Profiles and thread sizes

(GOST 9484-81)The standard applies to trapezoidal threads and establishes the profiles and dimensions of its elements.

MAIN PROFILE

An example of a symbol for a trapezoidal single-start thread nominal diameter 20 mm, step 4 mm and tolerance field of the average diameter 7e:

Tg 20 x 4 -7e

NOMINAL PROFILES

external and internal thread

h 3 - profile height external thread; H 4 - the height of the profile of the internal thread; d 3 - inner diameter of the external thread; D4- outside diameter internal thread; R 1 - rounding radius at the top of the external thread; R 2 - twisting radius in the cavity of the external and internal threads; a c - clearance at the top of the thread.

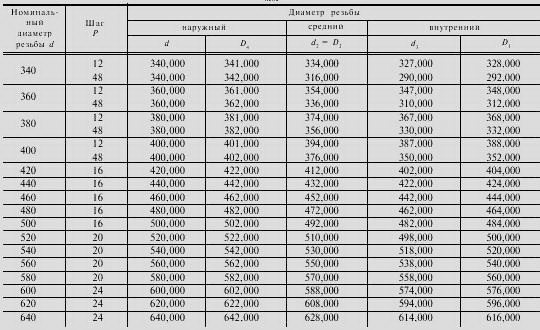

DIAMETERS AND PITCHES

trapezoidal single-start thread according to GOST 24737-81

Preferred diameters and steps are specified in GOST 24738-81. Numerical values of tolerances of diameters and steps - according to GOST 9562-81

DIAMETERS AND PITCHES

trapezoidal multi-start thread according to GOST 24739-81

Notes:

1. Steps in a box are preferred.

2. The steps indicated in brackets are not recommended when developing new designs.

3. Threads, in which the stroke value is marked with *, have a lead angle of more than 10 o. For these threads, the deviation of the profile shape must be taken into account during production.

4. In technically and economically justified cases, it is allowed to use other values of nominal thread diameters in accordance with GOST 24738-81.

5. When choosing thread diameters, the first row should be preferred to the second.

An example of a symbol for a trapezoidal multi-start thread with a nominal diameter of 20 mm, a stroke value of 8 mm, a pitch of 4 mm and a tolerance field of 8e:

Tg 20-8 (P4) - 8e

Same, left:

Tg 20-8 (P4) LH - 8e

The make-up length, if different from the thread length, is indicated in millimeters at the end of the thread designation, for example:

Tg 20-8 (P4) LH - 8e - 180

Numerical values of the lengths of make-up related to groups N and L - according to GOST 9562-81.

Landing in a threaded connection is indicated by a fraction

Tg 20-8 (P4) LH - 8H / 8e - 180

The numerical values of the tolerances of diameters d and D 1 - according to GOST 9562-81.

The numerical values of the tolerances of diameters d 2, d 3 and D 2 - according to GOST 24739-81.

Trapezoidal Thread Application

The trapezoidal thread of the screw is a lead thread that has a relatively large friction force, it is self-braking. The advantage for lifting technologies is that it does not require additional fixation in the rest position.

Trapezoidal thread is used to convert rotary motion into linear motion and is used primarily for rectilinear motion. It also finds its use as a lead screw in lathes or as a drive thread for screw press tables or bridges of vehicles.

Application examples for trapezoidal spindle threads:

Feed movement on machine tools (e.g. adjusting and lead screws);

- movement on the manipulator;

- traffic regulation lifting mechanisms and forklifts;

- movement of the shutter when locking injection molding machines;

- moving movement on assembly containers;

- vertical movement when working with a press.

Related Documents:

GOST 3469-91: Microscopes. Thread for lenses. Dimensions

GOST 4608-81: Metric thread. Interference landings

GOST 5359-77: Ocular thread for optical devices. Profile and dimensions

GOST 6042-83: Round Edison thread. Profiles, dimensions and limit dimensions

GOST 6111-52: Conical inch thread with a profile angle of 60 degrees

GOST 6211-81: Conical pipe thread

GOST 6357-81: Cylindrical pipe thread

GOST 8762-75: Thread round diameter 40 mm for gas masks and calibers for it. Main dimensions

GOST 9000-81: Metric thread for diameters less than 1 mm. Tolerances

GOST 9484-81: Trapezoidal thread. Profiles

GOST 9562-81: Trapezoidal single thread. Tolerances

GOST 9909-81: Conical thread of valves and cylinders for gases

GOST 10177-82: Thrust thread. Profile and main dimensions

GOST 11708-82: Thread. Terms and Definitions

GOST 11709-81: Metric thread for plastic parts

GOST 13535-87: Reinforced thrust thread 45 degrees

GOST 13536-68: Round thread for sanitary fittings. Profile, basic dimensions, tolerances

GOST 16093-2004: Metric thread. Tolerances. Landings with clearance

GOST 16967-81: Metric thread for instrumentation. Diameters and steps

GOST 24737-81: Trapezoidal single thread. Main dimensions

GOST 24739-81: Multi-start trapezoidal thread

GOST 25096-82: Thrust thread. Tolerances

GOST 25229-82: Metric conical thread

GOST 28487-90: Tapered tool joint thread for drill string elements. Profile. Dimensions. Tolerances

Details in machines, mechanisms, devices, as well as devices and structures are somehow connected to each other. These connections perform various functions, and are divided, first of all, into two types: mobile and fixed.

