Hydraulic tests carried out after the completion of installation work, they are mandatory for pressure and non-pressure water supply networks. For testing, a pump is required that pumps in the water supply high blood pressure that detects defects. The data obtained is entered into the act of testing water supply. Only after signing the act, the water supply can be used.

Purpose and order of tests

Hydraulic tests of water supply and drainage systems are carried out to check the tightness, reliability of the water supply system and the detection of defective parts. Testing is prescribed before the commissioning of a newly constructed network or after reconstruction ( overhaul). All detected defects are immediately corrected, and the tests are repeated until a satisfactory result is obtained. Tests are carried out twice: first preliminary, after them final.

At the first stage, water is injected into the water supply under pressure, the pressure should be one and a half times higher than the working one. Preliminary hydraulic tests of water supply pipelines are assigned with full access to ground and underground parts highways, before the installation of plumbing fixtures.

Testing is scheduled before the final finishing of the premises. Hydraulic tests of water disposal and water supply systems are carried out by specialists from the plumbing service.

Before the final stage of hydraulic testing of water supply, underground sections are closed, all installation work the section is being completed, but plumbing fixtures have not yet been installed. The exits are covered with plugs. During hydraulic tests of cold water supply, the pressure in the mains is increased by 1.3 times compared to the working one.

- Hydraulic tests plastic pipelines water supply is allowed to be carried out a day after the end of installation, at positive temperature;

- To carry out hydraulic tests of weirs in the house, the pipes are completely filled with water to the top of the risers. Preliminarily visually examine the condition of the pipes and correct noticeable shortcomings. If the fully filled weir system does not leak for 20 minutes, and the water is kept at the marked level, the system has successfully passed the test.

Test conditions

It is necessary to carry out hydraulic tests of water supply and drainage systems with all responsibility, realizing the complexity of the procedure. The result of the tests largely depends on the literacy of their conduct. Therefore, they are trusted only by specialists, those who know the measures safety and requirements for such checks.

- The temperature in the room or on the street (if the external water supply is checked) is not lower than +5 degrees;

- The water pipeline is filled gradually, starting from the main section. Then water is poured into risers and small local networks;

- First, the lower floors are filled, gradually rising higher and higher. This is necessary to force air out of the pipes and prevent the formation of air pockets;

- At the end of the hydraulic tests, the used water is drained from the water supply and sanitation system;

- During hydraulic testing of hot water supply, the temperature is measured at the extreme sections of the system. Water of the calculated temperature is poured into the system;

- During hydraulic testing of hot water supply, the condition of heated towel rails in bathrooms is tested;

- If it is necessary to test the efficiency of the water supply, all points of use in the riser are turned on at the same time. This test step is optional.

Progress of the preliminary test

The procedure for conducting a preliminary hydraulic test is regulated by the Building Norms and Rules:

- The water supply is filled and left without pressure for two hours.

- Increased pressure is slowly created for half an hour. Then you can check for leaks at the joints.

- The pressure is reduced to the calculated values, the state of the route is examined.

- Under such pressure of water, the route remains from 30 minutes or more in order to stabilize the deformed shape of the pipes.

- The inlet taps are closed and the water is slowly drained from the pipes with the help of a pressure test pump.

- The track is checked for leaks and noticeable problems.

The water pipeline was successfully tested in the case when no leaks were detected at increased pressure, the connections and fasteners were intact.

Before starting a hydraulic test of the water supply in apartment building should find out the staff operating pressure, check with the pressure limits of devices (collectors, hoses, filters, sensors).

Progress of the final test

In multi-apartment residential buildings the final hydraulic test of the cold water supply is carried out after the installation of plumbing fixtures:

- A working pressure is pumped in the water supply and maintained for two hours. If the pressure drops by 0.02 MPa, it is raised to the initial mark.

- In 10 minutes, the pressure is increased to test values and maintained for two hours.

Hydraulic tests of the cold water supply system are considered successful if the leakage is not higher than the table readings.

| D external pipe diameter, cm | allowed leak,

liter/min |

|

| For welded joints | For connections on seals (sockets) | |

| 6,3-7,5 | from 0.2 to 0.24 | from 0.3 to 0.5 |

| 9-11 | from 0.26 to 0.28 | from 0.6 to 0.7 |

| 12,5-14 | from 0.35 to 0.38 | from 0.9 to 0.95 |

| 16-18 | from 0.42 to 0.6 | from 1.05 to 1.2 |

| 20 | 0,56 | up to 1.4 |

| 25 | 0,7 | up to 1.55 |

| 28 | 0,8 | up to 1.6 |

| 31,5 | 0,85 | up to 1.7 |

| 35,5 | 0,9 | up to 1.8 |

| 40-45 | from 1.1 to 0.5 | from 1.95 to 2.1 |

| 50-56 | from 1.1 to 1.15 | from 2.2 to 2.3 |

| 63 | 1,2 | up to 2.4 |

| 71 | 1,3 | up to 2.55 |

| 80 | 1,35 | up to 2.7 |

| 90 | 1,45 | up to 2.9 |

| 100 | 1,5 | until 3 |

| 120 | 1,6 | until 3 |

Table 1. Permissible volumes of leaks on a segment of the water pipeline with a duration of 1 km

The data obtained as a result of hydraulic tests are entered in the acceptance certificate in as much detail as possible. plumbing system. This also includes information about the alterations and repairs made during the tests. The act of testing water supply is proof of the quality and excellent condition of the water supply system, readiness for operation.

