The pumping station is a set of equipment through which the organization is carried out autonomous water supply houses or cottages from sources such as a well and a well. Stations belong to the category of surface pumps - water is taken through a hose immersed in the source, while the unit itself is located on the surface.

This article will consider the Speroni Marina pumping stations, whose homeland is Italy. We will study the advantages and disadvantages of such equipment, their specifications and get acquainted with model range technology. Recommendations for the repair of pumping units will also be presented and their most frequent malfunctions will be given.

1 Device and connection of the pumping station

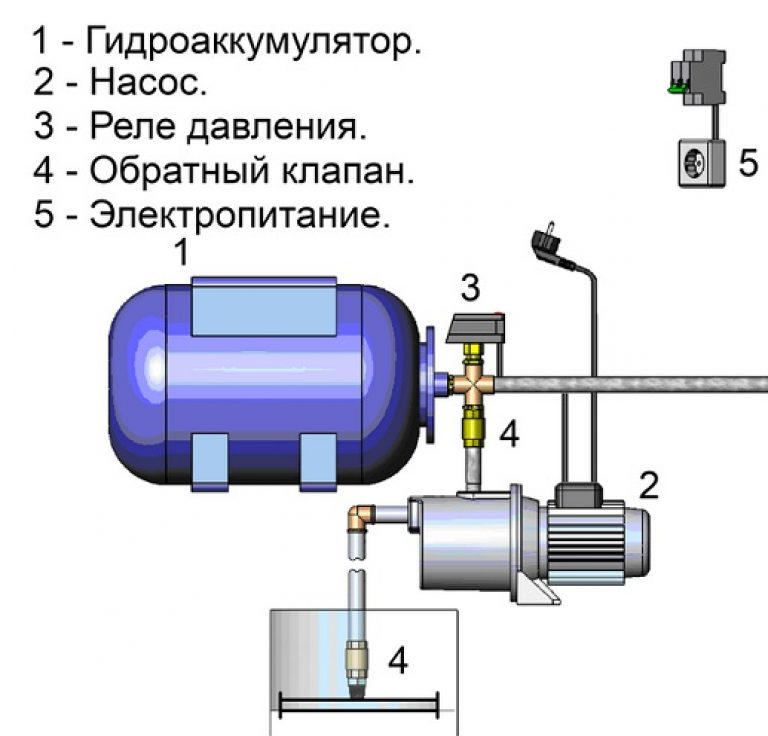

Design pumping stations Marina, which is produced by Speroni, is quite simple - in terms of layout, they practically do not differ from their counterparts in their price category. Unit device consists of the following nodes:

- centrifugal water pump;

- hydraulic accumulator;

- pressure switch;

- manometer;

- temperature sensor.