Fixed connection - connection of parts, ensuring the invariability of their relative position during operation. For example, welded, connections using fasteners, etc. A movable connection is a connection in which the parts have the ability to relative move in working condition. For example, gear connection.

Fixed and movable connections, in turn, are divided into detachable and non-detachable, depending on the possibility of dismantling the connection.

One-piece connection - a connection that cannot be separated without breaking the shape of the parts or their connecting element. For example, the connection is welded, soldered, riveted, etc.

Detachable connection - a connection that can be repeatedly disconnected and connected without deforming either the connected or the fasteners. For example, a threaded connection with a bolt, screw, wedge, key, gear, etc.

This article is devoted to an overview of threaded connections, the variety of which is encountered quite often in everyday life.

Threaded connection - connection of parts using a thread. Everyone knows what carving is, everyone has seen it. Many people also know that threads differ from each other, since they have different sizes, step and so on. However, not many people understand how this is regulated, and also that there is not only the metric thread that is familiar to us cylindrical shape but also many other types.

1. The concept of thread

A thread is a surface formed during the helical movement of a flat contour along a cylindrical or conical surface, in other words, a spiral with a constant pitch formed on this surface.

Figure 1 - Thread

By appointment, the threads are divided into fastening (in a fixed connection) and running or kinematic (in a movable connection). Often fastening threads have a second function - seals threaded connection, ensuring its tightness, such threads are called fastening-sealing. There are also special threads that have special appointment.

Depending on the shape of the surface on which the thread is cut, it can be cylindrical or conical.

Depending on the location of the surface, the thread can be external (cut on the rod) or internal (cut in the hole).

Depending on the shape of the profile, triangular, trapezoidal, rectangular, round, special threads are distinguished.

Triangular thread is subdivided into metric, pipe, conical inch, trapezoidal thread - into trapezoidal, persistent, persistent reinforced.

By the size of the pitch, the threads are large, small and special.

According to the number of threads, threads are divided into single-start and multi-start threads.

In the direction of the helix, a right-hand thread (the thread is cut clockwise) and a left-hand thread (the thread is cut counterclockwise) are distinguished.

In Figure 2, the entire classification of threads is presented in the form of a diagram:

Figure 2 - Classification of threads

In addition to the above classification, all threads are divided into two groups: standard and non-standard; for standard threads, all their parameters are determined by GOSTs. The main thread parameters are defined by GOST 11708-82. These are the so-called standard threads. general purpose. In addition to them, there is the concept of a special thread. Special threads are threads with a standard profile, but different from standard sizes diameter or thread pitch, and threads with a non-standard profile. Non-standard threads - square and rectangular - are made according to individual drawings, on which all thread parameters are specified. (More details in section 5. The operational purpose of the thread and its application).

3. Thread profiles and parameters

Thread profiles are characterized by the following features:

. metric thread has a profile in the form of an equilateral triangle with an angle at the top of 60°. The protrusions and cavities of the thread are blunt (GOST 9150-2002).

Metric threads are cylindrical and conical.

. pipe thread has a profile in the form of an isosceles triangle with an angle at the top of 55 °. Pipe threads can also be cylindrical or conical.

. conical inch thread has a profile in the form of an equilateral triangle.

Thread inch conical

. round thread has a semi-circular profile.

. trapezoidal thread has a profile in the form of an isosceles trapezoid with an angle of 30 ° between the sides.

. thrust thread It has a profile of an unequal trapezoid with an angle of inclination of the working side of 3° and the non-working side of 30°.

. rectangular thread has a rectangular profile. The thread is not standardized.

Rectangular non-standard thread

Thread parameters

The main thread parameters are:

Thread diameter(d) is the diameter of the surface on which the thread will be formed.

Figure 3 - Outside diameter

thread pitch(P) is the distance along a line parallel to the thread axis between the midpoints of the nearest identical sides of the thread profile, lying in the same axial plane on one side of the axis of rotation (GOST 11708-82).

Thread stroke(Рh) is the relative axial displacement of a threaded part in one revolution (360°), equal to the product of nР, where n is the number of thread starts. For a single-start thread, the lead is equal to the lead. The thread formed by the movement of one profile is called single-start, formed by the movement of two, three or more identical profiles, is called multi-start (two-, three-start, etc.). In other words, not one spiral, but two or three, is cut simultaneously on a bolt and nut. Multi-start threads are often used in high-precision equipment, for example, in photographic equipment, in order to uniquely position the position of parts during mutual rotation. Such a thread can be distinguished from the usual one by two or three beginnings of the turns at the end.

Figure 4 - Thread Pitch and Thread Lead

The thread is characterized by three diameters: outer d (D), inner d1 (D1) and middle d2 (D2). External thread diameters are designated d, d1 and d2, and internal threads in the hole are D, D1 and D2.

Figure 5 - Thread diameters

- external (nominal) diameter d (D) - the diameter of an imaginary cylinder described around the tops of the external (d) or troughs of the internal thread (D). This diameter is decisive for most threads and is included in the thread designation;

- average diameter d2 (D2) - the diameter of the cylinder, the generatrix of which intersects the thread profile in such a way that its segments formed at the intersection with the groove are equal to half the nominal thread pitch;

- internal diameter d1 (D1,), the diameter of the cylinder inscribed in the troughs of the external (d1,) or tops of the internal thread (D1).

The construction of a helical surface in the drawing is a long and complex process, therefore, in the product drawings, the thread is depicted conditionally, in accordance with GOST 2.311-68. On the rod, the thread is depicted with solid main lines along the outer diameter and solid thin lines along the inner diameter.