At the end of the hydraulic tests, the following documents are required for the commissioning of a cold or hot water supply system: working materials with notes on the features of the installation of the water supply and the coincidence of the final result with the project, a description of the changes; act of hydraulic tests; act with description hidden works.

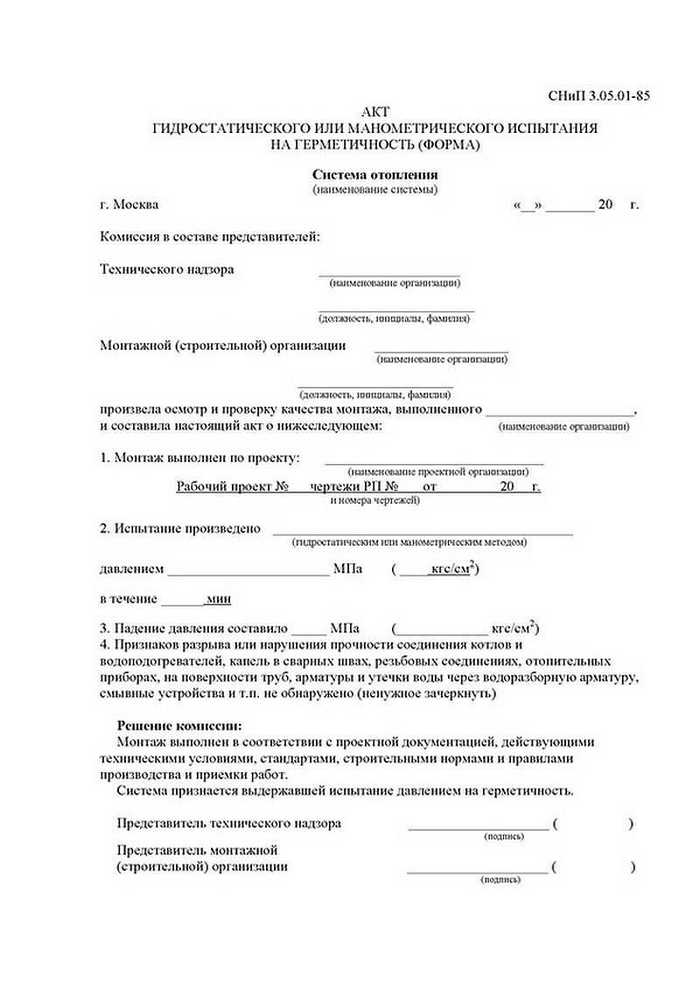

After all installation work on arranging the plumbing communications is completed, it is necessary to conduct a final test of the entire system in order to put it into operation in the proper form. Tests are carried out to identify possible defects in the work of communication and their subsequent elimination. Stages of work on verification and full information on it are entered in the form of the act approved by SNiP. A sample or example of a document can be seen in our material below.

About how to correctly fill out the form for testing the plumbing system and what such work is, in our article.

Important: testing the finished internal plumbing in most cases carried out hydraulically using a large number of water under pressure above the general average. If the external water supply is to be tested, then at a temperature of +5 degrees, the hydraulic method can still be used, and at lower temperatures, the pneumatic method is used (pumping the communication with air under high pressure). Both methods in professional circles are called pipe crimping.

Filling out the first part of the act

Before testing (pressure testing) of the finished water pipeline it is necessary to stock up on the form of the act, in which all important data will be entered. The act is an official document from Appendix 1 of SNiP 3.05.04-85. The name of the document sounds like “Act on the acceptance hydraulic test pressure pipeline for durability and tightness.

The very first information that needs to be entered in the document is the city in which the testing work is carried out and the date of the event. Below is a list of committee members who will test the indoor/outdoor plumbing system.

The commission should normally include:

- Representative of the organization that carried out the installation of all communications;

- Representative from the technical supervision service of the customer;

- A person representing the operating organization.

Moreover, it is worth prescribing the organization that the member of the commission represents, and his position in it, and his surname with initials.

Below in without fail you must specify detailed information about the tested object. That is, enter its full name (you can take it from project documentation), indicate the numbers of pickets available at the boundaries of the facility, the total length of the water pipeline and its diameter, as well as the material from which the communication is mounted and pipe joints are made.

On this, the "header" of the official document is considered to be completely filled out.