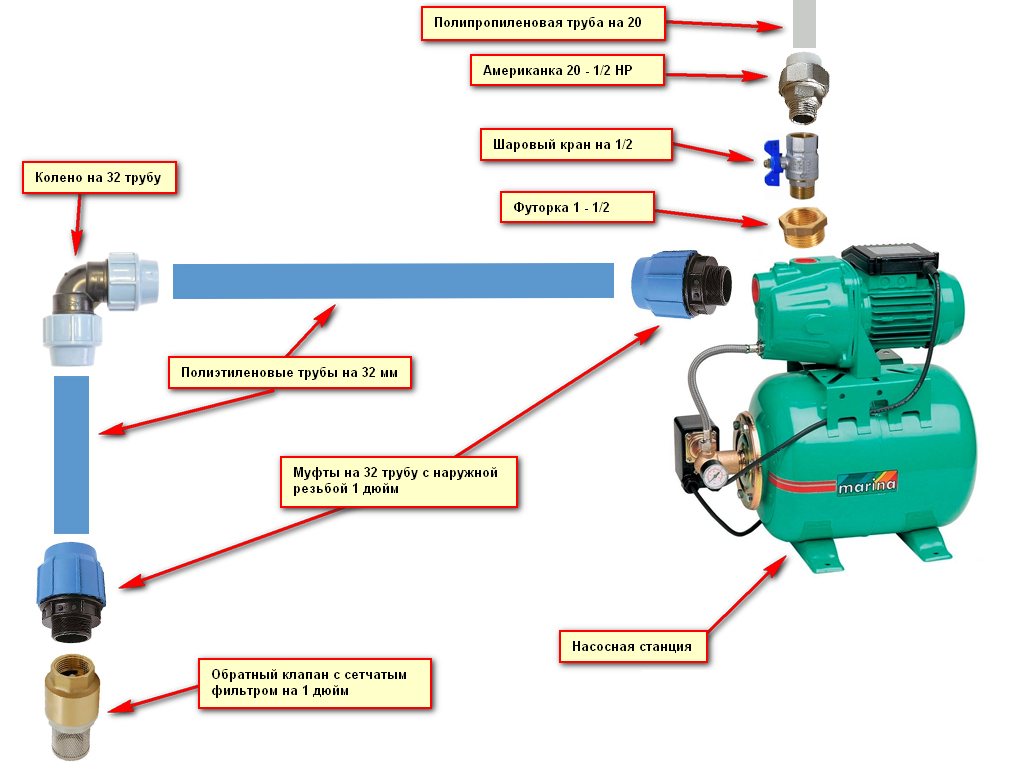

The device of the Marina stations does not imply the presence of a check valve, therefore, in order to increase the safety of the system, the user needs to mount it himself. The valve must be installed on the outlet pipe of the pump, it will prevent the movement of the pumped water in the opposite direction in the event of an unexpected shutdown of the equipment.

Also, it will not be superfluous to install a coarse filter at the inlet of the suction pipe, if it is present, the number of mechanical particles entering the pump is reduced, which has a positive effect on its service life.

The connection of such units does not require special equipment and can be done by hand. Initially, it is necessary to mount the pump carrying the water supply source, it must be located on a solid platform, which will eliminate vibrations during operation.

A water intake hose is attached to the pump, which is lowered into a well or well. Further, a supply plastic pipe is diverted from the station's accumulator, which is connected to water consumption points inside the house.

Upon completion of the connection, the operability of the system is checked - when starting up, the pump must be filled with water (a special hole is provided on its neck for this). During operation, the pump pumps water into the accumulator ( storage tank), when it is filled, the pressure switch is activated and the mechanism is turned off.

After the water in the accumulator has been used, the relay detects the reduced pressure and turns on the pump - this is how automatic adjustment, thanks to which the Marina station provides the house with water without your intervention.

1.1 Advantages and disadvantages

The popularity of Marina pumping stations is due to the presence of this equipment a number of operational advantages over competitors. The main asset is quality assembly because the pumps are made directly in Italy and not in China. These are reliable and durable units, the minimum service life of which before scheduled repairs is 3-4 years.

Among strengths also highlight:

- low power consumption;

- body and internal details from corrosion-resistant materials;

- low level of noise and vibrations in the course of work;

- availability of overload protection systems even in the cheapest models;

- the possibility of long-term operation in any power modes.

However, when choosing such a station for private use, it should be taken into account that the equipment is designed for pumping clean water, and use it as drainage pump will not work.

1.2 Marina pumping station - device, cleaning, start-up (video)

2 Model range of equipment

The product line of Speroni (Italy) includes 4 series of Marina pumping stations:

- marina cam- a budget option for water intake from wells up to 9 m deep;

- Marina APM - pumps for wells up to 50 m deep;

- Marina Idromat - units equipped with a regulator that turns off the pump when running dry.

Let's take a closer look at each of these lines.

2.1 Marina CAM

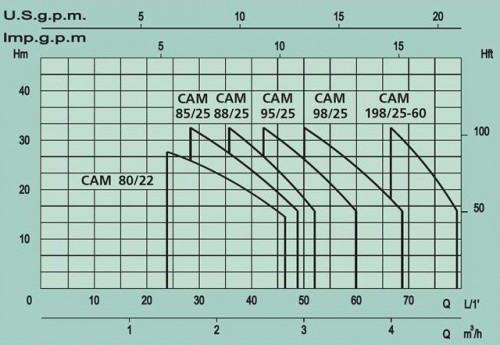

The CAM series consists of equipment made in a cast-iron or stainless steel case, with internal fittings made of food-grade polymers. Several models are presented, the power of which varies between 0.8-1.7 kW, and the head is 43-60 m.

The volume of the accumulator can be 22, 25 or 60 liters. These are the most affordable stations for private use, the cost of which starts at 7 thousand rubles.

Among the stations with the best price / quality ratio, we highlight:

- Marina Cam 80/22;

- Marina Cam 60/25;

- Marina Cam 100/25.

The Marina Cam 40/22 pumping station is equipped with a 25 liter hydraulic accumulator, the capacity of which will be enough for a family of 3 people. The capacity of the unit is 3.5 m 3 / hour, the maximum lifting depth is 8 m. The price is 9 thousand rubles.

Marina Cam 100/25 has similar specifications - 25 l tank, throughput 4.2 m 3 /hour, however, this model is equipped with a pressure boosting system, which significantly increases the delivery head - up to 45 m, compared to 30 m for CAM 40/22.

