Creating your own water intakes at your summer cottage has become not just a spirit of the times, but an absolute necessity. Due to the high demand for such objects, their prices are also rising. You can rent a drill and complete the necessary work in a few days, but you need to remember that it is impossible for a non-specialist to determine the technical condition of the unit by its appearance. As a result, it is very likely that you will have to pay for a broken mechanism and the work will not be completed. The simplest MGDU installation can be purchased for about 60,000 rubles, but the drilling depth (auger method) does not exceed 15 meters, which may not be enough. In such a situation, the best solution is a homemade drilling rig for drilling water wells.

The simplest water intake device is the Abyssinian well. To arrange it you don’t need any complicated equipment or devices. It is enough to get a “baba”, which is a 20-25 kilogram load, and make a backstock - essentially, a clamp that reliably covers the pipe being clogged.

An elementary device for punching Abyssinian wells is shown in Fig. 1, where:

1. Clamp for attaching blocks.

5. Grandmother.

6. Driven pipe.

7. Water intake pipe with a filter device. At the front end it is equipped with a spear-shaped tip, the diameter of which is larger than all other components. By raising and sharply lowering the woman, two people reach the water carrier at a depth of 10 meters in one daylight.

The drawing in Fig. 1 does not include a tripod. Without denying the effectiveness of this method, we note that with a tripod it is easier to control the direction of immersion, because the pit must be strictly vertical. It’s easy to make a tripod with your own hands from scrap materials.

Drilling classic water wells can be done using the percussion-rope method; the equipment for implementing this technology is so simple that it “asks” to be made by hand.

The drilling process is becoming increasingly popular for performing a variety of tasks related to excavation work on a suburban site. Using various equipment and devices in this way, you can build a site fence and a columnar foundation, plant trees or shrubs, with much less labor and material costs. However, the main area of application was and remains drilling wells with a small-sized installation, often made by hand.

Installations for making holes in the ground can be divided into the following types:

- Heavy stationary drilling rigs, moved to the next point in disassembled form, are used for drilling oil and gas wells.

- Mobile drilling rigs on various chassis designs, from car trailers to heavy trucks such as Ural or KamAZ. They move to the work site independently.

The advantages of such equipment are determined by the possibility of quick delivery to the work site and the limited space required for installation.

- Self-propelled drilling units. Intended for professional use when making water holes in various types of soils and for mining at great depths, including artesian aquifers.

Delivery to the work site is carried out on platforms, installation on site - under its own power.

Drilling rigs are often mounted as suspended equipment on various types of tractors or excavators.

- A special place among units of this purpose is occupied by MGBU (hereinafter -). Their popularity is determined by the following factors:

- ease of use, the unit can be successfully used even by an unqualified person who has studied the instructions for use;

- a wide range of works from use as a hole drill for making pits or leader wells, as well as other similar works, to drilling wells for water;

- small dimensions, making it possible to easily place the unit at the drilling site.

Types and types of small-sized drills

The range of products for this purpose is huge; it includes many models of foreign and domestic origin, as well as home-made units that successfully compete with other products.

Machines can be classified according to several criteria:

- by the method of drilling holes;

- type of device operation;

- according to the types of drives used - they can be electric, internal combustion engines or combined, when one of them is used at the operator’s choice;

- if possible, to the depth of drilling water wells;

- the method of moving the device to the place of work.

Classification depending on the method of penetration

Based on this indicator, classification can be made as follows:

- Units that perform drilling by rotating a rock-cutting tool. With this method, it fits tightly to the soil of the pit. The working fluid can be an auger drill, a drill column, a roller cutter, a chisel and other devices. For the rotational method, the maximum depths are limited in some cases.

- , based on the fall of the drilling tool, repeated cyclically. In this case, the rock is destroyed and brought up with a drilling tool when it is periodically removed from the pit. The main application is loose and soft soils; its use on hard soils is limited. The achievable depth is about 100 meters; further work is simply unprofitable. However, such a limitation often makes it possible to drill to artesian aquifers.

- Small-sized installations are often equipped with equipment for, but the complexity of the equipment and the high cost of the tools limit their use in private ownership.

- The MGBU does not use shock-rotational, fire-jet or discharge-pulse technologies for drilling wells.

A mini drilling rig, purchased for your own needs, or made by yourself, will greatly simplify the solution of many problems associated with the construction and development of the site. Eventually, she could start her own business.

Features of the work of MGBU

Each small installation has its own application features, depending on the drive power and the well drilling method used. Their common feature is their low weight.

