High-quality implementation construction work indoors only requires use high-tech materials at all stages. The use of new technologies in the production of components allows us to obtain not only strong, but also durable material.

Just 20 years ago, when installing and manufacturing sewer pipes, one type of material was used - cast iron. As you know, it is easily susceptible to rusting and corrosion. This significantly reduces the service life of the sewer system.

The modern construction market offers a new radical solution to this issue - corrugated pipes. Using them, the consumer will completely forget about problems with the sewage system in the house.

Advantages of corrugated pipes

- strength;

- durability;

- ease of installation and assembly;

- low cost;

- high functionality;

- resistance to damage;

- resistance to temperature changes.

World leading manufacturers

Corrugated sewer pipes are widely used. If they have been used in the Western market for quite a long time, then in the territory Russian Federation they arrived relatively recently.

In the post-Soviet space, the leaders in the production of corrugated pipes are:

- Corsis company

- Pragma company.

To help the consumer decide on the choice of manufacturer, you should carefully study the features of each material.

Corrugated pipes from the Korsis company

The manufacturer occupies one of the leading positions in the Russian market. Products from the Korsis company meet the highest quality standards.

Main features:

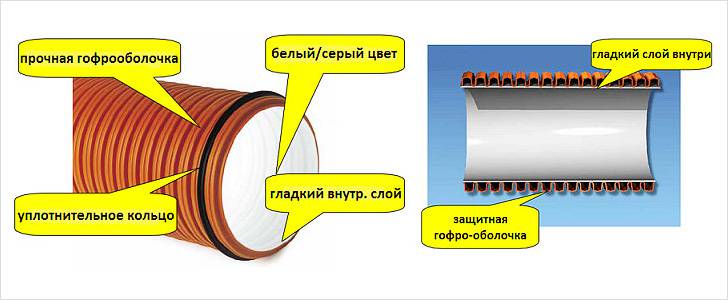

- Pipe surface. WITH outside it is corrugated and has characteristic roughness and irregularities. Inner side The pipes are quite smooth. To achieve this type of pipe surface, a special method is used in production - extrusion.

- Scope of application. Corrugated pipes are used for installation of wastewater systems and drain system sewer drain and drainage of drinking water.

- Persistence. Corrugated pipes can withstand water pressure under pressure of 10 atmospheres.

- Rigidity. The manufacturer supplies pipes of 2 classes: 4 and 8 in terms of hardness.

- Possibility of installation of products at various degrees of depth.

- Protection from damage. To protect against external damage, the corrugated surface of the pipe is covered with black material. It neutralizes ultraviolet radiation that hits it. The inner surface of the product is protected from dirt. A special white coating is used for this.

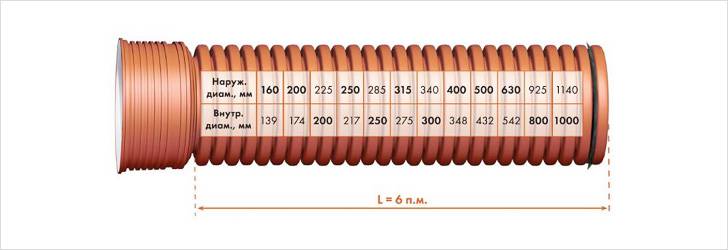

- Length. The company produces corrugated pipes in two length standards. They make up 6 linear meters and 12 linear meters.

Obvious advantages

Corrugated pipes have not yet become widespread. However, thanks to their undeniable advantages, they will soon be able to take a leading position.

- complete tightness during installation;

- high degree of strength;

- reliability;

- resistance to mechanical stress;

- resistance to chemical attack;

- the material is not subject to corrosion;

- low weight of products;

- possibility of transportation in any volume;

- ease of installation process;

- Possibility of use with other types of pipes;

- products can be bent and deformed if necessary;

- long service life;

- low price category.

Product installation

Korsis corrugated pipes can be installed to a depth of 1 to 15 meters.

When laying the pipe, you must adhere to the following rules:

- the surface of the pipe must be completely covered;

- the intercostal space of the pipes must also be filled;

- It is recommended to use granulated material for filling products. Closer to the surface, you can use soil or mineral.

Corrugated pipes from Pragma company

Pipes are made from special material polypropylene block copolymer.

