Ensure constant access to water land plot perhaps by arranging a private well and installing a reliable pumping equipment.

One of these devices, which has not lost its relevance and popularity for decades, is submersible pump Brook of Belarusian production.

Behind the compact body and high operational characteristics hiding the ability to quickly organize effective system home water supply.

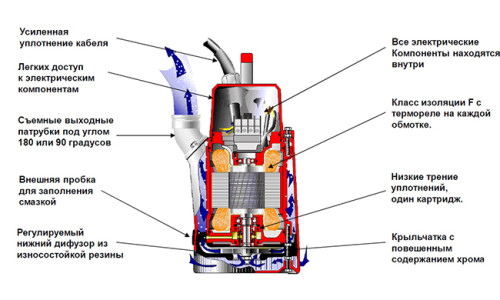

The Brook device is a submersible electric pump that is used to supply and pump liquid from water intake points up to 65 meters deep. With a low weight (only 4 kg), the device pumps up to 460 liters of fluid per hour.

The vibration pump is installed at the water intake point on flexible cable or rope. The Brook pump device provides for built-in sensors to determine the heating temperature of the device and turn it off in case of possible overheating. The metal case of the device is equipped with rubber seal which prevents damage casing pipe wells or wells when submerging or lifting the unit.

The central element of the design is the membrane, so the principle of operation is based on the vibrational vibrations of the membrane armature when the working pressure changes inside the device case. By means of a check valve, the membrane element pumps part of the liquid into the housing and, during the reverse movement, outputs it to the fitting located outside. A ¾ water hose is attached to the fitting, which ensures the timely supply of liquid to the end user.

One of the most popular models is the Brook 1 pump, used to supply fresh water. drinking water, the temperature of which does not exceed 35 degrees. The unit provides a strong water pressure up to 42 meters, is equipped with a 10-meter power cable. This model provides only the upper intake of water.

Equipment Specifications

Depending on the model and purpose vibration pump A brook may have the following characteristics:

- power consumption - from 150 to 305 W;

- operating voltage in the network - no more than 220 V;

- water pressure - from 35 to 62 meters;

- device performance when installed to a depth of 45 meters - 435 liters / hour. For 1 meter of depth, a similar figure can reach 1.4 cubic meters. m;

- the temperature of the liquid for pumping should not exceed 35 degrees.

The Stream pump with the specifications given above is capable of pumping up to 8 liters of water per minute. For all domestic and technical needs, the performance of the device is not enough, therefore it is recommended to turn on the liquid intake points one by one.

Advantages of submersible pumps

Vibration pumps Rucheek are distinguished by durability, workmanship and safety. The main advantages of the devices include the following parameters:

- The compact body and light weight make it possible to install the Rucheek water pump in hydraulic structures where it is not possible to install other pumping equipment.

- Availability and ease of use. There is no need to adjust and lubricate the working elements before installing the equipment.

- High quality materials used to make the case and structural elements.

- Ease of installation - the device is installed on a flexible cable or rope.

- The pump is equipped with an internal thermal protection, which switches off the device when the critical heating point of the housing is reached.

- Affordable repair and Maintenance. Ergonomic trickle pump and the characteristic, which is the main one, namely maintainability, favorably distinguishes it from direct analogues. The ability to carry out quick dismantling, replacement of any structural elements and assemblies, and then final assembly. Carrying out regular technological breaks every 2.5 hours for 15 minutes contribute to an increase in the operating life of the pump.

- Possibility of use for pumping liquid from well shafts, artificial and natural water sources, water collectors.

- Installation of equipment in drinking wells and wells with a low flow rate of the source.

The main types of pumps Brook

The availability and safety of the design determined the number of varieties of pumping equipment Brook. According to the type of water intake, the devices are divided into the following types:

- Models with lower water intake - H-40, H-25, H-15 and H-10. Deep pumps provide lower fluid inflow and reduced water flow rate. To prevent possible overheating of the case, such devices are equipped with a protection relay and an electrical cable from 10 to 35 meters.

- Models with upper water intake - B-40, B-25, B-15 and B-10. During operation, the body of the equipment is located in the water, which practically eliminates overheating of the working elements.

Areas of use of pumping equipment

Submersible pump Strumok is widely used for domestic and household purposes:

- water supply from a hydraulic structure - a well or a well;

- temporary replacement of the main pumping equipment;

- irrigation works;

- filling heating systems before starting work;

- pumping liquid from water receivers;

- organization of an autonomous water supply system using a single water distribution point.

