Water extraction is one of the most ancient crafts of mankind. Modern technologies make it possible today to drill wells more than a kilometer deep.

The more complex the soil structure and the further away the aquifer, the more powerful a water well drilling rig will be needed to get to the desired level. Our instructions, as well as the video in this article, will help you understand the drilling methods and types of installations used.

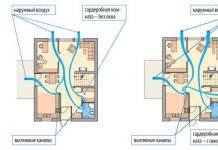

Types of wells and their development

Many people are interested in whether it is possible to build a well with their own hands. Theoretically it is possible, but in practice there are often so many difficulties!

Let's take a well. If the groundwater is located no deeper than six meters, problems may not arise.

So:

- Although, even at this depth, there may be a massive content of solid inclusions in the soil, which will greatly complicate excavation. But, in this case, you can at least dig a pit with an excavator.

What if the mine depth is 10-15m or more? In this case, you have to dig manually, and this can become truly hard labor. - In addition to the fact that this process is very labor-intensive, it also requires a lot of time. Plus, there's no guarantee that you won't end up on quicksand.

The sand content in quicksand water exceeds permissible standards. At the same time, any filter will quickly clog, impeding the flow of water into the well.

Conventional wells

A normally functioning water intake should be installed not on quicksand, but on a sandy aquifer. Most often, they are located at around 20-45 meters.

For a well this is an impressive mark, but for a well it is the minimum possible depth.

So:

- Sandy layers produce less water than calcareous ones, which lie much deeper. Therefore, service life cannot be predicted.

We can only say approximately - this is 7-10 years. As soon as the limit is exhausted, it needs to be deepened, or eliminated, and a new one drilled.

- Today, two drilling methods are used: rotary and auger (see). The essence of the first is the destruction of constantly moistened rocks with a drill.

It rotates due to the force of the rotor - hence the name of the method. The rotor can be installed either on a mobile drilling rig or on a stationary one with its own engine. - The walls of the shaft are strengthened with casing pipes, after which drilling continues with a roller bit. The deeper the drill goes, the smaller the size of the bit used. Typically, the rotary method is used for drilling to a depth of 50-55 meters.

- To medium depths (from 55 to 80 m) they drill dry, using an auger method. For this, a welded pipe structure is used. You can see her in the photo at the beginning of the article.

The auger has a spiral shape, and cutters are rigidly fixed at the end. They destroy the rock, which is fed “to the mountain” by a conveyor. When hitting particularly hard rocks, special drills with several cutters are used.

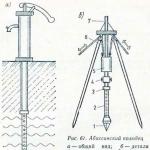

Tube wells

There is such a thing as . It is of small depth (up to 30m), and with a very small diameter.

Otherwise it is called a tube-type well. It usually does not exceed two inches - and this is only 5.08 cm.

So:

- To obtain a well of this diameter, a steel extension rod is manually driven into the ground.

Drilling water wells with mini installations greatly simplifies this task. And the price allows you to purchase it for personal use.

- In this case, ordinary gas pipes are used as casing pipes. They are threaded together into a long column called a “needle.”

This association is evoked by the first pipe with a cone-shaped tip. Its diameter exceeds the corresponding size of the pipes to eliminate friction and facilitate their passage through the soil. - In fact, the Abyssinian well is drilled using both of the methods described above. First, the work is done dry, with the largest possible drill (2 inches).

As soon as the well reaches the level of quicksand containing water, the drill is changed to a “needle” with a tip, and driving of all segments of the column begins one by one. - A perforated pipe wrapped with a special mesh is mounted to the section with the tip - this is a filter. All segments are connected to each other with couplings and sealed with silicone.

In principle, this technological process has much in common with the construction of conventional wells. The difference arises due to their dimensions: depth and diameter.

Artesian

The deepest are artesian. They are the ones who draw water from the limestone formations.

Despite the impressive depth, water can be supplied from an artesian well using a conventional submersible pump of the same power as in a well. It is mounted at the level of the nearest aquifer sandy horizon.

So:

- The static water level is set at the level of the nearest body of water. Equilibrium of the water column is achieved due to the influence of interlayer pressure on the one hand, and atmospheric pressure on the other.

The presence of water in calcareous horizons is guaranteed by nature itself, and its level does not depend in any way on the terrain or, for example, climatic conditions.

- Drilling wells up to three hundred meters deep is carried out using the percussion-rope method. Its essence lies in the fact that the impact projectile, consisting of a chisel, a rod, and a lock, is lowered into the well on a rope.

Falling from a certain height, the drill bit crushes the rock. - The efficiency of work in the face depends on the weight and speed of falling of the bit, its quality and the number of blows.

