No matter how high-quality the toilet bowl and fittings are, problems arise from time to time: either water is not collected, or vice versa, it constantly flows from the drain. All these problems are associated with fittings (drain and inlet valves), which are placed in the drain tank. Next, we’ll talk about how to install it, change, adjust and repair it yourself, with your own hands.

Internal organization

The toilet cistern consists of two simple systems: a set of water and its discharge. To troubleshoot possible problems, you need to understand how everything works and works. First, consider what parts the old-style toilet bowl consists of. Their system is more understandable and visual, and the operation of more modern devices will be clear by analogy.

The internal fittings of a tank of this type are very simple. The water supply system is an inlet valve with a float mechanism, the drain system is a lever and a pear with a drain valve inside. There is also an overflow pipe - through it excess water leaves the tank, bypassing the drain hole.

![]()

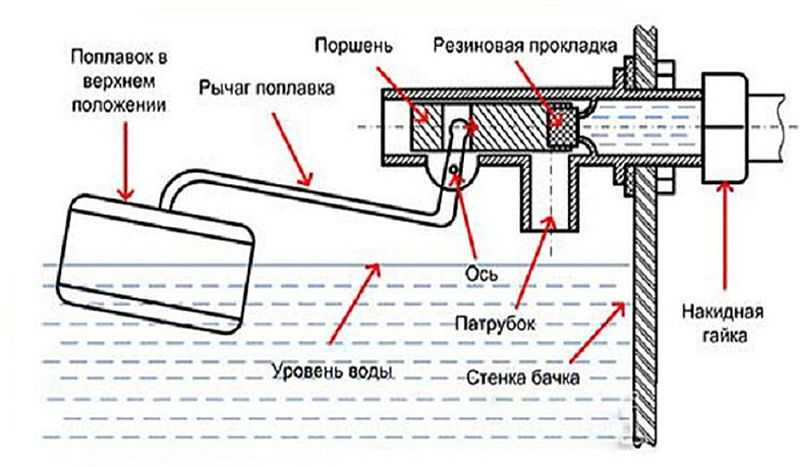

The main thing in this design is the correct operation of the water supply system. A more detailed diagram of its device is in the figure below. The inlet valve is connected to the float using a curved lever. This lever presses on the piston, which opens / closes the water supply.

When filling the tank, the float is in the lower position. Its lever does not put pressure on the piston and it is squeezed out by water pressure, opening the outlet to the pipe. Water is gradually drawn in. As the water level rises, the float rises. Gradually, he presses the piston, blocking the water supply.

The system is simple and quite effective, the filling level of the tank can be changed by bending the lever a little. The disadvantage of this system is a noticeable noise when filling.

Now let's look at how the drain of water in the tank works. In this embodiment, the drain hole is blocked by a pear of the drain valve. A chain is attached to the pear, which is connected to the drain lever. By pressing the lever, we raise the pear, the water drains into the hole. When the level drops, the float goes down, opening the water supply. This is how this type of cistern works.

Modern models with lever drain

They make less noise when filling the cistern for toilet bowls with a lower water supply. This is a more modern version of the device described above. Here the tap / inlet valve is hidden inside the tank - in a tube (in the photo - a gray tube to which the float is connected).

Drain tank with water supply from below

The mechanism of operation is the same - the float is lowered - the valve is open, water flows. The tank was filled, the float rose, the valve turned off the water. The drain system remained almost unchanged in this version - the same valve that rises when the lever is pressed. The water overflow system has hardly changed either - this is also a tube, but it is brought out to the same drain.

You can clearly see the operation of the drain tank of such a system in the video.

With button

Models of toilet bowls with a button have similar water inlet fittings (some with side water supply, some with bottom) and drain fittings of a different type.

The system shown in the photo is most often found in toilet bowls of domestic production. It is inexpensive and quite reliable. The device of imported units is different. They basically have a bottom water supply and another drain-overflow device (pictured below).

There are different types of systems:

- with one button, water is drained as long as the button is pressed;

- with one button, draining starts when pressed, stops when pressed again;

- with two buttons that release different amounts of water.

The mechanism of work here is slightly different, although the principle remains the same. In this fitting, when the button is pressed, a glass is raised that blocks the drain, while the stand remains motionless. In short, this is the difference. The drain is adjusted using a swivel nut or a special lever.

Installation and replacement of cistern fittings

A significant part of toilet problems are solved by adjusting or replacing the cistern fittings. In any case, you need to know how to disassemble and assemble the inside of the tank. This skill will definitely help you. When replacing, you must first dismantle the old device, and then install a new one. We will describe in detail the whole process, including the installation of new fittings.

How to remove the lid from the tank

If a drain tank with a button is being repaired, it is not always immediately clear how to remove the lid. This is easy to do: press the button, turn the ring.

If it doesn’t work with your fingers, pressing the button, consider its inner rim. There are two special slots. You can take a screwdriver with a narrow end, turn the ring a little with it. Then you can already twist it with your fingers.

