When working with porcelain tiles at home, the question often arises: how to cut porcelain tiles? This material is in some ways very similar to ordinary tile, but for the most part it has a number of striking differences. In this regard, most of the tools that are successfully used for cutting tiles are not suitable at all in this case.

Due to the high strength of the material, not all tools are suitable for cutting porcelain tiles

Features of the material

Porcelain tiles have gained popularity due to their unique properties, but these advantages complicate the process of cutting tiles at home.

The following features of porcelain stoneware should be highlighted:

- strength;

- wear resistance;

- frost resistance;

- fire resistance;

- aesthetics;

- durability;

- environmental friendliness;

- hygiene;

- antistatic.

Due to the almost complete absence of pores in the structure of the material, porcelain stoneware is super durable, it does not scratch, wear out, or crumble, but that is why it is very difficult to cut it yourself. What to do in such a situation?

Porcelain tiles are a very durable material

What tools are used

So, how to cut porcelain tiles at home? Hand tools are ineffective in this case. You should completely forget about the glass cutter. But there is a way out. First of all, it is worth mentioning a tool that is available in the arsenal of almost every real owner and craftsman - this is an angle grinder. With its help, you can successfully perform both straight cuts and figured cuts.

You cannot use a glass cutter to cut porcelain tiles.

Another tool is a tile cutter. It comes in two types: manual and electric. Since we are talking about porcelain stoneware, it is better to use the electric option. Of course, it will take up more space than an angle grinder or its manual alternative, but its performance is impressive.

You can use a device similar to an electric tile cutter, since you don’t have anything suitable. Replace the disk on a circular saw with a diamond one and you will get a good tool for working with porcelain tiles.

For fine work and shaped cutting, a jigsaw with a diamond thread is used; it is convenient to work with, and such a tool will be useful in other areas, not only for laying tiles.

If you plan to cut a large amount of porcelain stoneware, you can seek help from special companies that provide this type of service. They have all the necessary equipment for any kind of work. For figured cutting, the waterjet cutting method is used, but such a service costs quite a lot.

Bulgarian

The grinder is the number one tool; it can easily cut porcelain tiles. For this purpose, a diamond-coated disk attachment is used for dry cutting.

A universal assistant when working with porcelain tiles - grinder

In order not to bevel the cut line and not damage the tile, you must first outline the contours with chalk, pencil or marker. Then secure the porcelain tiles to a stable surface. The disc is installed in the direction of movement of the grinder.

Proceed to work after checking that the attachment is securely fastened. Step back a little from the marking line and start working. Move smoothly, slowing down at the edge. The disadvantage of using an angle grinder is the high probability of chipping, that is, defects. This is especially true for glazed tiles. Therefore, it is better to consider the option of using a tile cutter.

Tile cutter

The tile cutter, used to adjust the shapes and sizes of heavy-duty materials, is used in an electric version. It looks like a machine with a diamond blade. In this case, it is recommended to use a wet cutting attachment. The machine can conveniently secure the tiles, thus preventing them from moving during the process.

A powerful professional model of electric tile cutter will quickly cope with a large volume of tiles

How to cut porcelain tiles using a tile cutter:

- Fill the pan with water. This will ensure cleanliness while working. In the future, you need to change it often enough so that accumulated particles do not fall on the disk and damage it.

- Place the tiles on the work surface of the tile cutter.

- Hold the porcelain tiles with your hands, preferably on both sides if possible.

- Apply gentle pressure and guide the material towards the blade.

From time to time you need to clean off plaque from the disc so as not to reduce the efficiency of the tool.

A circular saw

How else can you cut porcelain tiles at home? If you own a country house or a private house, you probably have your own workshop. One of the most necessary tools in this case is a circular saw. It is a machine with a toothed disk. Since the work involves processing porcelain stoneware, you need to change the attachment to a diamond disc for dry cutting.

After the preparation is completed, the cutting line is outlined, you can begin to work. Press the tile against the table and carefully push it forward with both hands, taking care of your fingers. This option is suitable for large volumes of work with straight cuts.

Jigsaw

For complex shape cutting, the best option is to use an electric jigsaw and a diamond-coated file. With its help, you can carry out the finest work even on such a durable material as porcelain stoneware.

A good jigsaw and a special file will allow you to cut porcelain tiles efficiently.

Outline the outline of the cutout. To see where you are moving, you can lightly moisten the porcelain stoneware with water. Blow away dust as you work so that you can see the line and not clog the path of the cutting part.