The drilling tool changes depending on the structure of the soil layers encountered. For example, layers with hard rocky rocks are penetrated using drill cartridges.

There is another method for developing ultra-deep wells (from 600m). For this purpose, there are drilling rigs for drilling water wells using the rotary impact method.

In this case, telescopic impact rods and a bentonite clay solution are used, with the help of which the walls of the well are strengthened. Typically these are mobile units based on a powerful truck or tractor.

Similar equipment is equally successfully used for developing oil wells.

For country houses and summer cottages, autonomous water supply is of great importance. Every residential building needs its own source of clean drinking water, both for personal and agricultural needs. And when the soil characteristics do not allow digging a well, a drilling rig can be the way out of a difficult situation.

To install a water well drilling installation, you can use the services of qualified specialists, but, unfortunately, not everyone can spend a large sum of money on this. In some cases, installation by professionals is not possible due to certain site conditions. Then all that remains is to assemble the equipment with your own hands, and only if you have knowledge in this area and at least a little experience.

To have an idea of what a drilling rig is, you should consider some of its types:

- Small-sized shock-rope-type equipment;

- A screw machine that performs work without flushing wells;

- A rotary drill that additionally flushes the wells and removes rocks to the ground surface.

Such equipment is used most often, and in small private areas, mini-installations that use a shock-rope system are common.

Features of mini drilling rigs

Typically, MGBUs consist of drills of standard diameters. Such equipment is controlled by a load control unit, which also includes different engine operating modes. To lift the rod, a winch is used, which makes it possible to withstand loads of up to 4 tons.

Small popular models drill to a depth of 70 meters. Very often, manufacturers can produce equipment according to the required customer order.

At the same time, drilling equipment is capable of working not only vertically, but also drilling at a certain angle.

Different types of structures can work using:

- Electricity;

- Diesel fuel;

- Pneumatic equipment;

- Hydraulics.

Small dimensions allow the use of minimal human resources and convenient transportation of the installation. This explains the popularity of this type of drilling equipment.

Advantages of a small-sized drilling rig for drilling wells

This technique is in demand and is often used in private households. Its convenience and portability make the model popular among summer residents and owners of private houses.

This is not surprising, because it has its advantages:

- Drilling equipment is easily transported, its installation is characterized by simple preparation and easy installation;

- Equipment and available materials can be purchased at any time due to the wide range and availability;

- At the same time, the technique can be used to create a foundation and other construction work;

- The structure does not require a large number of maintenance personnel;

- The equipment is mobile and has compact dimensions, so it is suitable even for a small area;

The system can be powered by a generator. With all the positive qualities, the structure is also affordable. If desired, the drill for the installation posts, like other parts, can be made on your own.

If your well at your dacha is clogged, read expert advice on how to clean it:

What is a drilling rig?

The drilling rig consists of an above-ground and underground part, connected to each other.

The above-ground part includes:

- Drilling rig;

- Onshore drilling equipment;

- Equipment to ensure descent and ascent;

- Drive unit;

- Drilling fluid system.

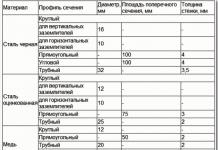

There are mast and tower towers and are made of rolled steel or pipes. The structure of the tower includes: balcony, gates, trestles, platform, couplers, stairs, belts.

In turn, the mast tower can be single-supported and the most common – double-supported.

The main elements of the mast: sections, fire escape, installation trestles, ladders (tunnel and flight), guy wires, balcony, safety belt, crown block frame.

The main characteristics of the tower are its height, load capacity, capacity to install pipes of different sizes, as well as the dimensions of the base, weight and candle size. The higher the installation, the greater the depth of drilling possible.

As a rule, any installation includes basic components. Drilling mechanisms include: auger, winch and hoist, hydraulic rotator - drilling gearbox. Energy technology can consist of internal combustion engines, it can be any motor - electric or hydraulic motor.

Devices with gas, liquid or mixed cleaning agents - swivel, pipes, mud pump, hoses.

In addition, the installation is equipped with an instrumentation system consisting of various sensors, a control system and equipment designed to contain water emissions. In MKBU, as a rule, elements of smaller diameters are used.

How to install a drilling rig with your own hands

Hand-assembled UKB uses precise drawings and detailed instructions.

To work you will need:

- Rope for hanging the cartridge;

- Mounting base in the form of a frame;

- Winch and motor.

The scheme is implemented in the following way:

- First, the collapsible frame is assembled. In a separate order, the parts of the impact cartridge are connected in order to remove the soil.