2.2 Marina APM

Well pumps of the APM series have a maximum water intake depth of 25 m (model 100/25) and 50 m (200/25). This is more power and overall equipment, the weight of which can reach up to 35 kilograms. As an example, consider the popular station Marina ARM 100/25.

Specifications:

- head - up to 20 m;

- throughput - 2.4 cubic meters / hour;

- centrifugal motor power - 1100 W;

- the diameter of the supply pipe is 1".

AWP 100/25 is made in a stainless steel case, the model is equipped with overheating protection and a water level control system in the hydraulic tank. ARM100/25 is designed for pumping clean water, without mechanical impurities, the temperature of which does not exceed 35 degrees.

2.3 Typical malfunctions and repairs

Marina pumping stations have established themselves as reliable and durable equipment, however, like any other equipment, they are not immune from breakdowns. We bring to your attention a list of the most common breakdowns and how to fix them:

- Lack of water supply when the pump is on, the cause of which may be loss of tightness in the conductive pipelines and worn check valve. First check if you forgot to fill the pump body with water. If it is, inspect the check valve and the tightness of its fit to the pump nozzle, and also check the condition of the intake pipe - all damaged components must be replaced. Similar problems are possible if the impeller is damaged, to replace which you will need to disassemble the unit.

- Water is supplied in jerks due to a damaged accumulator. The main malfunction of the hydraulic tank is a damaged membrane. To determine if it is intact, press the nipple (located on the tank body), if water flows from the nipple and not air flows, then the membrane is torn. It is quite easy to install the membrane, you just need to unscrew the fixing ring from the tank neck, pull out the old part and mount a new one in its place.

- Reduced water supply pressure. The reason for this can be either a faulty hydraulic tank or problems with the pump. In the first case, the depressurization of the tank is most likely to blame - inspect the case for cracks, repair the detected deformations and pump air up to normative value. If the tank is intact, the problem must be sought in the deformed impeller of the centrifugal wheel inside the pump.

