Plywood laser cutting machine: laser power, equipment price

Plywood is one of the best decor materials. In addition to its operational qualities, it is easy to process. However, mechanical curly cutting does not always give the desired result. Therefore, plywood laser cutting machines have been developed. This is an innovative technology that allows you to make complex three-dimensional drawings and patterns.

Plywood Laser Cutting Machine

Point thermal impact on decorative natural material partially destroys it. This is due to the formation of plasma, similar to arc welding. However, the plywood does not melt, but burns out.

The main component of the machine is a laser machine. It forms a concentrated radiation that affects the material. CO2 lasers are used for this. Semiconductor models do not have sufficient power and can only be used for artistic burning.

The procedure for performing figured laser cutting of plywood.

- Creating a drawing. Depending on the capabilities of the equipment, this can be done electronically or independently apply a pattern to the surface.

- Choice of cutting mode. The determining parameter is the laser power. It depends on the thickness and structure of the plywood. If the degree of heating is exceeded, the width of the cut will increase.

- Drawing formation. Its speed is affected by the power of the laser. The higher it is, the faster the process runs. However, this increases the area of darkening at the edges.

This is a general description of the technology and is subject to change depending on the parameters and functionality of the equipment. The average power of the laser machine is about 20 watts. It directly depends on the thickness of the plywood and the complexity of the pattern.

For work, it is best to use automated CNC processing centers for wood. This will increase accuracy and improve performance.

Features of cutting plywood with a laser

plywood cutting process

The main disadvantage of this type of equipment is its high cost. A number of advantages that are impossible for mechanical processing make wood laser centers very popular. They are used to complete production, are used to perform a small amount of work at home.

The defining advantage of laser cutting is the thin seam on the wood. It may be slightly larger than the beam diameter. Thus, maximum detail and exact correspondence of the result to the original layout is achieved.

This technology has the following features:

- a slight darkening is formed in the area affected by the beam. This is unavoidable but can be corrected by painting or varnishing;

- cutting requires no mechanical force. In the process, there is no surface deformation characteristic of classical processing methods;

- The quality of work is affected by the composition of the wood. It is not recommended to use sheets made of softwood. They contain a large amount of resins, which, when evaporated, affect the appearance.

For large volumes of production, it is necessary to provide a system for extracting fumes. This is done using local ventilation. The absence of chips significantly softens the requirements for working conditions when cutting plywood with a laser machine.

The surface of the processed material is preliminarily cleaned of dust and dirt. The presence of varnish, paint or similar decorative and protective compositions is not allowed.

List of cutting equipment

Professional Laser Cutting Machine for Plywood

To complete a professional production line, it is recommended to purchase specialized equipment. But in addition to the laser installation, other components must be present in it.

To ensure maximum automation of work, the laser head must move freely along the length and width of the wooden surface. To do this, install a special carriage that moves along the guides.

In addition, the following components are required for normal operation:

- electronic control unit. He controls the operation of the laser, gives commands to move it relative to the sheet;

- exhaust system for combustion products. Despite their small amount, without forced ventilation, the concentration of harmful substances will quickly increase;

- interface for entering information - drawing, machine operating modes, etc.

To perform a small amount of work, it will not be advisable to purchase expensive equipment. The best option is to use the services of specialized manufacturing companies. In this case, you only need to draw up the drawing correctly and select the material on which it will be applied.

In the video you can see an example of the operation of a machine for forming a pattern on the surface of a plywood sheet:

Overview of finished machine models

If you want to purchase a laser cutting machine for plywood, then pay attention to their difference in power:

- desktop. Designed for work at home or a small workshop with small workpieces. Power up to 80 W, price from 50,000 rubles;

- professional. It is used in small business in the production of designer jewelry, engraving, cutting materials to size. Power up to 195 W, price from 150,000 rubles;

- industrial. It is used on production lines of high power and throughput with increased requirements for quality and accuracy of work. Power from 3000 W, price from 450,000 rubles.

Consider machines from different price categories.

Main page

abcgdeezhziyklmnoprstufhtschshchyyeyuya

Laser cut plywood

Cut out a circle from plywood for a table, from birch knots - chairs, firewood.

Felling areas are areas on which a tree stand has been cut down, but the young growth has not closed.

And the armor we have made of birch plywood is glued on waterproof glue, this is also created by craftsmen over more than one year of work, although, I confess, many models are very imperfect.