- To make loosening the earth more productive, serrated protrusions are used at the bottom of the glass. In the upper part you need to make holes for attaching the rope.

- A bailer is necessary to clean the face. It may be homemade.

The electric drive device, in turn, will help to significantly save time, and the work will be more efficient. Overall the structure is a hollow square shape.

The main elements in it are:

- Frame;

- Winch;

- Special drilling hoses;

- Gearbox;

- A swivel that allows the drill string to rotate.

All parts, stand and support are connected by welding, after which the electric motor and platform are fixed, which will simultaneously move along the tunnel of the iron constructor. If it is decided that a hydraulic pile-driving machine will be used for drilling, you can make a hydraulic gearbox yourself.

Before you start drilling, you need to study all theoretical issues. About this on the next page:

The swivel provides the rotational motion that keeps the drill rig running.

In terms of its structure, it consists of simple elements:

- A body that can be made from scraps of thick-walled pipe;

- Metal rod;

- 2 partitions for O-rings;

- Flanges – top and bottom.

The device uses an O-ring and ball bearings.

If you know how to use a lathe and have a diagram, you can make a unit for the MKBU yourself.

To make it yourself, you should take into account some features of the operation of the mechanism:

- Materials, including steel for home-made execution, must be selected with high weldability;

- Since the device is subject to rapid wear, materials for the housing should be resistant to mechanical and abrasive effects.

Otherwise, you must strictly follow the installation diagram.

DIY homemade drilling rigs (video)

Drilling equipment for various needs is used everywhere, but as the most popular models for autonomous operation, compact modifications of the MKBU continue to occupy the first place. This is understandable - they are mobile, easy to use, do not require a large number of service personnel, and, moreover, are highly efficient.

Nowadays, your own source of drinking water on a private plot of land or near a country house is an important necessity.

In most cases, this issue is resolved, which is associated with a certain level of costs for the services of drillers.

In this case, using a device such as a small-sized hydraulic drilling rig will help you save money. She will help you drill a well yourself.

1 Purpose of small-sized hydraulic drilling rig

2 How does a small-sized drilling rig work?

A homemade drilling rig is equipped with a swivel that you can assemble with your own hands. It facilitates the transmission of driving torque from the gear motor to the rotating drill barrel.

2.1 Types of small-sized drilling rigs

Design features directly depend on the method by which the well will be drilled. If carried out, then the destruction of the soil is carried out using a load.

Now there are four main types of small-sized drilling rigs. It could be:

- Installation for percussion-rope drilling;

- Auger drilling rig;

- Manual rotary installation.

The cable percussion drilling unit is presented in the form of a frame, which has a triangular base. In this design, the working elements are presented in the form of a cable and a chisel attached to it (most often used) or. Auger-drilling units are used in cases where it is necessary to remove soil using an auger.

In this case, the resulting well is not flushed with a stream of water. Rotary drilling rigs perform their work based on the principle of hydraulic drilling.

Such units are characterized by extreme simplicity of design, and the electric motor in them is replaced by a hand lever. Due to the fact that this unit requires a large amount of physical effort applied to it, it is currently used extremely rarely.

2.2 How to make it yourself?

In order to make the simplest drilling device yourself, you will need a welding machine, an angle grinder, and a drill. You should know that a manual auger drilling rig is a very simple device, the operation of which is based on the use of manual labor.

In such installations, it would be most rational to use an electric motor in order to remove the drill to the surface. In order to create an installation for percussion-rope drilling, it will be necessary to construct an impact frame on which the impact projectile will be lowered and raised.

To facilitate operation, the installation is connected to a gear-type motor. It is used to wind the cable onto the drum.

A weighted bailer is attached to the cable. In order for the device to work with a high degree of efficiency, a cartridge is attached to it, the weight of which must be at least 80 kg.

In the process of rhythmically driving in the bailer, the face is gradually cleared of the clay soil accumulated in it. The main working element of such a device is the so-called “glass”.

It is made from a piece of thick-walled pipe, the diameter of which should be 80-120 mm. In addition, the heavier the material, the more efficient the drilling process will be.

Triangular teeth are cut at the bottom of the projectile, which help loosen the soil, and the lower edge of the glass is sharpened.

A series of holes are made on top of the glass, which are needed in order to securely fasten the rope. The length of the cartridge should be 1-1.5 meters.

In order to make it possible with a depth of eight meters, the structure is secured to the top of a special tripod tower.

A hole is made in the upper part of the product. It provides space for free movement of the barbell. As the bar goes down and up, its weight will increase.