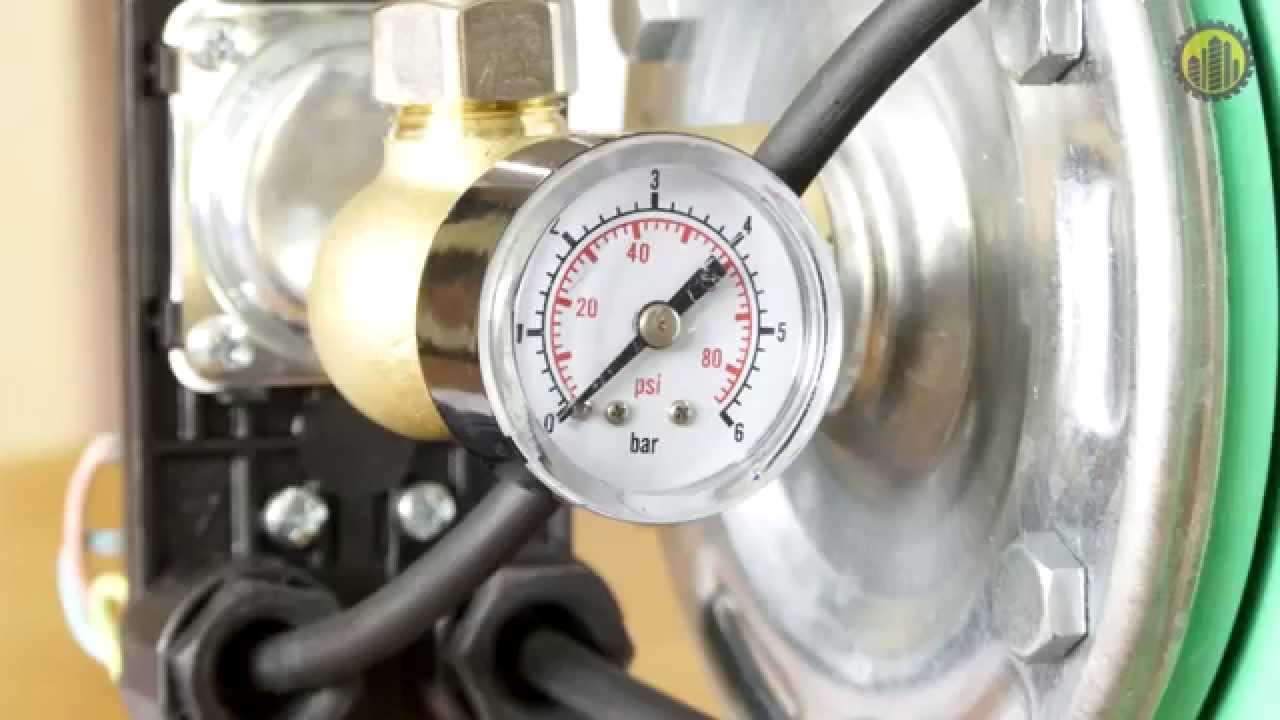

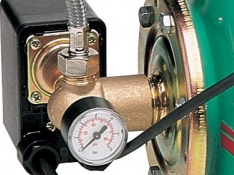

Separately, consider the situation when the pumping station does not want to work in automatic mode- the unit does not turn off when the tank is full and does not turn off when it is empty. The incorrect adjustment of the pressure switch is to blame here - it is usually calibrated at the factory, but there are exceptions.

The above diagram shows a standard pressure switch for Marina pumps. on it, under plastic lid case, there are two springs. Most of them rotate clockwise, she is responsible for minimum pressure in the tank, at which the station turns on. By rotating a small spring, we adjust the maximum pressure, upon reaching which the pump turns off.

Adjustment of the pressure switch must be carried out with the equipment disconnected from the mains. Before starting the calibration, water must be drained from the tank, the level of air pressure is also important - it must correspond to the value recommended by the manufacturer.

Marina Speroni pumping stations of various series are designed to provide uninterrupted water supply to summer cottages, gardens, private houses, etc.

Most often these products are used:

- for the organization of watering and irrigation of flower and vegetable gardens, various landings and lawns;

- for work with special garden sprinklers;

- for extracting water from various sources: tanks, water basins, streams, ponds, rainwater collection points and wells using the required filters.

Features of operation and technical characteristics of the Marina pumping station

All stations are equipped with a thermal relay that protects the motor from overheating. In the event that the temperature exceeds the permitted limit values, the pump switches off automatically.

All models of the Marina Speroni pumping station consist of the following main elements:

- power cord with plug;

- connecting fittings;

- manometer;

- pressure switch;

- hydraulic accumulator;

- surface pump.

After the pump is turned on, water fills the system in part from the check valve and up to end user. When water intake by consumers is completed, the water pressure in the water supply system increases to the maximum value set by the relay settings. After that, the specified relay turns off the pump.

A new opening of any water tap leads to the start of water entering it from the accumulator, where it is under excess pressure. In the process of water consumption, the pressure in this tank drops to the lower value, also set by the relay settings. After the pressure drops, the relay generates a command to turn on the pump. Water again begins to be pumped into the accumulator and supplied to consumers.

At the moment of reaching the maximum pressure in the accumulator, the pump is switched off, etc. the cycles are repeated until the water intake by consumers stops. The battery, absorbing a certain amount of water, plays the role of a damper for water hammer, which are extinguished in it. Such a technical solution allows to achieve energy savings and does not allow the engine to be overloaded.

Actually the accumulator has following construction: steel tank, having an internal anti-corrosion coating and equipped with a replaceable membrane, which is made of food-grade rubber, equipped with a pneumatic valve for pumping compressed air into it.

- disassemble and repair the pump yourself;

- operate it without grounding;

- operate without water;

- allow air to enter the suction line.

Technical characteristics of Marina pumping stations

| Pump Model | Hydraulic accumulator (liters) | Volume max l/min | Lifting height (m) max | Suction depth (m) max | Motor power (Watt) |

| CAM 100/25 | 25 | 70 | 32 | 9 | 1100 |

| CAM 100/RA | Not | 70 | 50 | 9 | 1000 |

| CAM 80/22 | 22 | 60 | 28 | 8 | 800 |

| CAM 80/RA | Not | 60 | 42 | 8 | 800 |

| CAM 40/22 | 22 | 60 | 28 | 8 | 800 |

| CAM 40/R | Not | 60 | 42 | 8 | 800 |

Installation of a pumping station and requirements for ensuring safe operation

The main requirement that the manufacturer imposes on the installation of the station is the fulfillment of all electrical work qualified electricians with the appropriate approval groups. These works must be carried out in strict accordance with the requirements of the PTE and PTB.

A mandatory requirement is the installation of an RCD rated for leakage currents of 30 mA.

The diameter of the pipe installed on the suction line of the station must not be less than the diameter of the inlet opening. In cases where the suction head is 4 meters or more, or the horizontal section of the water supply (suction line) exceeds 20 meters, specified diameter must exceed the inlet diameter.