Buying a scrapbooking machine for cutting is not only to facilitate your interesting and at the same time difficult work, but also to free up time for new searches and accomplishments in creative searches.

Plywood laser cutting machines: types, basics of choice

As for fires and uncontrolled logging, this is not a question of climate warming, but of Vladimir Vladimirovich Putin, who, having signed the new Forest Code in 2008, made such logging unpunished, leaving forests without foresters.

Laser carriers are discs, from the surface of which information is received.

Laser scanners are scanners that have low-power lasers as a source of radiation.

Laser guns are already something Hollywood IMHO))) I didn’t want to spoil the picture with button accordions))) Note 2: Your posts are highlighted in red to make it easier for you to find them in the general comment feed.

Laser technology is one of the most effective tools, the capabilities of which are comparable to the prospects.

Laser technologies this is not only safe and highly effective hair removal, the specialists of the LINLINE laser cosmetology clinic offer a number of other procedures based on laser technologies - laser peeling, photorejuvenation, acne treatment and others.

wood laser cutting prices

ArtMetall+ offers professional laser cutting services for wood, plywood and MDF.

We provide the highest precision, speed and cost-effectiveness of processing. The use of automated equipment allows us to cut both simple and the most original parts quickly and at an affordable price.

Call, clarify the nuances and order laser cutting of wooden products of any complexity!

Work process

Wood laser cutting is the most economical processing method, reducing waste due to high precision work.

It is especially advantageous to perform cutting of the same type of blanks. We provide cutting services for plywood and wood products in a wide range.

Laser cutting machine for plywood - inaccessible equipment or reality?

Such products are used to decorate interiors and make souvenirs.

The most difficult type of laser cutting of wooden materials is cutting plywood. During this work, the surface may ignite or the end face may be charred. This results in a darkening of the cut edge. To avoid end charring and fire, our installer constantly controls the intensity of the cooling air supply. In addition to automating the process, constant monitoring is needed.

In addition, different types of trees are cut by a laser in different ways.

It is necessary to individually set the optimal parameters for beam temperature and cooling intensity. If this is done incorrectly, then marriage is inevitable. We have the best equipment for wood laser cutting and professional fitters.

When cutting with a laser, there is no such damage to plywood sheets as when mechanically cutting elements of complex shape.

There are also no losses in the form of chips and sawdust. It is well known that burrs and torn edges are formed on the edge of parts after a mechanical cut. And the use of our technology provides a high quality cut surface. No dust and chips. This additionally makes wood laser cutting safer and more profitable.

Note! In addition to laser cutting of wood, we perform cutting of black and non-ferrous sheet metal, as well as offer bending and powder coating services for sheet metal.

Our advantages

- The main benefits of laser cutting plywood are high speed and precision processing at an affordable price.

This is achieved through equipment and professional staff. We have automated laser machines for cutting plywood and wood, as well as adjusters with work experience of 5 years or more.

- For designers, we provide unlimited opportunities to create unique wooden products.

High quality cutting and positioning of the laser beam provide the highest processing accuracy.

- We guarantee the safety of work. Due to the use of modern wood laser cutting technology, air is constantly supplied to the processing area. This cools the wooden surfaces. At the same time, no deposits remain on plywood or MDF, not to mention the ignition of the material.

- Better than our laser cutting is only artistic hand-carved wood.

But such products require a lot of time to process and are much more expensive.

Important! Despite the many advantages, the result of laser cutting depends on the qualifications of the employees.

The experience of our operators allows us to use various technologies and approaches necessary for high-quality processing of all types of plywood. We also cut plastic, plexiglass and aluminium.

The video shows photos of examples of laser cutting wood.

We guarantee high speed of manufacturing parts, evenness of cut, precise geometry and surface finish.

You receive the necessary blanks that exactly match the specified sizes and shapes. You will also like our prices and terms of laser cutting of plywood and wood. Call and order these turnkey services!

You can check the prices by phone: From Monday to Sunday from 9:00 to 21:00

Do you have questions about forged products? Fill out the form below and we will call you back.

The beauty of any product cut from plywood primarily depends on the quality of the material used, but an important role in this process is also given to the method of its processing.

Cutting plywood is most often done with a hand or power tool. Recently, laser cutting of plywood has gained wide popularity, which makes it possible to obtain high-class products.

Artistic laser cutting of plywood is indispensable for engraving and cutting out small openwork details.