Conducting system testing

- So, when checking, the water consumption from each plumbing point is taken into account. It should be at least 0.2 liters per second.

- It is worth considering the pressure of the water supply. This is especially important for the highest water intake points. In this case, the pressure should be at least 2-3 meters.

- It is also worth checking the compliance of the parameters of the entire system according to the design documentation. Here they check the length, diameter of the pipeline, as well as the materials from which it is made.

- Visual primary inspection of external and internal communications also avoids strong gusts of the system as a result of testing.

- Pressure testing of the water supply system consists in supplying water under high pressure to the system. The testing time is at least 10 minutes. The pressure when supplying water to the system should be one and a half times higher than the maximum allowable for a particular communication.

Example: household plumbing is able to withstand a maximum gauge pressure of 0.45 MPa or just 45 meters of water column. Therefore, to test such sewerage and water supply, it is necessary to apply a gauge pressure of 0.675 MPa or simply 67.5 meters of water column.

Testing is considered successfully passed if no leaks or breaks in the water supply (sewage) pipeline are detected under the influence of water.

Further completion of the act

- After the pressure test has been carried out, it is necessary to enter data on the nominal gauge pressure for a specific communication and data on the gauge pressure used in testing in the act of testing the communication for tightness.

- It is also worth indicating the brand of the pressure gauge that was used to test and measure the pressure readings in the system at the time of the test. Here you also need to specify the height of the location. measuring instrument relative to the pipe axis.

- Another parameter that must be entered into the act of studying water supply or sewerage for tightness is the time during which the communication strait was made.

- Further in the document indicate to what nominal value the pressure was reduced after the test. Lastly, the members of the commission conduct an inspection of the pipeline and sewerage and enter the results into an act.

Important: it is worth adding to the document all the stages of communication research that were applied in relation to a particular communication (whether the pressure periodically decreased when water was supplied, whether the water pressure was changed, etc.).

- If there were no violations in the tightness of the water supply / sewerage system, then it is recorded in the “Inspection results” column that no leaks or breaks were found at the time of the inspection.

- Below is the item "Decision of the Commission". In case of successful testing, the commission issues a permit for the commissioning of the water supply system.

- Below, all members of the commission must put their signatures indicating their surnames and initials, as well as their positions.

Upon completion of the installation of engineering systems, interested parties must sign an appropriate document - an act of examination of hidden works. The acts can be signed by representatives of the installation organization, the general contractor, technical and architectural supervision, representatives of the Customer, representatives of the design organization, representatives of the maintenance service, authorized persons and others.

Certifies that the corresponding engineering system is installed in accordance with the project. The act indicates - what works are presented for examination, by whom it is performed working draft, materials and equipment used during installation, the start and end dates of work, the decision of the commission on the acceptance of work and permission for further repair and construction work. If deviations from the project occurred during installation, this is also reflected in the act.

The act of hydraulic tests confirms that the test has been carried out and the system passed it. Hydraulic tests are carried out in accordance with building codes and regulations.

Heating and water supply systems are tested hydrostatically or manometric method in accordance with SNiP 3.05.01-85 (internal sanitary systems). More preferred is the hydrostatic method. The test is carried out with a pressure equal to 1.5 of the maximum working pressure. For different heating materials and water supply the test time varies, but in any case not less than 10 minutes.

The water supply system is considered to have passed the test if within 10 minutes of being under test pressure during the hydrostatic test method, no pressure drop of more than 0.05 MPa (0.5 kgf / cm²) and drops in welds, pipes, threaded connections, fittings and water leakage through flushing devices.

For the heating system, the pressure drop should not exceed 0.02 MPa (0.2 kgf/cm²).

Trial internal sewerage produced by the method of spilling water by simultaneously opening 75% of sanitary appliances connected to this section of the sewer. The system is considered to have passed the test if no leaks are found through the walls of the pipelines and through the joints. Trial internal drains produced by filling them with water to the level of the highest point. The test time shall be at least 10 minutes. The test is considered successful if no leaks are found during the inspection, and the water level in the risers has not dropped.

CERTIFICATE OF SURVEY OF HIDDEN WORKS AND ACTS OF HYDRAULIC TESTS (FORM)

installation work, covert work act and the act of hydraulic tests are carried out by us in accordance with all building codes and regulations. When contacting “construction teams” and private craftsmen, you will not receive any agreed working documentation, neither correctly performed installation and executive circuits, nor test reports upon the work performed. Therefore, you will not receive any guarantees for installation work. As a rule, private teams do not have the qualifications, experience and knowledge to perform engineering and technical support for work. It is not uncommon for these unfortunate installers, even in Russian, not to be able to talk about what kind of compliance building codes and the rules can be discussed? Therefore, if you want to engineering systems worked correctly, served for a long time and did not cause you unnecessary trouble - contact qualified specialists.

Kraft guarantees high quality works, clear documentary support of installation and design, and most importantly, an attentive attitude towards you!