After that, remove the button by pulling it up. Everything, the lid can be lifted.

Tank dismantling

To replace the old fittings of the flush tank, it must be removed from the toilet bowl. First of all, turn off the water supply, then drain the water from the tank. Then, using the keys, remove the water supply hose (it is attached to the side or bottom).

Next, you need to disconnect the tank from the toilet bowl. If you look under it from below, you can see the bolts that are tightened with nuts. So we unscrew them using a set of open-end wrenches or an adjustable wrench. Before that, place a container near the toilet or lay a rag - a certain amount of water always remains in the tank, when you unscrew the nuts, it will drain.

Having unscrewed two nuts - on the right and on the left, we remove the tank. There is usually a gasket on the bowl. If it is deformed or dried out, it is also desirable to replace it.

The tank is placed on a flat surface. There is a large plastic nut at the bottom of it. It holds the drain mechanism, we unscrew it. Sometimes the first turns have to be done with an adjustable wrench, but do not overtighten it - the plastic can be brittle.

Now the water drain mechanism can be easily removed.

We remove the water supply mechanism in the same way. With bottom feed, the fastening nut is also at the bottom (right or left of center).

After that, we look inside the drain tank. Usually, rusty sediment, small metal particles, sand, etc. accumulate at the bottom. All this must be removed, if possible, washed. The inside must be clean - trash that has fallen under the gaskets can cause a leak. After that, we begin the installation of new fittings.

Installation of drain tank fittings

Everything happens in reverse order. First, we install a new rack of the drain mechanism. We unscrew the plastic nut from it, put a rubber gasket on the pipe. It can be white (as pictured) or black.

We start the device inside the container, from the outside we wind the plastic nut. We twist it, as long as possible, with our fingers, then tighten it a little with a key. You can not overtighten - it will burst.

Now on the toilet bowl we replace the o-ring sealing its connection with the drain tank. Dirt and rust often accumulate in this place - we wipe it first, the seat must be dry and clean.

Inside the tank we install the fixing bolts, not forgetting to put the gaskets. We put the drain tank in place until it can be leveled. The main thing is to get the screws and the outlet part into the seats. We take a washer, a nut and screw them onto the screws.

When both nuts are installed, but not yet tightened, we level the container. Then, using the key, we begin to tighten the mount. We twist a few turns, then to the right, then to the left.

Lastly, install the inlet valve for the drain tank. It could have been installed earlier, but then it is inconvenient to install the mounting bolts - there is too little space. We also put a gasket on the outlet pipe, then install it inside, fix it with a nut.

The next step is to connect water to the same pipe. Before connecting the flexible hose for water, we open the water for a while, making it possible to remove the scale that accumulates every time after closing the tap, even for a short time. Having lowered a certain amount of water (substitute a bucket so as not to wet the floor), we connect the hose to the fitting (we turn off the water again).

Although the fitting is metal, it is also not necessary to tighten this connection strongly - first with your fingers, then one turn with a key. If drops are found when the water is turned on, you can tighten it another half turn. After that, we check if the system works correctly. If everything is correct, install the cover, fasten the button. You can test again. This completes the installation of the fittings of the drain tank. As you can see, everything can be done by hand.

Adjustment and repair

During the operation of the toilet, problems periodically arise - either it flows, or, on the contrary, no water is drawn into it. Sometimes, tired of the inconvenience, people buy new toilets. But in vain. Most of the faults are fixed in 10-20 minutes. Moreover, everything is so simple that everyone can handle it. You don't have to call a plumber. You can do everything with your own hands.

Water level adjustment

We are talking about devices with a lower water supply. After installation, the toilet cistern must be adjusted. By default, they come from the factory set to the maximum amount of water in the tank. This amount is often excessive. With a simple adjustment, we can reduce the volume of water in the tank. For this:

The same procedure is necessary if water constantly leaks from the tank. One reason is that the float is too high. Because of this, water flows through the overflow system.

With a side water supply and a float mechanism, the adjustment is even easier - we change the position of the float by bending its lever. On the one hand, it is easier, but on the other hand, it is more difficult. You have to bend it many times to achieve the required level.

Toilet cistern leaking

If the water in the toilet is constantly leaking, and its level is normal, we move on. There are several reasons for this leak. And if so, then the methods of elimination will be different.

- The sealing gum under the drain valve in the tank silted up, dirt got under it, a groove (or several) appeared on its surface. The method of treatment is to clean the existing gasket or replace it with a new one. To reanimate the old one, you need:

- turn off the water, flush it,

- remove the trigger mechanism by unscrewing the plastic nut from the bottom;

- pull out the drain valve, remove and examine the gasket, clean it of settled particles, if necessary (there are grooves), grind it with very fine sandpaper until smooth;

- reinstall, connect everything and check the operation.

Water is not drawn

Another problem that you can fix with your own hands is that water is not drawn into the drain tank. Most likely it's a blockage - a filter or tubes are clogged. Long talk, better watch the video.