When installing the suction line, it should be controlled that the slope of the line from the pumping station to the water intake is 1 or more degrees. Reverse angles are strictly prohibited.

Installation is carried out in the following sequence:

- The pump is placed as close as possible to the suction source.

- The suction pipe, equipped with a check valve, is joined to the end inlet. To do this, it is recommended to use a special adapter, which is not included in the delivery package and must be purchased separately.

- The pressure line is joined to the upper outlet of the pump.

- Through the filling hole, the suction line and the casing of the pump itself are filled with water. To do this, unscrew, then screw a special plug on the top of the pump.

- The presence of voltage in the network is checked.

- The pump is connected to the network.

When installing the pumping stations of the models listed in the table above, be sure to check that air is pumped into the accumulator at a pressure of 1.5-2 atmospheres. If the pressure is less, then it should be pumped through the existing pneumatic valve with a conventional automobile pump. The pressure in the specified device must be monitored monthly, after draining the water from the pressure line for this.

The main malfunctions of Marina pumping stations and methods for their elimination

The most common malfunctions of Marina pumping stations are described below.

Despite the fact that the pump rotates, no water enters the system. The reason for this situation may be:

- violation of tightness in pipelines;

- lack of water in the pump or pipeline;

- Check valve is not working properly.

You can fix the problem by performing the following steps step by step: check for the presence of water, if it is absent, add it through a special hole or lower the suction hose (or the pump itself) deeper. At the same time, it should be controlled that the distance from the water surface to the pump remains the maximum permitted.

If there is water, then check the check valve. With its technical serviceability, the tightness of pipelines is checked (at the joints) and the elimination of possible violations of the latter.

When it didn't work probable cause can be considered a failure of the pump due to the ingress of a large number abrasives (sand, for example). Here you will need to disassemble the pump and change its impeller or housing. In exceptional cases, the pump will need to be replaced.

In areas where the mains voltage is subject to significant fluctuations, its value should be checked. It is possible that the pump is not working due to its strong decrease.

The station began to work jerkily. Unnecessarily frequent switching on of the station may be due to damage to a part of the hydraulic tank, which does not allow the set pressure to be built up in it. You can eliminate the indicated cause as follows: press the nipple located on the back of the tank. If not air, but water comes out of it, the internal membrane, which has mechanical damage, should be replaced.

Another reason may be a violation of the tightness of the tank body itself. The place of breakdown should be found and sealed. In some cases, the problem is solved by simply pumping air to a predetermined pressure value (1.5 - 1.8 atm). This procedure is performed through a standard fitting on the product. Possible cause there may also be a violation of the tightness of the joints of the conduit in the suction section. Check and repair leaks.

The pump has stopped turning on. This happens when there is no power. It is necessary to check the integrity of the windings of the pressure switch or clean the burnt contacts. If the engine is burned out, it is easy to understand by the characteristic smell.

The pump turns on, but the impeller does not rotate. There are two reasons: either it “glued” to the body of the pump itself, or the capacitor broke. Most often, such malfunctions occur at stations that have not worked for a long time.

You can fix it like this: turn the impeller several times by hand, and the pump will start. If the capacitor fails, it will need to be replaced.

The station is constantly running and does not turn off. This is caused by malfunctions in the pressure switch. To fix the problem, it must be adjusted. These purposes are served by two springs placed on the relay: a small and a large one. The adjustment technology is described in the corresponding manual.

When executed in in full preventive and maintenance work of the pumping station, the likelihood of malfunctions is minimized. Identified malfunctions should be eliminated promptly and, preferably, by professional repairmen. This will allow you to as soon as possible ensure the restoration of water supply.

Pumping station - the equipment demanded and applied everywhere. It is a complex of interconnected devices, which is designed to take water and move it through pipelines.

Among the manufacturers, there are several brands whose products deserve attention. One of them is Marina, a brand of Speroni.

Equipment Features

Marina water supply pumping stations are produced famous manufacturer pumping devices. The instructions for the Marina pumping stations say that they are designed to supply clean water in automatic mode.

With its help, you can organize autonomous water supply of a small private house, improve the quality of water supply from central water supply, pump water out of a pool or other container.

Marina pumping stations are the most popular, because such a small and convenient installation allows you to organize comfortable watering of large plots of land. The device of the Marina pumping station includes:

- pump- the main part of the station. AT various models installed pumps of different capacity and principle of operation;

- hydrocollector- special membrane tank to store water. Marina water supply pumping stations are equipped with tanks of various capacities (from 25 to 100 liters), which are used for technical or food needs;

- manometer allows you to control the water pressure in the system;

- pressure switch implements the opportunity automatic shutdown pump in the absence of water;

- pipelines.