Figure 6 - An example of the image of the thread on the rod and in the hole

4. Thread designation

Thread designation usually includes letter designation thread type and nominal diameter. Additionally, the thread pitch (or TPI - threads per inch - the number of turns per inch), the number of starts for a multi-start thread, the diameter of the threaded hole, and the direction (left, right) can be given in the designation.

Metric thread- with pitch and basic thread parameters in millimeters. It has a wide range of applications with a nominal diameter from 1 to 600 mm and a pitch of 0.25 to 6 mm. The metric thread is the main fastening thread. This is a single-start thread, mostly right-handed, with a large or small pitch. The designation of a metric thread includes the letter M and the nominal diameter of the thread, and the large pitch is not indicated: M5; M56. For threads with a fine pitch, the thread pitch M5 × 0.5 is additionally indicated; M56×2. At the end of the symbol for the left thread, the letters LH are put, for example: M5LH; М56×2 LH. The thread designation also indicates the accuracy class: M5-6g.

Designation example:

M 30 - metric thread with an outer diameter of 30 mm and a large thread pitch;

M 30 × 1.5 - metric thread with an outer diameter of 30 mm, fine pitch 1.5 mm.

Although metric threads were not found wide application in sealed joints, however, this possibility is included in the standards. These are metric conical and cylindrical threads.

Metric tapered thread performed with a taper of 1:16 and a nominal diameter of 6 to 60 mm in accordance with GOST 25229-82 (ST SEV 304-76). It is intended for self-sealing conical threaded connections, as well as for connections of an external conical thread with an internal cylindrical thread having a nominal profile in accordance with GOST 9150-2002. The designation of a metric taper thread includes the type of thread (letters MK), the nominal diameter of the thread, and the thread pitch. The letters LH are placed at the end of the symbol for the left thread.

Designation example:

MK 30×2 LH - left metric conical thread with an outer diameter of 30 mm, a thread pitch of 2 mm.

Metric parallel thread (with profile)based on a metric thread (M) with a nominal diameter of 1.6 to 200 mm and a 60° point profile. Its main difference is in the screw, which has an increased radius of the thread cavity (from 0.15011P to 0.180424P), which gives the threaded connection based on a cylindrical metric thread higher heat-resistant and fatigue qualities. The metric cylindrical thread is denoted by the letters MJ, followed by the numerical value of the nominal thread diameter in millimeters, the numerical value of the pitch, the tolerance field for the average diameter and the tolerance field for the diameter of the protrusions.

The internal thread MJ is compatible with the external thread M if the nominal diameter and pitch match, i.e. a regular metric screw can be screwed into a nut with such a thread.

Designation example:

MJ6×1-4h6h - external thread on the shaft surface with a nominal diameter of 6 mm, a pitch of 1 mm, a tolerance field of the average diameter 4h and a tolerance field of the diameter of the projections 6h.

Inch thread differences from metric in that the angle at the top of the thread is 55 degrees for British standards BSW (Ww) and BSF or 60 degrees (as in metric) in American system(UNC and UNF), and the thread pitch is calculated as the ratio of the number of threads per inch of thread length. It is not possible to combine metric and inch threads, therefore, in countries with a metric system, only inch pipe threads are used.

In inch threads, all thread parameters are expressed in inches (most often indicated by a double dash placed immediately after the numerical value, for example, 3 "= 3 inches), the thread pitch is in fractions of an inch (inch \u003d 2.54 cm). For pipe inch threads, the size in inches does not indicate the size of the thread, but the nominal clearance in the pipe, while the outer diameter is actually much larger. A feature of pipe thread is precisely the fact that it takes into account the thickness of the pipe walls, which can be thicker or thinner depending on the material of manufacture and the working pressure for which the pipes are designed. Therefore, the inch standard of pipe threads is understandable and accepted throughout the world as an exception to the metric rules.

Inch thread diameters are not the only parameter that is important when choosing pipes. It is necessary to take into account: thread depth, thread pitch, outer and inner diameter, thread profile angle. It is worth noting that the thread pitch in this case is calculated not in inches or even in millimeters, but in threads. Thread refers to a cut groove. Therefore, the calculation is based on how many grooves are cut on one inch measured length of pipe. Say, ordinary water pipes have only two types of thread pitch: 14 threads, which corresponds to a metric pitch of 1.8 mm, and 11 threads - a metric pitch of 2.31 mm.

Table 2 shows the main differences between "inch" and "pipe" cylindrical threads in relation to the "metric" thread for the most common sizes of the above threads.

Threads marked with * should not be used if possible.

Naturally, such peculiar standards for calculating the diameter and pitch only confuse the determination of the required values. Therefore, tables were developed to determine the number of threads and the diameter of pipes in the presence of an inch thread. In addition, any packaging always indicates its value and standard. But all the same, the data are approximate, and a possible error should never be ruled out.

* When determining the size, preference should be given to the values of row 1.

It has a profile in the form of an isosceles triangle with an angle at the top of 55°, the tops and bottoms are rounded (GOST 6357-81).

The thread symbol consists of the letter G, the designation of the nominal thread diameter in inches, and the accuracy class of the average diameter. For left-hand threads, the designation is supplemented by the letters LH.

