A sheet of foam plastic 5 cm thick, which brickwork does it replace? What about 8 cm?

- I read the answers and go nuts. What kind of tusk do you need to be in order to compare them when answering the question on the equivalence of brick and foam bearing capacity... Of course, they compare thermal conductivity ...

- 5 cm of foam plastic is half a meter of brick !!! And don't listen to the reindeer herders!

- And brick and foam are different.

Formally, the thermal conductivity of red brick is 10 times greater than that of highly porous foam. (0.56 and 0.05 W / m * deg - respectively)

That is, boldly multiply the thickness of the foam by 11 and get the thickness of the brick wall.

- Hello the best one! 😉

You forgot to mention the conditions (parameters) of the assessment ...

1) If you mean thermal conductivity?. .

The engineer answered you.2) If we are talking about mechanical strength?. .

Styrofoam brick is NOT a replacement. Especially in seismic regions.3) Durability?

Brick will last longer.4) Resistance to environmental influences (changes in temperature, humidity, etc.) ?

Styrofoam, in this case, not even a building material... .5) Safety (physiological, chemical, ecological)?..

Again, the comparison will be in favor of baked clay (brick) ...And generally speaking.. . That's not what they teach you... ;-(

Styrofoam is NOT available a good choice material for construction or decoration.

And in this ODIN is absolutely right...Good luck to you! 😉

- no

- Extruded polystyrene foam Extraplex with a thickness of 20 mm in terms of its heat and sound insulating properties is equivalent to brick wall 370 mm thick

On the modern market building materials presented the widest selection various heaters, the use of each of them is due to certain requirements, depending on the purpose of the building, operating conditions and climate in the region. Most of the requirements for heaters correspond to polystyrene, which firmly occupies one of the leading positions in the market of our country.

Material Advantages

Styrofoam or expanded polystyrene is an array of gas-filled polystyrene granules soldered together, pre-foamed and molded by a non-press method. The material is made of different density, it depends on the size and number of granules in 1 m³. If the granules are large, their number per unit volume will be less, and the density of the material will be lower and vice versa, a large number of small granules attached to it high density and reduces thermal conductivity. Polyfoam has a number of advantages, which makes this insulation so popular:

- Excellent thermal insulation performance is one of the highest. Only polyurethane foam has higher thermal insulation properties, but its cost is much higher.

- Not big weight simplifies the delivery and installation process.

- Expanded polystyrene practically does not absorb moisture.

- Modern polystyrene is environmentally friendly.

- It does not support combustion, when exposed to high temperatures, the material simply collapses without ignition.

- Expanded polystyrene products have strength and rigidity.

- The material is one of the most affordable.

Of the shortcomings of this insulation, two significant ones can be distinguished: it cannot be used with high fire-fighting requirements for a building or room, since it will collapse in a fire. The second disadvantage is that mice gnaw on polystyrene foam. They do this in order to equip themselves with a warm nest, and not for the sake of food, which once again proves the environmental friendliness of the material, in basalt wool Mice don't make nests.

Back to index

Properties and parameters of insulation

Thermal conductivity is the transfer of thermal energy from one part of the material, which has a higher temperature, to another part, which has a lower temperature. That is, in simple words is the ability of a material to conduct thermal energy. This parameter is expressed in units of W / (m * K) and is called the heat transfer coefficient.

The decoding of the heat transfer unit is as follows: this is the amount of thermal energy in W that a material 1 m thick can transfer over an area of 1 m² at a temperature difference of 1 ° (Kelvin) for a certain unit of time. The heat transfer coefficient decreases as the density of the material increases, that is, the higher the density, the better its thermal insulation properties. Characteristic values at different densities are presented in Table 1.

Table 1

The value of thermal conductivity is the key to calculating the total resistance to heat transfer of building envelopes (walls, roofs, floors). The latter is denoted by the Latin letter R, the unit is expressed in m² K / W and shows how much heat in W passes through 1 m² of wall or roof area of a given thickness per unit time with a temperature difference of 1 ° K. This parameter depends on the material of the wall and its thickness, this can be seen from the formula:

Here δ is the wall thickness in meters, k is the thermal conductivity coefficient. For example, you can show how much heat is lost by 1 m² of polystyrene foam 1 centimeter thick with a density of 10 kg / m³ per unit of time at a temperature difference of 1 ° K:

R = 0.01 / 0.044 = 0.227 m² K / W.

