Independent installation of a gas boiler in an apartment or private house is complex both technologically and organizationally.

Important! We must not forget that gas is a highly dangerous fuel, and all work must be carried out by specialists. Otherwise, the risk of a fatal mistake is too great, the result of which will no longer be additional costs, but damage to the health and sometimes even lives of people.

About the types of gas equipment

Installation of gas boilers

Installing gas equipment in any case will require going through the authorities, obtaining the necessary permits and a whole heap of various documents. Both the devices and the room itself must meet the requirements and standards laid down in the regulatory documentation. Installation of units must be carried out according to the rules. However, before you start visiting regulatory organizations, it is worth understanding the types of gas equipment used for heating and hot water supply.

To create a complete heating and hot water supply system, you will need to install a double-circuit boiler. The unit must have all the necessary automation. Such devices are expensive, and their installation should only be carried out by specialists.

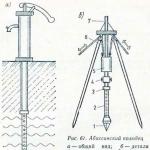

The budget option is to use gas equipment only to produce hot water. That is, we are talking about a gas water heater. Compared to electric heaters, it is more efficient and cheaper to operate. Even an expensive device will pay for itself in about a year and a half. Here you need to take into account that its installation is not permissible in all apartments. The advantage of water heaters is that you can easily install them yourself. You need to decide which option to choose based on specific conditions.

Boiler room at home

A full-fledged boiler room based on a gas boiler can be equipped in a country wooden house, in a cottage, or in an ordinary city apartment.

Its “heart” is a double-circuit boiler with automatic systems. Automation ensures not only security, but also the efficiency of operation of the entire network. It is on its operation that the provision of a comfortable temperature regime and the possibility of reducing gas consumption during operation of the device depend.

Despite all its advantages, installing a boiler with automation has one important nuance. In the event of a power outage, the unit will switch to minimal room heating mode.

About installation rules

There are a number of requirements for installing gas equipment:

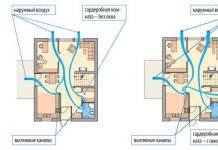

- The vast majority of models need to be located in a separate room. The exception is wall-mounted units - they can be mounted in non-residential rooms, for example, in the kitchen or bathroom, if their size allows. Before installing the boiler, it is necessary to ensure the required ventilation in the boiler room.

- The volume of premises for the installation of gas equipment with a closed chamber is not regulated, but the area must comply with the standards. In addition, the unit must have an outlet to the flue. It is unacceptable to bring it near the ventilation ducts.

- Horizontally located parts of the gas duct cannot be more than 3 meters long and have more than three turns. The flue outlet must be raised above the roof level by at least a meter.

- Wall-mounted models are mounted at a distance of 800 mm or more from the floor surface. No objects should be placed under the boiler, and a metal sheet must be laid on the floor. An expansion tank and an air valve must be installed.

Gas equipment cannot be installed in the following types of premises:

- In the apartments of an apartment building without a main gas duct - these are the majority of old buildings.

- In rooms with false ceilings and capital mezzanines.

It is almost impossible to install a floor model in an apartment in a multi-storey building. After all, this will require serious redevelopment with all the ensuing problems and costs. There are no restrictions on the installation of such equipment in a private home. Here it is better to make a separate boiler room, for example, in an extension. This room must meet the following standards:

- Entrance doors are no longer 80 cm.

- There must be a chimney that goes either to the roof or through the wall to the outside.

- The height of the boiler room must be at least 2.2 m. The room is equipped with a ventilation system.

A double-circuit boiler with automation will require a separate branch of electrical wiring. An additional 20 A circuit breaker is installed on it. It is advisable to provide backup power to the automation, capable of maintaining its operation in normal mode at least for a day. To do this, you can purchase a diesel generator or a UPS - an uninterruptible power supply.

Severe demands are placed on the gas duct. Its minimum diameter is 110 mm, regardless of the power of the installed equipment. The optimal diameter of the flue is calculated based on the power characteristics of the unit - the higher the power, the larger the diameter.

