Reinforced concrete cable trays and heating main trays of all standard sizes according to affordable prices with delivery in Moscow and the region. Quality assurance from RusGradStroy.

Drawings of reinforced concrete trays

Speaking about such a reinforced concrete product as trays, it is worth saying that, like other reinforced concrete products, they are made on the basis of reinforcing cage covered with selected medium-density concrete. Although in the manufacture of manufacturers can use different grades of concrete.

For example, trays for irrigation canals with a water flow rate of up to 5 m3/s should be made of heavy concrete with a density of 2200-2500 kg/m3.

All reinforced concrete trays are marked with the appropriate marking and are produced in accordance with GOST 23009-78. In addition, reinforced concrete trays are conditionally divided into two types:

- Products laid in the ground, which in practice are designated as LRG;

- Which are mounted on piles, special supports, slabs, etc. - denoted by the abbreviation LR.

No matter what type you buy, be it: heating main trays or industrial pipelines, they are subject to the same requirements.

First of all, reinforced concrete cable trays for heating mains and pipelines must be waterproof. But this quality is quite easy to achieve if you follow the manufacturing technology of reinforced concrete products and use only high-quality raw materials.

Yes, for making quality concrete you need selected sand, gravel and granite, high-quality cement and, of course, water. Although these ingredients are only suitable for the preparation of "classic" or "traditional" concrete. But after all, many manufacturers struggling to save production and reduce the cost of concrete can use a lot of other natural and artificial materials.

However, you should not worry that the concrete prepared at different enterprises will be unusable, because all concrete used for the production of trays must comply with GOST 10268-80.

Therefore, concrete for any products must be made from Portland cements of at least grade M400. However, this condition is relevant for engineering systems, which are used in any environment, except for aggressive ones. If we are talking about trays that are placed in soil with an aggressive environment, then sulfate-resistant Portland cements must be used in the manufacture.

During the construction and installation of heating mains, the main pipes through which the hot water must be placed in special protective trays.

Whatever the pipeline system of heat carriers, ground or underground, in any case, its elements must be protected from moisture or severe frosts. For this, boxes from trays are used, inside which pipes of the heating main pass.

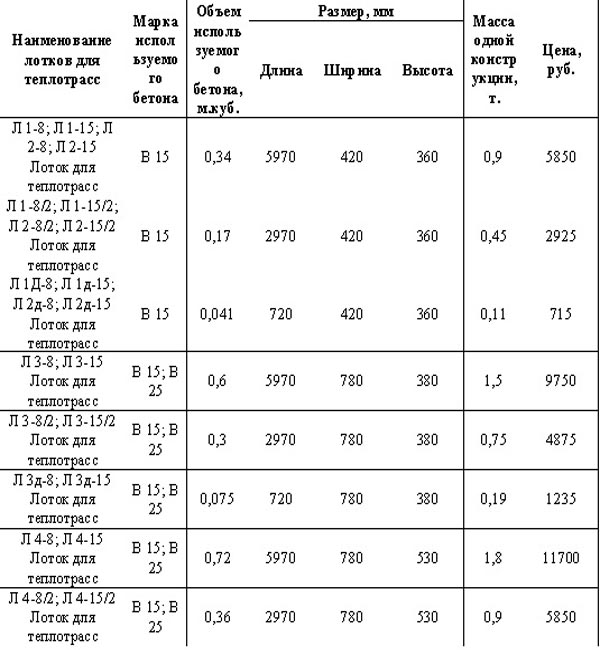

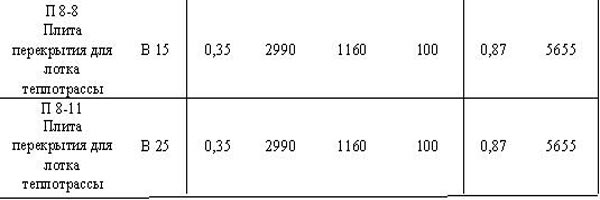

To have a complete picture of the dimensions of such concrete or reinforced concrete products as trays for protecting heating mains and the prices for such products, you should consider the table of relevant parameters:

Photo: sizes and prices of trays for heating mains

Photo: sizes and prices of trays for heating mains Pricing for the cost of trays for heating mains depends on their size, which the market presents in a very wide range.

The above dimensions and prices are only the most basic groups of trays, but there are also many other sizes that are used in different types construction.