This parameter is normalized, it cannot be less than that, which is written in normative documentation for each region. Given the difference climatic conditions in the vastness of our country and the duration heating season, the minimum normalized resistance to heat transfer of external walls for the southern regions is 1.8 m² K / W, middle lane- 3 m² K / W, and the northern ones - 4.8 m² K / W. The R values for different foam densities and different thicknesses are shown in Table 2.

table 2

Table 2 clearly shows that 100 mm thick foam can completely replace others. Construction Materials walls in the southern and middle regions, since this design corresponds modern requirements regulatory documentation (SNiP 23-02-2003). 5cm and 2cm thick material can be used for additional insulation existing buildings from brick or concrete, as the enclosing structures of these buildings do not meet modern energy saving requirements. At the same time, it is often advisable to use a 2 cm thick insulation for finishing walls from the inside of the room, it is cheaper than doing outdoor work, and does not take up much space from the room space.

Styrofoam (expanded polystyrene) and mineral wool are the most popular today thermal insulation materials. Each of them has its advantages and disadvantages, and has its own scope. Foam boards are recommended for use for external thermal insulation walls, mineral wool - for roof insulation and as a heat insulator during installation hinged facades. However, there is an opinion that these materials are interchangeable. Is it so? Let's try to figure it out.

Polyfoam: pros, cons and application features

Styrofoam - foamed plastic material - has an extremely low coefficient of thermal conductivity. It is the best thermal insulator on the planet. It is estimated that foam board 10 cm thick in terms of heat-shielding properties replaces 40 cm of wood, 60 cm of aerated concrete, 90 cm of expanded clay concrete, 150 cm of hollow brick, 400 cm of reinforced concrete.

Foam plastic also wins in comparison with mineral wool: 10 cm of foam plastic is equivalent in terms of thermal protection to 16 cm of mineral wool.

But polystyrene foam cannot protect from noise. It has no sound insulator.

As for vapor permeability, this characteristic varies depending on the density of the material. Low-density foam is close to cotton wool in terms of vapor permeability, high-density foam, although with difficulty, passes steam, so it can be used to insulate only very dense walls.

There is no consensus regarding the environmental friendliness of expanded polystyrene. The debate over the toxicity of polystyrene has been going on for decades. Even Soviet scientists proved that under certain conditions this material is capable of releasing toxic styrene into environment. However, the results of modern laboratory studies suggest that high-quality polystyrene foam is absolutely harmless. The meager amount of styrene that it emits does not have any effect on the human body.

Tip: before buying, be sure to check the content of residual styrene - the value of this indicator should be in the range of 0.01-0.05%.

The quality of the foam depends on its service life. The most durable are non-press grades PSB and PSB-S. They do not change their properties for 10-40 years. Extrusion lasts even longer - up to 80 years.

The most a big problem expanded polystyrene - high flammability. Styrofoam can catch fire from a single spark. When exposed to fire, it melts and emits black toxic smoke. To solve this problem, special additives began to be introduced into foam plastics - non-combustible and extinguishing the flame. So a new type of expanded polystyrene appeared - self-extinguishing brand PSB-S. This material cannot be ignited by a spark, but it has no fire protection.

Important: all types polystyrene foams must only be used for external insulation.

Minvata: main properties, advantages and disadvantages

Mineral (“stone”) wool is a fibrous material obtained by melting igneous rocks. The advantages of mineral wool are predetermined by the properties of the feedstock.

The undoubted advantage of this mineral insulation is fire resistance. The melting point of mineral wool is 800C. It not only retains all its properties in case of fire, but also prevents the spread of fire.

Mineral wool takes the second place in terms of heat-insulating properties after polystyrene, but at the same time it has a high hygroscopicity - in a humid environment, its heat-shielding properties deteriorate significantly. But unlike polystyrene, mineral wool does not prevent the passage of steam - the condensate that falls freely passes through its fibrous structure and evaporates from the surface.

Another advantage of mineral insulation is excellent soundproofing properties. Wool made of stone creates a reliable barrier to the passage of sound waves.

One of the main disadvantages of this material is a lot of weight. When calculating the cost of insulation, the cost of loading / unloading and delivery to the construction site should be taken into account. In addition, mineral slabs require more powerful supports, while foam plastic adds almost no weight to building structures.

Relatively environmental safety: there is evidence that one of the fractions of the fibers that form mineral wool has carcinogenic properties, and the binder material used in its production emits a highly toxic and extremely harmful substance for humans - formaldehyde. Like styrofoam, mineral insulation recommended for arranging external insulation.

Which is better: polystyrene or mineral wool?

Let's compare these two materials according to the main indicators:

- Thermal insulating properties. In terms of thermal conductivity, foam plastic has no equal. Minvata also loses to him.

- Fire safety. Mineral wool is highly resistant to fire, which cannot be said about polystyrene foam.