Auger drilling

Making a small-diameter hole in the ground is usually associated with exploratory drilling for water. Due to the heavy load on the drill string, the penetration depth is limited to 15 - 25 meters, unless flushing the well with water is used. To make this possible, the machine must be equipped with a swivel and a pump for water supply.

The purpose of this device is as follows:

- interruption of the rotational movement of the drill string;

- supplying water or washing liquid inside the column;

- transmission of axial force to the column from the feed mechanism.

Water along the drill string reaches the working area, after which the destruction of the soil occurs with its participation. Liquid supplied under pressure intensively cools the tool and simultaneously erodes and softens the rock. It rises upward along the drilled pit, simultaneously carrying out the drilling products. The use of flushing significantly increases the maximum drilling depth in this way, reaching depths of up to 70 meters.

Once the drill reaches the first aquifer, consisting of sand saturated with liquid, otherwise its masses will replenish the excavated soil and further advancement will become impossible.

This should be followed by replacing the drilling tool with a smaller diameter. Thus, the well acquires a telescopic structure, the upper casing column will continue to play the role of a caisson. Upon reaching the second unconfined aquifer and its high-quality opening, measures to equip the well are carried out in the usual manner.

The use of MGBU is not limited to drilling water wells. Using drilling tools of larger diameter, they are successfully used for drilling holes of various sizes or wells oriented towards high water.

Nowadays, your own source of drinking water on a private plot of land or near a country house is an important necessity.

In most cases, this issue is resolved, which is associated with a certain level of costs for the services of drillers.

In this case, using a device such as a small-sized hydraulic drilling rig will help you save money. She will help you drill a well yourself.

1 Purpose of small-sized hydraulic drilling rig

2 How does a small-sized drilling rig work?

A homemade drilling rig is equipped with a swivel that you can assemble with your own hands. It facilitates the transmission of driving torque from the gear motor to the rotating drill barrel.

2.1 Types of small-sized drilling rigs

Design features directly depend on the method by which the well will be drilled. If carried out, then the destruction of the soil is carried out using a load.

Now there are four main types of small-sized drilling rigs. It could be:

- Installation for percussion-rope drilling;

- Auger drilling rig;

- Manual rotary installation.

The cable percussion drilling unit is presented in the form of a frame, which has a triangular base. In this design, the working elements are presented in the form of a cable and a chisel attached to it (most often used) or. Auger-drilling units are used in cases where it is necessary to remove soil using an auger.

In this case, the resulting well is not flushed with a stream of water. Rotary drilling rigs perform their work based on the principle of hydraulic drilling.

Such units are characterized by extreme simplicity of design, and the electric motor in them is replaced by a hand lever. Due to the fact that this unit requires a large amount of physical effort applied to it, it is currently used extremely rarely.

2.2 How to make it yourself?

In order to make the simplest drilling device yourself, you will need a welding machine, an angle grinder, and a drill. You should know that a manual auger drilling rig is a very simple device, the operation of which is based on the use of manual labor.

In such installations, it would be most rational to use an electric motor in order to remove the drill to the surface. In order to create an installation for percussion-rope drilling, it will be necessary to construct an impact frame on which the impact projectile will be lowered and raised.

To facilitate operation, the installation is connected to a gear-type motor. It is used to wind the cable onto the drum.

A weighted bailer is attached to the cable. In order for the device to work with a high degree of efficiency, a cartridge is attached to it, the weight of which must be at least 80 kg.

In the process of rhythmically driving in the bailer, the face is gradually cleared of the clay soil accumulated in it. The main working element of such a device is the so-called “glass”.

It is made from a piece of thick-walled pipe, the diameter of which should be 80-120 mm. In addition, the heavier the material, the more efficient the drilling process will be.

Triangular teeth are cut at the bottom of the projectile, which help loosen the soil, and the lower edge of the glass is sharpened.

A series of holes are made on top of the glass, which are needed in order to securely fasten the rope. The length of the cartridge should be 1-1.5 meters.

In order to make it possible with a depth of eight meters, the structure is secured to the top of a special tripod tower.

A hole is made in the upper part of the product. It provides space for free movement of the barbell. As the bar goes down and up, its weight will increase.

In such cases, a winch mechanism should be used to lift the drill string. The tower itself can be made of either metal or wooden beams.

Today, many owners of country houses want to have their own source of clean water. Particularly popular are wells that can be drilled almost anywhere where an aquifer is present. The technology for forming such a system involves the use of special mechanisms. There are several types of such devices, among which are boreholes. It is quite easy to get acquainted with the technical characteristics of these devices on specialized websites.