Be especially careful when working on the edges, as these are the areas where there is the greatest risk of chipping.

When choosing a tool, consider the shape of the tile, the type of coating, as well as the amount of work required. Several elements can be trimmed using available tools. But for a large number of tiles it is better to use a special device - a tile cutter.

If architects in their activities were guided exclusively by the standards of manufacturers of finishing materials, then our cities would resemble identical cubic anthills. But fortunately, artistic taste and creativity keep pace with rational calculation. This, of course, adds worries to builders who are forced to do such work as: cutting porcelain stoneware, fitting wooden, plastic and metal elements, and many other operations necessary to realize the architectural design.

The architectural concept always brings into the work of builders the question of where and how to cut porcelain stoneware. Typical installation is not expectedPorcelain stoneware is a decorator’s dream come true about a material that combines the properties of ceramics and natural stone. Obtained by pressing powder from clay, sand and kaolin, ceramic granite fired in ovens has high decorative and performance qualities. The nature of production allows us to produce tiles of any color by introducing coloring oxides into the composition and any texture: glazed, matte, polished, structured. The material is stronger than granite, it is resistant to wear and aggressive environments.

The decorative panel is inscribed in the main background. The work was carried out cutting tiles - porcelain stoneware

The decorative panel is inscribed in the main background. The work was carried out cutting tiles - porcelain stoneware Methods for cutting porcelain stoneware

The durable, glassy surface places increased demands on its processing, so cutting porcelain stoneware is a task that requires special skills and tools.

Despite the fact that porcelain stoneware has become very popular and is used everywhere, there are few methods for working with it.

Their difference from each other lies in the use of different tools.

- Cutting porcelain tiles with a mechanical tile cutter;

- The same operation performed by an angle grinder;

- Working with an electric tile cutter;

- Waterjet artistic cutting of porcelain stoneware.

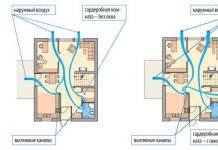

Conventionally, the methods are divided into two groups based on the likely location of the work - at home and at work. The first three techniques are used both at home and on construction sites, the last technique is mainly used at production sites, which is due to increased safety requirements, high consumption of water and electricity, and noise.

Working with a mechanical tile cutter

Most often, ordinary cutting of porcelain tiles, which does not involve artistic delights in the form of numerous cuts and corners, is done with a mechanical tile cutter.

The structure of porcelain stoneware is different than that of ceramics; there is a greater likelihood of chipping when it is broken. And yet, workers familiar with such a process as cutting tiles should not be intimidated by porcelain tiles.

It is important to follow the rules for working with this tool:

- You need to move the diamond wheel over the surface once, smoothly, with the same force along the entire length;

- The tile must be held firmly with your hand;

- To split the tiles, press the lever smoothly but vigorously.

Cutting porcelain stoneware with a mechanical tile cutter is characterized by speed and clarity of the break. The resulting chips and unevenness can be corrected with a grinding wheel.

The reliability of any mechanism depends on the quality of its technical care. Before using the tile cutter, you need to check the degree of wear of the diamond wheel and replace it if necessary.

Work as an angle grinder

The most affordable tool for working with ceramic tiles at home is a grinder. Considering the glassy, hard surface, a diamond wheel without slots is selected as a cutting tool for an angle grinder.

There are many detailed instructions on the Internet and technical literature on how to cut porcelain stoneware.

The main thing is to know the features of working with a grinder on ceramic granite:

- It is very difficult to draw an ideal, even line with a grinder, although you can achieve acceptable accuracy by first marking the cut location with a marker;

- When cutting, be sure to leave a 2-3 mm margin from the intended line towards the fault;

- There is no need to run the grinder over the stone several times; just make one cut slowly and smoothly, with strong pressure, then there will be fewer chips;

- The tiles must be securely fixed, preferably with clamps to the work table, since cutting porcelain tiles can only be done with considerable effort. A poorly secured tile can break out and cause trouble.

The unlimited freedom of movement of the grinder on the surface determines the ability to make arbitrary cuts on the material.

The disadvantages of this technique include loud noise and a lot of dust during operation.

The grinder is a tool of increased danger. When working with it, you must wear safety glasses and gloves.

Working with an electric tile cutter

Owners of electric tile cutters can tell you how to cut porcelain tiles correctly. This device increases the cutting accuracy and speed by an order of magnitude.

