Do-it-yourself installation of stainless steel railings is quite affordable for people who have the skills to work with metalwork and power tools.

To perform the installation you will need:

- angle grinder (grinder);

- electric drill;

- drills for working with stainless steel and wood;

- curly screwdrivers;

- building level;

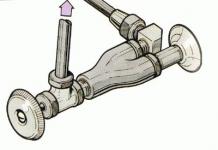

- mount and hexagon for it.

Mounting sequence

The first step in the installation of fences is the installation of the first and last racks that carry the main load. After that, a cord is stretched between them, which will indicate the trajectory of the installation of intermediate supports (balusters). To attach the racks to the floor, a special embedded panel is used. It should be installed no closer than 50 mm from the edge of the step.

Upon completion of the installation of all racks and balusters, the attachment points are marked in their upper end.

Next, install the fasteners that will be used as handrail clamps. Railings are mounted in pre-prepared mounts using special plugs and swivel mounts, which makes it possible to obtain a reliable and aesthetically beautiful stair railing.

Support post mounting options

In order to attach the support post to the surface of the floor or stairs, use:

Single mount

One of the fastest ways to fix racks. It consists in mounting the racks on one anchor, which will be fully responsible for the reliability of fastening. Despite the speed of work, this option is the least reliable in comparison with anti-vandal or flange mounting.

Anti-vandal fastening

It implies that holes will be drilled in the floor surface, into which mortgages will then be placed. The fastening of mortgages to the rack is closed with a special decorative lining. This mounting option has the highest reliability and load-bearing characteristics. Thanks to the use of modern equipment, it is possible to drill in almost any material: concrete, marble, stone, wood, granite, etc.

flange mounting

Represents fastening of a rack to a flange which is fixed by means of several anchors. Most often, flange fastening is performed on 3 anchors to ensure the highest possible level of reliability.

When choosing a method for attaching support posts, one should take into account the basic requirements of regulatory documentation in terms of permissible loads on stainless steel railings:

for structures that are installed in kindergartens, schools, residential buildings, medical institutions, recreation centers - 36 kgf / m;

for sports, gyms and stands - 180 kgf / m;

for all other premises, buildings and structures - 96 kgf / m.

An obligatory element of houses and cottages that have a second floor is a staircase. Adherents of environmentally friendly materials prefer to build wooden structures in their premises. Do-it-yourself installation of balusters on a wooden staircase requires preparation and careful completion of all stages of work. This article describes several ways to install additional protection elements for stairs.

wooden stairs

To ensure the safety of movement on a wooden staircase, building standards provide for the installation of balusters and handrails. Balusters are called rack-mounted railings, based on steps or and at the top coming to one level, where they are connected by a railing.

There are several types of racks:

- Flat.

- Round or square without decorative elements.

- Figured, cut out on machines according to the template.

- Carved. They are the most complex, since their central part is made with decorative cutting. Often these wooden balusters are produced as handmade products.

Each post has a rectangular base that rests on the rungs of a ladder. It is often longer than required by the height of the fence, but thanks to this, the length of each element can be adjusted. If the balusters rest on, their base is cut off at the angle at which the flight of stairs is located.

The central part is often made taking into account the decorative design. This is the most beautiful part, as it is decorated with simple or sculptural carvings.

The upper part of the wooden baluster is a support for the railing. Since the railing is at an angle, the support is cut at the same angle as the entire stair structure.

The device of the flight of stairs

Rack material

There is a wide variety of materials from which balusters are made:

- Concrete and plaster. Such racks are used in the design of outdoor stairs, as well as cornices. They are cast in molds using a reinforcing cage, and after being removed, they can be further polished and treated with special compounds.

- Stone. They are the most durable. Production of artificial stone is carried out by casting, natural balusters are carved from stone.

- Metal balusters. They are made by forging, welding or casting. There are straight and three-dimensional models. The installation of metal balusters will be in harmony with wooden flights of stairs with the right color scheme.

- Polyurethane. Their prices are lower than other options. They have a small mass, and their reliability is guaranteed by the presence of a metal rod.

- Wooden balusters. Constructions of both flat and three-dimensional forms are made from natural wood.

Requirements for installing balusters and handrails

So that the use of the stairs is not fraught with difficulties and those passing through it are not endangered, some requirements must be observed:

- The height of the fence should be about one meter (or 90 cm). This is enough to ensure safe movement on the structure. Thanks to this height, it will be convenient to lean on the railing when climbing the stairs.

- If the flight of stairs adjoins the wall, for ease of movement, it is necessary to install a railing at a distance of 5-7 cm from the wall surface.

- The racks should be at a distance of 10-20 cm from each other. If there are kids in the house, the optimal value will be 10 cm.

- Railings must withstand a side load of 100-120 kg.

- If not only adults, but also children live in the house, you can install another railing in the middle of the fence, which will be easy for children to lean on.

- The fastening of the balusters should be carried out in two places: at the bottom to the steps and at the top to the handrails.

- Handrails must be smooth. The possibility of entering a splinter with a wooden product should be excluded.

Installation of balusters

Balusters in the staircase

A row of balusters is located on one or two edges of the flight of stairs as a protection that ensures the safety of movement along the steps. Racks can be based on steps, or they can be on.

One or two balusters can be installed on the steps. So the balusters will rest on a horizontal surface. Racks will not need to be cut at an angle, so the process of preparing for installation will take less time. However, balusters installed on steps reduce the width of the stairs.