Water supply from a hydraulic structure

Such devices provide timely water supply for country house, cottages or baths. True, the low performance of the pump will allow you to alternately use the water distribution point - for showering, washing dishes or washing. In this case, the water pressure is determined by the depth of the water intake column, the deeper the structure, the less pressure. You should not connect an electric pump of this type to several buildings at the same time, this can lead to a reduction in the working life and overloads of the system elements.

Temporary replacement

To provide autonomous system water supply in a private household, the owners install powerful pumps. If the main equipment fails, the repair of which will take a lot of time and money, a simple Creek will become a fallback option. Even the low performance of the device will satisfy the basic needs of consumers.

Filling heating systems

In the process of building houses, the creation of autonomous heating systems is carried out earlier than the supply of water. Compact pumps are used to fill the water pipes. All work is carried out in next order: a large volume tank is filled with water, the first hose is lowered into it to supply water from the pumping equipment. The second hose is connected to the tap on the radiator. When the tap is opened, the pump starts and the system is filled. A manometer is used to determine the pressure level.

Fluid pumping

Often, a vibration pump is used to pump liquid and effluent from receivers and flooded technical rooms. The equipment allows you to remove excess water in automatic mode without the need for additional technology.

Possible malfunctions of the pump, their elimination

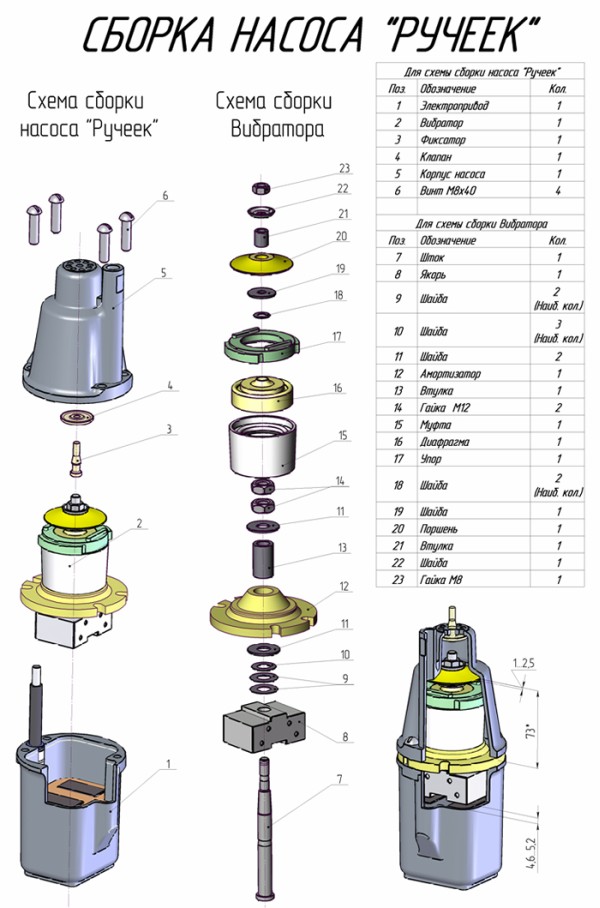

Quick repair of the pump Brook can be done with your own hands after a preliminary diagnosis of the breakdown and preparation necessary tools. Most often in practice, there are two types of malfunctions - violation of the tightness of the housing and valve failure.

Before you begin troubleshooting, you must carefully study the design of the pump. Instructions for the device include detailed description structural elements and a list of possible faults.

Leakage

When taking water from hydraulic structures, it is important to follow the safety rules when operating the pump. The greatest danger is caused by excessive vibrations of pumping equipment, when the contact of the body with the inner walls of the casing leads to a violation of the tightness of the structure. A similar outcome when the device is operated dry (without water).

Do-it-yourself body repair is carried out in the following order:

- dismantling the electrical part of the device;

- removal of the magnet;

- fine perforation of the case with a grinder;

- lubrication with sealant over existing perforated holes (used to restore automotive windshields);

- reassembly in order;

- drying of structural elements and housing;

- final assembly of the pump.

Valve failure

The second equally common problem is valve failure and its forced replacement. This is due to excessive clogging of the device with dust, dirt and small stones. To prevent further clogging, it is recommended to use external filter elements that are mounted on the suction base of the pump.

To replace the rubber valve, you can use a soft cork from a medical bottle or purchase a ready-made item. The old valve is removed, and a new one is installed in its place.