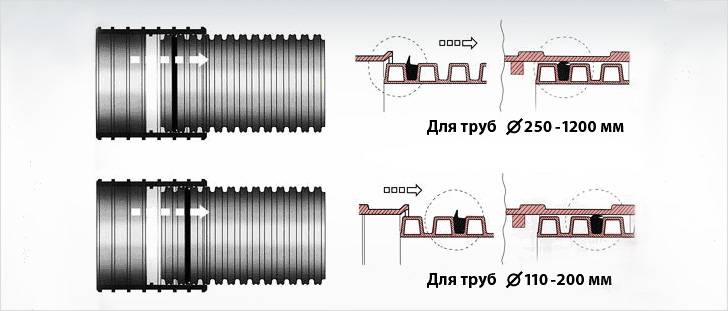

The design consists of a two-layer pipe. There are sockets on its surface.

Production features: 2 layers of pipe (internal and external) are manufactured simultaneously. To achieve this, the Pragma company uses the double extrusion method.

Use of corrugated pipes: sewerage systems.

Peculiarities

Corrugated pipes have a high degree of rigidity. The manufacturer managed to achieve this by making the outer surface with special ribs. Thanks to them, the corrugated pipe is able to withstand high loads. Among other features of the pipe design, one can note its smooth inner surface. Thanks to its design, a minimum degree of friction can be achieved. Thus, the formation of blockages is practically eliminated.

Pragma pipes are manufactured specifically for use in the Russian climate. Therefore, they have a high degree of resistance to temperature changes and difficult weather conditions. The design features of the pipes allow them to be used, installed and transported even in bad weather conditions, in particular at sub-zero temperatures.

Using pipes

Pipes can be used in almost any type of soil. The special corrugated surface allows the pipes to be used even in the most difficult areas.

Due to their characteristics, the pipes are able to withstand high levels of pressure. This allows them to be installed in areas passing under highways, by rail etc.

Pragma corrugated pipes are resistant to the most difficult materials, so they can be used as drainage systems in mining. Due to the high degree of stability of their design, Pragma pipes can be used in public utilities and in production.

Using corrugated pipes for installation sewer systems allows you to achieve their maximum durability and strength.

Corrugated pipe usually used in non-residential utility rooms(such as the attic), since the pipe is not aesthetically pleasing. Most often, corrugated pipe is used for wiring from the distribution panel to apartments. For a private home, corrugated pipes are used to protect cables and wires running along overhead power line to the house. However, there is an option with colored corrugation, which is quite suitable for installing wiring indoors.

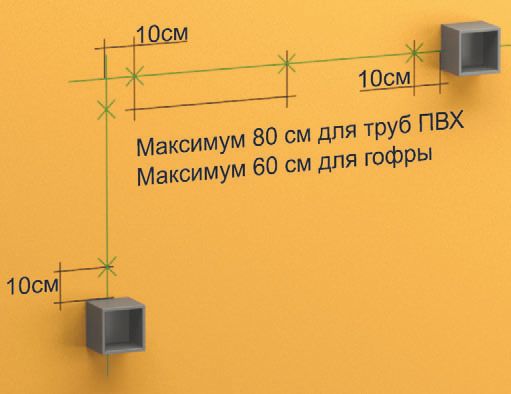

A small diagram of wiring in a corrugated pipe

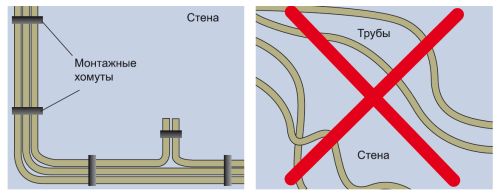

The beginning of the installation of corrugation is the drawing up of a diagram. Remember, pipes cannot be crossed with each other. Firstly, it is not aesthetically pleasing, and secondly, it contradicts safety requirements. Therefore, first carefully draw a diagram of the entire pipe layout for future wiring, eliminating intersections with each other. Once the drawing has been drawn up, we proceed to purchase all the materials and accessories, required quantity corrugated pipe. Let's start making markings.

You need to determine the diameter of a corrugated pipe correctly; to do this, take the entire number of wires that will need to be routed inside the pipe and check on a piece of pipe so that they all fit. The void must be at least half the internal volume of the corrugated pipe, otherwise pulling wires will be difficult or even impossible.