In such cases, a winch mechanism should be used to lift the drill string. The tower itself can be made of either metal or wooden beams.

Water is a basic need for every living organism on earth. Regardless of where we live, it is extremely important to have constant access to clean drinking water nearby. Of course, this resource is necessary not only for domestic purposes, but much larger volumes are needed in construction, metallurgy and manufacturing.

As you can see, such a resource as water is in the highest demand in the world, so the water drilling rig has always been the most popular. But it is worth noting that before purchasing a water drilling rig, it is necessary to have information about the area in which the well will be drilled, what rocks predominate in this region, and also how deep the groundwater lies.

Selecting a water drilling rig depending on the source

Water from underground can be artesian or groundwater. Groundwater is found in close proximity to the ground. That is, the depth of an ordinary village well is quite sufficient. In this case, there is no need to purchase high-power water drilling rigs. But it is worth noting that not in every region the groundwater is clean and suitable for long-term or even one-time use. This directly depends on the ecology of the region in which drilling is carried out. If the soil is contaminated, then the water contained in the soil is not only unable to saturate it with useful minerals, but moreover, it can poison it with chemical compounds and bacteria that are dangerous to health and life. Therefore, before purchasing equipment for drilling water wells, it is highly advisable to check the quality of the resulting water, because The results of drinking contaminated water can be very disastrous.

Artesian waters are a different matter. They lie deep underground, so they are significantly less exposed to harmful environmental influences. But at the same time, much more labor must be put in to extract it. In this case, a small-sized drilling rig for water is no longer suitable, and a more powerful rig for drilling wells for water is needed, because Artesian pools are found on average at a depth of 100 meters underground and deeper. For these purposes, the ideal option would be equipment for drilling water wells 2D3 and URB 2A2. This installation can easily make a well of the required size and provide access to the most important resource - clean water. In addition, the equipment for drilling wells under water produced by our plant is highly versatile, so after carrying out the work you need, you can use the machine for engineering, geological, geophysical work, as well as for mineral exploration.

"Drilling Technologies Plant" - water drilling rigs at an affordable price!

The Drilling Technologies Plant company offers everyone who wants to buy water drilling rigs, the price of which will pleasantly surprise you. We managed to achieve the most favorable terms of cooperation, because... Our company sells water drilling rigs exclusively of its own production, but at the same time we use the highest quality and reliable technologies and parts, which guarantees the most efficient operation and long service life of each tool. In our catalog, everyone can find the most suitable machine for drilling water wells, because... We offer both mini water drilling rigs and large water drilling rigs, videos and photographs of which you can also see on our website.

In this case, all that is required of you in order for the installation for drilling wells under water to be at your disposal is to contact representatives of the Drilling Technologies Plant company in any way convenient for you. Our qualified managers will advise you on all issues of interest, and will also help you choose the optimal equipment for drilling water wells, the price and capabilities of which will correspond to your goals and capabilities.

You cannot do without your own source of drinking water on a private plot of land. Most often, the problem is solved by drilling a well, and the most expensive cost item will be the cost of driller services. Trying to reduce costs, many craftsmen tried to master the drilling technology on their own and many of them managed to provide the site with water. First you will need a DIY drilling rig. Making it is not very easy, but it is possible.

What types of drilling rigs are there?

The design of the device depends on the method chosen for drilling the well. When percussion-rope drilling, the soil is destroyed using a load that is simply thrown down. The loose soil is removed and then the cycle is repeated until the depth of the well reaches the required dimensions.

Removing soil using a rotating drill is both easier and more difficult. Simpler because less physical effort is required, but more complex because such installations have a more complex design, their dimensions are larger, and the costs of their creation are higher. It is impossible to create some elements for a reliable drilling rig yourself. Some things will have to be purchased from a specialized company, others can be ordered from an experienced turner. But the result will be a completely professional unit that can be used on the side, starting a very successful business as a hired driller.

Note! Homemade drilling rigs can be used not only for, but also for installation of pile foundations.

Experts distinguish four types of small-sized drilling rigs (MSDU):

- Installation for UKB - percussion-rope drilling. It is a frame with a triangular base. The working elements are a cable and a chisel or bailer attached to it.

- Auger drilling rigs, in which soil is removed using an auger, without flushing the well with water.

- Rotary drilling rigs operating on the principle of hydraulic drilling.

- Manual rotary installations are the simplest option, in which manual labor is used instead of an electric motor. Due to the high costs of physical labor, this type of MGBU is used quite rarely.

To make even the simplest device of this type yourself, you will need a welding machine, a drill and an angle grinder, as well as skills in working with all these tools.

