A bathhouse, which is used only in the summer, can do without insulation. Insulation, as well as ventilation in the dressing room and bathhouse, are, however, necessary if these rooms are used throughout the year.

Ventilating the air will avoid the consequences of high humidity (mold, mildew), which will make it possible to save the wood from rotting and extend the life of the bathhouse. The ventilation system also ensures quick heating of the steam room.

Arrangement of the waiting room

The room must be warm enough, so you will need to insulate surfaces, including walls, floors and ceilings. You also need to organize heating and a supply and exhaust ventilation system.

Floor in the waiting room

In order not to spoil the feeling after the bath, the floor in the dressing room should be insulated. Typically, sanded and treated wood is used as flooring material. Special processing wood prevents the formation of fungus and mold that can appear in high humidity.

Thermal insulation of the floor is carried out as follows:

Waiting room ceiling

Ceiling insulation is carried out according to similar principles used for floor insulation. However, the choice of insulation here is more diverse and allows for both cheap and expensive materials. Basalt wool is considered the best option, as it is characterized by high fire safety and moisture resistance.

The main purpose of ceiling insulation is to reduce heat loss, as heated air is directed upward. Based on this goal, we use foiled polyethylene to reflect heat, the seams of which are treated with reinforced tape. We attach polyethylene to wooden blocks to the ceiling. We cover the ceiling with 120 mm clapboard.

Waiting room walls

Insulation interior walls We do it with our own hands like this:

We do insulation from the outside as follows:

- We use lathing from wooden block along the height of the wall. We place boards below and above, to which we attach the bars with metal corners.

- We place mineral wool between the bars.

- We lay a vapor barrier and glue the joints with tape.

- We arrange another lathing on top for facing work.

Windows can be of any size. Best option- double frame made of wood or double glazing.

Reasons for the formation of condensation in the dressing room

As a result of the difference between the temperatures in the dressing room and the steam room, condensation appears.

The following factors lead to the formation of condensation:

- the dressing room is too cold;

- the ventilation system is not equipped correctly;

- The outside temperature is too low.

Thus, to overcome the condensation problem, it is necessary to provide high-quality heating and ventilation.

Ventilation system in the dressing room

The functioning of ventilation in the dressing room is ensured both by the flow of air through window and door openings, and through special vents made in the wood. Air flow is regulated by special sliding plugs.

The size of the vents is usually 15-20 centimeters. The lower vent is located approximately 50 centimeters from the floor and not far from the combustion chamber. The second vent should be with opposite side, approximately 2 meters from floor level.

Forced ventilation of the room can be created using a fan installed in the exhaust hole. This device will make the removal of moist air more intense.

Waiting room heating

The ideal scheme is if one of the walls goes into the dressing room brick oven. In this case there is no need to create separate heating in the dressing room. However, a small heater will not be enough to heat all the rooms of the bathhouse. In such a situation, you can use any of the following types heating:

- You can use pipes that are laid through the combustion chamber to the compartment with stones. The essence of the idea: hot steam air enters the dressing room after watering the stones with water, and the steam itself remains within the steam room.

- You can install a system of air channels passing through all rooms of the bathhouse and equipped with valves.

- If the area of the dressing room allows, you can install an additional stove.

Advice! To prevent wood rotting, it is recommended to dry the wood after each heavy moistening.

Thus, to avoid excessive moisture and condensation, only ventilation of the waiting room is not enough. A set of measures is needed where, in addition to ventilation, it will be provided high-quality insulation premises.

When starting the construction of a bathhouse, each builder must clearly take care of quality. As a rule, a building of this type must be heated periodically, and it is intended for long-term use. Hours spent in this wonderful place are bound to bring physical and mental satisfaction. Proper ventilation in the dressing room can quite cope with such tasks.

No one will argue that the process of ventilating this room is capable of regulating the degree of air humidity, coordinating the ambient temperature, filling it with clean air and heating it. Of course, this cannot be done without significant financial costs.