Balusters mounted on steps

If you install wooden racks on, you can save the useful width of the steps, however, in this case, each baluster will need to be cut both from above and below. Both angles of inclination will be equal, as they correspond to the inclination of the flight of stairs. This method is used with sufficient thickness.

Mounting racks on studs

There is another method of mounting using studs using nuts glued into or steps. Such studs are screwed into the rack in the same way as it was written earlier. However, before mounting the rack on a step, not only is a hole for the stud made in it, but the upper part is also expanded by the diameter of the nut. Depending on the expansion depth, one or two nuts are recessed. They are placed flush with the wood and sit on the glue. When it is completely dry and the nuts are securely seated in the steps, the hole is filled with glue again and the hairpin in the baluster is twisted.

If the thickness of the step is small, you can drill a through hole in it and screw in a baluster with a stud, and tighten the nut with a large washer on the reverse side.

Sometimes balusters for a flight of stairs are already sold with glued studs, so the process of their installation is greatly accelerated.

For dowels

Since the main load is carried out on the pedestals, dowels can be used to fasten the balusters. This method is the most commonly used for wood structures.

Dowels are small cylindrical wooden spikes. They can be purchased in stores, or you can make your own. The price of such products is low, so they are very affordable. To perform all the work, it is necessary to prepare dowels and carpentry glue. The length of the dowels is about 10-12 cm, and the diameter is 0.8-1.2 cm.

Installing racks on steps involves the following sequence of actions:

- Preparation of all balusters. To do this, in the center of each step, a hole is drilled from below with a depth equal to half the length of the dowels and a diameter of 0.5 mm more than the fasteners.

- The holes in the posts are filled with glue and dowels are inserted into them. Excess glue is removed immediately. It takes about 2-3 hours to dry, so during this time you can do the markings on the steps themselves.

- When marking, it should be remembered that all points for installing balusters must be on the same line. Otherwise, there will be problems when installing the railing. The distance from the edge of the flight of stairs to the point of attachment of the rack must be sufficient to fit it on the steps. However, it is worth remembering that making a large indent significantly reduces the useful area of \u200b\u200bthe stairs.

- In the places of the exposed points on the steps, holes are drilled equal to half the length of the dowels and a diameter of 0.5 mm more.

- Glue is poured into these holes. They also lubricate the end of the rack. Then it is inserted into the hole. To prevent the baluster from tilting during the drying of the glue, it is fixed and set to the building level. It also takes 2-3 hours for the glue to dry.

Installation of balusters on dowels

If the racks are mounted on, the first stage of work should be cutting all the balusters at the angle of the flight of stairs. To check the correctness of the cut, you need to attach the stand to the bowstring and make sure that it stands vertically, strictly according to the level.

By installing the racks on it is possible to set them at a greater or lesser distance than the width of the steps. When drilling holes in the balusters themselves and the bowstring, it is worth remembering that they must be made not perpendicular to the cut, but strictly vertically. You also need to correctly calculate the depth of the holes.

After all the balusters are securely in place in the flight of stairs, you can begin to prepare them for the installation of railings.

For self-tapping screws

The easiest way to fasten is to use self-tapping screws. This method can be done even by people who do not have skills in carpentry. In addition, there is no need to wait until the wood glue dries in order to proceed to the next stages of work. For the installation of balusters, long self-tapping screws are used - 8-10 cm. It is desirable that they be made of stainless steel.

Installation of racks on self-tapping screws

Installation of balusters is carried out in the following way:

- A slightly smaller hole is drilled in the place where the self-tapping screw is screwed into the baluster. This is necessary in order to avoid cracking of the wood at the installation site and thus to avoid weakening the strength of the fasteners.

- In order for the self-tapping screw, driven into the material at an angle, to be completely drowned in wood, a small depression of the diameter of the cap and a small depth is made in place of the cap.

- Then, self-tapping screws are screwed into all balusters at an angle of 45 °. At first they are not driven all the way, but only so that their tip barely protrudes outward at the bottom of the rack.

- In order for all the balusters to be placed in one row, it is necessary to make markings. To do this, you can take a fishing line or a thin cord and pull it along the flight of stairs.

- Then follows the installation of balusters. To do this, each rack is put in its place and the screw is screwed to the end, firmly fixing it to the step. The head of the self-tapping screw is completely recessed into the tree. It is very important at this point to ensure that all balusters are level.

- Chopsticks matched by color are inserted into the recesses formed in place of the screwed screws. Then they are sanded flush with the surface of the baluster and varnished along with the entire structure. Another option for filling the hole is to use wood putty or wax.

- After placing all the balusters on the same line and level, proceed to the installation of the railing.

Joining balusters and railings

After installing all the racks, the final stage of working with a wooden staircase is the installation of a handrail or railing. These items can be installed in the following ways:

- Dowels.

- Threaded pins.

- Self-tapping screws.

Balusters prepared for railing installation

Dowels

The use of dowels is due to the fact that the main load is not carried out on the railing, it rests on the supporting pillars. To do this, a hole for dowels is drilled in each rack. The same work is done on the railings. So that later it can be securely fixed, the holes are made according to the qualitative markings. Dowels are inserted into holes filled with glue, after which handrails are put on them. Then, for several hours, the entire structure must be left until the glue dries completely.

Threaded studs

When fixing the handrail in this way, it is necessary to accurately determine the center of the baluster and the center of the railing. First, holes are made for the studs in the racks. For additional reliability of fastening, glue is poured into the holes and then the fasteners are screwed into the racks.