Structurally, an electric tile cutter is simple and consists of two main parts - a work table and an electric drive. Despite its simplicity, there are a great many modifications of this instrument. The performance of the device, and therefore its price, depend on the inclusion of additional mechanisms that increase the functionality of the tool. Thus, the power of the electric motor determines the size of the cutting disc. A larger diameter circle on the device removes, for example, the question of how to cut thicker porcelain tiles.

The trade offers a wide selection of models of electric tile cutters of any size, power and configuration. All of them are divided into two subgroups.

The first is mechanisms with a fixed electric drive. In this option, the material is fed under the cutting edge by hand, which requires maximum concentration and requires certain experience in carrying out the work.

The second group is devices with a movable cutting tool, when the drive moves along a special guide. This is the safest way to cut porcelain tiles.

If you work with power tools at home, then the main problem is not the noise (you can negotiate with your neighbors), but the gigantic amount of dust that accompanies the work of the grinder. A special water tray included with the electric tile cutter removes the question of where to cut porcelain tiles, since all dust during the cutting process is absorbed by the liquid.

The main advantages of electric tile cutters:

- The speed and ease of cutting allows you to master large volumes of tile laying in a short time;

- There is no need for additional edge processing, the cut is smooth and clean;

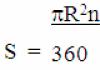

- A special rotary mechanism with divisions fixes the position of the disk at an angle to the table plane; you can cut porcelain stoneware at 45 0 or at another angle;

- A skilled specialist will use this tool to cut segments of any shape in tiles, and even rectangular holes;

- There is a special high-strength porcelain tile for the floor. How to cut such material? Only with an electric tile cutter.

The subtleties of working with this device include the need to adjust the feed speed in different sections of the cut. At the beginning and end of the tile - slow feed, in the middle - fast feed. This order of work helps to solve the question of how to cut porcelain stoneware without chipping at the ends of the cut.

During the cutting process, control your every movement, press the tile tightly to the table and use a protective shield or glasses, as fragments may fly out.

For some users, a description of how to cut porcelain tiles is not enough.

Videos available on the Internet visually represent this process.

Waterjet cutting

This type of processing is used only in production areas using special equipment, and accordingly it has different tasks.

Cutting porcelain tiles at 45 degrees is a completely doable task with an electric tile cutter and even a grinder.

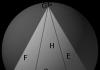

But complex profiles, elements of mosaic panels, figures and individual shoulder-length compositions can only be cut using special machines. Typically, they use a method of cutting the material with a mixture of water and abrasive powder fed into a nozzle under high pressure. Figurative cutting of porcelain stoneware is carried out with an extremely thin jet, so the precision of execution is very high. Large artistic orders for the design of public buildings and premises, for example, train stations and metro stations, are carried out using this method. It's nice to watch how porcelain stoneware is cut on these machines.

The video presented on the video resource pages is impressive.

Of course, the price of such production is high. If you need to cut a couple dozen tiles for your home hallway, then forget about waterjet cutting. One order will cost more than several of the best mechanical tile cutters. It’s better to read and choose a method and tool that fully meets the tasks.

The basis of every construction project, be it home renovation or shopping center decoration, is planning and calculation. Based on the volume and complexity of the upcoming tasks, a material processing method and tool are selected.

How to cut porcelain stoneware tiles depends only on these conditions. The choice is yours.

Cutting porcelain stoneware at home is carried out using various devices. Let's talk about them.

Ceramic granite, also called kerogranite, is a finishing material of artificial origin, which in its appearance and performance qualities differs little from natural stones. It is used for finishing residential apartments and public spaces, as well as for high-quality cladding of facades of various buildings.

Initially, porcelain stoneware was used exclusively as tiles for installing floor coverings in objects with heavy loads. It was installed in industrial workshops and public places. In recent years, the scope of use of the described material has expanded significantly due to its special properties. Ordinary consumers liked the following unique characteristics of ceramic granite tiles:

- antistatic;

- environmental friendliness;

- external aesthetics;

- frost and wear resistance;

- hygiene;

- durability of operation;

- fire resistance;

- high strength.

Ceramic granite tiles

In addition, ceramic granite does not crumble, does not wear out during use, and does not scratch even under significant loads. All these advantages also lead to a significant disadvantage of the material - it is very difficult to cut it with your own hands, without resorting to the help of specialized companies.

Difficult does not mean that cutting porcelain tiles at home is absolutely impossible. Next, we will describe all the tools with which you can independently cut ceramic granite products according to the geometric parameters you need.

Hand tools are practically not used for porcelain tiles. They are not capable of cutting such durable material. Experts advise using the following devices in cases where you need to cut porcelain stoneware:

- Bulgarian;

- tile cutter;

- jigsaw with wire (diamond);

- a circular saw.