Any of these trays will perfectly ensure the safety of any heating pipeline and protect against soil mobility, aggressive environments of soil composition or precipitation, as well as from the influence of temperature differences.

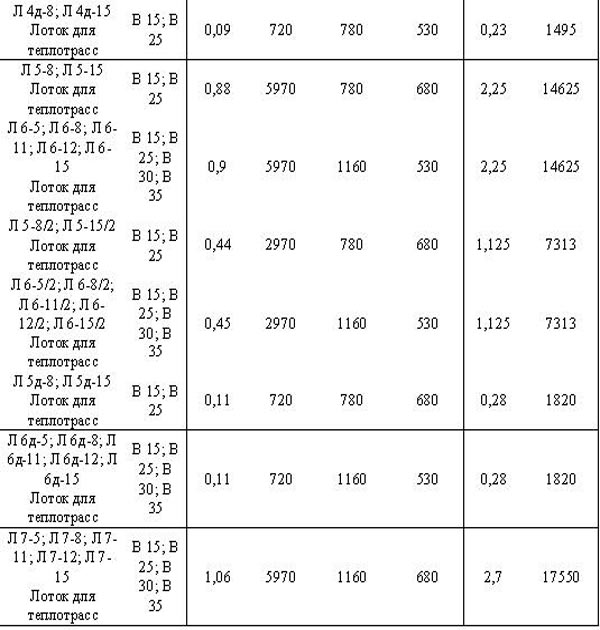

Dimensions according to GOST and prices of slabs for covering trays

Like any box, the design of the trays in without fail requires laying over the floor gutter. This must be done so that when filling with earth, it does not fall directly on the pipes.

Otherwise, the whole meaning of the idea of \u200b\u200bthe room is lost. pipeline system into trays. Overlappings for trays are rectangular slabs of concrete or reinforced concrete, which must necessarily correspond to the dimensions of the concrete trays themselves.

Important! In addition to overall parameters, floor slabs must necessarily be made of concrete of the same grade as the trays.

This will preserve the integrity of the material structure of the entire box, consisting of a tray and a ceiling, which will be able to last for more than a dozen years.

Market building materials offers the following plate sizes:

- plate length - found 740-2990 mm or more;

- plate width - found 400-2460 mm;

- height (or thickness) - found 50-160 mm;

- the weight of one unit of the plate is 100-2940 kg.

However, before any design construction works it is necessary to make preliminary calculations. But for such calculations, information is always required on the dimensions of the plates for the trays and their prices.

To understand what approximate prices exist for certain tray floor slabs, you can familiarize yourself with selective information about their parameters and costs:

Photo: information about the sizes of plates for trays and their prices

Photo: information about the sizes of plates for trays and their prices Thus, the larger and thicker the plate, the more expensive it will be. After all, much more raw materials are spent on its manufacture, which means that the price, respectively, will become more than for the plate, which is thinner and smaller in size.

Thanks to preliminary information on the cost of floor slabs, it will be much easier to plan construction and make calculations for laying heating mains in trays.

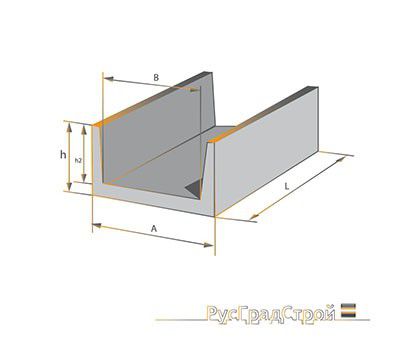

Scheme

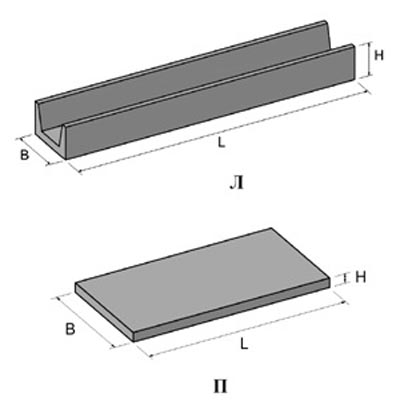

Schematically, the trays for heating mains look like they are concrete gutters with the letter “P”. In fact, it is so.

Rectangular trays are used for laying in the ground in order to lay heating or hot water pipes inside them. Height refers to the height of one side of the gutter.