Cutting process

Laser cutting of plywood is still a rather little-studied way of processing this material.

This is due to the fact that for quite a long time laser equipment was very expensive and not very efficient.

But modern technology has stepped far ahead in the study of this issue. Currently, such work can be carried out on their own.

Laser cutting of plywood is performed using a point impact of a beam with a powerful charge of energy on the surface of the material being processed. With this method, non-contact processing is performed, as a result of which the appearance of waste is excluded.

A homemade laser for cutting plywood is assembled from a DVD drive and a matchbox.

At the point of contact between the laser beam and the processed sheet, a sharp surge in temperature occurs, which leads to the evaporation of the wood structure and ensures the appearance of a cut.

The thickness of this cut does not exceed 0.01-0.02 mm, thereby increasing the accuracy of processing.

Such do-it-yourself processing of plywood is very relevant when performing engraving or cutting out various small figured products.

But be aware that laser cutting leaves dark edges on the part. This is caused by the charring process that occurs due to the increase in the temperature of the wood.

Processing in-house

For laser cutting, the main source of radiation is a gas tube.

Such a gas consists of several components:

- nitrogen.

- Helium.

- Carbon monoxide.

A discharge of electric current is applied to this tube, which provokes the appearance of monochrome radiation. This radiation passes through a system of mirrors and is directed to the surface of the material. In this case, the power level of the laser tube should not be less than 20-25 watts.

When laser cutting, you need to choose the right elements for power transformation.

For the convenience of work, such tubes must be equipped with a powerful cooling system.

A cooling system will be required, as the shell of the tube becomes very hot during operation. Therefore, it must be provided with a second shell through which the coolant will constantly circulate.

Such a cooling system can be built from a water tank with a volume of 80-100 liters. This container must be equipped with a water pump and filled with coolant. Most often, freon is used as such a liquid.

In addition, in order to achieve good radiation, it is necessary to use a high-quality transformer that will convert electricity into a high-frequency signal.

You also need to take care of the exhaust system and blowing the room.

Laser cutting on wood at home

This is a necessary factor, since during operation there is a strong smoke in the space due to the combustion of processed products. In addition, small fires of crafts can occur during work, so you should always have a bucket of water on hand.

Cutting plywood with a laser is a rather expensive type of processing.

But, despite this, it allows you to get products with high quality and processing accuracy at the output.

If necessary plywood are often asked what cutting methods are best used to produce a particular product or item. In this case it often doesn't matter plywood price. It is difficult to distinguish between all the different cutting options. Therefore, we propose to briefly consider the most popular, widely used plywood cutting methods.

open plywood can be implemented in several ways. The easiest and most affordable for everyone is the use of conventional hand wires. But since the material of plywood is quite dense, at least compared to a regular spruce plate, you will have to spend a lot of effort to cut thick plywood.

Laser cutting plywood

You can use an electric saw blade to install a conventional hand saw.

Home-Cutting is a very effective method that allows you to easily cut thin and thick plywood, but this method is also suitable primarily for cutting connected with straight lines, in addition, the cutting method is likely to form a large number of chips on the surface of the material .

If you need to cut, for example, a semi-circular or shaped element, you can use a saw blade to cut sheet materials.

It can be manual and electric. However, it is difficult to achieve high quality. Often, once such cutting tools are positioned on bonded edge edges, the cuts can cause irregularities and achieve high dimensional and feature accuracy, "repeatability" is not possible.

Therefore, if you need to perform quality cutting, especially if you need it plywood milling on a large scale, it is advisable to consider using specialized equipment or to cut to order.

The equipment that allows cutting high quality plywood varies depending on the material being cut.

Most common laser cut plywood, plywood milling and cutting on a cutting machine.

Let's think about these methods:

Forming machine cutting is one of the easiest cutting methods.

You can also order this kind of cutting from a hardware store. But cutting such machines can only be done in a straight line, which greatly enhances the scale.

When using milling and laser cutting plywood on CNC machines, there is a much wider possibility of cutting plywood.

Cutting plywood with a laser This allows the elements to be produced without machining the material, so that the appearance of a cut or cup at the edge of the material is completely eliminated.

The diameter of the laser beam is so small that it can cut products with a size of several millimeters with a complex geometric shape.

The maximum thickness of plywood that can cut through a laser beam depends on the power of the laser and is often limited to a thickness of 15-20 millimeters.