Calculation of required parameters

It is known that the ventilation of this building is directly dependent on the operation of the stove. Taking into account the fact that the area of the steam room is calculated based on the parameters for each person of 4 meters square. Many people are divided on the height of the ceiling. While some make it minimal, others decide exactly the opposite.

Of course, a small and low room heats up much faster. However, it will be difficult to be in an excessively cramped bathhouse; in a bent and uncomfortable position, your back and shoulder girdle will quickly get tired. Still, a small amount of space must certainly be above your head. In this case, you can wave a broom without any problems and enjoy taking a steam bath.

Ventilation in the bathhouse vestibule itself, relating to the firebox of the room, is located in the underground zone and appears to be a specially constructed channel. Its removal can be observed in the place where there is a metal sheet that protects the bathhouse from possible fire.

Return to contents

Ventilation device: features

The construction of the ventilation duct is associated with the systematic operation of the duct, the diameter of which will be larger than the chimney within 20%. In this option, oxygen will fill the room. The flow of air from the underground is completely eliminated. The bathhouse will always be fresh and clean.

In addition, such ventilation may also have an underground purpose. The ventilation box will be located on outside buildings and clearly go outside. WITH inside it is closed with a special grille, and from the inside with mesh material that protects against insects.

The presence of a firebox in the steam room indicates the construction of 2 such boxes, each of which performs its own functions: the first lets air into the room, and the other acts as convection. Arranging a podium would be a very comfortable purpose. For such purposes, near the wall with supposed ventilation, a row of bricks in 3 rows is placed on the side. Its height should correspond to 24 cm. This method is built up to the brick screen. Upper part should be covered with bricks. Bricks are not laid at the location of the furnace. In this way, air flows should enter under the oven. Then the end part is mounted. Another box is built to its logical end; the stove ash is fixed in the end part. To ensure that the floor surface remains intact and is not damaged by accidental hits, something is placed under it.

When the podium is built, a furnace is installed on its base. Built in corner space The heating structure allows you to systematically limit the loading of the brick box. It is possible to install the furnace at corner points on iron plates. After this, the heated equipment of the bath should be lined and erected protective screen made of brick. It must be equipped with two doors. They provide the steam room with high-quality ventilation and uniform heating of the air.

Return to contents

Air outlet: additional points

All the heated walls of the stove in the sauna dressing room, called mirrors, are located near the floor.

In this way you can warm up this part of the building well. Floor heating is obtained due to the radiation of infrared rays from a radiant mirror.

The arrangement of the shelves differs in some nuances: they do not have to be in a vertical position and block the heat from this element in ceiling area. Furnace equipment is certainly equipped with chimneys in several versions. This will help in the best possible way absorb heat during fuel combustion.

Sometimes, during the process of warming up the bath, you can observe a large amount of smoke in the room. In this case, we can talk about the presence of cooler air in the room compared to the outside temperature. As is known, cold air much more massive than the warm one, so its weight is greater. A cool layer of air appears in chimneys. It must be pushed in order for the stove to be lit. For such purposes, it is imperative to build a door in the outlet pipe of the stove to help remove unnecessary ash. You can burn paper there. These simple tips will help rid your sauna stove equipment of excess smoke.

The absence of such a device gives rise to the possibility of ventilating the locker room in the usual way - simply by opening the doors for a while. Once the temperature is balanced, the stove will heat up. It is quite possible for the stove to re-ignite.

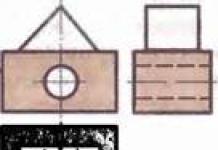

Bath ventilation options: a – air intake above the floor; b – air intake from above; c – air intake from under the floor; d – air intake from the recess.

In such rooms of a small area, the dressing room can serve several purposes simultaneously. This room is a room for dressing and undressing, resting after procedures, and a transition area for going outside. This room can also be adapted for storing firewood. Here you can install washing machine. When calculating the dimensions of this room, it is necessary to assume how many people will take water procedures here. It is necessary to take care of the convenience and comfort of people. They should be able to undress and dress without difficulty.