The sides are low, and there are very high - it all depends on how many pipes they will be used for. The same is true with the width of the tray, especially the inner width.

After all, this parameter also differs according to the criterion - for how many pipes, and what diameter the use of the tray is calculated.

Photo: trays for heating mains schematically

Photo: trays for heating mains schematically The overlap parameters for the tray must necessarily match the parameters of the tray. So, for example, the width and length of the floor slab should be the same, and their outer walls should either match end-to-end, or the dimensions of the slab should be slightly more sizes tray walls.

Everything should be done in order to close the tray with pipes passing inside it like a lid. Thanks to this protective system, not only pipes remain intact for a long time, but also their thermal insulation.

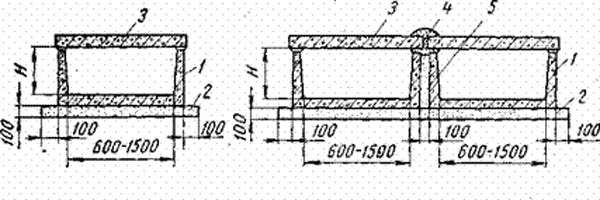

Important! It should also be noted that trays can form different type channels. But, first of all, it must be said that these channels are impassable and do not at all look like collectors, inside which not only pipes are laid, but also, if necessary, workers can move.

Trays are used only for impassable channels of thermal or water networks. For a small number of pipes with a small diameter, it is sufficient to use single-cell or two-cell structures from trays and ceilings.

The pipes are laid in the tray element, and then the tray is covered with a plate from above, like a lid.

Photo: single-cell or two-cell tray structures

Photo: single-cell or two-cell tray structures Such structures are called - impassable CL channels - they consist of such elements:

a) single-cell box;

b) two-cell box;

1 - tray;

2 – sand cushion for the installation of the box;

3 - tray floor slab;

4 - fixing dowel made of cement;

5 - sandy layer.

In such pipeline communications, pipes for supply and return purposes usually pass.

Therefore, they perfectly fit in such structures, while maintaining the integrity of the thermal insulation of pipes for a long time and preserving their surface from aggressive effects. ground water, soil composition or atmospheric precipitation.

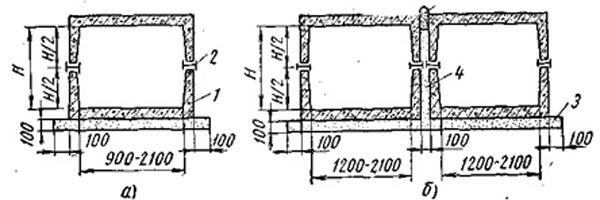

However, not always all communications of heating mains can fit in a tray element in the form of a gutter.

You have to either buy too expensive huge trays, or use a cheaper option - install two trays on top of each other using an I-beam, a special mounting profile, the cross section of which is in the shape of the letter "H".

The I-beam turns out to be a kind of connecting element that forms a lock between two concrete trays installed on top of each other, with the bottom apart and the capacity of the gutters inside.

Photo: two trays are stacked on top of each other using an I-beam

Photo: two trays are stacked on top of each other using an I-beam Such building solutions allow you to organize a box for laying pipes in it. large diameters and more pipelines, if necessary.

Channels of this kind are called - impassable class KLS - and consist of the following elements:

a) single-cell two-part;

b) two-cell two-part;

1 - tray made of reinforced concrete;

2 - connection - I-beam;

3 - sand cushion;

4 - sand layer in the gap between the trays;

5 - fixing key made of cement.

If passage channels are built from large trays, then a narrow tray is installed inside it to drain water from the channel.

It is strictly forbidden to allow flooding with groundwater or meltwater in the space of the box where the pipelines of heating pipes are laid.

The situation is exactly the same with impassable channels, which must be hermetically sealed or cemented on the sides at the joints, if these are two-piece structures consisting of two trays.

Any preparation or design of such construction works for the installation of heating main trays always requires careful attention. When calculating, you should know not only the cost of materials, but also suitable sizes trays.

The floor slab is conditionally designated by an alphanumeric combination.

- They indicate the type of product, the serial number by size and the calculated equivalent load in tf / m2.

- Additionally, the letter "a" denotes the brands of plates, whose working reinforcement is located in the upper zone and these plates are the bottoms of the channels.

- Plates of intrashop channels with a small depth are marked with the letter "b".