After the glue is completely dry, it is necessary to attach the railing to the posts so that the attachment points of the studs are displayed on the back of the railings. This way you can clearly define the places where you need to make holes. Before attaching the railing to the posts, it is necessary to coat all the holes with glue.

self-tapping screws

Installation of railings with self-tapping screws

When installing railings with self-tapping screws, it is very important to choose the right fastening length. If you use excessively long self-tapping screws, when fully tightened, the tips can protrude to the outer surface of the railing, which is a very bad indicator.

Making markings for cutting the top of the racks

Installation of a wooden balustrade

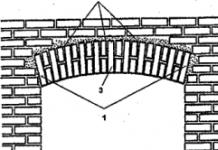

A balustrade is a railing of stairs, balconies, terraces, as well as various elevations. It consists of curly columns, which in their upper part are connected by a handrail or railing. On stairs, such railings are located between floors, at the beginning or at the end of a flight of stairs. If we talk about balconies and terraces, then in such places this design, starting from the pedestals and ending with all the racks, is located on the same line. This greatly simplifies the installation process, since there is no need to cut the top of the balusters at an angle.

The height of the balustrade, as well as the railing, should be about 90 cm, the distance between the posts 10-20 cm.

Balustrade

It is also important to determine the location in the flight of stairs of all pedestals (support pillars). They are about twice as thick as the uprights (balusters). They can be planted on studs or dowels. The length of the fastener should be about 10 cm.

If the pillars do not rest on a wooden surface, but on concrete, then it is necessary to make mortgages in it, to which a bolt-screw is subsequently welded. In order to put a pedestal on this bolt-screw, a hole of the appropriate diameter and length is drilled in it, and then the pole is simply screwed onto the fasteners.

If the floor surface is made of plank material, the fastening of the pillars is carried out in the same way as the installation of balusters on or the wooden surface of the steps. Often in wooden structures, the lower post is placed on the last step and pressed against the riser.

Upon completion of the installation of the pedestals, you need to clearly mark the location of the racks. They must all be on the same line. You also need to correctly determine the cut line of the railing so that they fit correctly with the pedestals.

One way to fit the railing on all balusters is to make a groove along the entire length of the railing to a depth of about 8 mm. The sample width corresponds to the width of the racks. This can be done with a machine.

To securely install the railing, you can fix a thin bar on top of all the racks using self-tapping screws. A railing is laid on top of it and is also fixed with self-tapping screws. It is worth remembering that their length should not be large so that they do not protrude through the railing. Additionally, the handrails must be fixed to the support posts. Using glue, it will be possible to further strengthen the entire structure.

Having completed all the work on the installation of a wooden balustrade, you can secure being at a height and give a solid appearance to a staircase, terrace or balcony.

Today we will consider the issue of fastening balusters and railings when arranging wooden stairs. Even a person who is not tempted by the intricacies of carpentry understands how rich and noble the appearance of wooden stairs is, how difficult they are to manufacture and install.

Calculation and production of parts

The fencing of a wooden staircase consists of three key elements:

- Railings - horizontal or inclined elements for which a hand grip is carried out.

- Balusters - vertical supports between steps and railings.

- Pillars or pedestals - vertical racks against which the ends of the railing rest. Usually the pillars have chiseled or carved heads.

The details of each group are made individually, after which they are assembled at the installation site. Pillars and balusters are made mainly by turning, and railings - by milling.

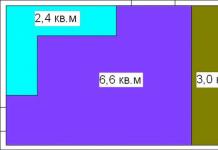

It is necessary to start the calculation of the fence from the railing, including straight and curved segments. In general, the configuration of the railing is determined by the shape of the stairs in plan. For the base in the calculations, the outer edges of the steps are taken, the railings are located with some indentation from them to the center of the flight of stairs. The offset is necessary so that the fulcrum of the pillars and balusters is not located on the very edge. The amount of indentation is determined by the section of the supports, plus some arbitrary value is added, which is dictated by aesthetic considerations. It is also necessary to take into account such specific circumstances as the overlap of spans in the plan, achieving a symmetrical indent on adjacent flights and at the same time maintaining the width of the passage as much as possible.

In space, individual parts of the railing can be located strictly horizontally and under the general slope of the stairs. Calculation of the length and dimensions of the horizontal segments can be done by displaying the railing sketch on the stair plan drawing. Inclined elements are calculated in a similar way, but to calculate their actual length, it is necessary to divide the projection length by the cosine of the angle at which the flight of stairs is inclined relative to the horizontal normal.

When calculating pillars and balusters, several requirements apply, the most important of which is the height of the fences. According to GOST, the railing of stairs must rise above the plane of steps by at least 90 cm in residential buildings and at least 120 cm in public institutions and on street flights of stairs. The axial profile of the pillars and balusters can be arbitrary, but there are certain requirements: the thickness of the pillars in the plane of the support must be at least 10% of their height, the balusters can be 2-2.5 times thinner. The length of the balusters should be equal to the height of the fence + 7-10%, while in the base part a uniform profile (preferably faceted) should be maintained for a length of at least 5% of the total. Pillars are made in the amount of at least two for each flight of stairs, the number of balusters is equal to or twice as high as the number of steps.

The width of the railing in the plan should be less than the thickness of the faceting of the pillars in the junction zone by approximately 30-50 mm and more than the thickness of the balusters by 15-20 mm. The milling profile can be arbitrary, but the rounded top with two longitudinal necks for a more secure grip is considered the preferred option. The length of the handrail segments should have an allowance of 50-80 mm on both sides for cutting and fitting.

Pre-assembly and preparation for installation

Before starting the installation of the stairs, it is necessary to pre-assemble the straight segments of the railing on the adhesive joints. The spatial arrangement of the handrails is a guide for calculating the attachment points of the vertical elements of the fence. Since the railing is precisely machined and has a flat bottom edge, it is convenient to use it as a straight rail for further marking.