It should be noted that cutting after laser cutting changes color (burns). Depending on the task, this can be a negative and positive feature of laser cutting.

Where it is necessary to draw a quality line or plywood milling, but so that the material at the cut does not change color, it is better to use milling plywood.

This allows you to both cut and penetrate material only at a certain depth, drain, process depression and more. Even though this cutting method involves mechanical action on the material using special plywood, it can actually eliminate chips and a bunch of cuts.

Modern milling and laser cutting implemented on CNC equipment (computer controlled).

To start the cutting process, you need a ready-made layout in electronic form. If the layout cannot be created, you can order it directly from a company offering milling services or laser cutting materials.

plywood cutting cost mainly calculated by the thickness and the number of liquid meters.

Nevertheless, CNC binding to plywood has its own characteristics and, if there are a large number of individual elements of a small size, the cost of cutting can be increased. This is due to the need to spend time with frequent introductions to the material, as well as a large number of "blank" passages between elements.

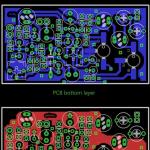

Below the image, you can see how the laser and laser were achieved on the product sanding plywood.

The edge of the workpiece after laser processing has changed color, in contrast to the cutter of the workpiece.

It should be noted that the dark edge of the plywood emphasizes the contours of the product, which can be used for decorative purposes.

Finally, it should be noted that not only the methods of cutting plywood are distinguished, but also its characteristics.

Plywood panels are made of beaded veneer or veneer, the surface can be floor and not polished. Thickness, moisture resistance, type of adhesive material, the presence or absence of surface defects also differ. Since all of these parameters depend plywood price You can download stuff without going over the surplus for unnecessary overpriced properties.

Below the video you can see the process of making a plywood product using milling and laser cutting.

| VIDEO: Milled plywood |

Buy plywood in St. Petersburg St. Petersburg and order to cut in the cutting center " Profrezka«

The ArtMetal+ company offers professional laser cutting services for wood, plywood and MDF. We provide the highest precision, speed and cost-effectiveness of processing. The use of automated equipment allows us to cut both simple and the most original parts quickly and at an affordable price. Call, clarify the nuances and order laser cutting of wooden products of any complexity!

You can check the prices by phone: From Monday to Sunday from 9:00 to 21:00

Work process

Wood laser cutting is the most economical processing method, reducing waste due to high precision work. It is especially advantageous to perform cutting of the same type of blanks. We provide cutting services for plywood and wood products in a wide range. Such products are used to decorate interiors and make souvenirs.

The most difficult type of laser cutting of wooden materials is cutting plywood. During this work, the surface may ignite or the end face may be charred. This results in a darkening of the cut edge. To avoid end charring and fire, our installer constantly controls the intensity of the cooling air supply. In addition to automating the process, constant monitoring is needed.

In addition, different types of trees are cut by a laser in different ways. It is necessary to individually set the optimal parameters for beam temperature and cooling intensity. If this is done incorrectly, then marriage is inevitable. We have the best equipment for wood laser cutting and professional fitters.

When cutting with a laser, there is no such damage to plywood sheets as when mechanically cutting elements of complex shape. There are also no losses in the form of chips and sawdust. It is well known that burrs and torn edges are formed on the edge of parts after a mechanical cut. And the use of our technology provides a high quality cut surface. No dust and chips. This additionally makes wood laser cutting safer and more profitable.

Note! In addition to laser cutting of wood, we perform cutting of black and non-ferrous sheet metal, as well as offer bending and powder coating services for sheet metal.

Our advantages

- The main benefits of laser cutting plywood are high speed and precision processing at an affordable price. This is achieved through equipment and professional staff. We have automated laser machines for cutting plywood and wood, as well as adjusters with work experience of 5 years or more.

- For designers, we provide unlimited opportunities to create unique wooden products. High quality cutting and positioning of the laser beam provide the highest processing accuracy.

- We guarantee the safety of work. Due to the use of modern wood laser cutting technology, air is constantly supplied to the processing area. This cools the wooden surfaces. At the same time, no deposits remain on plywood or MDF, not to mention the ignition of the material.

- Better than our laser cutting is only artistic hand-carved wood. But such products require a lot of time to process and are much more expensive.