- Vapor permeability. Minvata surpasses polyfoam in vapor permeability by about 10 times.

- Hygroscopicity. Polyfoam can be used in a humid environment without loss of consumer properties. Stone wool is critical to moisture.

- Price. Styrofoam wins here - this is the cheapest building material.

- Weight and ease of installation. Styrofoam weighs much less than mineral wool. It is more convenient to handle, but more difficult to dock.

- Environmental Safety. Both materials are not recommended for interior work.

- Biological and chemical resistance. Minvata is resistant to all organic matter and fungi. Expanded polystyrene is critical to the effects of organic solvents, but is not susceptible to

As you can see, the choice of insulation is a complex and multifaceted task. When deciding, one should take into account specific conditions and your own priorities. Give preference to proven insulation systems. Don't forget to select optimal thickness thermal insulation.

Recently insulated the balcony, if you're interested.

Of the modern heat insulators, penoplex is considered the most effective. This insulation material is made from extruded polystyrene, which automatically makes it cheap, but superior in technical specifications, such as, moisture absorption and sound insulation, other heat insulators.

Penoplex production and varieties of material

Penoplex production is organized according to the following technology: small polystyrene granules in a sealed chamber are exposed to high temperature(130 0 C-140 0 C), as a result of which they melt, and after adding porophores they foam. Porophores are synthetic additives that, when heated, release nitrogen and carbon dioxide, which, after cooling the foam, turn into frozen air bubbles, evenly distributed throughout the material.

Components of porophores for the production of extruded polystyrene foam (foam plex):

The frozen foam may contain some synthetic fillers, the presence of which determines the direction of the use of insulation - for walls, foundations, etc. The most common additives are flame retardants to increase fire safety (reduce the degree of flammability), antioxidants to protect the material from oxidation on outdoors, antistatic substances to relieve static and dynamic stress during the operation of the heater, light stabilizers (protection against negative impact UV radiation), modifying additives, etc.

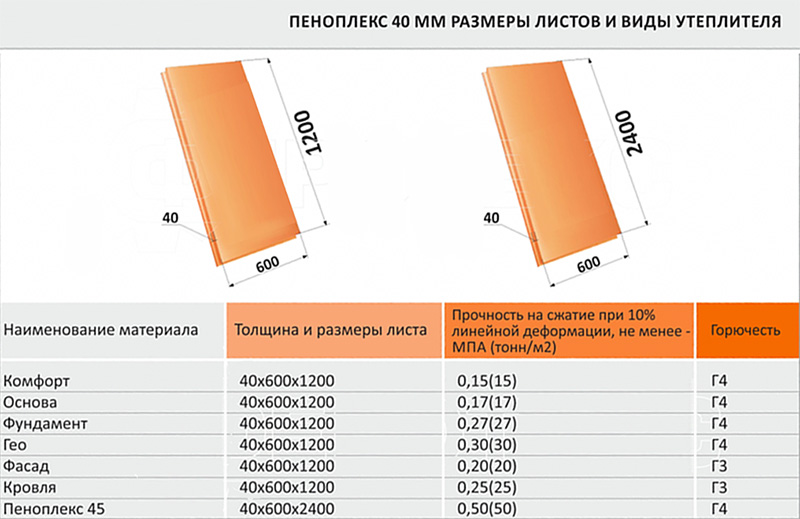

Polystyrene foam under pressure is extruded from the extruder chamber onto a conveyor for final formation into slabs or blocks. The percentage of gases in the insulation reaches 98% of the total volume of the finished foam, so the products are light in weight with impressive dimensions. Dimensions for each functional line of insulation are shown in the tables below.

Small size pores (0.1-0.3 mm) and their complete isolation from each other guarantees high thermal insulation performance of any grades of foam. For different construction objects, it is necessary to select the appropriate series and brands of insulation, since structures can be operated in different conditions:

- Brand "K" is designed for insulation of pitched or flat roofs and roofs. Specific gravity(density) series "K" - 28-33 kg / m 3;

- Series "C" - insulation for internal and external walls with a substance density of 25-35 kg / m 3;

- Brand "F", basement and basement. Material with high moisture resistance, biological stability and specific gravity ≥37 kg/m 3 ;

- Penoplex brand "Comfort" - a universal series of insulation with a density of 25-35 kg / m 3. Direction of application - insulation of apartments, houses, basements, balconies and loggias;

- Brand "45" has the most high performance frost resistance and strength, specific gravity 35-47 kg / m 3. Designed for thermal insulation roadbed, runway, and other heavily loaded objects and structures.