Sometimes, at the corners and turns of flights of stairs, the distance between flights forces the installation of short handrail inserts between the posts. Depending on the configuration of the stairs, these sections are assembled either from one or more radius segments, or from linear segments. The railing elements are prepared and glued in advance, the connection is made on hidden domino-type spikes, or on 2-3 cylindrical dowels.

Also, before starting work, wooden dowels for fastening balusters and pillars should be stocked in the right amount. It is also desirable to cut the poles themselves to size: if this could not be done in the workshop, then due to the significant section, processing with a miter saw is not possible. It is better to mark the perimeter of the base part under the square, making sure that the end of the last line coincides with the beginning of the first. Trimming is carried out along this line with a hand saw with a fine tooth, it is advisable to alternately go deeper into each face by 3-5 mm. For greater certainty, you can fix the limit rail with clamps.

Marking and fastening of pillars

The posts are the base for positioning the entire stair railing. They are located on each upper and lower step of each flight of stairs. If there are intermediate platforms, including turning ones, this rule must also be observed. At the same time, the uppermost post may be common for railings and balustrades.

Factory poles are of two types: solid and box-shaped, that is, glued from strips of thick plywood or wood panels. It is very important that each post has a straight edge at the junction of the handrails, because in the case of docking with a round support, factory trimming of the railing edges is required, which greatly complicates the installation process.

Hollow pillars are fastened through a boss - a 150-200 mm piece of timber, the outer dimension of which corresponds to the cavity of the pillar as much as possible. The boss is attached through a through axial hole by means of a pin screwed into a step or platform. This method of fastening allows the column to rotate around its axis and a small transverse play for its precise positioning. The gluing of a hollow column is carried out on a glue of a thick consistency, the lower end is preliminarily lubricated with a small amount of sealant, this belt around the perimeter will prevent excess glue from being squeezed out.

A - box-shaped pole with fastening through the boss. B - one-piece pole with fastening on a dowel. 1 - pillar; 2 - base; 3 - plinth; 4 - hairpin or anchor; 5 - dowel

A - box-shaped pole with fastening through the boss. B - one-piece pole with fastening on a dowel. 1 - pillar; 2 - base; 3 - plinth; 4 - hairpin or anchor; 5 - dowel

Monolithic pillars are fastened to one large (20-30 mm) dowel or to several small ones evenly distributed over the support area. With this method of fastening, it is desirable that the junction of the pole to the site be framed by a plinth, which helps to hide the adhesive seam and increase the plane of support. If there is a skirting board, you can also use the tie-down method for cabinet furniture, since the niches for the nuts will eventually be hidden anyway.

Alignment of pillars is better with parallel standing pairs, that is, at intermediate platforms where flights of stairs converge. The distance between the posts should provide a sufficiently large gap between the lower handrail and the steps of the upper march. In the longitudinal direction, the position of the pillars is determined by two long straight slats laid on the edges of the steps of converging marches. The plane laid out through the line of intersection of the rails is the ideal position for installing the posts. If necessary, they can be moved towards the spans, but not back, otherwise the railings will overlap. When paired poles are positioned on platforms and turns, the end ones are marked according to the same principle, it is important here that the pairing with the railing is performed at the same height.

Trimming, installation of balusters

Looking ahead, we note that the sequence of fastening the balusters to the steps, to the handrails, as well as the handrails themselves to the pillars, can be different depending on the method of assembling the fence. Previously, all balusters must be cut and mark the places of their fastening.

The bottom of the balusters is best mounted on dowels with zero tolerance by drilling the steps to a depth of 20 mm. To mark the centers of the holes, it is necessary to shoot a vertical plane parallel to the end of the steps with a laser level. If the balusters are installed in the amount of one piece per step, it is enough to find its middle using a square, based on the riser. When installing balusters in pairs, it is necessary to achieve their uniform pitch, for which the protrusion of the upper step above the lower one is beaten off with a square, and the remaining “clean” width is divided so that the centers of the balusters are 1/4 of the resulting segment from the edges.

When installing balusters, it is important to keep their heads strictly on the same line.

When installing balusters, it is important to keep their heads strictly on the same line.

Balusters with a figured profile should be aligned in length with respect to the handrails. To do this, they are laid out on a flat plane, combining the profiles along their widest part. Next, a line is drawn under the long straight rail, which serves as a marking for trimming at a right angle.

An oblique cut of the top of the balusters is carried out on a miter saw or in a precision miter box. Trimming of balusters is carried out in groups for each flight of stairs. First you need to determine the actual slope of the stairs by laying a rail on the edges of the steps and beating the horizontal axis along it with a laser level. According to this markup, with the help of a bevel, a template is made, according to which the saw turntable is fine-tuned.

Before oblique trimming, centering holes are made at the ends of the balusters, their depth should be sufficient to deepen the dowel at least 40 mm after trimming. In the lower part, drilling is carried out after trimming the balusters along the length. It is quite simple to do this: first, dry and strictly vertically, two extreme balusters of each span are installed, which are temporarily fastened together with a regular rail with a straight edge aligned with the upper edge of the oblique cut. Then, one by one, the balusters are put in their place, the excess length is determined with a caliper and the lower end is cut, if necessary, deepening the center hole and be sure to number the parts.