An ordinary grinder is quite effective. With its help, both figured cutting of porcelain stoneware and straight simple cutting are performed. To do this, the tool must be equipped with a special disk for dry cutting. Such a nozzle must be diamond coated.

When using a grinder, it is recommended to first outline the contours of the cut with a marker, regular pencil or chalk. Then you will never damage the tile or get a bevel along the cut line. Porcelain stoneware should be firmly fixed on some stable device (for example, on a workbench), and a sprayed nozzle should be installed in the direction of movement of the tool.

Cutting porcelain stoneware with a grinder

Now you can start cutting the tiles. The grinder's movements must be performed smoothly; near the edge of the product, it is advisable to slow down the speed of movement of the tool. With some effort you will get an even cut. True, there is a possibility of chipping.

If you don’t want to get a lot of defective tiles, use a tile cutter instead of a grinder. It can be manual or electric. The first is a device with a carbide or diamond disk, which is fixed with a holder.

A manual tile cutter (it must be mounted on a durable frame, which guarantees the safety of the work and minimizes labor costs) can cut stoneware up to 1.2 cm thick. This tool is usually used for cutting corners and making straight cuts. To obtain round holes in the tiles, you need to use a tile cutter with a ballerina - a special device designed specifically for these purposes.

An electric tile cutter provides higher quality work. It comes with an upper and lower engine. The function of the sawing device in it is performed by a diamond disk, which is cooled by water when using the tool. In this case, wet cutting of porcelain stoneware is carried out.

Working with an electric tile cutter

The disc on the electric attachment allows you to make cuts at a 45-degree angle. You cannot do this kind of work with a manual tile cutter or grinder. The disc must be taken as sharp as possible. The efficiency of cutting, as well as the absence of defects, depends on the quality of its sharpening and strength parameters.

How to cut porcelain tiles with an electric tool? Refer to the following diagram:

- Mark the ceramic granite product.

- Secure the tiles to a special platform.

- Fix the diamond blade in the tool and make sure it is securely fastened.

- Apply a shallow scratch to the tile according to the markings. Please note that the disc should extend 0.8–1 cm further from the edge of the product.

- Break the tile into pieces along the scratch made, applying the required force.

When using a tile cutter, the risk of damage to the cut products is minimized. Therefore, it is used much more often than the grinder. In addition, the diamond blade on a tile cutter cuts the material faster. In a short time you can process a huge number of porcelain stoneware products at home.

If you decide to use such a disk, follow the following pro tips:

- always make cuts from the front side of the tiles;

- handle small chips that may form during work;

- Use minimal force when cutting items to prevent them from splitting.

A jigsaw with diamond wire makes it possible to perform complex shaped processing of products that interest us. It is rarely used by home craftsmen, as it requires certain skills in using such a tool. However, there is nothing difficult in its use. You only need:

- carefully monitor the movement of the wire (first mark the contours of the cutout you need on the tile);

- constantly blow off dust from the surface of the workpiece (in this case, the cutting thread will follow a clean line and cut the material efficiently);

- Moisten the porcelain tiles a little with water;

- pay special attention to processing the edges of products where there is a high risk of chipping.

Processing the edges of the product from chipping

Direct cutting of a large number of tiles can be performed using a unit with a gear-type disk, which many home craftsmen have. You need to mount a disk (diamond) on such an installation, with which you can carry out dry cutting.

The principle of using the “circular” is as follows:

- mark the cutting line;

- press the ceramic granite product to the work surface with both hands;

- move the tile forward onto the rotating disk.

Using a circular saw requires maximum care. The tiles have to be moved manually, which can lead to serious injury to your fingers. Be extremely careful when working with this tool!

Porcelain stoneware is one of the hardest materials used for various coatings (floors, walls, kitchen tables, etc.). During the installation process, there is a need to cut porcelain tiles. For large volumes, the recommendation is clear - a professional tool. At home, you can get by with one of the following methods, or a combination of them (especially if you take into account the little tricks):

- angle grinder (grinder);

- manual tile cutter.

The raw materials, consisting of clay, kaolin, quartz sand, feldspar and mineral additives, are pressed under high pressure and then sintered at high temperatures. The resulting material has virtually no pores and has a hardness equal to that of corundum (7 – 8 on the Mohs scale). It is inferior in hardness to only a few materials, such as diamond, sapphire, ruby, etc. At the same time, thin tiles (3 mm and thinner) are quite fragile.