The Brook device is a reliable, safe and practical device used in private households to supply water. In addition, the vibration pump contributes to solving issues with pumping out wastewater and cleaning hydraulic structures.

Currently, the Malysh submersible pump has gained great popularity among many summer residents. It is low cost and has great performance. Furthermore, this pump produces high pressure, which causes a strong supply of liquid. But having good specifications, the Malysh pump is very unreliable in operation. Moreover, the type of these breakdowns can be very diverse.

Scheme of installation of pumps "Kid" in the well.

Types of faults

Malfunctions of this pump occur during operation. Their nature can be very different and arise for the following reasons:

- valve failure;

- traction break;

- breakage of the power magnet;

- winding overheating.

The device of the pump "Kid" with an upper water intake.

The principle of operation of this pump is quite simple. When connected to an electrical network that has a frequency of 50 Hz, the pump armature is attracted by a magnet. After the remagnetization of the pole occurs, every 1/2 period, the armature is thrown back.

This is done with a shock absorber. That is, during the passage of one current discharge, the armature is attracted 2 times. Accordingly, for 1 s at a current frequency of 50 Hz, the attraction of the armature occurs 100 times.

A piston is located on the rod with an anchor, therefore, the frequency of its operation will be equal to the number of attraction of the armature. The volume of fluid that enters the pump body is limited by this piston and valve creating a fluid chamber.

The device of the pump "Kid" with a lower water intake.

The pumped water is saturated with air, as a result of which it has elasticity. Being subjected to mechanical influences from the side of the piston, it creates a springy effect in the hydraulic chamber.

The liquid in the pump is subjected to repeated compression and expansion, and its excess enters the outlet pipe.

The valve of the device lets water in through the suction part of the pipe and does not allow it to flow in the opposite direction. Thus, the liquid is pumped using the Malysh pump.

Back to index

Performing repairs

many owners summer cottages very often they replace a broken pump with the same model. Accordingly, the old mechanism can be used as a "donor" when the 2nd unit breaks down.

For example, there are 2 broken pumps at your disposal. In 1 of them there was a break in traction, and in the 2nd, the winding burned out. Any person can repair such pumps (assemble from 2 devices 1). To do this, you need to have little skills in working with tools and have minimal technical knowledge.

The most difficult step in eliminating the breakdown of the pumping device will be the process of disassembling it. This must be done carefully so as not to damage anything, since the device consists of 2 halves, which are pulled together with 4 bolts. During the time the pump is in the water, metal fasteners are subjected to "souring". To untwist these connections, it is necessary to wet them with kerosene and leave for 30-40 minutes. Kerosene will help eliminate the "nitrous" that has appeared.

To repair the pump, you need to unscrew the bolts from it with a screwdriver. In order to make it more convenient to disassemble it, you can prepare a special holder that will fix the device in a vertical position. It may also happen that the above measures do not help, then you need to cut bolted connections. You can do it with a grinder. After that, the same procedure must be repeated with the 2nd unit.

Known for its unpretentious maintenance, budget cost and the ability to pump water over long distances.

But the pump is a complex technique and it happens that it fails.

If you have standard tools from the garage and technical skills, you can repair the Baby pump at home.

Main reasons for failure

Advice from practice: installation mechanical filter ensures the necessary purity of the incoming water to the pump.

Frequent problems

For disassembly, you need to unscrew all the screws that connect the case to each other. It is recommended to apply small notches to the body, during subsequent assembly this will facilitate the process.

Expert advice: when disassembling the pump, you need to unscrew not one screw at a time, but loosen each one a couple of turns.

A pump that has been running for several years will probably turn sour bolts; lubricants to remove rust will not help here. In this case, we use a power screwdriver, if it didn’t help, we cut off the screw caps with a grinder. Then replace the factory bolts with hexagon socket screws.

When assembling the pump, pay attention to the position of the gasket and the upper part of the housing - they must match. Or if you have made notches, be guided by them.

Experienced advice: after assembly and repair, check the performance in a container of water so as not to take the pump out of the well again.

How to repair

Almost all breakdowns can be repaired at home.

Almost all breakdowns can be repaired at home.

Consider step by step how to properly start repairing the Kid in the mechanical part:

- The hose must be connected tightly, do not let water through. Use secure fasteners.

- brush check valve from dirt.

- If there is vibration when the pump is in the well, but no water is coming in, the problem is in the mechanical part.