To buy a Marina pumping station, you need to know:

- Characteristics of the water source (well, well), in particular: the water level in it, the diameter and depth of the well.

- Distance from the source to the places of consumption;

- The desired level of pressure in the system.

- Number of water intake points.

Models and prices

The Marina pumping station is available in several modifications. There are three model lines on sale - CAM, RSM and ARM. The price of the Marina pumping station mainly depends on the type, performance of the pump in it and the capacity of the accumulator.

Now more about each category:

- Marina ARM pumping stations. These devices are equipped with ejector-type pumps, thanks to which the Marina APM 100/25 pumping station can extract water from a well with a depth of about 25 meters, and APM 200/50 is designed to lift water from a depth of fifty meters.

- Marina CAM pumping stations. Pumping stations of the CAM series are based on centrifugal self-priming pumps, so the suction depth is not more than 9 m (in practice, about 6-7 m). This series features the most big variety models. Their main differences are the power and performance of the pumps, as well as the capacity of the storage tank and the material of the case. For example, the Marina 40/22 pumping station with a power of 800 W has a maximum capacity of 50 l / min and is made of corrosion-resistant cast iron, and the tank capacity is 22 liters. Pumping station Marina 80/22 has more high performance(up to 60 l/min) and is made of stainless steel.

- Marina RSM pumping stations. The RSM series is represented by pumping stations with multistage pumps that provide increased water pressure in the system - up to 100 l / min, but have a small suction depth (up to 7 m).

Thus, we can conclude:

- Marina pumping stations of CAM series- it's simple budget solution for a wide range of household needs. The scope of these devices is in the country, for irrigation, to pump out water from a shallow container (pool, tank, etc.), to increase the water pressure from the central water supply. You can buy Marina CAM pumping stations at a price of 10 to 22 thousand rubles, depending on the pump power;

- APM series pumping stations- the most expensive of all, but they make it possible to pump water from great depths and raise it to a considerable height. Therefore, their scope is the supply of water from wells, wells, and also on their basis it is possible to mount an autonomous water supply system even two-story house. The Marina 100/25 pumping station costs about 15,000 rubles;

- RSM series pumping stations, providing good water pressure, it is advisable to use for organizing water supply at home with short distances to a water source, for irrigation, washing cars, etc. The price of the Marina RSM 5/25 pumping station is about 1600 rubles.

Thanks to high quality, relatively low price, simplicity and reliability of Italian pumping stations, they are in great demand. Their advantages:

- small size;

- low noise;

- ease of installation and adjustment;

- availability of spare parts and high maintainability;

- reliability of work;

- autonomy, does not require constant supervision;

- dry running protection.

![]() The disadvantages of these pumping stations include:

The disadvantages of these pumping stations include:

- the difficulty of adjusting the pressure switch, but there is detailed instructions to the Marina pumping station, which helps in solving this issue;

- rapid corrosion of the tank flanges in case of condensate formation on it. This problem is solved by additional processing of the flanges with a corrosion-resistant material, for example, simple mounting foam;

- opportunity to work only clean water free of sand, mud and algae. But in practice, the station operates in water with impurities, but this reduces its service life. There are filters for water purification.

We will also give the opinions of buyers - reviews of the Marina pumping station can be found without problems, due to the popularity of equipment of this brand.

Petr A., 48 years old, Surgut:

There is a pumping station Marina APM 100/25. Works great - evenly, and delivers water without interruption. The station, of course, hums a little, but we don't hear any noise from the basement. For interest, I noted the time: I pumped up a tank of 120 liters in 7 minutes.

I am very pleased with the purchase - there are almost no problems with the installation, the factory settings are quite suitable.

Anton, 30 years old, Samara:

For several years we have been using the Marina pumping station to supply water from the well to the house on the second floor. I will note the advantages: good performance, compact size, ease of installation and operation - the automatic mode of operation makes it possible to simply use tap water.

For 4 years there were no repairs and failures. Good device.

Equipment overview (video)

Faults and their elimination

Like any operating device, there are malfunctions of the Marina pumping station. These can be pump breakdowns, a malfunction or imbalance of the pressure switch, problems with the accumulator or pipelines.

It is better to entrust the difficult repair of the Marina pumping station to specialists from the service center, but you can also diagnose a malfunction and carry out minor repairs on your own.

- If the station is turned on, it works, but the water does not flow - there may be several reasons:

- the pump is not filled with water. It must be filled through a special hole;

- large output between the casing and the impeller of the pump. In this case, you will have to buy new ones, fortunately, spare parts for the Marina pumping station can be found without problems;

- low voltage in the network. This problem is solved by installing a voltage stabilizer.