A manual auger drilling rig is the simplest device for drilling wells using manual labor. You can use an electric motor to lift the drill to the surface

The simplest MGDU for cable percussion drilling

To create such a drilling rig you will need to do:

- collapsible bed;

- percussion cartridge (“glass”);

- bailer

To facilitate drilling work, the installation is connected to a gear motor, on the drum of which a cable with a fixed chuck or bailer is wound. To operate effectively, you will need a cartridge weighing about 80 kg. Using a bailer, the face is cleared of destroyed soil. The bailer is also quite effective on clay soils.

The main working element of this type of drilling rig is the cartridge or “glass”. To make it, you will need a piece of thick-walled pipe with a diameter of about 80-120 mm; the heavier the material, the better. Triangular “teeth” are usually cut out at the bottom, which loosen the soil, but you can leave this part of the cartridge flat. In addition, the lower edge of the “glass” is usually sharpened. Several holes are made on top to securely fasten the rope. The length of the cartridge can vary within 1-2 meters.

Making a drilling rig for percussion-rope drilling is not difficult; you will need a fairly heavy bailer (drilling tool), a strong rope, a frame and a winch with a motor to make the work easier

In cable percussion drilling, a bailer is used to excavate soil. The photo shows a homemade version of a tool for percussion-rope drilling, which allows you to loosen and extract soil

The simplest design of a screw MGBU

The working element of such an installation is a drill. To make it you will need a steel pipe with a cross section of 100 mm. The upper end of the pipe is equipped with an external screw thread. At the opposite end, a screw screw with a diameter of about 200 mm is made. One or two turns of the auger will be enough. Two steel knives should be welded to the ends of the auger so that in a vertical position they are at an angle to the horizontal surface of the soil.

To make it more convenient to rotate the drill, you need to take another piece of pipe about 1.5 meters long and weld it to a tee that has an internal screw thread. The tee is screwed onto part of the collapsible rod. The length of a section of such a rod is also 1.5 meters.

Drilling rig diagram: 1 - drill; 2 - knob; 3 - tee; 4 - collapsible rod; 5 - coupling; b - tripod; 7 - hole; 8 - winch; 9 - gear

The drill is driven into the ground, turned three times, then removed to remove loosened soil. The process is repeated until the depression reaches approximately one meter. Then the rod must be extended, for which another section of steel pipe is attached to it using a coupling.

To construct a well more than eight meters deep, you will need to secure the structure to a special tripod tower. In the upper part of this structure you need to make a hole in which the rod will move freely. Since the weight of the rod also becomes impressive as it increases, a winch should be used to lift the structure. The tower can be made of either metal or wood.

The operation of such a drilling rig is clearly demonstrated in the following video:

How to make a reliable design?

In order for a well drilling rig to be reliable and allow drilling work to be carried out at a professional level, it is necessary to purchase a number of elements manufactured in a factory using high-precision technology. You will need to purchase:

- swivel;

- drill rod;

- paddle drill;

- gear motor;

- motor pump with sleeve;

- hose for supplying drilling fluid.

The frame for mounting this equipment can be made independently from durable steel.

The diagram clearly shows the structure of a factory small-sized drilling rig with a swivel, drill rod, drill, electric motor, winch, pump, etc.

The swivel is necessary to transmit the driving moment from the gear motor to the drill, as well as to supply the flushing solution. The swivel body contains a moving part on which the drill rods are attached. Flushing liquid is supplied through a special sealed pipe. Although the design of this element is not complex, the service life of the entire drilling rig depends on the quality of its execution. Due to high loads, high-strength steel should be used to manufacture the swivel, while maintaining a minimum gap between the moving elements of the device. A low-quality swivel will fail after making several holes.

The drill rod is selected depending on the type of drilling (percussion, rotary, flushing, etc.). The rod can have a round or hexagonal cross-section. It transmits the driving moment directly to the drill. During operation, the bar goes down and needs to be increased. For connection, special locks with a special conical or trapezoidal (rectangular) thread are used, ensuring the most reliable connection. Liquid is supplied into the well along the internal section of the rod, which softens the soil and allows drilling to be carried out more quickly and successfully.

A drill is a working element designed to crush soil. For professional use, special three-bladed drills are suitable, which are rotated in a cyclic manner. The diameter of the drill can vary between 80-350 mm. This element is made from high-quality steel into which high-strength plates are fused, for example, VK-8. On hard soils, it is recommended to use multiple drilling passes. First, so-called exploratory drilling is carried out with an 80-mm drill, then the well is drilled with larger diameter drills until the hole reaches the required dimensions.