- If the motor does not start, the problem lies in the electrical part.

- After disassembling the pump, pay attention to the valve, if it is faulty, replace it with a new one or make it yourself out of rubber.

- When a knock on the body is heard in the pump, it means that the electromagnet is not fixed. Make a groove on the magnet and the case with a grinder, 1 mm deep. Fill it with sealant and install the magnet.

- The play in the piston indicates the flaring of the washers. Remove the old washers in the core, replace with new ones. Then tighten the housing nuts well.

When the above methods did not come up, and visually all the details are intact, it's time to start repairing the electrical part. You will need a tester to detect an open or short in the thermal switch, cable and electromagnet.

Rewinding the reel

If you need to rewind the spool, prepare expendable materials and tools:

If you need to rewind the spool, prepare expendable materials and tools:

- wire brand PETV;

- epoxy compound replacement kit (epoxy resin, plasticizer, hardener);

- electric stove;

- winding machine (you can also manually);

- soldering iron;

- a hammer.

When rewinding the coil, you will need to melt the epoxy. It is toxic, so work on the street or in the garage. We put the flooded electromagnet on the tile, wait until the epoxy heats up to 165 degrees. This will be seen by the toxic haze that appears.

Carefully knock the electromagnet out of the case against a wooden object, while the electromagnet looks straight down. When the magnet changes its position, take it out. We clean the heated case from epoxy resin, you can use a screwdriver or a metal brush.

We knock out the electromagnet from the coil with a wooden wedge.

We knock out the electromagnet from the coil with a wooden wedge.

We do not clamp the coils in a vise, we only hold them with our hands.

Once the magnet is removed, unwind the coil, stripping all of the epoxy off.

Submersible pump "Brook" has long become popular with gardeners, owners of private houses. Its first model was developed and produced in Belarus more than 40 years ago. Later it began to be produced in other republics. former USSR and in countries Western Europe. For its miniature size and weight, it is called "Kid".

Usually this pump is used for watering summer cottages, pumping water from basements, inspection pits, filling heating systems, supplying houses with drinking water.

Device specifications

Submersible pump "Brook" can pump water from any reservoir, well, well, watering barrel. However, it must be below the water level. The water should be clean, fresh, without sand and silt suspension. If sand is present, an additional filter must be used.

The pump is produced with two types of water intake: "Brook 1" with an upper intake and "Brook 1M" with a lower one.

The pump is lowered into the water on a nylon cord, which is included in the kit, or on any other suspension. During operation, the body vibrates strongly, so it should not touch the walls and bottom of the container. Otherwise, its tightness will be violated or the case will collapse.

Specifications:

- supply voltage - 220 V;

- power consumption - 225-300 W;

- weight - 4 kg;

- maximum lowering depth - 7 m;

- maximum height of water rise - 60 m;

- productivity - 450 l/hour;

- time continuous work- 12 hours;

- cable length 5-15 m.

The given characteristics are averaged, for various models may vary slightly.

The last digits in the model specification indicate the length power cord. Its length can be 5, 10 and 15 m. It is not known in advance at what depth the pump will work, so it is better not to save money and purchase it with maximum length cord.

Many people misunderstand what "the maximum height of the water rise is 60 m" means. This is the maximum pressure that the pump can create. It corresponds to 60 m of water column or 6 atmospheres. It should be noted that the pressure at the outlet of the hose will always be less than at the inlet. Even if you use a fairly thick hose with a diameter of 1 inch (2.54 cm), then due to internal friction, for every 10 m of the horizontal section of the hose, the pressure drops by 1 atmosphere.

The device and principle of operation of the pump

The device of the vibration pump is quite simple. The aluminum case, consisting of two parts, is filled with epoxy resin electromagnet. Next to it is a steel rod that can move along the longitudinal axis of the body. The rod is attached to the body with a rubber shock absorber. The rod oscillates the diaphragm, which creates compression and rarefaction in the body cavity. In the upper part of the body there is a hole for suction of water and a branch pipe for connecting a hose. The water suction hole is closed with a rubber valve when the stem moves up.

The principle of operation of the vibration pump eliminates the presence of rotating parts and bearings. This ensures the high reliability of the water pump "Brook".

The tightness of the connection of the body parts and the input of the supply cable is so reliable that the pump can be in the water for years.

Since the suction hole in the pump "Brook 1" is located in the upper part of the body, the ingress of sand, small stones, debris from the bottom of the tank is excluded.