Designation example:

G 1 1/2-A - cylindrical pipe thread with a size of 1 1/2", accuracy class A;

1/4-20 BSP - Whitworth pipe cylindrical thread according to B. S.93 standard (England).

has a profile similar to that of a cylindrical pipe thread. It is possible to connect pipes with a conical thread (taper 1:16) with products having a cylindrical pipe thread GOST 6211-81.

The thread symbol consists of the letters R, the size of the nominal diameter in inches. The designation Rc is used for pipe tapered internal threads. The symbol of the left thread is supplemented by the letters LH.

Designation example:

R 1 1/2 - pipe conical outer thread with a size of 1 1/2 ";

R 1 1/2 LH - pipe thread conical outer left;

Rc 1/2 - pipe thread conical internal;

BSPT 1 1/2 - conical pipe internal thread according to B. S.93 standard (England).

With a profile angle of 60°, GOST 6111-52 is cut on a conical surface with a taper of 1:16.

The designation consists of the letter K and the thread size in inches with an indication of the dimension, it is applied on the shelf of the leader line, as with pipe threads. Designation example:

K 3/4″ according to GOST 6111-52. 3/8-18 NPT designation according to ANSI/ASME B 1.20.1 (USA).

Serves to transfer movement and effort. Trapezoidal thread profile is an isosceles trapezoid with an angle between the sides of 30°. For each diameter, the thread can be single-start and multi-start, right and left GOST 9484-81.

The main dimensions, diameters, pitches, tolerances of a single-start thread are standardized according to GOST 24737-81, 24738-81, 9562-81. For multi-start threads, these parameters are in GOST 24739-81.

The symbol for a single-start thread consists of the letters Tr, the value of the nominal thread diameter, pitch, tolerance field.

Designation example:

Тr 40×6-8е - trapezoidal single-start external thread with a diameter of 40 mm with a pitch of 6 mm; Tr 40×6-8e-85 - the same make-up length 85 mm;

Tr 40×6LH-7H - the same for the inner left.

The numerical value of the stroke is added to the multi-start thread symbol:

Tr 20 × 8 (P4) -8e - trapezoidal multi-start external thread with a diameter of 20 mm with a stroke of 8 mm and a pitch of 4 mm.

It has a profile of an unequal trapezoid. The profile cavities are rounded, there are three different pitches for each diameter. Serves for transmission of movement with large axial loads GOST 10177-82.

Thrust threads are denoted by the letters S, then indicate the nominal thread diameter in millimeters, the thread pitch (travel and pitch, if this thread is multi-start), the direction of the thread (do not indicate for the right thread, for the left letter LH), and thread accuracy class.

Designation example:

S 80×10 - single-start thrust thread with an outer diameter of 80 mm and a pitch of 10 mm;

S 80 × 20 (P10) - two-start thrust thread with an outer diameter of 80 mm, a stroke of 20 mm and a pitch of 10 mm.

Special thread with a standard profile, but a non-standard pitch or diameter, denote: Sp M40 × 1.5 - 6g.

Rectangular thread (square). A thread with a rectangular (or square) non-standard profile, so all its dimensions are indicated on the drawing. It is used to transfer the movement of heavily loaded movable threaded joints. Usually performed on load and lead screws.

It has a profile obtained by conjugation of two arcs of the same radius. GOST 13536- 68 defines the profile, basic dimensions and tolerances of round threads. This thread is used for the spindles of mixer valves and toilet taps GOST 19681-94 and water taps. There is only one diameter d = 7 mm and pitch P = 2.54 mm.

Designation example:

Kr 7 × 2.54 GOST 13536-68, where 2.54 is the thread pitch in mm, 12 is the nominal thread diameter in mm.

A similar profile has a round thread (but for diameters 8 ... 200 mm) according to ST SEV 3293-81, put into effect directly as State standard. The thread is used for hooks of cranes, as well as in conditions of exposure to aggressive environments.

Designation example:

Rd 16 - round thread with an outer diameter of 16 mm; Rd 16LH - round thread with a diameter of 16 mm, left.

5. Operational purpose of the thread and its application

Threaded connections are widespread in mechanical engineering (in most modern machines, over 60% of all parts have threads). According to the operational purpose, threads are distinguished general use and special, designed to connect one type of parts of a particular mechanism. The first group includes threads:

1.) Fixing- metric, inch, used for detachable connection of machine parts. Their main purpose is to provide complete and reliable connection parts under various loads and at various temperature regime during long-term operation.

2.) running or kinematic - trapezoidal and rectangular, used for lead screws, screws of calipers of machine tools and tables measuring instruments etc. Their main purpose is to ensure accurate movement with the least friction, and for rectangular threads, also the exclusion of self-unscrewing under the action of an applied force; Thrust (in presses and jacks) and round, designed to convert rotational movement into rectilinear movement. They perceive great efforts at relatively low speeds. Their main purpose is to ensure smooth rotation and high load capacity(for precision micrometric instruments, a metric thread of increased accuracy is used). Round thread is widely used for water taps in accordance with GOST 20275-74 and in such elements as mixers, taps, valves, spindles in accordance with GOST 19681-94 (Fittings sanitary water folding).

3.) Mounting and sealing (pipe and reinforcing) - tubular cylindrical and conical metric inch and conical, used for pipelines and fittings, their main purpose is to ensure the tightness of joints (excluding shock loads) at low pressures.

Pipe cylindrical thread according to GOST 6357-81 is used on water and gas pipes, parts for their connection (couplings, squares, crosses, etc.), pipe fittings(gate valves, valves, etc.).