Peculiarities

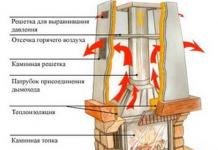

A water well is a small cylindrical structure reinforced with a special rigid frame. The formation of such systems is carried out using drilling machines. Technically, these devices consist of several mechanisms interconnected by various fasteners. Drilling rigs have been around for a very long time, as they were used to extract various minerals. Extracting water with their help has not been practiced for very long, especially in the private sector. Drilling rigs allow you to solve such basic problems as:

- formation of holes of small diameter. They are used to solve small engineering problems;

- drilling of exploratory wells. They are used to obtain information about the condition of soils and aquifers;

- drilling wells to search for or extract liquid or gaseous minerals, such as oil;

- drilling water wells. These mechanisms are relatively simple. This applies to structures that are used to form shallow holes.

Wells of this type can have different depths. Depending on this, there are several types of wells.

- Tube well. This is the shallowest well, having a depth of no more than 12 m. Only the upper aquifers are used as a source of water. Once drilled, no dirt, leaves or other debris will be able to get into this hole.

- Sand well. A recess of medium depth, which can reach no more than 30 m. The service life of such a system is about 15 years. In this case, the well may periodically become clogged with sand, and it will need to be cleaned.

- Artesian well. The depth of such a “well” can exceed 100 m, so special technologies and mechanisms are used to drill such holes. Drilling rigs of this type are highly powerful and complex. But such water sources can be exploited for 50 years.

The design of drilling rigs may vary depending on the origin. Regardless, such mechanisms have the following common elements:

- frame– the support can be either a metal structure or a self-propelled vehicle or other complex system. The strength of such an element is determined depending on the maximum drilling depth;

- drilling device– these elements represent a system of mechanisms that set in motion the drill itself or another object that destroys the soil. When drilling, several types of tools can be used that are intended for specific soil layers;

- drive unit– technically, this device can be either an electric or diesel engine or human physical strength.

Many well drilling machines have a more complex structure, as they consist of various auxiliary components.

Kinds

Drilling rigs are a very popular product in the market. The scope of their application can be both industrial and household. Depending on this, such mechanisms can be divided into several types.

- Industrial. Such machines are used for drilling deep wells. They are distinguished by high power and performance. Very often they are used with various auxiliary equipment. Similar mechanisms are used in the formation of oil wells. A prominent example could be a floating platform equipped with a powerful drilling rig.

- Mobile. Drills of this type are intended for forming water wells. They are equipped with low-power drives (electric motors and others), with the help of which it is possible to form a hole up to 100 m deep.

- Manual. They are the simplest designs with which you can drill relatively shallow wells up to 15–20 m, depending on the type of soil. These homemade small mechanisms are used in the domestic sphere.

If desired, they can be built manually from scrap materials.

Depending on the drilling technique, the machines are divided into several groups.

Shock-rope

The formation of wells occurs using a special cartridge, which is made in the form of a kind of pipe with a pointed end. Soil destruction occurs under the device’s own weight. To increase the impact energy, the bowl is specially raised to a certain height above ground level. Among the disadvantages are low permeability and the impossibility of organizing fairly deep wells. Impact-rope models are used in everyday life for digging wells.

But it should be noted that such mechanisms can work even on rocky soils, which is not always possible to achieve with other tools.

Screw

They are one of the most common types of machines. Augers of various shapes and sizes are used as drills. The simplest models can even be used manually. The drill is placed in a rotary manner into the ground, which leads to crushing of the material, while the soil is located between the blades. To remove it, the working body is periodically removed and cleaned of dirt. The units are driven both manually and using various types of engines.

Handheld models can be lightweight, making them compact and easily portable. But if you drill rocky soils with an auger, its efficiency can drop significantly.

Rotary rotary

Machines of this class are characterized by high productivity, as they allow you to pass through the ground relatively quickly and efficiently. Technically, the design consists of a vertical pipe and a cutting element. As the knife passes to the destruction surface, water is supplied under pressure. This allows you to soften the soil and make it more pliable. Liquid is also needed here to clean the hole from soil. Such an operation can be carried out in two main ways. The first involves supplying water through a rod, and the dirt is already removed through the hole in the well itself. The second approach is completely the opposite. The well is filled with water, and the dirt itself is removed using special equipment and sediment.

It should be noted that almost all drilling rigs have a similar structure to the structure described earlier. This applies not only to devices for forming water wells, but also to oil mechanisms. But powerful machines are already using stronger materials that can withstand high loads. Therefore, it is impossible to build such equipment independently without the use of special technologies.

Manufacturers

The popularity of drilling rigs is increasing every day, which is due to the fact that systems of this type are used to solve a variety of problems. The production of machine tools is carried out by many companies, among which there are several of the most popular.