Speaking about window openings, it should be understood that they must be of medium size, their location should not be lower than 1 m from the floor surface. For better heat retention, it is necessary to take care of double glazing of these structures. The doorway should be well finished and usually opens outwards. The materials for its manufacture will be traditional bases. The door in the dressing room should be upholstered with outside. Additional equipment verandas will also bring significant convenience to the use of this room. In this part of the building you can relax comfortably by placing necessary furniture. In addition, the veranda will retain the heat of the bath.

Very often, the equipment of a bathhouse is related to the location of the heating in next room. This is often done when building a Russian bathhouse. Ventilation with this method is calculated based on these facts:

- comfort of service;

- absence of smoke, litter and burning in the room;

- there is no need to add firewood every time, moving throughout the entire bathhouse, thereby letting in cool air;

- by heating the steam room, you can also heat the adjacent room; the temperature of the hot compartment should not be subject to changes;

- you can stack and store firewood without any problems;

- as a result of installing a door made of tempered glass you can add some zest to the interior design; You can put a fireplace here, as the moving flames are noticeably calming nervous system, creating additional comfort and peace.

To combine the stove with the firebox in the next room, a slot is made from the plane of the wall, which is 3 cm larger than the tunnel for the firebox, trimmed with brick. After this, warming measures are carried out using basalt wool. This material ensures that the wall does not come into contact with a very heated stove, therefore it is protected.

Right installed ventilation will ensure the comfort and safety of bathhouse visitors.

Regardless of the type of bath, ventilation is installed according to general rules and engineering requirements for bathhouse premises. Read below about the ventilation system of the bathhouse and its nuances.

- Ventilation ensures the comfort and safety of visitors

In an hour, one person emits up to 18 liters of carbon dioxide. Without ventilation in a small, crowded steam room, the concentration of carbon dioxide will reach life-threatening levels in a short time. Removed from the room through ventilation carbon dioxide and oxygen comes in.

- Ventilation is necessary for the sauna to operate.

According to the laws of physics, wood in the firebox will burn only when oxygen is supplied. The oxygen supply system is installed separately from all ventilation.

- Proper ventilation will extend the life of the room

Moisture concentrated after the bath has been in operation negatively affects the structure, causing fungus and mold. Ventilation will prevent moisture accumulation.

Ventilation standards

Air exchange in steam rooms and saunas is calculated according to several standards.

By building regulations, exhaust hood for public buildings is calculated based on a frequency of 1 time per hour. For dry heat baths, a frequency of at least 5 times per hour is recommended.

It is possible to control standard indicators only when using forced ventilation. Natural air exchange depends on natural factors. Ventilation in the dressing room is carried out based on the same air exchange standards, but the minimum amount of air for one person is also used - 30 m 3 / h.

The ventilation scheme in the bathhouse takes into account the direction of supply and removal of flows and complies with the following principles:

- Fresh air is supplied close to the firebox; it is preferable to ventilate the floor in the bathhouse to allow oxygen to enter the furnace;

- Air distribution devices (grills and diffusers) for organizing air exchange are made of wood, which does not emit harmful substances when heated;

- During installation, a standby hood will be organized, which will operate continuously during periods between use of the steam room.

Types of ventilation

Bath ventilation is divided into two groups:

- natural ventilation, operating under the influence of natural factors without the use of electrical equipment;

There are many reasons for the formation of condensation in a bathhouse, the main ones being:

Ventilation hole diagram

Ventilation hole diagram All these factors negatively affect the level of condensation, forming moisture on the walls, ceiling and floor, which can adversely affect the quality and strength of the materials from which the bath vaults are built.

Scheme of condensation formation in the dressing room

Scheme of condensation formation in the dressing room To avoid side effects from the effects of condensation on the surface, you should know what to do to save the room. They will help with this special means, equipment or just proper care behind the bathhouse space.

Condensation is not just innocent moisture on surfaces. Due to this phenomenon, the following may occur:

All these moments are extremely unpleasant for those who have erected a wonderful structure for a pleasant pastime in their private sector.