- The pump does not turn off at all or turns on very often:

- the membrane of the Marina pumping station was torn. It is easy to replace it by buying the right one;

- low air pressure in the hydrocollector. In this case, it is necessary to quickly pump air into the tank through the spool located on it. The pressure in the tank should be about 1.5 bar;

- The pressure switch is not working properly. In the event of a relay failure, the repair of the marina pumping station will consist in replacing the entire assembly. If the pressure switch requires adjustment, the instructions for the Marina pumping station can help in this case.

- You can hear how the pump works evenly, but the water is supplied intermittently. Most likely, air is leaking somewhere - at pipeline connections or due to low water levels in the reservoir.

- The pump hums but does not work.

- this happens after a long storage of it without use. Try turning the pump impeller with your hands;

- perhaps just insufficient voltage in the network;

- the capacitor has failed.

- The pump does not turn on at all. The pump motor may have burned out, this can be understood by the smell of burning near the device. In this case, it is more correct to entrust the repair of the Marina pumping station to experienced craftsmen.

Self-adjustment of the Marina pumping station is easy to implement. The instructions contain a diagram of the Marina pumping station, where you can see the main components and parts of the apparatus, as well as how to install and configure them.

In order for the station to work for a long time, it is important to regularly check the pressure in the hydraulic tank in order to preserve the membrane. Every few months, check the correct operation of the pressure switch using a pressure gauge. Timely inspection and prevention of malfunctions will save you from repairs.

Often, the entire repair consists in replacing a failed node. Spare parts for the Marina pumping station are easy to purchase in specialized service centers or stores selling pumping equipment.

So, the Marina 100/25 pumping station may require the replacement of tank flanges due to corrosion. The price of this part is slightly less than 1000 r. The pressure switch costs about 1500 r. The work of specialists itself costs from 400-600 rubles - for diagnostics. About the same amount for minor repairs.

The Marina pumping station is a complex of interconnected equipment designed to take water and transport it through a pipeline.

Fluid is taken from wells and wells through a hose immersed in the source, and the pump itself is located on the surface.

1 Description of Marina pumping stations

Marina pumping stations are designed to supply water in the "automatic" mode by the manufacturer Speroni Marina (Italy). With the help of such a setup, autonomous system water supply in a private house, increase the pressure of water from the central water supply, carry out watering personal plot or pump water out of the tank.

Key components of the Marina pumping station:

- Pump - main element stations; various modifications are mounted in terms of performance and principle of operation.

- Hydrocollector - a membrane tank (25-100 l) for the accumulation of technical or drinking water.

- Manometer - monitors the water pressure in the pipeline.

- Pressure switch - turns off the pump after the water supply stops.

- Pipeline accessories.

When buying a pumping station, the characteristics of the water source, the water level in it, its depth, the distance from the well or well to the place of consumption and the number of water intake points are taken into account.

1.1 Connecting equipment

The design of the Marina pumping station does not include a check valve, so you need to install it yourself. To prevent the reverse movement of water in the event of an emergency shutdown of the engine, the valve is located on the outlet pipe of the pump. It also does not hurt to install a coarse filter on the inlet pipe, which will reduce the amount of harmful impurities that reduce the life of the equipment.

Connecting these nodes does not require special skills and equipment and can be done independently.

To begin with, install the pump near a water source, and place it on a stable solid base to avoid vibration during engine operation.

After that, a suction hose is connected to the pump, which is immersed in the source of water intake. Stations are diverted from the accumulator plastic pipe, which will supply water to the house, and connect it to the indoor water intake points.

Next, they check the performance of the system: turn on the pump and fill it with water through a special hole in its neck. During operation, the pump supplies water to the accumulator. As soon as it is filled, the pressure switch will work and the engine will turn off. After processing the water with a hydraulic accumulator, the relay determines how much the pressure in the line has dropped and turns on the pump. So the Marina pumping station (Italy) supplies water to the house automatically without external intervention.

1.2 Marina pumping station: device, cleaning, start-up (video)

2 Marina pumping stations: models and characteristics

Trade brand Marina (Italy) manufactures surface and submersible pumping stations for domestic use and you can purchase a water, drainage or fecal pump, as well as special installation for irrigation or fountains. All pump equipment of the manufacturer is divided into two conditional groups:

- Models that only work with clean water– SVM, SCK, SCM, SKM. Equipped with Marina SCM 100-10 pump or MarinaSVM submersible pump. The surface pump Marina KS 801/P also works with clean liquid. Only for a clean working environment is the Marina APM 100/25 pumping station with a capacity of 2.4 m 3 / hour.