A separate category is produced sandwich panels, which are an improved heat insulator for insulating attics and mansards, facades and foundations of buildings. Sandwich panel has 2-3 layers and cement chipboard as the bottom layer.

Operational and technical properties of penoplex, advantages and disadvantages

- Thermal conductivity - 0.03 Wm 0 С, the indicator does not decrease even with strong moisture;

- Water resistance - 0.4-0.6% when immersed in water for 24 hours and for a month;

- The vapor permeability of the material can be compared with the same indicators of roofing material with a layer thickness of 20 mm;

- Chemical passivity: penoplex does not react to contacts with mortars and most aggressive substances. Substances with which Penoplex contact is contraindicated: kerosene, acetone, formaldehyde, benzene, xylene, toluene, formalin, methyl ethyl ketone, ether, diesel fuel, gasoline, tar, paints and epoxy resins;

- High mechanical resistance to stretching, compression, tensile forces and multi-vector pressure. The compressive strength index of foam plastic is 0.2-0.5 MPa;

- Biological neutrality - penoplex does not get sick with mold, does not decompose and does not rot;

- Wide range of operating temperatures - from -50 to +75 0 С. Temperature Range for each brand is indicated on the packaging;

- Combustibility groups for different brands are different, from G1 to G4, depending on the operating conditions;

- Environmentally friendly material without the use of phenols and freons in the production;

- Guaranteed service life ≥55 years without notable losses in properties.

Advantages of penoplex:

- Thermal conductivity properties make it possible to use penoplex even in the Far North - multiple freeze / thaw cycles of the material do not affect its characteristics;

- Light weight makes it easier to transport, store, store and insulate the object, makes it possible to lighten the foundation and not to strengthen the ceilings;

- Simple installation without the help of specialists and special tools- penoplex is easily cut with a regular hacksaw or cutter;

- Safety and environmental friendliness - you can work with the material without personal protective equipment;

- Low cost of all brands of insulation. Even with a high consumption of a heat insulator, the cost of its purchase and installation pays off in 2-3 seasons.

Disadvantages of penoplex:

- Low fire safety - a material of any combustibility group, even with flame retardant additives, can ignite with the release of acrid toxic smoke;

- Low coefficient of vapor permeability, and under certain weather conditions - negative. Therefore, penoplex is not recommended for internal insulation of the walls of the house. To save optimal conditions operation of the insulation, it is necessary to provide forced ventilation in the house and ventilation of channels in the walls insulated with foam plastic;

- The destruction of the material when exposed to ultraviolet radiation - sun rays. It is necessary to protect the insulation layer with plaster or other methods;

- Due to the smooth surface, the adhesion of foam plastic with solutions is rather low, therefore, it is necessary to fix the insulation only on dowels or special expensive glue, but not on mortars.

Heat-insulating material "Wall" - properties and characteristics

The Wall brand is a renamed Penoplex 31 insulation with flame retardant additives, which has been improved for use in the insulation of “wet” facades, building foundations, plinths and basements, partitions and walls of houses from the outside and inside, roofs and attic space. Characteristics of foam brand "Wall" - in the table below:

Insulation brand "Foundation" - parameters and properties

The Foundation brand is a renamed Penoplex 35 insulation without fire retardant additives, which can now be used to create thermal insulation for the bases and plinths of buildings, blind areas and basements. The strength, water resistance and thermal conductivity of the series are its main advantages. The characteristics of the "Foundation" are given in the table below:

Penoplex "Roof" - properties and characteristics

Foam insulation of the "Roof" series is a renamed material "Penoplex 35", which is recommended for use in the insulation of pitched and flat roofs any design. The use of the "Roof" series makes the further operation of the roof as simple as possible, since the reliability and long service life of the insulation minimize the possibility of repairing the roof surface. The popularity of this innovative insulation material It is also caused by the fact that greenhouses and summer gardens can be arranged on such a surface - such currents are now in fashion. Penoplex withstands so much high loads that a load of soil up to several tons is nothing to him. Characteristics of the brand of insulation penoplex "Roof" - in the table below:

"Comfort" - a universal brand of heat insulator

"Comfort" - a universal brand of heat insulator Heat insulator brand "Comfort" - properties and characteristics

Penoplex "Comfort" is a modified and improved "Penoplex 31C" with universal characteristics. The material is actively used for insulation suburban buildings, country houses and cottages. High installation speed and minimal labor costs popularize the insulation among private homeowners - it is used to insulate the subfloor, foundation and basement of the house, basement and roof, walls and partitions inside and outside the building. Penoplex "Comfort" has high rates of moisture resistance and thermal conductivity. In the line of the penoplex series, the Comfort brand is recognized as universal.