Important! Despite the many advantages, the result of laser cutting depends on the qualifications of the employees. The experience of our operators allows us to use various technologies and approaches necessary for high-quality processing of all types of plywood. In addition, we carry out cutting

If you urgently need professional laser wood cutting, order it at Yuda. With the help of the service, you will find qualified carpenters from Moscow and the Moscow region, who will qualitatively perform all work on wood and plywood processing. Experts use reliable equipment in their work.

Features of laser cutting

Yudu performers qualitatively and in a short time perform laser cutting of wood using a plasma laser machine. If necessary, part of the work is carried out by a manual engraver. Cutting wood with a laser to order has the following advantages over milling with a CNC machine:

- carving process takes place with a minimum consumption of material

- the method ensures the durability of the product

- the laser beam easily and accurately cuts an array of plywood of any thickness

- using a laser device, you can create a pattern with a 3D effect

Due to this, the cost of the work done is significantly reduced. In addition, Yudu performers offer affordable prices in Moscow for creating wood products using a laser.

The craftsmen that you will find with the help of Yudu work with all kinds of materials:

- hardboard

- pine

- oak

- birch and many others

Yudu performers will carve any pattern on the sheet plywood layout. Specialists can cut out beautiful plates with the image of flowers, animals, dedicatory inscriptions. The laser allows you to create an accurate pattern of any complexity.

Why is it worth ordering the services of Yudu performers?

The site has registered experienced private craftsmen and representatives of companies that work around the clock. Yudu performers will cheaply make high-quality laser cutting on wood to order. With the help of the YouDo service, you will find specialists who will carve the workpiece at your home.

Yudu performers have experience in laser wood engraving. In their work, professionals use only reliable and modern laser machines. Carrying out cutting or engraving of wood, specialists will take into account all your wishes. Yudu performers will make any product that you need out of plywood:

- decorative element of the interior

- souvenir with a gift inscription

- wood panel or other decoration

How much does laser engraving on wood cost?

The services of Yudu performers are inexpensive. On the site you will find masters who can agree with the cost of the work you proposed. The price per linear meter is assigned depending on:

- layout size

- pattern complexity

- workpiece material and thickness

If you need laser cutting on wood, order it from Yudu performers by filling out an application on this page.

From 10r / meter cut.

We process not only plywood, but also numerous wooden surfaces such as oak, beech, ash, pine, etc. But plywood is an excellent material for processing with high flexibility parameters. Cutting wood and plywood with a laser involves a thermal effect on the material, as a result of which the cut is processed by combustion. Cutting plywood and wood with a milling cutter is carried out using a high-precision CNC milling and engraving machine. Both processing methods have a number of advantages. The choice depends on the idea of your final product and layout. Figurative cutting of wood requires skill and excellent creative abilities, then finished products acquire a finished aesthetic appearance.

Figured cutting of wooden and plywood surfaces

Figured cutting of wooden and plywood surfaces has a number of features, depending on the properties of the material, its thickness and size. The standard dimensions of a plywood sheet are 1525 x 1525 mm, 2440 x 1220 mm, 3000 x 1500 mm, the thickness can vary in the range of 3-40 mm. We offer only high-quality raw materials for the manufacture of finished products - FK and FSF, grades 1\2, 2\2, Sh2. The materials used are devoid of knots and unevenness, and careful double-sided grinding guarantees the production of aesthetic and attractive products.

Wood is a special material. It is characterized by increased strength, original texture, which allows it to be used in various areas of work, from repair to creativity. Environmental safety and visual beauty make the tree in demand in production and in everyday life.

An apparatus for laser cutting wood will help you to make various elements on your own. This device, due to the thermal effect on the texture, provides a long service life, as bacteria and microorganisms that negatively affect the natural material are destroyed. Such a device does not leave any waste in the form of chips or sawdust, so the device for laser cutting wood can be used at home as well.

Device types

For woodworking in modern workshops, including home ones, modern machines are used that have numerical control. With your own hands, you can assemble the following types of machines:

- floor;

- desktop.

Floor-standing (installed directly on the floor) - the working surface of the device is from 0.5 m to 2 m. It is optimal to use them for production purposes, since they require a special room (workshop). The case is monolithic, due to which vibration is reduced. Direction of work:

- engraving;

- cutting;

- open.

Machines for desktop placement - differ in the compact dimensions of the case. They can be used both in the home workshop and in a specialized production room. They are equipped with a good optical system, which allows even a non-professional to achieve high quality indicators.