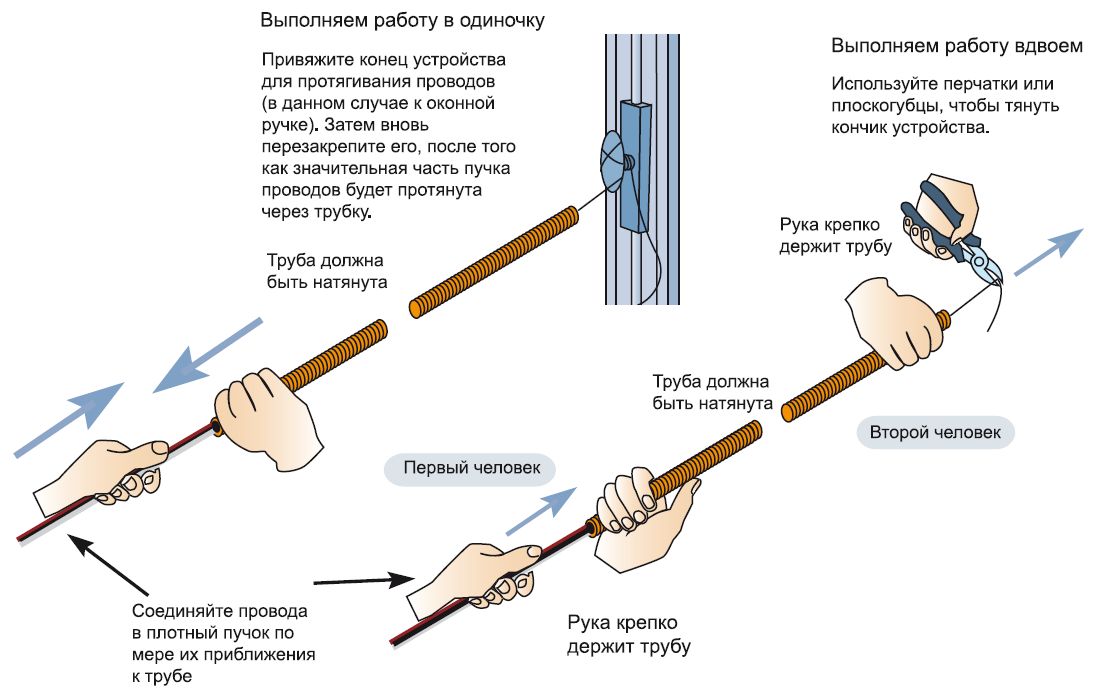

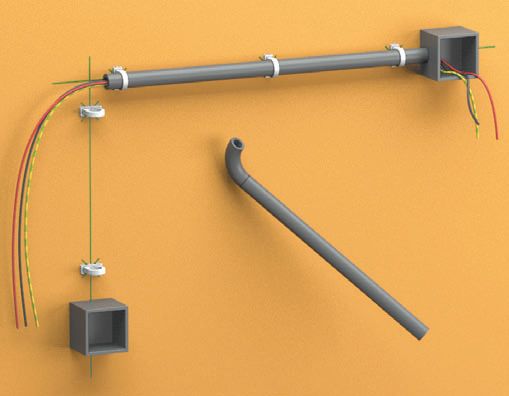

How to thread wiring into a corrugated pipe

Corrugations are available with and without a probe. If there are small areas, you can use corrugation without a probe. If the length of the wire that needs to be threaded into the corrugation is very long, then the corrugation is needed with a probe wire.

How does the wire pull happen?

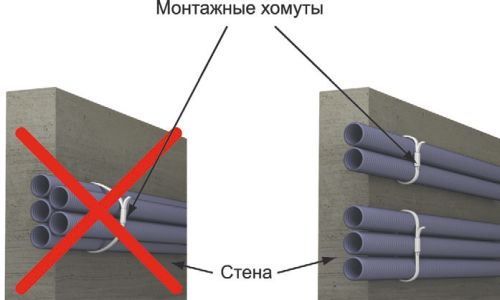

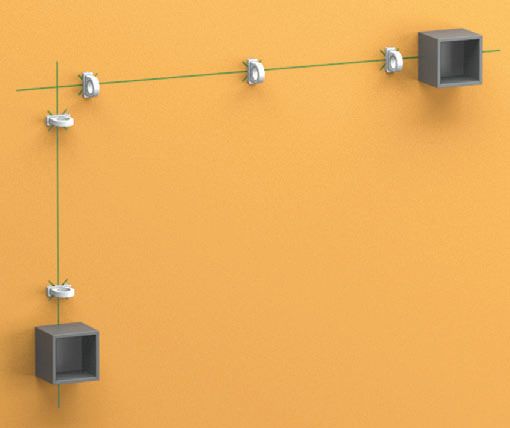

We tie the end of the cable to the end of the probe wire, and grab the pipe tightly with our hand. At the other end of the wire, the wire is pulled through the corrugation. Several cables must be tied at the same time, and the pipe must be straightened for pulling. Markings are made and points are marked for drilling holes for corrugation fasteners. Often in open method When laying corrugated pipes, plastic clips are used, which are secured to the ceiling and walls using dowel nails and screws.