Insulation scheme various rooms in the bathhouse

Insulation scheme various rooms in the bathhouse However, there is no need to sound the alarm if you think in detail about the methods of dealing with the “disease” of the room with high humidity, then everything will work out and you can forget about this problem forever.

The steam room is never separate standing element in a bath system, it is necessarily combined with several functional rooms. As a dressing room is a mandatory structure for bath complex, it is also necessary to comply with all comfort conditions. Ventilation in the dressing room is designed to provide this room with an influx of clean, oxygen-enriched air. Constant influx air in the dressing room is also necessary for effective drying of bath items.

Several systems are suitable for ventilating the dressing room: mechanical (forced), natural and combined. Forced mechanical ventilation consists of installing a fan in the room, which will pump clean air into the room.

The natural way ventilation consists of ventilating the room through open windows. It is advisable to open both windows and doors in the room at the same time.

The combined air ventilation system consists of installing compulsory system injection of clean air and exhaust air exhaust through the toilet or washing room.

Ventilation of the bath does not end only at the dressing room and steam room; it must also be installed in the washing room. Air circulation and condensate drainage will help prevent moisture from accumulating in the bathhouse sink.

Ventilation washing department has certain nuances. In addition to the clean fresh air that comes through ventilation holes, it is necessary to provide a vent in the floor. Specialized exhaust hole between roughing and clean version the floor is equipped with a fan, and exhaust pipe is displayed on the roof of the washing compartment of the bath complex.

Thanks to this ventilation scheme in the washing room, the greatest comfort for relaxation and washing procedures is achieved.

It doesn’t matter what type of bath complex is chosen for construction, high-quality installation air ventilation system- that's what's really important. In a bathhouse made of foam blocks, logs or frame steam room it is necessary to install only a combined or mechanical view ventilation, since natural ventilation does not guarantee the safety and durability of the structure.

Combined type Suitable for those steam rooms that are located directly in the house, and not in a separate room. There are several standard schemes organization of air inflow and outflow, depending on the type of steam room.

Combined type of ventilation - perfect choice for steam rooms located directly in the house

Most often, sauna lovers choose a Swedish type of construction for their steam rooms, called bastu. In such convection steam rooms, clean air is taken from the street, and it is also discharged to the street. The exhaust duct is installed under or next to the stove, and a damper is installed on the duct itself.

The box is installed at least thirty centimeters from the floor, and a pipe is led up the wall, which goes into a through hole right under the ceiling. A valve with a damper is also installed on the ventilation hole.

Air intake equipment is installed on the wall opposite the furnace. It is best to choose an air intake box made of wood.

Ventilation of the steam room according to the bastu type is carried out according to the following scheme:

- Cool, clean air from the street circulates along the stove from the intake duct, heats up and rises.

- As the stove heats up, warm air masses near the ceiling begin to gradually put pressure on the cold air at the bottom of the room and gradually warm up the walls of the steam room.

- Hot air masses press against cold air and gradually, increasing pressure forces hot air out into the vents.

The popularity of this type of baths is high due to comfortable conditions inside the steam room. And the undoubted advantage is the possibility of installing bastu at home, in any convenient location. There are even apartments equipped with baths according to this principle.

The principle that must be followed if you start building a bathhouse is to ensure air circulation and avoid stagnation. The supply and exhaust ventilation system is the most suitable option for a frame bath. It will allow clean air to move freely throughout all rooms of the bath complex, and will effectively remove polluted air outside.

Supply and exhaust ventilation perfect for frame baths

For proper operation The system requires two air channels. Using the first channel, clean air enters the steam room, and the second provides effective removal heated air. The first channel must be placed almost flush with the floor, when the second is placed right at the ceiling. This difference in hole placement provides effective traction. No holes need to install damper small sizes, this will allow you to control the movement of air masses.

Basic scheme for constructing ventilation for frame room includes: channels for pipes, pipes from the furnace, dampers, doors, through holes.

In frame wooden bath the principle of a supply and exhaust system is relevant only in the case when at least one wall has a connection with the street.

Since ancient times, the correct Russian bathhouse was built from wooden log house. Logs were used only from winter logs, since all its pores were sealed with resins and the movement of juices stopped. Such baths served for several decades, even with the use natural ventilation in the form of through ventilation.