- If necessary, the resistance of the plate to aggressive media is indicated by the letter H. Additional plates are marked with the letter “d” at the end of the marking.

- Slabs with a length of 1495 are marked as /2.

As an example of plate marking, consider P 6 / 2-15 b (1495x 780x 120 mm), where:

- П - slab of overlapping of channels from tray elements;

- Digit - serial number of the size;

- Number - design load index;

- a - channel bottom plate.

Tray and channel overlapping slab - a rectangular slab for covering channels, tunnels, thermal chambers from tray elements. The task of the slab is to maintain tightness and protect underground channels engineering communications from destruction of insulation, collapses of soil and moisture ingress.

Floor slabs are placed on trays, and then welded with metal brackets. Some slabs can play the role of the bottom of the channels, being laid under inverted trays. The slab is produced as a flat square, the upper edge of which may be slightly smaller than the bottom - this shape allows better distribution of the vertical load.

The floor slab is used both in aboveground and underground channels, and laid under the sheets of iron and highways. The depth of such channels under the soil layer is from 0.5 to 6 meters. And this means that the coating plate must withstand sometimes enormous loads. The material helps to transfer vertical temporary and long-term loads to the slab - heavy concrete B 25 (M200-300) and high-quality steel reinforcement classes A-I and A-III. Reinforcement of floor slabs is carried out welded meshes and frames made of bar reinforcement and wire, the frame is laid under protective layer concrete 15-20 mm.

Plates intended for operation under the eroding effect of groundwater are additionally protected against corrosion. For this in concrete mix special additives are added. Thanks to them, the plate can long term resist the effects of aggressive chemical environments. Anti-corrosion treatment also have all the embedded products of the plates.

Mounting of plates takes place using the method of loopless mounting using sling holes. Less common are slabs in the design of which mounting loops are laid.

Channel tray covers are characterized by increased frost resistance (F300), which allows the plates to be transported frequent drops temperatures characteristic of middle lane. high class waterproof together with high-quality waterproofing guarantees dryness to the channel. The seams and slings between the tray elements and floor slabs, after welding the brackets, are sealed with mortar or mastic, and the channel is hydro and vapor barrier.

Channel slabs of the P series are not recommended for covering buildings. The solid shape of the slab does not allow manholes and other vertical holes to access the channel. Therefore, when constructing such a corridor, slabs with OP holes are also used. For ease of cleaning, intrashop drainage systems are arranged with ceilings made of removable shields.

Transport and storage

Coating slabs, unlike most reinforced concrete products, are transported in the “on edge” position. Stacked concrete plates should not be higher than 2.5 meters. Under the bottom row of slabs, on a leveled base, it is laid wood spacer with a thickness of at least 3 cm. Products are transported by various means of transport, securely fastened, using gaskets and linings at the locations of the lifting loops.

Spaka Enterprises LLC manufactures and sells reinforced concrete products - reinforced concrete products that are widely used in the construction industry. The presence of modern production facilities provides an opportunity to produce a wide range of quality products. Thanks to multi-stage control, the customer receives reinforced concrete products that comply with all applicable norms and standards.

Our company manufactures and sells optimal prices the following concrete products:

- pillows FL for strip foundations;

- driven piles;

- FBS foundation blocks of various brands and sizes;

- rings of wells for water, gas pipelines, communication networks, sewerage;

- floor slabs of all types;

- landings and marches;

- airfield and road plates;

- runs and beams;

- heating trays.

In addition to the listed concrete products, we produce and sell other reinforced concrete products, and also offer to buy non-metallic materials - cement, sand, expanded clay. A complete list of materials is presented in the catalog on the pages of the site.

Advantages of reinforced concrete products from Spaka Enterprises LLC

The company uses exclusively high-quality raw materials, special additives and components in the manufacture of products. The production of reinforced concrete products is based on the use functional equipment and the latest technologies. Our products are strong, durable, reliable and meet all established requirements.

The company employs highly qualified specialists who strictly comply with the standards. Competent managers will help customers to choose concrete products for the construction of objects for various purposes. An individual approach to the requirements and wishes of the customer provides an opportunity to effectively solve problems of varying degrees of complexity.

Other advantages of buying concrete products from us:

- Products fully comply with TU and GOST.

- Detailed consultations are offered when buying reinforced concrete products.

- A personal manager accompanies the order until it is fully completed.

Dial our contact number in Moscow and order reinforced concrete products with delivery to the site!