Boiler connection

Gas heating boilers installation and configuration

The main parameter when choosing a gas boiler is its power. It should be sufficient to ensure the normal functioning of the heating network, but at the same time not excessive. With excess power, there is a high risk of cracking the heat exchanger. So-called acid condensate can also form when the return temperature drops below the gas dew point - 56 degrees. The high-power unit quickly warms up the system and goes into standby mode until the temperature drops to certain parameters. After cooling, the boiler turns on again, but powerful heat exchangers have high thermal inertia, so acidic condensate may form before it is reheated.

The optimal power should be determined on the basis of thermal calculations. The excess power must be within the permissible run-up. In a private house, you will have to do thermal calculations yourself or invite specialists. For apartment buildings, such data can be found in the technical inventory office.

Before installing the boiler, it is necessary not only to equip the room, but also to collect the necessary documentation:

- A gas supply agreement is not required when installing a water heater.

- Documents for the meter - without this device it is prohibited to connect gas heating and water heating equipment.

- Documents from the BTI on amendments to the technical passport of a house or apartment. The new plan must take into account the location of the boiler room.

- Technical passport for boiler equipment.

At this stage, you can submit an application to the gas service for the development of design documentation and specifications. You can install the device yourself before receiving the finished project, but provided that the room fully complies with the standards and is approved by regulatory services. Gas connections should only be made by gas service employees. A suitability statement must be obtained from a gas engineer before commissioning.

If you connected the boiler to the gas mains yourself, there is practically no chance of getting an engineer’s opinion. Such work should only be carried out by gas specialists. You can install the hydraulic and electrical connections of the boiler yourself. As a rule, all the necessary requirements and instructions can be found in the instructions for the device.

Project and specifications

Boiler check

Design and technical specifications (technical conditions) are the most important documents for the installation of a gas autonomous heating network. Technical conditions are drawn up in the gas service. In essence, this document is an official permit to install equipment. For premises that fully comply with the requirements of regulatory documentation, registration of technical specifications takes about 14 days.

Project documentation is developed after receiving the specifications. In essence, it represents a diagram for installing the unit and laying the gas pipeline. For a private house, the project must include a highway route through the site. This documentation is also developed only by licensed design specialists.

Approvals

Even documents developed by specialists must be approved by regulatory gas services. All this can take up to three months, depending on the complexity of the developed project. Along with the project documentation, it is necessary to submit to the gas services:

- Heating device data sheet and operating instructions.

- Certificates for equipment.

- Conclusion of the examination.

Let's start installation

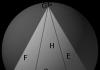

Installation diagram of a double-circuit gas boiler

Wall-mounted and floor-standing gas boilers must be installed by specialists licensed to perform such work. The work is carried out in a room with a temperature of at least +5 degrees and in several stages:

- Preparing the hole through which the coaxial pipe or flue will be discharged.

- Installation of the unit. Wall-mounted - on a bracket, floor-mounted - on a pre-prepared place.

- Connection in hydropiping.

- Installation of a gas tap, meter, if it was not installed previously, and sensors.

- Connecting the unit to the electrical wiring and grounding it.

- Exiting the coaxial pipe outside the house.

- Filling the system with coolant and pressure testing.

- Check for gas leaks.

Conclusion

Regardless of the type of equipment you purchase, only gas specialists should install a boiler in a house or apartment. Independent work is allowed only partially and provided that it does not require intervention in the gas main . All documentation on the basis of which the boiler is installed must be approved. Only the simplest water heaters, that is, geysers, can be installed independently.

Gas heating boilers are an excellent way to create a space heating system. They are quite economical and capable of demonstrating decent efficiency. However, such heating systems are sources of increased danger and, therefore, during the construction process it is necessary to follow the rules for installing a gas boiler.