Modern baths logs can last for hundreds of years, and it is not at all necessary to choose a certain type of log house, thanks to correct system ventilation.

Specifics bath room requires high-quality organization of the ventilation system. Large amounts of moisture, high temperature, hot water steam, residues of burning particles, smoke, combustion products in the air solid fuel etc. - all these factors require constant ventilation. At the same time this process should be carried out not only after the completion of the procedures, but also directly during their implementation. Ventilation in the dressing room is as important as for other sauna sections and is connected to common system ventilation.

Features of the bath

Differs in characteristics:

- Occasional use. Heated at regular intervals, not used every day. The rest of the time the temperature inside is not regulated. It is not a residential building.

- High humidity. When used, it is exposed to large quantity water, water vapor. Due to the large temperature difference, condensation may collect on the ceiling of the waiting room.

- Hot air. High temperature inside is one of the main characteristics of the bath structure. Hot air from excess humidity prevails inside the washing room and steam room. It makes it difficult to breathe freely and puts a strain on the body.

- Solid fuel. As a rule, it is heated with wood, the combustion products of which, along with the smoke, partially enter the building.

- Minimum windows. The building is always built with a minimum number of windows to avoid heat loss. The steam room is deprived window openings at all. Largest quantity windows are located inside the waiting room.

- Carbon monoxide. If the air exchange inside the bathhouse is not properly organized during its use, there may be a risk of carbon monoxide poisoning.

The need for ventilation

Ventilation must be done during heating, as well as after completion of all procedures.

For heating and direct use:

- ventilation helps to establish air exchange so that the polluted air flow leaves the room, being replaced by a cleaner, but warmer one;

- fresh air supply is needed directly for the furnace;

- adjustment of temperature and humidity specific air environment baths;

- maintaining more comfortable temperature inside the waiting room, relaxation area.

Ventilation after visiting:

- allows you to dry the bathhouse to prevent the appearance of mold and mildew on wooden finishing elements, accessories, etc. Excessive dampness in a poorly lit space can easily provoke mold and rotting of wood;

- long-term exposure to moisture wooden structures will lead to distortion of the original parameters and properties (for example, doors and window sashes will close poorly and loosely);

- The pores of mold fungi in a poorly ventilated room are in the air, there is a constant smell of dampness and musty air. This prevents you from feeling comfortable when visiting the bathhouse;

- ventilation after taking bath procedures is also necessary for the building itself. It will last longer and function better if it is thoroughly and regularly ventilated and equipped with a proper ventilation system.

Types of ventilation

Proper ventilation in the dressing room and other sections of the bathhouse is generally organized according to the same natural laws as the ventilation systems of other premises and buildings. Ventilation according to the supply method is:

- natural - the intake and removal of air masses occurs according to the physical laws of replacing warm air with incoming cold and heavy air;

- mechanical - does not take into account natural processes. Fans are installed inside ventilation openings and ducts to forced air exchange indoors;

- combined - combines listed species. As a rule, the exhaust is mechanical, the inflow is organized in a natural way.

Ventilation in the bathhouse is organized naturally using ventilation openings and window vents. After the visit, the doors are additionally opened for final drying of the washing and steam rooms, as well as the dressing room.

A forced ventilation system is installed if there are signs that the existing ventilation scheme is not effective:

- Condensation collects on the ceiling of the dressing room if hotter water vapor from the washing room or steam room gets there;

- the appearance of mold, initial signs of rotting wooden elements finishing;

- constant dampness that cannot be removed by ventilation;

- unpleasant smell of the bathhouse.

How is the ventilation of a bathhouse arranged?

Most often, the bathhouse is equipped with natural ventilation. Supply ventilation openings are mounted at the bottom of the walls, 10-15 cm above the floor level. If there is a stove with a firebox in the dressing room, the inflow is located close to the stove so that the incoming flow warms up without reducing the overall temperature inside the room.