With a corrugated pipe diameter of 16 mm, the fasteners are placed at a distance of 30–40 cm. Corrugations with a diameter of 32, 40 mm require the placement of clips at a distance of 20–30 cm from each other. Then all the holes are drilled, a plastic dowel is inserted into them and screws are screwed in to press the clips. Next, the corrugation with wires is inserted into the clip. To disconnect the corrugation, simply pull the pipe towards you.

There are mounting options using a metal bracket and a tightening clamp. If appearance the pipe does not matter, you can use a tightening clamp, this option is also convenient if installation needs to be done quickly. With one clamp, fastened with a dowel-nail or screw, it is possible to connect several corrugations, tightened with a clamp.

Metalsleeve V living rooms not applicable, located only in technical rooms. Metal hose is mainly used for laying information cables(Internet, TV cable). Thus, the metal hose acts as a screen for external electromagnetic radiation; the pipe is necessarily grounded.

PVC pipes are mounted in the same way as corrugated ones. They are used in utility and non-residential premises where wiring requires additional mechanical protection. Clips or other type of fastening can be placed less frequently than in the case of corrugated pipe, since PVC pipes They hold their size well and do not sag.

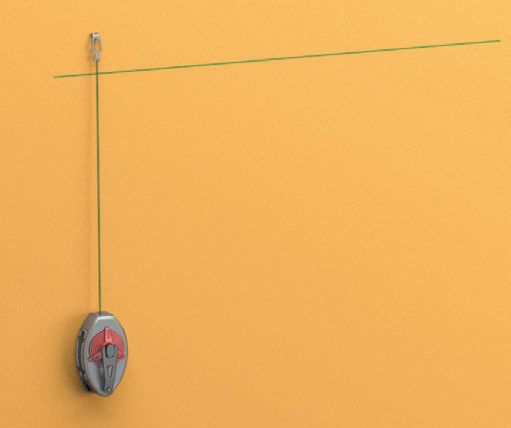

Step 1. The wall is marked using a beating - a dyed thread.

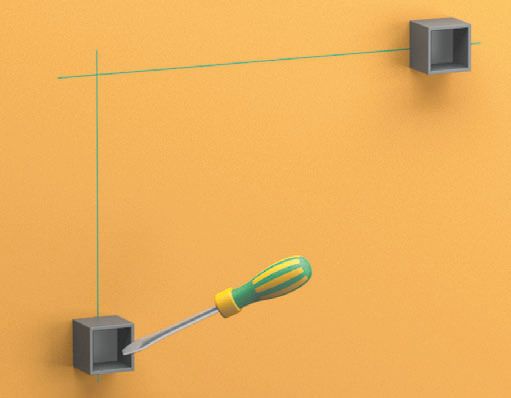

Step 2. Installation of installation and junction boxes.

Step 3. Places for attaching clips for future pipe laying are marked.

Step 4. Installation of clips.

Step 5. The pipes are cut into several pieces of the required length, and then secured into clips, adjusting the size of the accessories.

Step 6. The wire is pulled through the pipes and finally installed.

Recently in stock building materials a new element has appeared - a corrugated pipe for heated floors. Performance characteristics This material is significantly superior to those of pipes made of polypropylene and copper, and the main advantages of corrugated pipes are its excellent strength and ease of installation.

Corrugated pipe is easy to install, durable and unpretentious

Important characteristics of pipes for heated floors

The installation of a water heated floor is carried out under a concrete screed, and therefore special requirements are placed on the quality of the pipe, because to repair the damaged area, you will have to dismantle the floor and also break up the concrete layer. That is why pipes for water heated floors must have a certain set of characteristics.

What should be the pipes for water heated floors?

Quality, long term service, ease of installation and unpretentiousness are obvious requirements that apply not only to the pipes themselves, but also to most other building materials and products. In addition to them, water pipes for heated floors must meet a number of requirements:

- Reliability. It is believed that the service life of pipes should be comparable to the service life of the building, and therefore be at least 50 years.

- Plastic. On average, water contours are 60-120 meters long, and when laid they form many bends. That is why pipes must be plastic, not be damaged and not lose their qualities in places of bending. In other words: the easier the pipe bends, the easier its installation will be.

- Impermeable to oxygen. Oxygen entering the pipes - main reason formation of corrosion and destruction of walls.

- Price. A warm floor usually contains enough large number pipes, so their price should be affordable.

- Mechanical strength. Since the pipes are used on the floor, they must be able to withstand high mechanical loads. In cases where they mechanical strength is low, experts recommend laying an additional layer of reinforcing mesh on top of them to protect them from destruction.