- Dirty fluid models - TF, STF, ECMDS, SXG. Drainage included submersible pump Marina SXG 1100

Marina pumping stations come in the following modifications: CAM, ARM and RSM. The cost of stations depends on the specific model, pump power and volume of the accumulator.

2.1 Characteristics of the categories

Marina APM: at stations of this category, an injection or ejector pump is installed, thanks to which the Marina APM 200/25 pumping station raises water from a depth of 50 meters, and Marina APM 100/25 can pump water from a well up to 25 meters deep (equipped with Speroni pump APM 100).

marina cam: these units are based on self-priming centrifugal pumps Marina (Pump Marina CAM 100/A-HL, Pump Marina KPM 50 SET), so the maximum suction depth is not more than 6-7 meters. This series of stations is the most diverse. The main differences between the models are the performance of pump equipment and the capacity of the hydraulic accumulator. The capacity of these stations reaches 60 liters per minute.

So, pumping unit Marina 40/22 is made of high-strength cast iron, its capacity is 50 liters per minute, and the volume of the accumulator is 22 liters. Station Marina CAM 80/22HL processes 60 liters of water per minute and is made of stainless steel. The Marina CAM 100/25HL stainless steel pumping station is considered more powerful: the throughput is 4.4 m 3 / hour, and the tank capacity is 25 liters. Pumping stations of this series solve the widest range of household tasks: from watering a personal plot to increasing pressure in the central water main.

Marina RS: this the lineup equipped with multi-stage pumps providing water pressure in the system up to 100 l / min, with a small suction depth (no more than 7 m). Thus, the Marina RSM 5/60 pumping station creates a head of up to 60 m and a maximum suction depth of 4 m. With the help of RSM installations, it is advisable to organize water supply when close range water source to the point of supply.

2.2 Advantages and disadvantages of pumping stations

All Speroni pump units (Italy) have a number of advantages:

- affordable price;

- small dimensions and weight;

- ease of installation and maintenance;

- low noise level;

- do not require constant supervision, since they work completely in automatic mode;

- protected from "dry running";

- it is not difficult to purchase spare parts for the Marina pump - drainage or water.

Along with this, there are also disadvantages of the equipment:

- accumulator flanges are susceptible to corrosion if condensate forms on them. The solution to this problem is to additionally treat them with a corrosion-resistant material;

- it is difficult to regulate the pressure switch, but the user manual helps to cope with this task;

- stations designed to work with clean water must be additionally equipped with a filter, since impurities reduce the life of the equipment.

3 Terms of use

Speroni equipment (Italy) is not designed to work with water, the temperature of which exceeds 30 0 С. If this condition is not met, the station may fail. After the end of the season, water must be drained from the tank, and the station itself must be transferred to a room with a temperature not higher than 40 0 C.

To prolong the life of the unit and the safety of the membrane, it is necessary to regularly check the pressure in the tank. Also, once every few months, it needs to be checked with a pressure gauge and pressure switch.

If a complex breakdown occurs, it is better to entrust the repair of the pumping station to specialized specialists. You can deal with minor problems on your own.

3.1 Types of malfunctions and methods for their elimination

The station is running, but the water is not flowing:

- There is no water in the pump. In this case, water is poured through a special pipe.

- Between the pump housing and its impeller formed a large output. Repair of the pumping station will consist in the acquisition and installation of new spare parts.

- There is a weak voltage in the network - you need to install a stabilizer.

The pump runs continuously or turns on frequently:

- Breakage of the membrane - the part is changed to a new one.

- The pressure in the tank has dropped - they pump air into the tank through a special spool. Optimal pressure in the hydrocollector - 1.5 bar.

- The pressure switch does not work correctly - the repair of the pumping station in this case consists in replacing this unit. You can adjust the relay according to the user's instructions. This operation is performed with the equipment turned off. Before starting the adjustment, all the water is drained from the tank and the air pressure level is checked: if it is high, it must be bled to the optimum value.

The pump hums but does not pump water: the main reason may be that the device has been stored without use for a long time. To eliminate this problem, it is enough to manually scroll the pump impeller. Also, there may not be enough voltage in the network. One of the reasons for this malfunction may be the failure of the capacitor. Repair of the pumping station consists in replacing it with a new spare part.

If the pump does not turn on at all, then this indicates a breakdown of its engine. In this case, it is necessary to entrust the repair to the specialists of the service center.

Regular inspection and preventive maintenance extend the life of the equipment and save users from breakdowns.