Tapered pipe threads according to GOST 6211-81 are used in pipe joints at high pressures and temperatures (in valves and gas cylinders) when increased tightness of the connection is required.

Assigned to the second group, special threadhas a special purpose and is used in certain specialized industries. These include the following:

1.) metric tight thread- thread made on the rod (on the stud) and in the hole (in the socket) along the largest limit sizes; designed to form threaded connections with an interference fit.

2.) metric thread with gaps- thread necessary to ensure easy make-up and break-out of threaded connections of parts operating under high temperatures when conditions are created for setting (joining) oxide films that cover the surface of the thread.

3.) clock thread (metric)- thread used in the watch industry (diameters from 0.25 to 0.9 mm).

4.) microscope thread- thread, designed to connect the tube with the lens; has two sizes:

4.1) inch - diameter 4/5 "" (20.270 mm) and pitch 0.705 mm (36 threads per 1"");

4.2) metric - diameter 27 mm, pitch 0.75 mm;

5) ocular multiple thread- recommended for optical devices; thread profile - isosceles trapezoid with an angle of 60 °.

Operational Requirements to threads depend on the purpose of the threaded connection. Common to all threads are the requirements of durability and make-up without adjusting independently manufactured threaded parts while maintaining the performance of the connections. Summarizing briefly, the main threads used for operational purposes can be displayed in the form of the following table:

6.Determination of thread size

As a rule, threads on different fittings look similar, which makes it difficult to visually determine the type of thread. The thread on the fitting is determined by measuring the main parameters with a thread gauge and caliper and comparing the results with the thread table.

Figure 7 - Measurement of thread parameters

There are two types of thread gauges: with stamp M 60o - for metric threads with a profile angle of 60 ° and with brand D 55o - for inch and pipe threads with a profile angle of 55 °. On each comb of the thread gauge for metric threads, a number is stamped indicating the thread pitch in mm for inch and pipe threads - the number of steps in a length of 25.4 mm (1 "= 25.4 mm).

7. Thread cutting methods

The main methods for making threads are:

- cutting them with cutters and combs on lathes;

- tapping with dies with thread-cutting heads;

- cold and hot rolling with flat or round rolling dies;

- milling with special thread milling cutters;

- grinding with abrasive wheels.

The choice of thread production method depends on the type of production of thread dimensions, the accuracy of the workpiece material, etc.

Figure 8 - Threading tool

1. Threading with cutters. With the help of threaded cutters and combs on screw-cutting machines cut threads both external and internal (internal thread starting from a diameter of 12 mm and above). The method of threading with cutters is characterized by relatively low productivity, therefore, at present it is used mainly in small-scale and individual production as well as when creating accurate screws of lead screw calibers, etc. The advantage of this method is simplicity cutting tool and relatively high accuracy the resulting thread.

2. Threading with dies and taps. Dies on their own design features divided into round and sliding. Round dies used in assembly blanking and other works are designed for cutting external threads with a diameter of up to 52 mm in one pass. For larger threads, dies of a special design are used, which actually serve only to strip the thread after pre-cutting it with other tools. Sliding dies consist of two halves gradually approaching each other during the cutting process. The tap is a steel rod with a thread divided by longitudinal straight or helical grooves forming cutting edges. The same grooves serve to exit the chips. According to the method of application, taps are divided into manual and machine taps.

3. Thread rolling. The main industrial method of thread manufacturing at present is knurling on special thread rolling machines. The part is clamped in a vise. In this case, when great performance high quality of the product is ensured (shape, size and surface roughness). The process of thread rolling is to create a thread on the surface of the part without removing chips due to plastic deformation of the surface of the workpiece. Schematically, it looks like this. The part is rolled between two flat dies or cylindrical rollers having a threaded profile and a thread of the same profile is extruded on the rod. largest diameter rolling thread 25 mm smallest 1 mm; thread length 60…80 mm.

4. Thread milling. Milling of external and internal threads is carried out on special thread milling machines. In this case, the rotating comb cutter plunges into the body of the part at radial feed and mills the thread on its surface. Periodically, there is an axial movement of the part or cutter from a special copier by an amount equal to the thread pitch during one revolution of the part.

5. Grinding precise threads. Grinding as a method of creating a thread is mainly used to obtain an accurate thread on relatively short threaded parts, such as threaded plugs - gauges, thread rollers, etc. The essence of the process is that grinding wheel located to the part at an angle of rise of the thread during fast rotation and with simultaneous slow rotation of the part with feed along the axis by the value of the thread pitch in one revolution cuts (grinds) part of the surface of the part. Depending on the design of the machine and a number of other factors, the thread is ground in two to four or more passes.

8. Types of foreign threads

In the world, several well-deserved respected standards are used in such countries as Great Britain (BS), Germany (DIN), France (NF), Japan (JIS), USA (UNC). The main reasons for their difference are traditionally different systems of measures and methods for specifying thread sizes in different countries as well as special applications for threads. However, over the past century, the metric standard ISO - International Organization for Standardization (International Organization for Standardization) has strongly established its position in the world, which in turn has contributed to the mutual understanding of technical specialists.

The most common types of foreign threads include:

- Metric ISO

- Whitworth thread (Whitword Thread)

- Trapezoidal thread

- round thread

- Thrust thread

The given summary table describes the compliance of more than twenty types of threads (general machine-building oil and gas assortments), and refers to domestic and foreign regulatory and technical documents regulating this area.