Maintenance and repair

The Brook does not need maintenance.

Repair of the pump can be done independently or given to a specialized workshop.

The main difficulty is to unscrew the 4 fixing bolts that tighten the parts of the case. Usually they cannot be unscrewed, so you need to carefully cut them off with a grinder. To facilitate disassembly in case of re-repair, new galvanized or non-ferrous metal bolts must be installed. Nuts should be self-tightening with plastic inserts: they do not unwind with strong vibrations.

Typically, pump repair comes down to replacing a valve, which wears out over time. A spare valve is sold with the pump. If there is no such valve, you can make it yourself from cork from plastic bottle. A sign of valve wear: the pump buzzes, but does not pump water.

Sometimes the stem fails. It can be machined, but a homemade stock will not last long. You need to find and install the original.

The most a big problem occurs in the event of a breakdown of the electromagnet coil. It will be problematic to remove, rewind the coil with your own hands, install it in place and seal it.

Disadvantages of the Vibratory Pump "Brook"

One of the disadvantages of the Brook vibration pump is a loud sound during operation. If you use it only for watering, you can put up with it. But if you use the pump to operate a fountain, overflow or circulate water in the pool, then the hum of the pump will interfere and annoy. For these purposes, it is better to use pumps of a different type.

With the help of "Stream 1" you can download only part of the water above the suction hole. It will not be possible to completely pump out water from the tank.

Adapters and quick-release fasteners are not provided for connecting the hose. The hose connection has round section(some models have notches), so the hose is often disconnected due to vibrations. You have to crimp it with a knitting wire or a clamp. Disconnecting the hose is then problematic.

The pump device does not provide for automatic shutdown. The user himself has to monitor the water level. "Brook" is cooled by the water in which it is located. If the pump runs idle, it quickly heats up and fails.

float device for automatic shutdown can be purchased separately. Many owners make their own.

High reliability, proven for decades, low cost compared to foreign analogues, ease of maintenance and repair have made the Rucheyok pump an indispensable assistant.

Of course, it will not be possible to solve all problems with its help. For pumping water and other liquids in large volume need a more powerful pump.

Self-repair of the pump type Kid, Aquarius, Brook

Do-it-yourself repair of a vibration submersible pump such as Malysh, Aquarius, Brook

Gardeners and summer residents are very popular submersible vibration "Kid" type pumps, and other modifications that work on the same principle. They are inexpensive, productive, create a sufficiently large pressure and have high pumpability (i.e., they can supply water over a sufficiently long distance). But, unfortunately, these pumps are not very reliable. Moreover, their breakdowns are very diverse. Where the valves leak, where the thrust breaks, problems with the pump winding, power magnet, short circuit or break. There are quite a few simple malfunctions that are easily fixed, but after repair, for example, replacing rubber valves, the pump does not pump or pumps very weakly. Here you still need to properly adjust and assemble the pump. To understand how to properly adjust the pump - consider the principle of operation and important points correct adjustment.

Principle of operation and design

Vibratory submersible pumps are inertial type pumps. The operation of inertial pumps is based on the excitation of oscillatory processes in the liquid, which contribute to its movement.

When the pump is turned on electrical network with a current frequency of 50 Hz, the armature is attracted to the magnet. When the poles are remagnetized, the shock absorber throws the armature back every half a period. That is, for one period of the current wave, for those who know electrical engineering, the armature is attracted 2 times. Accordingly, per second at a frequency of 50 Hz, the armature is attracted 100 times. The piston located on the same rod with the anchor vibrates with the same frequency.

The volume in the pump casing, bounded by the piston and the valve, forms the hydraulic chamber. Since the water pumped by the pumps is a two-component mixture containing dissolved and undissolved air, it has some elasticity - it springs when mechanical action, which happens in the hydraulic chamber when the piston oscillates.

Water, like a spring, compresses and decompresses and its excess is pushed into the pressure pipe - in this way the pump pumps water. At the same time, the valve allows water to enter and restricts the exit of water through the suction holes.

Pump modifications

The maximum flow determined during the operation of vibration pumps without pressure, depending on the adjustment, ranges from 1 to 1.5 m3 / h.

The power consumed by the pumps is indicated in the range from 180 to 300 watts. In fact, pumps adjusted to the nominal parameters consume power from 190 to 220 W in the range of pressure from 1 to 40 m. With increasing voltage, productivity, current and power increase. When the voltage drops to 200 V, the performance decreases by 25%. Thus, vibration pumps can operate with voltage fluctuations inherent in rural areas and suburban areas.