Handrail fastening

The handrail can be attached to the posts by various methods, among which the most popular are fixing on spikes or self-tapping screws with making through holes. The first method is more time consuming and often spiked mounting cannot be done without a groove router with fine adjustment of the inclination of the sole. In the second case, installation is easier, but mounting holes remain on the backs of the pillars, which must be closed with decorative plugs.

Railing with railing

Railing with railing

Fastening railings to balusters is done in two ways. Simple - by railing and a little more complex - on wooden dowels. The choice of mounting method depends entirely on the profile of the handrail: when fixing to an intermediate rail, a rectangular groove must be selected at the appropriate depth at the bottom of the product. The handrails for mounting on dowels should also have a groove equal to the width of the base part of the balusters, but it is intended solely for masking the attachment points and should have a depth of 5-7 mm.

The final assembly of the fence, as mentioned, can take place in a different sequence. When attaching to the railing rail, first balusters are glued to the steps on the dowels, after which the rail is mounted, and then cutting and fastening the railings with self-tapping screws from below. When installing balusters on dowels and attaching handrails to poles with self-tapping screws, all railings are first glued, while drilling in them must be carried out with a tolerance: in this case, landing on liquid nails will allow for more accurate alignment. If the balusters are attached to the dowels, and the posts to the handrails - with a spike connection, the pedestals are installed last, which requires the simultaneous positioning of all elements of the stairs in a short glue setting time.

Handrail finishing

As a rule, railings of wooden stairs are assembled from already primed and painted parts. In such cases, it remains only to disguise the places where the railings are spliced, where they adjoin the pillars and balusters to the steps, where gaps up to 1-1.5 mm thick can form. To fill the gaps, you can use an acrylic sealant or wood paste based on natural wax.

If the wooden parts do not have a protective coating at the time of assembly, the gaps in them are sealed with wood putty, and then the entire fence is primed and painted along with the stairs. It is recommended to apply two coats of a transparent water-soluble primer, followed by fine sanding to remove the raised pile. Next, the steps are covered with stain or azure in 2-3 layers. It is recommended to choose two coats of transparent polyurethane varnish as the main protective coating.

The railing on the wall (for walls) is installed horizontally along the flight of stairs in cases where one or both sides of the stairs are limited by walls along the entire length of the flight. In this case, it makes no sense to install railings on racks, since there is nowhere for a person walking up the stairs to fall (there are walls), but you need to hold on to something, especially when it comes to people of the elderly or children. Both of them need support for their hands on at least one wall. This is where the wall handrail comes to the rescue, single or double, depending on the installation location.

As a rule, in private houses and cottages a single wall is installed (this is what a wall handrail is sometimes called), and in medical or children's and school institutions - a double one. At the same time, safety standards regulate the installation height of double handrails at the level of 900 and 700 mm for the low-mobility category of citizens (the elderly and the disabled), and for children, the same indicator is normalized by heights of 700 and 500 mm, respectively. Of course, in private houses there is no height regulation, everything is limited by common sense, convenience and aesthetics. Traditionally, wall handrails are located at a height of 900 mm from the floor.

All these indicators are important to consider at the design stage. The Azbuka Peril group of companies in Moscow will complete an order for you at all stages of work, from design development to turnkey installation.

|

|

|

|

|

Design features of the walls

There are several fundamental differences by which wall railings and handrails are chosen:

There are several fundamental differences by which wall railings and handrails are chosen:

- double handrail for the disabled on the ramp;

- double metal handrails for pensioners and the elderly;

- double children's railing;

- in all other cases, a single model is put.

The first three options, depending on the width of the stairs and the length of the march, are made with a tie at the corners or breaks at the corners, but a tie in the form of “donuts” at the end to ensure safety in accordance with GOST and SNiP standards.

In commercial and private facilities, single handrails are tied at turns for greater comfort, but this increases the cost of the railing, as the material consumption of the finished product increases. The cost is especially affected by the need to manufacture radius-bent or screw handrails, since this kind of work requires a special expensive tool and a highly qualified contractor. Our company has many years of experience in the production of both straight and curved railings made of stainless steel, wood, ferrous metal, brass or plastic (PVC).

|

|

|

|

|

wall railing material

Ferrous metal handrails are the cheapest, but to protect against corrosion, they must be coated with primer enamel or powder paint. The first option is easy to tint without the help of hired contractors, but such a coating does not last long, so you will have to correct the look of the metal handrail on the walls every year. On the other hand, if the product is installed indoors, the service life increases significantly, and its restoration will not be required for many years.

Ferrous metal handrails are the cheapest, but to protect against corrosion, they must be coated with primer enamel or powder paint. The first option is easy to tint without the help of hired contractors, but such a coating does not last long, so you will have to correct the look of the metal handrail on the walls every year. On the other hand, if the product is installed indoors, the service life increases significantly, and its restoration will not be required for many years.

In the case when it is required to install a wall handrail outside the building (on the street), a powder-coated coating is best suited, since the paint layer is literally “baked” in a special oven along with the railing, creating a uniform polymer layer that is very resistant to mechanical damage and does not allow corrosion. On the other hand, this option is much more expensive than its traditionally painted counterpart and does not provide for the possibility of partial restoration at the cleavage site, except for a complete replacement of the coating, which is equivalent in cost to the manufacture of a new wall.

Stainless steel

The most optimal combination of price and quality for a railing in a house is a stainless steel handrail. Polished steel is ideal for both office and private home, because silvery highlights, scattering sparks of light around, give rise to a unique feeling of joy and optimism. Indoors, without fluctuations in humidity and temperature, it is enough to choose AISI 201 stainless steel, outdoors - its more perfect analogue AISI 304. Well, along busy highways and routes, you need to use AISI 316, because only its properties will preserve the brilliance and beauty of the railing for many years even under the influence of an aggressive environment.

|

|

|

|

|

Wood or plastic?