Since Table 8 above only gives general idea about abundance different kind threads and documents regulating them, and a large amount of data does not allow to fully compare and compare the threads of domestic and foreign standards, consider for example compliance various types triangular thread which is more common than others in general engineering.

and couplings to them. Specifications»

OST NKTP 1260 "Inch thread with a profile angle of 55 degrees"

The thread profile is an isosceles trapezoid with an angle of 30° between the sides (Figure 3, c). Trapezoidal thread can be single and multi-start, right and left.

The diameters and steps of a single-start trapezoidal thread in the range of diameters from 12 to 50 mm are given in Table. 2. The same dimensions and number of starts for multi-start threads are given in Table. 3.

Thread designation examples:

trapezoidal rhno-leading with a nominal diameter of 36 mm and a pitch of 6 mm:

TgZbhb; the same, left-hand thread:

Tg 36x6 LH;

trapezoidal, three-start with a nominal diameter of 40 mm, a pitch of 3 mm and a stroke of 9 mm:

Tg 40 X 9 (RZ)

Examples of thread designation in the drawing are shown in fig. 5. at

Table 2. Diameters and pitches of a trapezoidal single-start thread according to GOST 24738 81, mm

| Diameter d | row | - | - | -" | - | - | ||||||

| - | - | - | - | - ■ | 30, | |||||||

| step | p | |||||||||||

| R* | 3;8 | 3;8 | 3;8 | 3;8 | 3; 10 | |||||||

| Diameter d | row | - | - | - - | ||||||||

| - | - | - | - | - | ||||||||

| step | R | 8, | ||||||||||

| R* | 3; 10 | 3;10 | 3;10 | 3;10 | 3;10 | 3;10 | 3;12 | 3;12 | 3;12 | 3; 12 |

Note: 1. When choosing a thread, the first row should be preferred to the second;

2. Preferred steps are marked with *.

Table 3. The main dimensions of the trapezoidal multi-start thread according to GOST 24739 81, mm

| d | thread pitch | Thread stroke with number of starts | ||||

| Row1 | Row 2 | R | R* | |||

| (8) | ||||||

| - | - | |||||

| - | - | |||||

| - | - | |||||

| ,-. - | - | (16) | (20) | |||

| - | - | |||||

| - | (20) | |||||

| _ | - | |||||

| - | (24) | |||||

| - | - | |||||

| - | (24) | |||||

| - | - | |||||

| - | (21) | (28) | ||||

| - | - | |||||

| _- | (28) | |||||

| ■ - | - | |||||

| - | (32) | |||||

| (24) | (36) | (48) | ||||

| - | - | |||||

| - | (32) | |||||

| - | (24) | (36) | (48) |

Note: A thread whose lead value is in brackets has a lead angle of more than 10°.

The carving is persistent.

The main purpose of the thread is to transfer an axial load in one direction by means of a screw, for example, in jacks, presses, etc. The thread profile is an unequal trapezoid (Fig. 3, d).

: > v Diameters and pitches of thrust threads in the range of diameters from 16 to 42 mm are given in Table. 4.

Thread designation examples: "

thrust single-thread right with a diameter of 32 mm with a step of 6 mm:

the same, left-hand thread:

S32x6LH. In the drawing, the thread is indicated as shown in fig. 6.

Rice. 6

Table 4. Diameters and pitches of thrust threads according to GOST 10177 82, mm.

| Diameter d | Step | ||

| Row1 | Row 2 | R* | R |

| - | |||

| - | |||

| - | 3;8 | ||

| - | 3;8 | ||

| - | 3;8 | ||

| - | 3;8 | ||

| - | 3;10 | ||

| - | 3;10 | ||

| - | 3;10 | ||

| - | 3;10 | ||

| - | 3;10 | ||

| - | 3;10 |

Note^. When choosing thread diameters, the first row should be preferred to the second.

Steps that are preferred when developing new designs.

Pipe cylindrical thread.

This thread is used in cylindrical pipe connections and connections of an internal cylindrical thread with an external conical thread.

The profile (Fig. 3, b) and the main dimensions are established by GOST 6357 81. The values \u200b\u200bof the main dimensions of a cylindrical pipe thread are given in Table. 5.

The pipe thread designation (Fig. 7, a, b) consists of the letter G and the thread size in inches, for example:

This designation is conditional, because. indicates the diameter of not the thread, but the hole in the pipe (nominal bore DN at a certain wall thickness). The outer diameter of the pipe thread will be larger than indicated in the drawing. For example, the designation G1 corresponds to a pipe thread having an outer diameter d=33.25m designed for pipes with an internal diameter of 1" (25.4 mm).

Pipe cylindrical thread of the same diameter (nominal DN) can be performed on pipes with different wall thicknesses and even on a solid rod.

Rice. 7. Conventions pipe cylindrical and conical threads: a) cylindrical pipe thread G 1 1/2;

b) thread of the same size internal, left; c) external pipe conical thread; d) internal pipe conical

Table 5. The main dimensions of the cylindrical pipe thread

GOST 9484 - 81

Trapezoidal thread has a profile with an angle of 30°. thread pitch measured in millimeters.

Trapezoidal thread used in the nodes of mechanisms for converting rotational motion into translational, for example: lead screws of machine tools, power screws of presses, lifting screws, etc. Threads of this type can withstand heavy loads.

