Unlike centrifugal units (see), screw pumps for wells are capable of pumping liquids with a high content of mechanical impurities. If we talk about organizing an individual water supply for a private household from a sand well, then such a pump would be the best choice, since the presence of sand in the water does not affect its reliability and performance.

Device and operation of screw pumps

It is easiest for a person far from technology to explain the device and principle of operation of a screw pump using the example of a conventional meat grinder.

Design features

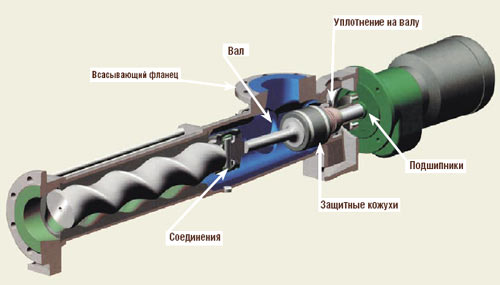

As in a meat grinder, the main working part of the device is an auger (therefore, such pumps are often called auger pumps), enclosed in a rubber cage. But it is not connected directly to the rotating shaft of the engine, but with the help of a cardan transmission, which ensures their slight misalignment.

When the shaft begins to rotate, the screw connected to it performs a complex movement around its axis, which in turn also rotates along a circle whose radius is given by the eccentricity of the screw. As a result of such movement, cavities are formed between the turns of the screw and the cage, which constantly move in the direction from the suction hole to the outlet pipe.

The liquid that has entered these cavities is gradually injected into the chamber, from where it is forced out under pressure, and in the meantime, pressure is reduced in the receiving part of the pump, so water from the well rushes into it.

Note. In this design, there are no parts between which solid inclusions in the liquid could get stuck - they are carried out with it. Therefore, screw pumps for wells can be used for pumping contaminated water with a high content of impurities.

Depending on the number of screws, these devices can be single-screw or multi-screw. But in systems of individual water supply from wells, they are usually used with one screw.

To obtain clean drinking water at the outlet, a coarse mesh filter is often mounted on the suction pipe of the device, which does not allow large particles of sand or silt to pass inside. If this is not enough, then fine filters are already installed on the surface, most often in the technical room of the house. Which ones are determined after water analysis (see).

Maintenance and operation

A simple and reliable design guarantees consumers a minimum of costs and time for the maintenance of such equipment.

So:

- The pump screw and rotor are cooled by the pumped water, so it practically does not need preventive maintenance, which is very convenient, since for this it would have to be periodically taken out of a deep well and then reinstalled.

- But even if repair or replacement of some parts is required, the well-thought-out design of the unit will allow you to do it yourself, without resorting to the services of specialists and the use of sophisticated equipment.

- The long service life of such pumps is also explained by the absence of vibration during operation, despite the high power and high speed.

- They are practically silent, so even if the well is equipped in the basement of the house, the operating equipment will not create discomfort.

Note. If necessary, a screw borehole pump can be used to supply water from reservoirs and reservoirs, as it can work in any position - both vertical and horizontal.

Downhole installation

Submersible screw pumps are mounted in the same way as centrifugal and any others. They also have an elongated cylindrical shape with a suction hole in the lower part, an outlet pipe and lugs for a cable in the upper part.

A metal cable holds the device at a given level, and power is supplied to it through an electrical cable. A hose or pipe is connected to the outlet pipe, through which water is supplied upward.

Instructions for connecting and installing the pump:

- Assemble the device and make sure it works;

- Connect the pressure hose to the nozzle and tighten it with clamps in several places along the entire length with a cable so that the latter does not sag;

- Install float switch if it is included;

- Attach the safety metal cable. This is a very crucial moment: if the cable breaks, getting the pump out of the well by pulling it by the cable will be problematic and fraught with breakage;

- Carefully lower the unit into the well to the required depth. by making a mark on the hose or cable in advance;

- Fasten the cable to ;

- Connect the screw pump for the well to the mains and check its operation.

The device must not vibrate or make loud noises or thuds. If this is not the case, then somewhere you made a mistake or there are problems in the mechanism itself.

Popular models of household screw pumps

Screw pumps are produced by many domestic and foreign manufacturers.

Among the most common and popular among our consumers are the following brands:

- Aquarius (Promelectro, Ukraine). Aquarius submersible pumps are compact and high power, can be used to supply water from wells, open reservoirs and wells with an internal diameter of at least 10 cm. Great for plumbing in a country house, irrigation and irrigation systems, as well as for pumping water from pools , reservoirs, flooded cellars. The kit includes a synthetic cable for installation in a well or well.

- . These deep hole screw pumps made of stainless steel are also multifunctional and versatile. Are applied to the device of water supply of private houses, garden and farms. They have high power, can work smoothly for a long time, the thermal protection of the engine is built into the design.

- Unipump ECO VINT (Russia). These pumps are distinguished by their low price, high pressure and low productivity, which is the best solution for sources with a small flow rate - wells and sand wells. The absence of vibration does not allow turbidity to rise from the bottom of the well, and even with a high content of mechanical impurities in the water, the throughput of the device does not decrease.

Conclusion

It is definitely worth giving preference to screw pumps in cases where the quality of the water in the well leaves much to be desired. You can do its cleaning after rising to the surface, but the auger design device will cope with the extraction in the best possible way.

After watching the video in this article, you will better understand how it works and what are its advantages over other submersible pumps.