The immersion depth indicated in the marking means at what level the pump can be immersed under a layer of water, in this case - 3 m.

Although the pump shell withstands much more pressure, we stopped at 3 meters. For the Bavlensky "Kids" and the Belarusian "Brooks" this is enough. If the pump is drowned deeper (up to 5-7 meters) - there will be no problems.

The most common breakdowns and how to fix them

During a short period of operation without immersion in water, the pump heats up and the aluminum housing expands out of proportion to the compound ( epoxy potting magnet) and in view of the lack of plasticity, the latter has a detachment of the filling from the pump housing ... the situation is greatly aggravated by an increase in vibration when working without water at all (during pumping dry .. as a result, the complete detachment of the magnet and the absence of a gap between the vibro piston and the magnet - the absence piston movement...

The treatment is simply impossible ... it was performed in the conditions of a car service on the occasion of being there

First of all, we separate electrical part(we disassemble the vibration pump) by tapping the case with a hammer, we make sure that there is no fastening (the sound does not immediately feel the solidity of the contents) of the magnet .. we take it out of the case, make longitudinal and transverse grooves on it with a small grinder (less than 2 millimeters deep) inside the case in a chaotic manner, then we coat it with a thin layer of "glass" sealant (the one with which glass is glued into foreign cars) - it is very durable and strong - ordinary sealants are up to it like the moon !! and press the magnet into the body using a press with a force of about 250-300 kilos (with less to push because of the viscosity of the sealant) I admit that instead of a sealant, you can use some adhesive composition but I was at the auto service

let it cool down and put it back together..

The first, most important, with a serviceable valve and piston, is the gap between the electromagnets of the coils and the piston, the gap should be 4-5 mm. If the gap is smaller, the coils will break if the motor overheats more. It is calculated as the difference between the depth of drowning of the iron of the coils in the housing and the value of the protrusion of the iron of the piston above the rubberized spring flange.

The second valve should play freely on the rack, if you try to blow from the side of the water intake, the air should flow freely in both directions. The valve must not be damaged! It is advisable to unlock the rack from the outside with two nuts. We're done with the valve.

Third is the piston. It must also be without mechanical damage, and shape distortion, and be quite elastic. The nut of which it is fixed on the sleeve, rivet.

All this turned out to be very good for us, and the question lurked, why is it buzzing, and not shaking? It turned out that inside the piston block, its sleeve (on which both the piston and part of the iron of the electromagnet sits) is screwed with a nut to a rubberized flange (such as a spring membrane), and is unlocked with another nut. So these two nuts are completely untwisted (((. In order to see this, it was only necessary to disassemble this block by removing the piston, removing the clearance adjustment washers, remove the thrust ring and pull off the rubber membrane (from the piston side!). to this disgrace. Having removed the aluminum cylinder, tightly clamp the piston sleeve to the rubberized flange-spring, unfasten it, and assemble everything back. We measure the gap, if it goes beyond 4-5 mm, then there are washers on this sleeve, 0.5 mm thick, adding or removing them from one side, we can change the gap in any direction...

Gathering our happiness Special attention you should pay attention to the correct installation of the cover - the tube through which water comes out of the motor should be on the same side as the hole on the rubberized flange-spring))). We tighten, or rather twist (collect) our miracle, and check. If the jet beats at least a meter (by immersing the motor in a full bucket of water and plugging it into the network), then everything is OK! If not, we disassemble, check everything again ..

A little from the big personal experience: the comrade from above said correctly about setting up the magnetic system, the gap is 4-5 mm. checked with a rod, the depth gauge rod at the end of the coils, and on the mating surface. then the same on the mobile system, the depth gauge rod on the rubber, but do not press, and on the end of the anchor yoke. on the piston: you need to set it like this, the depth gauge rod to the edge of the piston touch, the end on one of the four shoulders. we assemble a moving system, a glass, rubber, a ring with four ears, we hold this ring as evenly as possible without distortions and pressures, the depth gauge rod into it, the end face to the edge of the piston, the data must converge with the body.

And in the end, the final assembly is the pump housing with a valve installed in it that blocks the inlets. Between the valve and the body there is also a gap of 0.6-0.8 mm, which ensures the free flow of water in the absence of pressure.

We invite you to consider our

Setting up the vibration pump

If the vibration pump stops working for no apparent reason, before disassembly