Note! Cutting material of such hardness will not work with hand glass cutters, stone blades or jigsaws. They can only be used as an auxiliary tool.

Let's look at two ways to cut tiles at home. The methods have limitations, which will be discussed below, as well as ways to circumvent these limitations. They can achieve acceptable results, but it is better to cut porcelain tiles using professional equipment. Only it will give a guaranteed result in an acceptable time with a relatively large amount of work.

Cutting with a grinder

An angle grinder (grinder) is a universal tool for cutting and processing a variety of materials. Due to its versatility, it is not classified as a special tool. In the household, you can solve many issues with the help of an angle grinder.

In order to cut porcelain stoneware, almost any grinder is suitable. There is no need for high power. It is even preferable to use a small, lightweight tool. RPM is more important than power. A powerful tool will cut the tiles faster, but speed can have a negative impact here - it will turn out less neatly.

The main issue is the selection of the cutting wheel. It is the choice of circle that you should pay special attention to. And we are not talking about the landing size (that goes without saying).

Selecting a cutting blade

The material is cut only with diamond discs. Diamond blades are produced in two types: solid and segmented. For best results, it is recommended to try different cutting wheels to make cuts. For cutting porcelain stoneware, there are features when using both solid and segmented discs:

In addition to the type, the discs differ in a whole set of parameters: the density of diamond coating, the height of the cutting edge, the thickness of the disc, etc. It is better to follow the recommendations of the disk manufacturers. The disks themselves usually indicate for what purposes they are used.

For cutting with a manual grinder, discs with a thickness of less than 2.0 mm are not acceptable. The height of the cutting edge should be greater than the thickness of the tile (affects the cleanliness of the cut).

Advice! Before each cut, check the condition of the disc. For any deviations, the disc is replaced, otherwise the risk of chipping increases.

Technology

- Mark the tiles. The best way to do this is to use a construction marker.

- Place the tiles on a flat surface. In some cases, it will be more convenient to secure the tiles to the surface with clamps or secure them in a workbench.

- To obtain an even cut, you can additionally strengthen the metal strip with clamps along the cutting line. Then you will have to cut along it.

- Cutting is carried out from the front side, since the output produces the largest number of chips. You can make double cuts. First, make a small furrow on the front side, and make the main cut on the back side. This method will minimize damage to the front surface.

- If there are no strict requirements for the cut, then you don’t have to cut it all the way. After making the cuts, break the slab with your hands.

- It is recommended to lead the instrument starting from yourself.

- Additional sanding of the cut if necessary.

When using an angle grinder, be sure to use protective equipment:

- a suit covering legs and arms;

- safety glasses (preferably a mask);

- protective gloves or mittens;

- a respirator (for a significant amount of work is required).

Advantages of using an angle grinder:

- The ability to cut an element of almost any shape. Curly cutting requires good tool skills;

- Possibility of trimming tiles already laid in place;

- Tool availability.

Flaws:

- injury hazard;

- it is very difficult to obtain geometrically accurate sections;

- greater difficulty in obtaining a clean cut without chips;

- low speed;

- a lot of dust and noise.

With a grinder you won't be able to get the perfect cut the first time. To obtain precise cuts without chipping, cut with a distance of 2-5 mm from the line. Then it is brought to the required dimensions by grinding. This is a rather labor-intensive operation and takes a lot of time, so it is recommended to carry out it only with elements that will be in a visible place.

Or they use a trick, as in the video below:

Cutting with a manual tile cutter

There is only an electric tile cutter for porcelain stoneware. There is no specialized manual tile cutter for porcelain stoneware. But for these purposes you can use a good quality manual tile cutter. You will most likely not be able to find a cheap suitable tool, and if you use one, the result will simply be a broken tile.

Basic requirements for the tool:

A good frame with a powerful stiffener. Otherwise, when a tile breaks, the frame will bend and the tile will break out of line;

- No play in the carriage (usually depends on the thickness of the guides). With use over time, any manual tile cutter begins to play. Therefore, it is not recommended to use old, untested ones;

- The thicker the tile, the thicker the diameter of the cutting roller should be;

- The carriage should move smoothly. This is achieved by special bearings. A bearingless carriage can also have a smooth ride, but according to experience, it doesn’t last long and is unstable, i.e. One time it rolled smoothly, but the next time there was no guarantee.

Technology

- Mark the tiles; it is recommended to use a construction marker.

- Lay the tiles on the tile cutter exactly along the line.