- "IzhNefteMash" The company has been producing drilling equipment for over 50 years. The company's products include many items. The most popular tools of this brand are drilling submersible drainage pumps, rod equipment, mixing plants that are used for cementing mines, and many others.

- "Drilling equipment". This is another company with many years of experience that produces equipment for drilling oil and gas wells. The manufacturer produces turbo drills, screw pumps and much more. The mechanisms are distinguished by high productivity and quality of work.

- "Geomash". The equipment of this company is used in construction, as well as for drilling water wells. The manufacturer produces a variety of self-propelled mechanisms capable of solving various problems. Many of them can form seismic and hydrogeological wells.

- Bauer. This German company, which has also been known on the market for more than half a century. Under the auspices of this brand, a lot of drilling rigs are produced for both industrial and construction use. It should be noted the high quality of the equipment produced, which is achieved due to the fact that the company produces all components for the mechanisms independently.

The most popular machines are the Bauer BG 28 and Bauer MBG 24 models, which are used by many professionals.

In addition to the fact that people need water, the body is also very demanding on the quality of this product. It is for this reason that small-sized drilling rigs are becoming increasingly used. This is due to the fact that, using this installation, it is possible to extract water from underground sources that have not yet been contaminated.

Installation device

The main advantage of a small-sized drilling rig is that it can be used without hiring specialists. Installation, configuration and further operation of the unit are quite simple, and therefore almost anyone can handle it. The equipment consists of the following main elements:

Additional work

The weight of a small-sized drilling rig never exceeds 30 kg, which allows it to be transported using a passenger car. The sale of goods is carried out in an already assembled form, and therefore it is only necessary to prepare a platform and install the device. Most often this takes about an hour. However, if the soil is quite problematic or weak, it may take much more.

Settings options

It is important to understand that the design of small-sized drilling rigs is a complex of equipment. The choice of a specific complex depends on what type of soil will have to be worked with, as well as on factors such as the geological section. The most compact units with low weight are easy to assemble and disassemble. Two workers can cope with this task. The temperature range in which the device can be used is from -30 to +40 degrees Celsius. It is also important to note here that the design of the device and the power of the electric motor - 2-3 kW - allow you to connect the equipment to a regular 220 V network. In addition, there is a certain division into classes, depending on the method used for drilling. It can be rotational, impact, complex and several other types.

Models and specifications

Small-sized drilling rigs of the RB-50/220 series. These devices can be supplied with rods of 1, 1.5 and 1.8 meters. Their diameter is 48 mm, and the main material for production is St40X steel. The drilling depth of such installations ranges from 50 to 70 meters in the presence of an electric motor with a power of 2.2 kW. Experts recommend additionally equipping the machine. The main purpose of the unit is to work with soil that contains solid particles up to 20 mm in size.

Small-sized water drilling rigs of the RB-100/380 series. These units are more powerful representatives of the same class. To power them, a 380 V generator is required. The depth of the well that the equipment can drill is 100 meters. The power of the electric motor in the cars is 4.4 kW. Another necessary condition for the operation of such an installation is the presence of a mud pump with parameters of 900 l/min.

The main positive and negative qualities of MGBU

Small-sized water drilling rigs are considered the most popular product among stationary and self-propelled types of machines. The advantage of a mini-installation over these types is the following:

- The possibility of simple and convenient transportation, as well as the small dimensions of the assembled product.

- The operation process does not require special attention; repair and maintenance of the machine is quite simple; this work is carried out at the drilling site.

- Possibility of using the unit in places where there is limited space.

- Quite low cost of the device when compared with stationary or self-propelled types.

- It is possible to carry out all the work with even unprofessional workers on site. The number of required personnel is 2 people.

Among the disadvantages, it is worth highlighting that the average power of the engines is quite low, and therefore drilling a well more than 100 meters deep is impossible.

Equipment prices

It is worth noting that the price of a small-sized installation depends not only on the technical parameters and operational characteristics, but also on the model of the device. In addition, the cost formation process is carried out on contractual terms.

For example, the RB series model 50/220 V will cost around 59 thousand rubles. A model of the same series, but powered by a 380 V network, and having the ability to drill a well 100 meters deep, will cost 119 thousand rubles.

If we talk about the units that belong to the UKB-12/25 series, as well as all the modifications available for these units, they operate not only from electric engines, but also from gasoline ones. This greatly expands the possibility of their use. However, at the same time, the cost of the unit also increases significantly. The approximate price of such a model for drilling wells is 215 thousand rubles.

A used small-sized drilling rig for drilling water wells will naturally cost less. However, when purchasing a device in this way, you should understand that it has already served a certain period of time and, most likely, will soon fail.