Own water supply is considered a huge plus in almost any summer cottage. It does not require much effort from the owner in order to get water. If there is not enough water, then if necessary, you can easily equip a well. You can easily extract water from it, but for this you will need to connect a borehole pump.

Due to the simplicity of the design, submersible pumps are installed in the well, which can also be called deep pumps. From the name you can understand that the structure will be completely in the water. Here we will talk about how to connect a submersible pump to the network and the water supply system with our own hands. If necessary, you can read about.

Preparatory work

In order for an uninterrupted water supply system to be provided on the site, you need to monitor the operation of the device.

A minimum kit may be required to ensure water production. To date, the minimum set for supplying water from a well or well should consist of:

- Deep pump.

- Check valve.

- float sensor.

- Relay to provide pressure check.

- Hydraulic accumulator tank.

- Control block.

Now we need to consider each device separately. Thanks to this, you will be able to understand what they are intended for.

A pump is a power element that is capable of supplying water from a well. The check valve is a special membrane, the installation of which must be performed at the outlet of the power unit. Also, the design prevents the backflow of water.

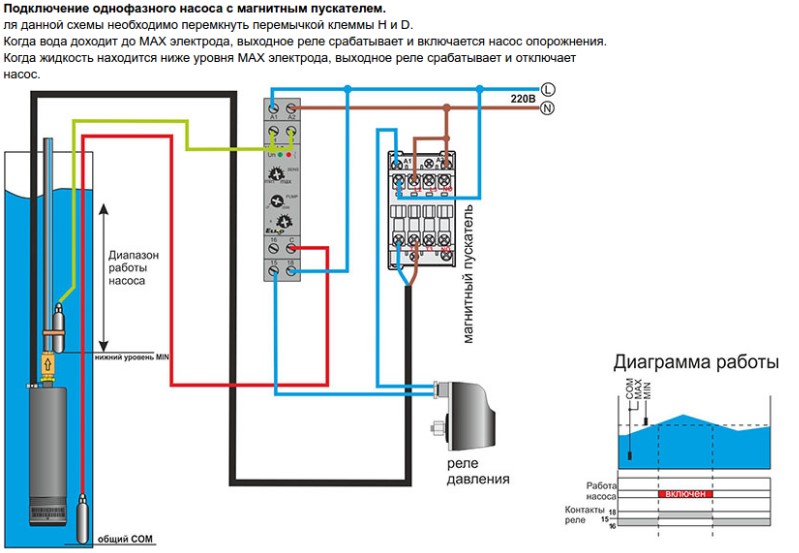

Float sensor - this element can be attributed to automation. He monitors the water level in the well. In most cases, it depends on its position whether permission to start the engine will be given. Sometimes devices may install a level sensor instead. If you do not know how to connect, then below we have presented a diagram.

The pressure switch is another element that can be attributed to automation. It controls the start of the submerged unit and will be able to regulate the pressure in the water supply.

A hydraulic accumulator is a special passive system that allows you to maintain pressure in the pipe. The device is able to smooth out sudden pressure surges. The system cannot work independently and a pressure switch can be used in pairs.

Now you know all the elements of the system that may be required to connect a submersible pump to automation.

You can connect the borehole pump through the RCD. It allows you to control the insulation of the included devices and cable. If the problem is identified in time, then you can save a lot of money.

To install the pump and ensure a normal water supply, the following materials may be required:

- Plumbing unit.

- Special tank.

- Pressure switch. This device, you need to choose based on the capacity of the tank.

- Coupling "American".

- Collet clutch.

- Fitting.

The installation and connection of the submersible pump begin to be made from the piping of the accumulator. If you do not know how to assemble, then you should study the photos that we have placed below:

The first step is the preparation process. In the second photo you can see how the threaded connection is wound. Now you should establish an American connection. Now you should complete the installation of the pressure switch and pressure gauge, which will be required for visual control. After completing this stage, you can begin to dismantle the outgoing elbow, which is made of PVC. In the next picture you will see the installation of the collet and pressure pipe. In 10 photos you will see how the finished group will be connected to the water supply.

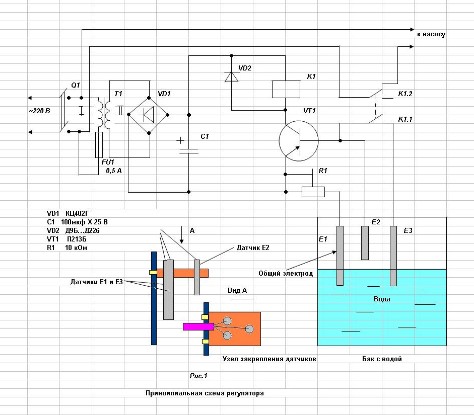

The last steps include opening and connecting the relay unit. If the system will consist of one automation unit and a pressure sensor, then the “LINE” and “MOTOR” inputs are designated on the terminals of the device. If you choose perfect automation, then it will consist of an electronic unit. The control unit is able to provide uninterrupted water supply to the system. Thanks to this, the engine will be protected from drying out. If the water level decreases or increases, then the unit will be able to perform a soft start or stop. Below is a diagram of the control unit.

If you want to get acquainted with the information in detail, then in the video below you can see the technology for assembling a water pressure boosting system. We also presented a video showing the process of installing a submersible pump in a well.

It was a detailed instruction that tells how to connect a submersible pump to the network and the water supply system. As you can see, everyone can cope with such a task, but you should approach the task responsibly and then everything will work out.