For those customers who appreciate natural materials, the option with wooden railings on the wall is certainly preferable. We suggest using oak or beech, as the most durable and strong wood species with special treatment with wear-resistant varnish and preliminary tinting in color. However, it should be noted that wood is an expensive material, especially if corner ties are needed. Although here you can save money by using metal fittings - hinges or bends at the junctions of the handrails will play the role of a bundle, but will not affect the price as much as if docking was used by building up a tree.

For those customers who appreciate natural materials, the option with wooden railings on the wall is certainly preferable. We suggest using oak or beech, as the most durable and strong wood species with special treatment with wear-resistant varnish and preliminary tinting in color. However, it should be noted that wood is an expensive material, especially if corner ties are needed. Although here you can save money by using metal fittings - hinges or bends at the junctions of the handrails will play the role of a bundle, but will not affect the price as much as if docking was used by building up a tree.

A plastic wall handrail allows you to imitate a wooden texture and save a lot in price, especially when you need cornering ties in the form of bends along the radius, but this material is not durable, so PVC handrails cannot be installed outdoors. Under the influence of direct sunlight, the plastic not only burns out, losing its gloss, saturation and color, but also sags between the fasteners. Indoors, a plastic handrail on the walls is also recommended to be used with caution, as it is easy to scratch it with keys, bracelets, even just a ring or ring on your finger. So the choice of material and cost must be approached consciously and be sure to first consult with the specialists of our company, having found out all the details. Please note, this is completely free.

Gold and luxury

The most common types of stair railings are wooden, metal, forged, cast and combined. All elements of the staircase fencing (railings, handrails and balusters) are usually made in the same style and should be in harmony with the appearance of the steps and side stringers. There are many ways to fasten the railing of stairs, and you will receive detailed information about the most commonly used of them in this material.

Despite the fact that railings are considered a minor detail of the stairs, their role is great, since they mainly provide safety and convenience when moving along a flight of stairs.

Learn how to make handrails for stairs from various materials.

Basic elements and requirements for stair railings

The main elements of stair railings are railings, handrails and balusters.

Railings are railings for flights of stairs that protect a person from falling out and provide ease of use of the structure.

railing- this is an element of the fencing of stairs of various configurations, which, firstly, serve to ensure convenient movement along the stairs and prevent a person from falling outside the fenced structure, and secondly, they are a fairly noticeable element of the interior. The design of the railing plays an important role in choosing a fence.

As shown in the photo, wood, concrete, metal and glass are most often used as materials for stair railings:

Glass is mainly used to fill the space between the uprights.

handrails- this is a narrower concept that corresponds to the upper part of the railing, it is for them that a person holds on when climbing or descending stairs. These are special fencing elements that are fixed to balusters on one or both sides of the flight of stairs. They can also be attached to the wall. Thanks to the use of the overlay on the railing, a comfortable grip of the hand is ensured.

Balusters- support posts, with which the fence is fixed to the stairs. In addition to the carrier, they also perform a decorative function.

See how the railings, handrails and balusters look in the railings of the stairs in these photos:

Compliance with the requirements for the installation of stair railings (GOST and SNiP) is necessary to ensure safety during ascent and descent. Therefore, the height of the railings of stair structures should be from 90 cm to 1 m. Racks should be mounted from each other at a distance of about 60 cm. The space between the balusters must be filled. When attaching the handrail to the wall, the distance from it to the wall should be from 7 to 10 cm.

Pay attention to the photo - the overlays on the railings of the stair railings are made smooth and even, without interruptions:

It is desirable that their cross-sectional area is 5 cm. Handrails for stairs should have a rounded end and protrude 30 cm beyond the step line.

Railings of stairs made of different types of wood (with photo)

Despite the fact that stair railings, combined from various materials, have recently been very popular, wooden railings remain one of the most common.

Wooden balusters are perhaps the most common type of wooden stair railings. Their installation on the stairs is carried out in the lower and upper parts of the structure. At the bottom, the balusters are mounted in the lower step, and in the upper part they are fixed in a wooden handrail and connected to each other by pillars.

Balusters railing stairs made of wood can be of various types and sizes. The standard section of each of them is 45 x 45 mm, on wider stairs you can install balusters with a section of 50 x 50 or 60 x 60 mm.

Unfortunately, wood, by its nature, can quickly lose its structural and decorative properties. Over time, its strength may be lost, it may darken noticeably, especially in the open air.

But, despite this, wood is a suitable and quite practical material for handrails and railings of stair structures, especially inside the house.

As you can see in the photo, conifers (for example, pine, cedar, larch), as well as oak, walnut, cherry and beech are most often used for wooden staircase railings:

In many ways, the choice of wood species depends on the design preferences and material capabilities of the owner.

How to make wooden staircase railings with your own hands (with photo)

Before fixing the elements of the staircase railing (balusters, handrails and other structural details), you must first putty, sand and varnish. After that, you need to design a device for further drilling axial holes in balusters and pillars. To do this, you need a drill mounted on a chipboard board. For centering, it is recommended to screw an oak bar to the chipboard, in which a hole for the drill is made in advance.

Then, to make the staircase railing with your own hands, you need to screw the bar as a guide for the baluster. Moving the balusters to the drill, you should make a hole exactly along the axis of the balusters and pillars.

Using a milling machine in the handrails, it is necessary to carve grooves and a rail. The rail must be made according to the size of the bottom groove. Subsequently, it will be screwed to the balusters. The decorative rail must be machined to the size of the upper groove.