First of all, please note that all equipment designed to work with gas (be it a boiler, pipes, connecting fittings or other devices) must have the appropriate certificate. You cannot use equipment designed, for example, for water supply systems, to create gas communications. As a rule, the installation of gas boilers and heating systems based on such devices also requires the involvement of workers who have the appropriate permits and have undergone training. But in extreme cases, you can install a heating system based on a gas boiler yourself.

Unified rules for installing gas boilers in homes

To ensure trouble-free and safe operation of gas heating equipment, it is necessary to follow a number of strict, but fairly simple to follow rules.

Requirements for the premises under the boiler room

First of all, remember that natural gas is an extremely flammable substance and its use in unprepared and inappropriate premises can lead to very unpleasant consequences.

However, gas heating boilers with a power of up to 60 kilowatts can be installed in any, even unprepared, premises. But the boilers must be single-circuit. If the heating boiler has a second circuit, its installation in a kitchen area is prohibited.

To install gas heating boilers with a power of up to 150 kilowatts, you can choose any floor of your home. However, if you plan to install a more powerful heating system, then it can only be placed in the basement or basement.

Please note that according to existing standards, per 1 kilowatt of gas boiler power there should be 0.2 cubic meters of the volume of the room in which it is installed. Also, the gas boiler room in a private house must have a ceiling height of at least 2.5 meters and provide convenient access to any element of the heating system. The walls of a gas boiler room must be fire resistant with a rating of at least ¾ hour. Just like with other placement options, a separate gas boiler room must have natural light, that is, it must have a window in the outer wall of the house.

Requirements for chimneys of gas boilers

Chimneys of gas boilers of heating systems also have their own installation rules. Their incorrect operation can lead to the accumulation of combustion products and tragic consequences.

The required minimum chimney diameter is indicated in the specification for your gas boiler. In this case, its inlet cross-section must coincide with the cross-section of the outlet of the gas boiler.

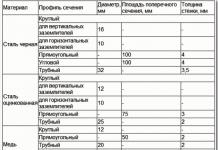

To ensure the removal of combustion products, the upper edge of the chimney must be placed at least half a meter from the roof ridge. As a rule, round chimneys are used for gas heating, the walls of which are made of ferrous metal or stainless steel.

When creating a heating system project, it is necessary to ensure that the chimney of a gas boiler has no more than three bends or turns. The initial section of the chimney directly adjacent to the gas boiler must be at least 25 centimeters.

Obtaining permits

Due to the fact that gas heating is a source of increased danger, it is necessary to obtain a number of permits before installing it.

At the initial stage, you need to secure the connection to the gas supply pipe with an agreement. Before the construction of the heating system, a gasification project is developed and approved. Only after the project has been approved by an authorized organization can you begin purchasing equipment and directly installing it.

Rules for installing a wall-mounted gas boiler

After approval of the project, at the purchase stage, be sure to check the availability of fastening devices in the delivery kit. If the manufacturer does not include them in the kit, they must be purchased separately. Be sure to request a certificate for the gas boiler you purchase. Check the boiler markings and the information specified in the safety certificate.

At the preliminary installation stage, thoroughly bleed the internal piping system of the boiler. Remove all transport plugs. The pipes are cleaned with a low-pressure water stream; the water will remove small debris and dust.

Make sure that the wall material on which you plan to place the gas boiler is made of non-combustible material. Otherwise, it must be reinforced with a fireproof coating more than 3 mm thick. With this placement, the boiler itself must be placed no less than 45 mm from the wall surface.

The installation height of a gas boiler is 80 to 160 cm. There should be no other electrical or gas equipment or any flammable materials at a distance of at least 20 cm from it.

When installing the mounting brackets, check their horizontal and vertical positions with a building level.

In the event that the design of a gas boiler requires draft in the chimney, we form and check the exit routes for combustion products. There are also so-called “non-chimney” boilers, in which combustion products are removed by forced air circulation through an exhaust fan.

Gas connection to the boiler is carried out with the mandatory participation of a certified specialist. During installation, only metal pipes and special connecting devices are used.