Trapezoidal thread lettered Tr- English. trapezoidal

- Tr 28 × 5- diameter 28mm pitch 5mm

- Tr 28 × 5 LH- diameter 28mm pitch 5mm thread left

- Tr 20 × 8 (P4)- diameter 20 mm, pitch 4 mm and stroke 8 mm multi-start thread

- Tr 20 × 8 (P4) LH- diameter 20 mm, pitch 4 mm and stroke 8 mm multi-start thread left

d- outer diameter of the external thread (screw)

D– outer diameter of the inner thread (nut)

d2– average external thread diameter

D2– average diameter of internal thread

d1– internal diameter of external thread

D1– internal diameter of the internal thread

P- thread pitch

H is the height of the original triangle

H1– profile working height

| Trapezoidal thread | |||

| Thread diameters d | Step | ||

|---|---|---|---|

| Row 1 | Row 2 | ||

| 10 | 1.5; 2 | ||

| 11 | 2 ; 3 | ||

| 12 | 2; 3 | ||

| 14 | 2; 3 | ||

| 16 | 2; 4 | ||

| 18 | 2; 4 | ||

| 20 | 2; 4 | ||

| 22 | 3; 5 ; 8 | ||

| 24 | 3; 5 ; 8 | ||

| 26 | 3; 5 ; 8 | ||

| 28 | 3; 5 ; 8 | ||

| 30 | 3; 6 ; 10 | ||

| 32 | 3; 6 ; 10 | ||

| 34 | 3; 6 ; 10 | ||

| 36 | 3; 6 ; 10 | ||

| 38 | 3; 7 ; 10 | ||

| 40 | 3; 7 ; 10 | ||

| 42 | 3; 7 ; 10 | ||

| 44 | 3; 7 ; 12 | ||

| 46 | 3; 8 ; 12 | ||

| 48 | 3; 8 ; 12 | ||

| 50 | 3; 8 ; 12 | ||

| 52 | 3; 8 ; 12 | ||

| 55 | 3; 9 ; 14 | ||

| 60 | 3; 9 ; 14 | ||

| 65 | 4; 10 ; 16 | ||

| 70 | 4; 10 ; 16 | ||

| 75 | 4; 10 ; 16 | ||

| 80 | 4; 10 ; 16 | ||

| 85 | 4; 12 ; 18 | ||

| 90 | 4; 12 ; 18 | ||

| 95 | 4; 12 ; 18 | ||

| 100 | 4; 12 ; 20 | ||

| 110 | 4; 12 ; 20 | ||

| 1. When choosing a thread, priority is given to the first row. 2. The thread pitch in the highlighted color is preferred. |

|||

The operation of the drives of many machines, equipment and mechanisms is based on such a process as the transformation of rotational motion into translational motion. This principle is used, for example, in the drives of measuring machines and equipment, control systems for gate valves and valves, scanning tables, robots and machine tools.

In order to effectively convert the rotation of a certain part into the translational movement of another part, a screw-nut pair is most often used. Such transmissions are products that have a general machine-building application, and it should be noted that the performance, functionality and reliability of that equipment largely depend on how well they are designed and manufactured. constituent parts which they are.

Due to the fact that the screw-nut gears have an increased smoothness of engagement, they are almost completely silent during operation. Their design is relatively simple, and one of the undoubted advantages is that their use allows you to achieve a considerable gain in strength. By and large, the screw-nut transmission from a technical point of view is no different from a conventional threaded connection, however, since they are used to transmit movement, they are made in such a way that the friction force in the thread is minimal.

In principle, this can be achieved by using a rectangular thread, but it also has its drawbacks. For example, it cannot be cut on standard threading machines, and compared to trapezoidal threads, it has a much lower strength. These factors lead to the fact that rectangular threads are rarely used in screw-nut gears. They are most common trapezoidal thread, which has a large, medium and small pitch, as well as a persistent thread.

Most often in gears, a screw - nut can be found trapezoidal thread, which has an average step. It, but with a small step, is used when it is necessary to provide a small movement, and with a large step - when the device is operated in difficult conditions. In addition, due to the profile features, trapezoidal thread can be successfully used in mechanisms requiring reverse movement. Such threads are single and multi-start, right and left.

Materials used in screw-nut transmissionThe main requirements for those materials that are used in screw-nut gears are wear resistance, strength and good machinability. As for those screws that are not hardened, they are made of steels A50, St50 and St45, and those that are hardened - from steels 40HG, 40X, U65, U10. Nuts are usually made of bronze BrOTsS-6-6-3 or BrOFU-1.

Trapezoidal thread is widely used to make various screws that are used for various production equipment. For example, for machine tools, lifting devices, presses. This thread looks like isosceles trapezium, while the profile angle can have various meanings: 15, 24, 30, 40°. In the process of operation of the screw, on which the trapezoidal thread is cut, friction forces appear, which are caused in a natural way. That is, due to the presence of lubricant, surface roughness, as well as the profile angle.

Thread types

To date, there are such types:

- Metric. It serves to fix several elements. Cutting conditions are set in the regulatory documentation. The profile is a triangle with equilateral angles. This indicator is 60 °. Screws with metric threads are made with small and big steps. The first type is used to fix thin-sheet elements to create increased tightness. This type of connection can be found in precision optical instruments.

- Conical. It is made in the same way as the previous view, but twisting is done to a depth of 0.8 mm.

- Inch. To date, there is no regulatory document that would indicate the dimensions of the thread. Inch thread is used in the repair of various equipment. As a rule, these are old devices and devices. Its main indicators are the outer diameter and pitch.