Look at the photo - to fix the staircase railing, you will need studs 10 cm long and 8 mm thick, they must be screwed into balusters:

For ease of tightening, it is best to use nuts. But keep in mind that this method of attaching balusters is only suitable for hardwoods.

After screwing in the studs, the nuts must be removed. The same must be done with the poles, only in this case the screw-in stud must be 10 mm thick. In the lower step, make a hole with a diameter of 7 mm and screw the post into the step. After that, the column must be unscrewed, leaving the hairpin in the steps.

The step should be attached to the floor with an anchor bolt, hiding it with a pillar. To install the top pole, you need to mark the place. A self-tapping screw should be screwed into the center, and then a fishing line should be pulled between it and the hairpin of the lower step. On each step, using a square, it is necessary to draw the lines of the axes of the balusters, mark their centers.

Then, using a thin drill, make a small indentation. Using a special device for drilling perpendicular holes (with a 5 mm drill), you need to make holes in the steps for the installation of balusters. After that, you can screw the studs into the balusters and twist into the steps. Using a square, you need to check the axes of the balusters.

Now you can start assembling the entire march. It is necessary to cut off the two extreme balusters at the desired angle, set them strictly vertically using a level.

You need to fasten the rail with adhesive tape and apply cutting lines along it, along which all the balusters should then be cut. After that, it is necessary to fasten the railing rail to the balusters and put a handrail on it.

The ends of the handrail should be cut at the selected angle so that they fit snugly against the posts, and then screw them to the rail with self-tapping screws. When cutting posts and balusters with a miter saw, it is recommended to wrap the ends with tape to avoid chipping.

After the marches are ready, you can proceed to the device of the balustrade. The post must be fixed against the wall and fixed with an anchor bolt. Next, you need to cut and lay the under-balustrade rail between the posts. Middle balusters should be screwed to the rail on the reverse side with euro screws. The end balusters must be bolted to the floor through the lath using anchor bolts. Then it remains to fasten the railing rail.

Now you can start fixing the handrails of the wooden railings of the stairs to the pillars. To do this, you need to drill a hole in the handrail. With the help of a chisel, you need to remove the excess. Next, a stencil is made, which is applied to the handrail, after which a mark is drawn. Using a thin drill, you need to make a hole, and then widen it using a thick drill.

Next, you need to put a handrail on the railing rail and circle the end on the pole. Having attached a stencil, you need to mark the surface for the hole. Then you should drill a hole, screw the euro screw into it, after which the screw itself must be unscrewed. Having placed the handrail on the railing rail, it must be screwed using a euro screw.

Thus, it is necessary to secure all the top posts and balustrade posts. The lower poles can be fastened with self-tapping screws or euro screws, twisting them at an angle.

After that, it remains only to close the railing rail with a decorative one. To do this, you need to cut it into pieces of a suitable size, grease the inside with silicone and insert it into the handrail, fixing it with adhesive tape for reliability.

Installation of wooden railings for stairs is shown in these photos:

Metal staircase railings: types of filling and types of material

In addition to wooden, one of the most common in modern home design are railings for stairs made of metal.

It is very important to pay attention to the implementation of the fences, which are necessary to fill the space between the racks. Thus, the safety of movement on the stairs is ensured. Partitions in fences are required for the device if there are small children in the house.

There are several main types of filling metal railings stairs:

- Classic type. Such fillings of fences consist only of vertical or inclined balusters.

- Fencing with solid panels is a set of wide sheets. As a rule, such panels are used when combining railings with glass.

- Filling with crossbars. In this embodiment, the void between the balusters is closed with horizontal metal bars - crossbars or handrails, which are located parallel to the handrails.

Before manufacturing metal railings for stairs, you should decide on the type of material (metal). It can be aluminum, iron, cast iron or steel.

The choice of material will depend on many factors, the main of which is the purpose of the product.

For example, for outdoor railings it is recommended to use stainless steel, from which nickel-plated railings are made. Cast iron will work too.

Pay attention to the photo - of all metal railings for indoor stairs, aluminum is ideal, with their help you can create the most complex shapes (screw or rotary):

Iron due to the complexity of processing, as a rule, is used in the mass production of fences. It is not suitable for self-production.

According to the manufacturing method, metal railings can be divided into prefabricated, welded, forged, cast and combined.

Making prefabricated and welded metal railings for stairs in the house with your own hands (with photo)

Prefabricated railings for stairs.

The railing is assembled from steel or aluminum elements. In the first case, upon completion of work, the railing is painted, in the second case, a special protective coating is applied. Aluminum railings are easy to install, relatively cheap and light. Due to the lack of welding, prefabricated fences are not only easy to assemble, but also easily and quickly dismantled.

According to the method of applying the protective layer of the metal railing, the stairs in the house can be divided into polymer-coated railings, anodized aluminum railings, and chrome-plated steel railings.

Welded railings for stairs.

Welded railings for stairs are made of steel or ferrous metal. They are quite strong and durable. Do not be afraid of their original appearance, because with the right finish they turn out to be very beautiful. To give the desired shape to stainless steel railings, the method of "cold" metal bending is used. This type of construction is characterized by the presence of various geometric ornaments.

Welded iron railings also have disadvantages, such as their susceptibility to corrosion and therefore the need for regular painting. When using stainless steel railings, these problems do not arise. Their service life is about 50 years.

As you can see in the photo, stainless steel stair railings for a country house are so practical that they do not need painting or any special additional care:

If the need arises, repairs to the railings can be easily carried out on their own by treating the surface using polishing agents, grinding or satin finish.