If your gas boiler has electrical appliances, we connect it to the electrical network through a separate circuit breaker protecting against short circuits and overheating.

The first start-up of a gas heating boiler must be carried out in the presence of a specialist from the gas company, after carefully checking that all installation rules have been followed.

Rules for installing a floor-standing gas boiler

Floor-standing gas boilers have greater power compared to wall-mounted ones and require stricter installation rules.

When installing a floor-standing boiler, as a rule, a branched heating system is also installed, distributing heat to several rooms or several floors. Therefore, even before purchasing a boiler, it is necessary to draw up a design for the heating system and understand the location of all its elements, including the correspondence of the location of the outlet pipes of the floor-standing boiler to the inlet pipes of the heating system.

A floor-standing boiler can also be installed on a solid wooden floor, however (unlike a concrete floor) it must be protected with galvanized iron or clinker tiles. In this case, the non-combustible base must extend beyond the front side of the boiler by at least half a meter.

Like the wall-mounted option, floor-standing gas boilers are carefully checked according to the building level during installation. When installing such boilers, a high-quality chimney system must be equipped

Water heating systems based on gas boilers require the installation of a hardness filter for the incoming water flow.

Please note that each water supply and intake pipe must be equipped with devices that facilitate their dismantling. This is done in order to replace any of the system elements in case of repair. Valves are also installed on all pipes.

The rules for installing a floor-standing gas boiler also require its connection and first start-up only with the participation of a specialist from the gas company.

Rules for installing a gas boiler: training video

Today, gas boilers and water heaters are used everywhere both for heating water and for heating houses. For the most part, separate single-circuit boilers or one single-circuit boiler and an indirect heating boiler are used for heating and hot water supply, which creates certain inconveniences in their placement. Therefore, in houses and apartments with low hot water consumption, the installation of double-circuit gas boilers, which combine water heating for both household needs and heating, is becoming increasingly popular. The installation of gas boilers is associated with a number of specific difficulties, related more to compliance with the norms and requirements for boilers than to the process of their installation.

The design of double-circuit gas boilers is essentially similar to the design of a conventional single-circuit boiler, where a gas burner heats a heat exchanger with a coolant. The main difference is the ability of double-circuit boilers to simultaneously heat water for heating the house and for household needs. This is achieved through the combined placement of pipes for heating and hot water supply in the heat exchanger.

At first glance, the heat exchanger of a double-circuit boiler looks like an ordinary coil with a radiator grille. But it is necessary to note the following: the coil of a double-circuit boiler is most often a combination of 2 in 1 pipes. Inside the main pipe through which water for heating flows, there is another one for hot water supply. At the same time, one more very important point should be noted. Water in such a double heat exchanger circulates in opposite directions in each of the circuits. This was done specifically to improve heat transfer and this must be taken into account when designing and connecting the water supply and heating system to a double-circuit boiler.

The presence of two heating circuits at once also affected the number of connected pipes. In contrast to the single-circuit one, where there were only three pipes, supplying and discharging water and one supplying gas. There are five such pipes in a double-circuit boiler. The diagram depicting a double-circuit gas boiler shows the following (from right to left):

- pipe with incoming coolant for heating;

- supply pipe for hot water supply;

- gas supply pipe;

- pipe with outgoing hot water for water supply;

- pipe with outgoing coolant for heating.

Important! Before using the above diagram when connecting your own boiler, carefully study the manual for it. It is quite possible that your boiler will be connected slightly differently. For example, both inlet pipes are on the right side, and both outgoing pipes are on the left.

It is also worth noting that today on the market you can find a double-circuit gas boiler, both wall-mounted and floor-standing. In addition to the installation method, the difference between them is that the floor-mounted one requires a separate room - a boiler room, while the wall-mounted one can be installed in the kitchen or in a place reserved for the boiler. We will look further at where and how to install gas heating boilers.

Standards and requirements for the installation of gas boilers

It should be noted right away that the installation and connection of a double-circuit gas boiler can only be carried out by specialized organizations that have permission and a license for this activity. Self-installation and connection is fraught with fairly high fines. But still, you will have to do some work on preparing to connect the boiler and obtaining the necessary permits yourself.