Penoplex protects the soil from heaving during freezing - when the soil is insulated with this material, the freezing point of the soil will rise. This series is optimal for thermal insulation of road and railway tracks, runways and technical areas of airfields. Comfort slabs retain their unique characteristics during the entire period of operation. Characteristics of the brand of insulation penoplex "Comfort" - in the table below:

It is a delusion to think that foam and polystyrene are brother materials. Some properties of foam can be equated to the parameters of the foam, but not combustibility and water absorption.

Manufacturers have long mastered the manufacture of both non-combustible foam plastic and well-burning foam plastic. But the truth is that foam plastic cannot ignite spontaneously, but in the zone open fire it will only melt, releasing carbon monoxide (CO) and carbon dioxide (CO 2) gases. If the fire is eliminated, then the penoplex will not even smolder.

Below is a list of frequently asked questions and answers related to PENOPLEX ® thermal insulation:

Differences between PENOPLEX ® and non-pressed expanded polystyrene (PSB)

Plates PENOPLEX ® and expanded polystyrene (PSB) differ in production technology. Pressless expanded polystyrene is created by "steaming" microgranules with water vapor in special form and their increase under the influence of temperature. PENOPLEX ® thermal insulation is produced by mixing polystyrene granules at elevated temperature and pressure with the introduction of a foaming agent and subsequent extrusion from an extruder. That is why PENOPLEX ® expanded polystyrene is called extruded. Also, thanks to the production technology using this technology, PENOPLEX ® obtains a closed finely porous structure, which in turn ensures high strength, almost zero water absorption, as a result - biostability and the highest durability of PENOPLEX ® boards. An important factor also is the lower thermal conductivity of PENOPLEX ® in comparison with non-pressed expanded polystyrene (PSB), which allows to reduce the thickness of the required thermal insulation by about 30%.

Which insulation to choose: PENOPLEX ® or mineral (stone) wool?

What is better PENOPLEX ® or mineral wool? This is a question that quite often arises from private developers. Each of these materials has its own advantages. For example, PENOPLEX ® is practically indispensable in loaded structures and in a humid environment, while mineral wool shows itself better in sound insulation. In addition, some types of mineral wool have more low price, but this plus often disappears due to Low quality such wool, as a result - a large shrinkage, as well as the need for a greater thickness of thermal insulation.

PENOPLEX ® is distinguished from mineral wool by a number of characteristics:

- lower thermal conductivity.

- high compressive strength

- absolute moisture resistance (PENOPLEX ® does not absorb water, due to which it retains its thermal insulation properties throughout the entire service life).

- absolute biostability (PENOPLEX ® is not a matrix for the development of bacteria, mold and other microorganisms).

- ease of installation (PENOPLEX ® does not require special means protection when working with it).

What is the density of PENOPLEX ® ?

Density of PENOPLEX ® boards for private use ranges from 23 to 35 kg/m3. For the professional segment, this figure can reach up to 45 kg/m3. At the same time, it is important to understand that the density of PENOPLEX ® is not a key factor in determining the scope of the material. More important is such a characteristic as compressive strength. The strength characteristics of PENOPLEX ® vary over a wider range. The minimum compressive strength at 10% deformation for PENOPLEX ® boards is 0.12 MPa, such boards are used for unloaded structures (for example, for wall insulation). Plates intended for insulation of foundations have higher compressive strengths - 0.3 MPa, since it is these structures that take on the main loads from the building. PENOLEKS ® grades intended for road construction and structures with increased loads can have a strength of 0.50 MPa and above.

A wide range of characteristics makes it possible to use PENOPLEX ® boards for insulation of almost any structure, both in cottage and low-rise buildings, and in industrial and civil construction.

What is the melting point of PENOPLEX?

The temperature range of application of PENOPLEX ® boards is in the range from -70 to +75 degrees Celsius, which allows using this material in any climatic zones.

At temperatures above 75 degrees Celsius PENOPLEX ® can change its mechanical properties in the direction of reducing the strength of the material.

How many bricks does PENOPLEX ® replace?

If we compare materials in terms of heat-insulating properties, then a PENOPLEX ® slab 50 mm thick (λ=0.034 W/m2°C) will replace 1280 mm masonry on a heat-insulating mortar made of solid single brick (λ=0.82 W/m2°C). (According to GOST 530-2012 Ceramic brick and stone. General specifications. Table D.1 - Thermal characteristics of solid (conditional) masonry).

On average for thermal insulation properties 1 cm PENOPLEX ® replaces 25 cm brickwork, but it should be remembered - for each separate species bricks (silicate, ceramic, clinker), this comparison will be different.