving elements (FEM) around the building outside.

The width of the blind area depends on the type of soil and the amount of eaves overhang (200 mm more than the eaves overhang) and is accepted as 600-1000 mm. The transverse slope (from the building) is 5-10% for crushed stone and cobblestone blind areas and 3-5% for asphalt concrete and concrete ones.

The base material is selected to ensure the waterproofness of the blind area as a whole. Sand is mainly used with a bedding layer of fatty clay or concrete.

Light pits. To illuminate and ventilate basements and basements, windows are installed in the outer walls below ground level, and in front of the windows there are wells called pits.

The walls of the pits are made of brick, concrete with waterproofing on the outer surface and must be at least 150 mm above the ground level. The bottom of the pit is made of concrete with a slope of 1.5% from the building.

It is advisable to cover the pit from above with a decorative metal grille with a translucent coating (for example, made of a polycarbonate sheet).

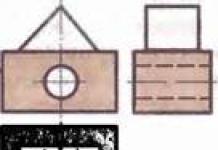

Rice. 6.18. Light pit plan

Swimming pools can be designed in almost any shape and size. The pool bowl is made of monolithic reinforced concrete. After pouring the concrete, the inner surfaces of the bowl are leveled with plaster mixtures, and after the plaster layer has dried, a PVC “liner” film is installed, which is both waterproofing and lining of the pool.

The set of equipment for sewerless swimming pools includes:

Non-sewage filter unit;

Electric heater or heat exchanger;

Hydromassage;

Accessories for pool care;

A set of pool water care products.