- Pipe cylindrical. This type is isosceles triangle, whose upper angle is 55°. Such an internal thread is used to connect pipelines, as well as parts made of thin sheet material. It is recommended when there are special requirements for the tightness of the connection.

- Pipe conical. The internal thread must comply with all the requirements of regulatory documents. Sizes are completely standardized. It is used to connect various types of pipelines.

- Persistent. This view is an unequal trapezoid, where one of the sides is inclined by 3 °, and the other by 30 °. The first side is working. The shape of the profile, as well as the diameter of the steps are determined normative documents. In accordance with them, the thread is made with a diameter of 10 to 600 mm, while the maximum pitch is 24 mm. They are used where increased holding forces are required.

- Round. The thread profile consists of various arcs interconnected by straight lines. The profile angle is 30°. This type of thread is used for those connections that are exposed to aggressive environments.

- Rectangular. It is not enshrined in any regulatory documents. Its main advantage is high efficiency. Compared to the trapezoidal type, it is less durable, and also causes many incomprehensible moments in its production. The main place of application is jacks and different kinds screws.

- Trapezoidal. It has the shape of an isosceles trapezoid with a profile angle of 30°. Trapezoidal thread, the dimensions of which are fixed in the documentation, is used to connect various elements of production equipment.

Manufacturing conditions

Compared to other types, trapezoidal threads are much easier to manufacture.

That is why it is often used in various fields. The most popular is the acme screw, which has a profile angle of 30°. The production technology is very similar to that used for cutting rectangular threads. But still there are significant differences regarding the accuracy and purity of workmanship. Trapezoidal thread cutting is no different from the same procedure with a rectangular view. On the this moment there are several such ways.

Making a screw with one cutter

A trapezoidal single-start thread is made in the following way:

- the workpiece is prepared and channels for sharpening are made;

- the cutter is sharpened according to a specially prepared template;

- installation and fixing of the sharpened element are carried out. It should be positioned so that the centers coincide and are parallel to the cutting axis;

- the equipment is turned on and the workpiece is fed for threading;

- the finished part is checked according to the finished template.

Cutting with three cutters

This method is as follows:

- preparation is being prepared;

- three cutters are sharpened - straight, narrow and profile;

- installation and fixing of the prepared elements. They can be located either perpendicular or parallel to the axis of the thread. It all depends on the angle of inclination.

Common manufacturing method

It is in production that the cutting of trapezoidal threads takes place in this way:

- checking and adjusting working equipment;

- thanks to the slotted cutter, small indentations are made on the screw;

- using a narrow slotted element, the screw is cut to a certain diameter;

- with the help of a profile slotted element, final production trapezoidal thread;

- the finished part is checked according to the ready-made templates.

Trapezoidal thread: dimensions

As stated earlier, this species thread has the shape of a trapezoid, in which the angle between the sides can have different values. All main dimensions are set in accordance with GOST.

For a single-start type, a trapezoidal thread (dimensions - GOST 9481-81) has dimensions and steps of various diameters - from 10 to 640 mm. In addition, it can be multi-threaded, as well as twisted to the left or right side. These indicators are normalized by GOST 24738-81.

Where is used

For the functioning of any element, such as a machine or mechanism, it is necessary to perform mandatory condition: rotational movements must be converted to translational.

This principle is used for the manufacture of various machines, devices, control systems used in the industrial sector.

Thread Benefits

The efficiency of work on the transformation of rotational movements into translational ones is carried out with the help of a nut and a screw. Despite the fact that these parts look simple, they require care in their manufacture. It is these parts that determine the performance and reliability of not only constituent elements but also all working equipment.

Multi-start thread features

To endow the screw with strength characteristics and increase its stroke, a multi-start trapezoidal thread is used. In this case, all parameters, such as the height of the thread, its diameter, are exactly the same, with a single-start view. The only difference is the number of moves per step. For example, three-start threads have a lead three times their pitch. All this can be seen in the pictures.

Let's give an example to make this view understandable to everyone. Everyone uses ordinary lids for preserving vegetables and fruits. To open them, you need to make a minimum of effort. When using cylinders large diameters getting into the grooves of a single-thread thread is much more difficult. That is why they use multi-pass.

This type of thread can be determined visually, just look at the picture.

You can see exactly how many turns go from the beginning of the screw. Multi-threaded threads are manufactured using complex technologies, and, accordingly, are more expensive.

Other advantages

Trapezoidal joints have many positive qualities. That is why they are used in various manufacturing industries. The most common area is mechanical engineering. So, their advantages include the following:

- ability to assemble and disassemble various devices unlimited quantity once;

- convenient disassembly and assembly process;

- reliability of threaded connection;

- easy manufacturing process;

- self-regulation of the compression force;

- production of parts in various designs.

Connection Disadvantages

There are not so many negative aspects of this type of connection. One of them is the occurrence of a large stress in the depressions. In addition, they cannot be used in devices and mechanisms that have high vibration, as the screws can unscrew themselves, which is not a good sign.

Therefore, it is necessary to monitor this, and in the event of such a situation, correct the position of the screws.

Such a quality as cost can be attributed to both positive and negative sides.

Single-start threads cost significantly less than multi-start threads. Here everyone chooses according to personal preferences. Many design organizations use multi-way threads, as they are reliable and durable.

So, we found out what this type of connection is like a trapezoidal thread, its dimensions, advantages and disadvantages.