The following recommendations and rules are excerpts from the main regulatory documents, such as SNiP 42-01-2002 “Gas distribution systems”, as well as SNiP II-35-76 “Boiler installations”, Code of rules for the design of autonomous heat supply systems SP-41-104 -2000. These regulatory documents describe in detail what can and cannot be done when installing gas equipment. We will consider the main most important requirements for installing gas boilers.

1. The room where the gas boiler will be installed must be at least 4 m2 with ceilings not lower than 2.5 m;

2. The doorway in the room must be at least 80 cm wide;

3. The room must have a window opening. The window size is calculated based on the following requirements - for 10 m2 of area, a window with an area of 0.3 m2;

4. It is necessary to have high-quality ventilation in the room to ensure constant gas combustion. The hole area should be 8 cm2 per 1 kW of boiler power. This also applies to boilers with a closed combustion chamber, for which coaxial chimneys are used, combining the functions of removing combustion products and supplying air to the boiler;

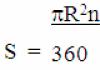

5. The diameter of the chimney is selected according to the power of the boiler itself and is calculated using a special formula. In general, boilers from 30 kW to 40 kW are most often used for heating a house. Accordingly, chimneys with a diameter of 130 mm and 170 mm are installed;

6. The upper end of the chimney should protrude 50 cm above the roof ridge. If a coaxial chimney is used, its outlet end should protrude from the air intake by at least 20 cm;

7. The gas pipeline in the house must be made of metal pipes. But to connect the boiler to the main line, you can use flexible corrugated pipes;

8. The boiler must be equipped with a special automatic current and thermal protection;

9. The room with the boiler must be equipped with a gas analyzer;

10. Installation of gas boilers in basements is permitted only for private houses. For apartment buildings, installation of gas boilers is permitted only in the kitchen or in specially designated boiler rooms;

11. Each boiler must be equipped with a gas meter;

12. The room must have a cold water pipeline;

13. In the room where the boiler will be installed, the walls must be leveled and plastered;

14. Boilers cannot be installed on combustible surfaces, in corridors, in the bathroom, in a dormitory, on a balcony, in rooms without windows or vents, in the basements of apartment buildings;

15. The boiler must be placed at least 15 cm from the wall. There should be a minimum of 20 cm from the top edge of the chimney to the ceiling. The outer part of the chimney should protrude 30 cm from the wall of the house. The installation height of a wall-hung boiler should be 0.8 - 1 m from the floor, and a heat-insulating panel should be placed between the wall and the boiler.

Important! If the boiler is a double-circuit boiler with a closed combustion chamber, then the presence of windows in the room is not necessary.

By following these simple rules, you can easily obtain permission to install a double-circuit boiler at home. Of course, it would not be amiss to become more familiar with SNiP, since the above rules are general and certain restrictions are possible for each specific case.

Coordination of installation with authorities

When installing double-circuit boilers, compliance with SNiPs is only a small part of the hassle that you have to face. The most time will be required to obtain the necessary permits and approval of installation. To obtain permission you must do the following:

1. To connect a private house or apartment to the city gas supply, you must obtain technical conditions for the connection. To do this, we write an application to the city gas service. The application must indicate the estimated volume of gas consumed per hour. It will take 1 to 2 weeks for your application to be processed. After which you will be given technical installation specifications.

2. Having received the technical conditions, it is necessary to develop a gas supply project. In essence, this is a diagram for installing a boiler, laying a gas pipeline and connection points. In a private house, this also includes a diagram for laying gas communications around the site. The project is developed in a specialized bureau by design engineers with a license for the design of gas communications. Contacts of companies performing design can be easily found in Gorgaz.