Wood processing is also carried out with compact machines. Using them, you can create a variety of volumetric products with your own hands. Distinctive features are small dimensions, the ability to create strong and durable parts with high detailing of the pattern. The design of the marker is such that it is based on a high-tech optical system.

Device device

When assembling a laser wood cutting machine with your own hands, you should take into account the features of the device. Main criteria:

- laser;

- cooling system;

- Control block.

The laser is the main working element. Its head must rotate and move without restriction in any direction. For this purpose, a set of parts is used - guides and special carriages;

The cooling system is a significant element. The serviceability of its work largely determines the quality of the products;

The control unit or electronic module of the device is a control mechanism that monitors the movement of the laser. Controls additionally its power.

The complex arrangement of machines is necessary to achieve ideal results of the work performed. It is important that the required parameters can be entered using a computer. This will allow you to set the functionality of the modes, the features of the patterns, the duration of the cut.

Attention! It is necessary to organize a good ventilation system in the room where the wood laser cutting machine will be installed. The removal of combustion products is obligatory, since during operation a large amount of fumes harmful to health is formed.

Advantages and disadvantages of homemade devices

In order for the production process to bring positive results and the part or element to be durable and beautiful, it will be necessary to take into account both the positive and negative aspects of home-made devices and laser cutting in particular. Knowing the pros and cons will allow you to make the best choice. Main positive aspects:

- minimum or adjustable cutting width (from 0.01 mm);

- the possibility of engraving on wood;

- settings for laser cutting plywood;

- the ability to independently create complex drawings;

- high accuracy of work performed.

The edges of the part are even and smooth, which is also a plus. Additional benefits are expressed in saving time when performing work of any complexity. With your own hands, complex drawings or volumetric elements can be created in just a few hours.

There is no need to expend physical strength, since the device performs all the necessary actions independently, guided by a given program.

When choosing equipment, it is very important not to forget that there are disadvantages. The disadvantages of laser devices are:

- high cost of components for them;

- the impossibility of self-manufacturing of the laser itself;

- short service life of the main equipment elements (laser tube works no more than 8 thousand hours);

- liquid cooling is required.

Therefore, you need to assemble a laser machine yourself if a person has fairly high professional skills or is ready to perform a large amount of work. For the first steps in this direction of activity, it is recommended to choose a device that can function without software.

Important! Laser cutting is based on the action of a powerful beam, which creates a cut with high temperature. In order to avoid smoke, you will need to create a blowing system. It is necessary in order to reduce the likelihood of ignition of the material.

At home, the system can be a glass box with forced-type ventilation built into it.

Technology and features of cutting plywood

When assembling a device for laser cutting plywood, it must be taken into account that the technology of work has a number of features:

- in the area of impact of the laser beam, where a slot passes or a hole is formed, a slight darkening remains;

- the previous process cannot be avoided, but can be decorated with varnish or paint;

- for the implementation of cutting does not need to apply mechanical effort;

- during operation, there is no deformation of the plywood surface.

An important feature to consider when choosing a material for cutting is that it is not recommended to use plywood sheets if they are made from pine or other softwoods. This is due to the fact that wood contains resins in its composition, which reduce the quality of products, as they evaporate. As a result, the visually finished element may change. There are no shavings or other plywood cutting waste - this reduces the requirements for the workshop.

Features of cutting wood at home

Before starting to perform work related to the impact of a laser on a tree, you will need to carefully study the technology of the device. The first start-up is recommended to be carried out under the supervision of a specialist or with full protection of hands and eyes.

The basic wood cutting process consists of the following steps:

- production of a model using a special computer program in 2-D or 3-D format;

- creating a product template;

- fixing a workpiece of a certain size on the working surface;

- turning on the laser machine.

The obtained parameters of the future product will need to be entered into a special program, which the computer will independently study, make the necessary calculations, adjust the values \u200b\u200bor changes corresponding to the existing template.

An additional work step is to periodically check the cooling tube, since the liquid contained in it can evaporate under the influence of high temperatures. After that, the master must control the cutting process, if the equipment does not have the function of automatic shutdown upon failure or at the end of the specified program.

Thus, laser machines for cutting wooden elements or plywood are an ideal choice for both a professional and a novice craftsman who strives to produce quality products. The choice of equipment components should take into account the positive and negative aspects, as well as the available volumes of work to be done.