- Carefully draw a line away from you with light pressure. In this case, it is important to maintain the same pressure throughout the entire line. Important! A line is drawn on porcelain stoneware once. Drawing multiple lines is unacceptable. Otherwise, the fault may not go along the line.

- Place the foot on the tile and press to break along the line.

- Sand the cut if necessary.

Please note the restrictions on using a manual tile cutter:

- only straight cuts through the entire tile;

- it is almost impossible to accurately break off strips less than 6 - 7 cm (depending on the thickness of the material);

- problematic, with chips, oblique lines break if the cut hits the ribs on the back side.

Advantages:

- speed of work;

- absence of dust and noise;

- ease of operation.

To obtain particularly neat lines, you can use the same technology as for the angle grinder. Draw a line with an indentation of 2-3 mm, and then sand it to the desired size. Used only in visible places.

Little tricks

These two methods do not exhaust all methods. With their help, you can get an acceptable result for any cuts at home. Round holes in the material are made with ordinary tools without any special nuances: drills with carbide coating, ballerina drills, crowns. The only difference is that due to the hardness of the material, the cutting tool will fail faster.

To solve the problem of laying tiles, you can use an integrated approach:

- The easiest way to cut tiles is with a manual tile cutter. It is recommended to cut the bulk of the tiles with it;

- Tiles with cut edges, covered with skirting boards or overlays. In this case, it will be enough to use a manual tile cutter or grinder (in limited cases);

- There are few tiles with an exact fit. Adjust by sanding;

- Lay all intact tiles. Depending on the available tools, adjust the tiles that are covered with baseboards and trims. The remaining elements should be accurately measured and marked on the tile. Either rent a professional tile cutter, or take it to the nearest construction company that has such equipment and cut it.

Advice! If you need repairmen, there is a very convenient service for selecting them. Just send in the form below a detailed description of the work that needs to be performed and you will receive proposals with prices from construction teams and companies by email. You can see reviews about each of them and photographs with examples of work. It's FREE and there's no obligation.

Porcelain tiles are a popular finishing material suitable for both interior and exterior decoration. When planning to carry out repair work on your own, it is important to figure out in advance how to cut porcelain stoneware, as well as stock up on the necessary tools for this. Let's figure out how to do this quickly and efficiently.

Porcelain stoneware is a highly durable material, the processing of which requires certain skills and appropriate tools. The best device for giving this material the required shape is a specialized machine. But given the fact that not everyone has such a device, the question of what exactly to use to cut porcelain stoneware at home is a frequently asked question among visitors to construction sites.

Devices such as an ordinary grinder will help you successfully cut porcelain stoneware panels and tiles on your own, without resorting to the use of special equipment. You should choose among these tools taking into account the goals pursued in a particular case and the characteristics of the material at your disposal.

Cutting porcelain tiles with a tile cutter

The most compact and inexpensive device, well suited for cutting porcelain stoneware at home, is a tile cutter. Direct cutting is quite simple. The main thing is to follow a few simple rules:

- Before starting work, it is important to make sure that the existing tool is correctly equipped and in good working order;

- The material to be cut should be marked by drawing clear lines on its back side with a marker or directly with a tile cutter;

- The tile cutter must be installed on a hard and stable surface;

- Cutting the material should be carried out as smoothly as possible, applying force “from yourself”;

- It is best to apply pressure on the tool evenly throughout the cut: this way you will be able to avoid unwanted chips and crumbling of the material;

- After the cut is completely prepared, pieces of porcelain tiles can be easily separated by applying light pressure from either side.

This method is relatively simple and will require you to have minimal skills in working with a tile cutter. However, it is only suitable if it is necessary to create cuts in a straight line. An ordinary grinder will allow you to perform shaped cutting of porcelain tiles at home.

Cutting porcelain stoneware with a grinder

An angle grinder equipped with a fairly thin diamond blade will allow you to quickly and accurately cut porcelain tiles at home. The process of giving the building material the required shape will consist of several stages:

- The porcelain tiles to be cut should be firmly secured to a stable surface with the face down;

- Before starting work, it is important to mark the future cut as clearly as possible on the back side of the material;

- When performing direct cutting, it is necessary to apply force “from yourself” and act smoothly in order to prevent chipping and crumbling of the material;

- While working, you should use special glasses to protect your eyes from construction dust;

- It is best to process the finished cut with fine sandpaper to give the product the proper smoothness and ensure safety during its subsequent use.

You can get more detailed and visual information on how to properly cut porcelain stoneware by studying the photo and video instructions provided in this article.