3. After creating and finalizing the project, it is sent to Gorgaz or another competent service (Raigaz, Oblgaz, Mingaz). Project approval may take from 1 week to 3 months. The approval period depends on the complexity of the project itself. Along with the project, it is also necessary to submit a number of related documents:

- boiler technical certificate;

- instructions for its use;

- certificate of compliance with technical and sanitary requirements;

- conclusions of the examination on the boiler’s compliance with all necessary requirements.

These documents are supplied with the boiler from the manufacturer, so it is important to check their availability when purchasing the boiler.

Of course, it is possible to reject the project. In this case, you should receive an official document with the refusal and reasons for the refusal, as well as a list of changes for the project. After making changes and resubmitting for approval, you will receive permission to install the boiler.

Installation of a double-circuit gas boiler

Having decided on the installation location of the double-circuit gas boiler, as well as connecting all communications from the hot water supply (hot water supply) and heating to it, you can begin installing the boiler itself. It is necessary to immediately make a reservation that, regardless of whether it is a wall-mounted or floor-standing boiler, the same materials and components will be required for its installation and piping. Below is a general list of what is required for reliable operation:

- Ball Valves;

- coarse filter;

- magnetic filter;

- mesh filter;

- gas filter;

- sweeps;

- flexible corrugated hose;

- pressure gauge;

- thermostat;

- coaxial chimney;

- safety valve 3 bar.

Important! The quantity and configuration of related materials depends on the connection diagram of the gas boiler.

A double-circuit wall-mounted gas boiler can be installed in almost any room permitted for it. You can install it yourself, but the direct connection of gas equipment is carried out by a specialist who has the appropriate certificate to perform this type of work. Connecting the boiler yourself will entail fines.

Connecting a double-circuit gas boiler begins with preparing the site for its installation. First of all, this concerns the supply of pipes for hot water and heating, as well as preparing the opening for the chimney and lining the wall with fireproof material. As soon as everything is ready, we begin installation of the boiler:

1. The first step is to flush the boiler pipe system to remove any dirt particles from the system that may have entered during the factory assembly of the boiler. Then we put the previously removed plugs on them.

2. The wall-mounted boiler is mounted on special strips that are included in the kit. The installation height of a wall-mounted boiler should be 0.8 - 1 m from the floor. We drill holes in the wall for the planks and secure them to the wall with self-tapping screws. For reliability, anchors can be used instead of self-tapping screws.

Important! It is necessary to monitor the horizon of the installed slats. The correct placement of the boiler itself depends on this. The slightest misalignment can lead to rapid failure of the boiler heating system.

3. Install the boiler on the mounting strips. Let's check how level it is. If necessary, we correct and fix it.

4. We find the incoming pipes and first attach ball valves to them, and then filters for coarse or fine water purification. This will allow, if necessary, to shut off the entire system for washing and cleaning the filters.

6. The next step is to install the squeegees. They are the ones that will connect the boiler with pipes from the hot water supply to the heating.

Important! We do not touch the gas supply pipe of the boiler. The installation of the meter, valves, as well as its connection and pressure testing will be carried out by a specialist from the gas company who has permission to carry out this type of work.

7. Let's move on to connecting the heating system. If you are connecting the boiler to an old system, you must first rinse it several times to remove scale and salts from it.

8. We connect the squeegee with the heating pipe connected to the boiler. If necessary, a circulation pump can be installed between the outlet and the pipe.

Important! We make sure that the arrows on the taps, drains and filters point in the direction of movement of water from the system to the boiler.

8. We complete the heating connection procedure by connecting the outgoing pipe from the boiler to the heating system. At the same time, we make sure that the direction of water movement on the fittings corresponds to the real one.

9. Connect the hot water supply. All work is essentially identical to connecting the heating, with the difference that instead of a coarse filter, a fine filter or magnetic filter is installed.

10. Attach the chimney to the boiler. To do this, a chimney pipe is inserted into the previously prepared hole and then connected through an elbow to the chimney fitting in the boiler itself.