Not all pipes for heated floors on the construction market meet all of the above requirements. Products made from cross-linked polyethylene, copper, metal-polymer pipes, as well as corrugated stainless pipe for heated floors. However, the latter has advantages that make it the most desirable material for installing underfloor heating systems.

Advantages of corrugated water pipes

As mentioned above, the main advantages of corrugated water pipes are their strength and ease of installation. In addition, a metal corrugated pipe for heated floors has the following advantages:

- Undemanding. Unlike pipes made of copper and plastic, corrugated material does not require preventive cleaning and periodic replacement, so it can be safely filled with a thick layer of concrete or covered with panels.

- Safety. Corrugated pipe is resistant to ultra-high temperatures and does not deform even from boiling water (which cannot be said about polymer materials).

- Ease of installation. To install the pipe, no special equipment is required (for example, in the form of welding equipment and a soldering iron for connecting polypropylene pipes).

- Flexibility. The corrugated pipe for a warm water floor easily bends under the right angle, taking the required position and direction. Thanks to this, you can collect the most complex circuit warm floor without much effort and with a minimum amount of connecting fasteners.

- Operational endurance. Corrugated pipe is resistant to corrosion, mold and development harmful microorganisms. It is also not afraid of rodent attacks, so it can be used in basements and in warehouses.

- Wear resistance. The corrugated pipe can withstand massive water hammer pressures of up to 65 bar.

- Versatility. Corrugated pipes for heated floors can serve as heating radiators, as they have very high thermal conductivity and heat transfer.

Choosing corrugated pipes for installing a heated floor system

When buying a pipe for organizing a heated floor system in your home, you should pay attention not only to how well it meets the requirements listed above; Equally important are the following characteristics:

- Pipe length (coil footage). The pipe must be long enough to lay one circuit without additional connections. This will prevent potential water leaks at fasteners and help create a more reliable and predictable system.

It's important to remember that maximum length pipes on the circuit are limited by its diameter. Thus, the length of a circuit built with a pipe 16 mm in diameter should not exceed 70 meters; 20 mm in diameter - 90 meters; 25 mm in diameter - 120 meters.

- Pipe diameter. The most in demand are pipes with a cross section of 16, 20, 25 mm. Choosing between thick and thin pipe, it should be remembered that a thick pipe has greater heat transfer, however, filling such a pipe requires a significantly larger volume cement mixture, which, in turn, leads to an increase in the floor level and an increase in the load on the flooring and ceilings.

- Manufacturer. The cost of the pipe, as well as its quality, vary depending on who produced it. Today they are producing corrugated pipes Russian manufacturers(Ruvinil, Neptune, Kofulso) South Korea(Lavita, Hydrosta), Germany (Meibes).

- Mechanical strength. This is one of the most important requirements. Metal walls withstand not only pressure from concrete screed, but also internal pressure water in the circuit. At the time of emergency water hammer, the pipe must be able to withstand a pressure of 10 bar.

Installation of water corrugated pipes

Laying the contours of a heated floor system is not the best simple work, however, if you have experience working with conventional metal or plastic pipes, even a beginner can do it.

The sequence of actions for installing corrugated water pipes is as follows:

- First of all, it is necessary to waterproof the floor using a waterproofing membrane, rubber paint or a ready-made composition based on plasticizers.

- After waterproofing, the floor surface is covered with expanded clay concrete or mortar screed.

- A reflector (for example, based on foil) is laid on top of the screed, and a metal mesh is placed on it.

- At a distance of 15 cm from the wall, a corrugated pipe is laid (loop pitch - 20 cm) in accordance with the selected laying pattern.

When determining the loop pitch, you should know that the corrugated pipe heats the floor surface at a distance of 10 cm, so a 20 cm loop completely covers a 40 cm wide zone. To provide a zone with comfortable temperature the loop can be up to 30 cm wide.

- A corrugated pipe (stainless steel) for a warm floor is attached to a metal mesh using a plastic tie, the “tails” of which are cut off after installation.

- Before filling, the system is pressure tested for 3 hours with a pressure of about 7 atm.

- Then beacons are placed on the floor surface.

- The screed solution is prepared according to the selected recipe.

- The solution is poured to a height of 5 cm for every 20 cm of area.

- The screed takes about 1 month to dry (3 weeks in summer, a little over 4 weeks during the rest of the year).

- The first start of the system is carried out in two stages: the first time, water is started at a temperature of no more than 25 degrees for 24 hours; at the second stage, the water temperature rises to 40 degrees, the screed is dried for several days, after which the heated floor is turned off.

- The tiles are being laid.

You can get acquainted with the installation process of corrugated water pipes by watching this video.