In addition, under the finished floor should be placed ventilation duct, leading fresh air directly to the oven. The pipe entrance begins inside the foundation of the bathhouse, the exit is below, near the combustion compartment.

Supply openings are also located in the steam room. They are placed at the bottom (for the stove, if it is placed there), at the top for proper circulation air flows.

Exhaust vents remove excess hot, humid air and also carbon monoxide, if there is a possibility of its occurrence. They are mounted 10 cm below the ceiling, opposite the inlet openings or diagonally so that the air exchange covers the room area as fully as possible.

It is not recommended to install ventilation openings on the ceiling, as this will lead to rapid cooling of the bath room or dressing room. It is important to organize ventilation so that fresh air comes in regularly, replacing hot stale air, while temperature indicator the premises did not decrease and remained comfortable. You should also avoid a situation where the supply flow excessively cools the lower tier of the bath. The temperature transition from the upper to the lower tier should be gradual and not cause discomfort.

Requirements for dressing room ventilation

Proper ventilation in the sauna dressing room is organized with your own hands, following the criteria:

- supply, exhaust flows must be of the same volume;

- The direction of the air flow should be strictly organized from the dressing room to the bathroom or vestibule. When the air moves back, foreign odors may get inside;

- the outlet of the ventilation opening is located at a height of at least 2 m above ground level;

- if the hot air flow is removed from the steam room through air ducts, it would be advisable to use it to organize heating of other rooms of the bath;

- It will be effective for the waiting room combined system ventilation when installed mechanical hood, A supply air served naturally;

- the air exchange rate should be 3;

- Mounted fans must be moisture resistant.

How to make ventilation in the dressing room

It is not difficult to organize a ventilation system in the dressing room on your own, taking into account the basic patterns of natural air exchange. The easiest way to do this is when the foundation is being built, the frame of the bathhouse. Ventilation openings are provided for the foundation. Ventilation openings are also left near the walls, calculated in advance and commensurate with the layout of the future building.

Step-by-step instructions on how to properly ventilate a waiting room:

- The location of the steam room door is determined. It is best to place it closer to the stove to maintain temperature balance;

- an opening (15-20 cm) is laid on the opposite wall from the steam room door;

- the distance from the ceiling to the edge of the vent is 10-15 cm;

- the supply opening must be equipped with a sliding plug to regulate the volume of hot air removed;

- To improve the speed of removal of moist hot flow from the dressing room, it is recommended to install axial fan. It will create an area low pressure and the supply air flow will be drawn in naturally;

- Instead of an exhaust vent, you can install a ventilation duct that will take in hot, humid air and discharge it outside. This method is effective;

- on the wall opposite from the hood (or the diagonally opposite corner) an inlet opening of the same size is installed;

- height from floor to opening – 50 cm;

- if the stove firebox is located in the dressing room and the flow of fresh air is necessary for heating, a separate ventilation supply duct is installed. It is placed under the floor, starts from the opening inside the foundation, and is supplied directly to the combustion chamber of the furnace.

For the ventilation device in the waiting room to be effective, you must adhere to the following recommendations:

- additional ventilation in the bathhouse using window vents is desirable;

- the waiting room itself must be insulated, since when big difference temperatures, condensation may accumulate here (moisture, foggy suspension under the ceiling);

- ventilation openings are also necessary for the steam room so that high-quality circulation of air masses occurs;

- If possible, the waiting room should be made spacious at the rate of 1.3 m² per person, since smaller dimensions can create inconvenience and discomfort;

- the waiting area should be warm to provide comfortable conditions for relaxation after the steam room;

- there should not be a sharp temperature difference between rooms, as well as between tiers of air space;

- The supply channel, which supplies fresh air to the furnace firebox, is recommended to be made of galvanized steel, with a built-in plug that can be used to regulate the supply flow.

The level of comfortable conditions inside the premises, the service life of the building, and the microclimate, which directly affects human health, depend on how well the ventilation of the bathhouse structure is organized.

Friends! More interesting materials:

Ventilation in the apartment with your own hands. How to organize?

Ventilation in the apartment with your own hands. How to organize?