Important! If you bought a boiler with an open combustion chamber, then the chimney pipe must meet the following conditions:

- the pipe must be made of metal resistant to acidic environments;

- the chimney is installed above the ridge of the house;

- a cleaning hatch must be installed in the chimney itself;

- the chimney itself should consist of no more than three elbows;

- parts of the chimney from the boiler to the exit to the street should not exceed 25 cm.

A double-circuit floor-standing gas boiler is also installed in the manner described. The key difference in installing a floor-standing boiler is the allocation of a special room for the boiler, where fire protection is installed on the floor and walls. In addition, the boiler itself is not attached to the wall with brackets, but is most often fixed to the floor.

Upon completion of the installation of the double-circuit boiler, all that remains is to wait until it is connected to the gas pipe and put into operation. This stage of boiler installation is carried out by a specialist from the gas company. It should be noted that if you have never performed this type of work before, it would be better to seek help from the experts. Of course, all the work will cost a pretty penny, but the safety and reliability of the connected boiler will also be much higher.

The task is not easy. The boiler cannot be hung haphazardly, since the safety of the people living in the house often depends on how correctly the wall-mounted boiler is installed.

This is due to the fact that the installation of this device is carried out in strict accordance with the technical requirements and standards adopted in Russia at the legislative level.

That is why installing a wall-mounted boiler with your own hands is an extremely labor-intensive and difficult process for a beginner.

Stages of preparation for boiler installation

Before the owner of the house starts, you will need to collect some documents:

- agreement on supplying the house with gas;

- technical specifications and installation diagram of the gas system, approved by the relevant authorities;

- written permission from the gas inspector to install the equipment.

Boiler installation rules and regulations

Gas heating equipment is installed in accordance with developed and approved technologies that ensure the safety of its operation.

- The question of how to install a wall-mounted boiler begins with preparing the room for it. The room must meet certain requirements: the boiler room can be located anywhere in the house, except for the bathroom, living rooms and toilets. However, when installing wall units, this requirement may be relaxed depending on the type of boiler. The volume of the room is from four square meters, the ceiling height is from two meters. The width of the doorway is at least 800 mm. Also in the room there should be natural lighting of the boiler through the window. In this case, the window size must correspond to 0.3 square meters. for every 10 sq.m. premises.

- The rules for installing a wall-mounted gas boiler regulate the supply of a certain volume of fresh air through supply ventilation to the place where the boiler is used. An insufficient amount of incoming air may be due to the accumulation of a substance hazardous to health and life in the room.

- : the standards for its placement are such that there must be more than 10 cm from the wall to the surface of the boiler. If this distance is less than required, the wall must be protected with a fire-resistant coating.

- Gas pipes can be metal, but not plastic.

- The chimney opening must correspond to the power capabilities of the boiler. In this case, its height must be at least 5 m, provided that the chimney is installed above the ridge on the roof of the house. When installing a chimney, it can have no more than three bends.

- When organizing a power supply system, it is necessary to provide a circuit breaker with current protection and thermal protection.

- In the room where the boiler will be located, there must be a gas sensor connected to a relay. In the event of a gas leak, the sensor must send a relay signal to block gas flow. In addition, an audible alarm should sound.

- Installation of a wall-mounted gas boiler; when starting it up, regulations require that the device be provided with a gas meter.

- If there are other gas appliances near the boiler, then the distance between the appliances is set at at least 20 centimeters.

- When installing, the requirements even affect the completeness of the equipment. The boiler package must comply with the standards and contain: a manual, fasteners, a paper template for installation, special keys and fasteners.

- The installation height of the wall-mounted boiler is 80 cm - 160 cm from the floor surface.

If all these requirements are met, then there is no doubt about the reliability and fire safety of the gas heating system. It should be kept in mind that the heating system must be regularly maintained by employees of the city gas service.

A simple piping of a wall-mounted double-circuit gas boiler, the photo of which you see on this page, can be done by your master, or you can...

In order not to spend money on a full-fledged chimney, you will need a coaxial pipe for a gas wall-mounted boiler. The installation, the photo of which is published on this...