There are two types of welding when installing staircase railings: semi-automatic and argon-arc. Semi-automatic welding has one drawback: a large amount of spatter during operation. They are absent in argon-arc welding, therefore this method is the most popular. When using it, the seam looks more accurate and lends itself well to further processing, which consists in stripping and polishing. The handrail is fastened using a hardware assembly or by gluing using special glue.

Forged, cast and combined railings for stairs (with photo)

Forged fences.

Wrought iron stair railings have an exquisite appearance, but the process of their manufacture is rather complicated. They are produced according to an individual project by artistic forging. At the request of the customer, it is possible to create any finishing options, different styles (from light openwork structures to strong and massive ones).

Look at the photo - forged railings of stairs can give any interior a special charm of antiquity:

In addition, such railings are varied in color: they can be with a golden sheen, silver or copper. Their only drawback is their high cost.

Cast fences.

For the manufacture of cast fences, you must first prepare a sample of the product, according to which the mold will be cast in the future. After that, it can be filled with molten metal (bronze, cast iron, brass).

When the material hardens, it should be further processed. Casting has a number of advantages: strength and durability, as well as a variety of resulting shapes.

Combined fences.

Combined fences combine elements from different materials. For example, railings can be powder coated chrome material, handrails are made of steel, glass inserts can serve as an addition to the railing, etc.

Thanks to this variety, combined railings can be considered as a universal solution suitable for any stair design.

A variety of forged, cast and combined railings for stairs in the house is presented in these photos:

Installing stair railings: how to attach handrails and balusters

It is very important to securely install stair railings, as the safety of people depends on this.

There are several ways to make a staircase railing in a private house.

Attaching the handrail to the wall.

The handrail is attached to the wall when the ladder is located near it. With this option, racks are not needed, the installation of handrails will take place using special brackets.

Their size should be calculated in such a way that the distance from the handrail to the wall is no more than 10 cm.

Brackets for handrails are cast and articulated. When using hinged brackets, it becomes possible to adjust the inclination of the handrail, which is very convenient when operating the stairs.

This design is easy to assemble and also easy to dismantle.

Attaching balusters to stairs.

Balusters can be installed in three ways.

- Single fastening of balusters is the simplest, but at the same time less reliable way. In this case, the stand is fixed only on the anchor (dowel).

- Flange mounting involves mounting the flange on self-tapping screws. For greater reliability of fastening, it is recommended to use several self-tapping screws.

- Anti-vandal fastening of fences is the most reliable. In this case, it is necessary to drill holes in the steps using a drill, and then place mortgages in them, on which the pipes for the railing will subsequently be fastened.

Fastening balusters to the end of the step.

The baluster is mounted on the end using two anchors.

There are four ways to attach balusters to the end of the step.

Fastening of balusters on two expansion anchors through the sleeve

At the end of the step, you need to drill two recesses. Expanding anchors should subsequently be inserted into them through the holes in the uprights and bushings with decorative overlays so that the end of each anchor protrudes slightly.

It is necessary to tighten the cap nut on it, which performs expansion and fixing functions.

Lateral fastening of balusters.

With side mounting, the balusters should be threaded into special holders and fixed. Expanding anchors in this case fix the balusters to the flight of stairs.

When mounted on two expansion anchors without the use of a sleeve, the post fits snugly against the end of the step. This installation differs from the first method only in that it does not require the use of a sleeve.

Fastening balusters to a chemical anchor.

In this case, fastening is carried out on chemical or liquid nails, which are an adhesive substance that penetrates deeply into concrete. Such a chemical anchor is characterized by a fairly strong fastening.

This method is recommended to be used when it becomes necessary to fix the stair railing into a concrete structure. So, an anchor and a hairpin must be inserted into the hole filled with the mixture. After the balusters are fixed, you can proceed to the residual installation of the railing - in the same way as when installing the “on a step” method.

Installation of stair railings: how to install a railing

Installation of railings in the railing of stairs by the method of fastening to a step must begin with marking the places where future racks will be located. They should be at a distance of 5-10 cm from the edge of the step and at a distance of 30-60 cm from each other.

First, install the first and last pillar. To do this, with a single fastening in the steps, it is necessary to drill holes with a depth of 12 cm and a diameter of 16 mm. Anchors (dowels) must be inserted into the pits, on which balusters will be mounted.

For flange mounting, drill three holes 8 cm deep and 1.2 cm in diameter, into which you will then need to insert dowels.

The flange must be fixed with self-tapping screws, then install the rack into it. During installation, it is necessary to ensure that the input pillars are located strictly vertically, as they will become a guide for the rest of the balusters.

To install the stair railing, it is recommended to first pull the cord over the top of the end posts. Then you need to install the balusters, aligning them with the cord. Next, you need to make sure that all the balusters are vertical, after which you should attach them to the steps.

Stainless steel handrails must be cut to the desired length at a right angle before installation. Then you should mark the places where the holes will be drilled by attaching the handrail to the uprights. After installing the hinges, the handrails can be fixed.

If the gap between the uprights is filled using crossbars, then they should be divided into segments of the desired size, several fixation points on the uprights should be determined and holes drilled. Then you need to fix the crossbars on the balusters. If glass panels are used to fill the space between the racks, then special holders must be attached to the rack and the panels should be fixed with their help.

The disadvantage of the method of fastening the railings of the stairs by the “on a step” method is the reduction in the width of the march. Therefore, this method is not recommended for narrow stairs. Here it would be preferable to mount the rack at the end.