Installing plumbing is half the battle, it is necessary that it works properly. For example, for a toilet bowl, the most important thing is that water is used sparingly and is regularly supplied to the tank. Namely, there are all the mechanisms that regulate the flow of water. The shut-off valve for the toilet bowl is used to release water into the tank. With the help of special levers, the water supply is regulated.

Valves come in different modifications, and you should decide which one to choose, focusing on the design of your toilet. There are models that connect to the side, and there are models that connect to the bottom. Based on the variety of tanks, the locking mechanisms are also different.

Check valve types

The classification of valves can be approached from different angles. Valves differ from each other in the material from which they are made. Most often it can be found from alloys, for example, bronze, brass. They are distinguished by their strength and resistance to corrosion, which is important, as they are constantly surrounded by an aggressive environment.

The designs of such valves can be very different, both very simple and complex. If you decide to buy an expensive drain system, then in it the entire mechanism with levers is made of metal. In cheaper models, the shut-off and filling valves are made of different materials, which makes it possible to change each unit separately in case of a breakdown. It's much more convenient.

Other materials that go into making a check valve are polymers. In this case, the efficiency of work will directly depend on the quality of the plastic. This will also affect the cost of this node.

Now it has become not uncommon when it can happen that expensive fittings will work much worse than cheap ones. Here, probably, it all depends on the quality of manufacture of these parts.

Check valve design

According to their design, shut-off valves can be of two varieties:

- Separate.

- Prefabricated blocks.

In the first version, the shut-off valve is mounted separately from the drain valve. Only water connects them together. The filling mechanism most often has any shape with a float, which, while filling the tank with water, rises along with the level and, thus, closes the water supply valve. The drain structure is mounted completely separately and can be of various configurations with keys, pedals, and so on. The main advantage of such a separate design is that it is possible to repair or replace each valve individually.

The prefabricated model is installed immediately and all valves are interconnected. This is a much better guarantee of quality work if everything is well adjusted. The disadvantage of this design is the impossibility of do-it-yourself repair. These models can be seen in modern designs of toilet bowls. If you decide to install such a mechanism on your old tank, then most likely you will not succeed.

The locking mechanism of the toilet bowl also differs in the way it is connected to the water supply. The shut-off valve can have: top, bottom, right, left connections. This must be taken into account when you decide to replace the internal contents of the tank with new components, because the diameter of the drain and fitting may differ.

Most of all, the mechanisms with the upper and lower connections differ from each other. In both cases, the valve closes from the effect of thrust on it, which is associated with the float. When installing such a system, it is necessary to make a good balancing of the float, the efficiency of work will depend on its quality.

In Russian toilets, most often water is supplied from above. The big disadvantage of this supply is a strong noise during filling the tank. In imported tanks, the bottom connection is mainly used. Water flows silently, and such models look more stylish.

If you have a tank with a top water supply, then the connection should be made only after installing the tank itself. It is possible to connect the bottom reinforcement even before its installation.

Valve installation process

It is best if you install the fittings that you purchased with the toilet. In this case, there is no doubt that all the details will match each other. If your tank has a separate shut-off and drain mechanism, then you can, of course, purchase them separately.

In order to install a shut-off valve, you will need:

- Wrench.

- Pliers.

- Water faucet.

- Open-end wrenches.

- Gaskets.

- Hose.

It is not so difficult to install the locking mechanism with your own hands. To begin with, it is necessary to equip a drain unit in the tank, while paying special attention to the tight connection. A gasket must be used between the base and bottom of the tank. You should put the tank on the toilet bowl, between them there must be a rubber ring to eliminate friction. Now you can screw on the tank.

If water is supplied from below, then it can be brought even before the tank is installed in its place. It is necessary to follow the good fastening of the gaskets, they are able to prevent leakage. There are no such difficulties for the top water supply, since everything is located above the water. Next, you need to push the tube and tighten the nuts well on both sides.

At the next stage of work, you need to connect the hose to the water supply fitting, install a faucet. In case of necessary repairs, it will be possible to shut off the water supply. After the water is supplied, it is necessary to adjust the float. At the same time, it should be taken into account that water should not reach the edges of the tank, from them it should be 15 centimeters lower.

At the last stage, the water drain is mounted, for this it is necessary to insert the structure into the opening of the tank lid and fix it. For this, decorative elements are often used. The instructions for completing all the stages of work are simple, so everyone can handle it.

Shut-off valve malfunction

Before proceeding with the elimination of all malfunctions in the operation of the drain tank, it is necessary to find out the mechanism for attaching the cover. If you accidentally break it during removal, you will have to change the entire tank.

The most common cause of inefficient operation is the float. There are such shortcomings:

- Float tilt.

- Membrane wear.

- The shut-off valve allows water to pass through.

- A hole in the float.

In order to adjust the float, you must carefully consider its mount. Often it is enough to change the bend of the float or its fixation and the problems are solved.

If it's all about the shut-off valve, then you have to change it. This must be done in a certain sequence:

- Release all water from the tank.

- Disconnect the valve from the water supply.

- Remove lever.

- Take out the old valve.

- Put in a new one and screw it on.

- Fill the tank with water.

- Adjust float.

Check valve selection

If you find any malfunctions in the operation of the drain tank, then you must approach with all responsibility the purchase of replacement parts. The efficiency of the entire mechanism will depend on the selected fittings.

With the right choice, installing such equipment will be quite easy. Arriving at the hardware store, do not rush to purchase the first kit that caught your eye. You have to make sure it fits 100%.

When purchasing a new locking mechanism, you should pay attention to a number of subtleties:

- You need to buy a valve of a similar design and principle of operation.

- All components of the valve must move freely; if the slightest sticking is detected, another option must be selected.

- All gaskets supplied must be elastic and flexible and free of any cracks. For reliability and confidence, it is better to immediately purchase a spare set.

- Even in the store, you need to carefully examine everything for the presence of distortions, deformations, cracks and other defects. Here, even the slightest discrepancy will then affect the operation of the mechanism.

In addition to these nuances, we must also take into account that in order to replace the shut-off valve, you will definitely need a set of tools and materials. The shut-off valves must necessarily match your tank and water outlets, only in this case the installation will be successful.

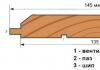

Inlet fitting with diaphragm valve (for toilet bowls)

Inlet valve device with a membrane valve (for toilet bowls - compact)

The inlet (filling) fittings in the cisterns of toilet bowls are different. In modern compact toilets, fittings with a membrane valve are usually used - the idea is clearly not a Soviet engineer. The design solutions of the engineers of the Soviet school have always been distinguished by their simplicity, which increased the reliability of the system, and in the event of a failure, the possibility of fixing the problem with available improvised means. And this applies not only to toilets, but also to spacecraft, the design of which Americans still admire. In Soviet toilet bowls, even with a cast-iron tank, even with a plastic one, even in compact toilet bowls, inlet fittings of the simplest design with a stem float valve were installed. Water is drawn into tanks equipped with such fittings slowly, unevenly and noisily, sometimes very noisily: with howling, grinding and rattling. But on the other hand, almost any adult man could adjust the fittings of the Soviet toilet bowl, and even my mother-in-law liked to dig deeper in the tank without waiting for the advice of specialists.

Quite another thing is the filling fittings of modern toilet bowls - compact with a membrane float valve. Water is drawn in quickly, although not always quietly, everything depends on the quality of the fittings, it is blocked immediately. But filling fittings with a membrane valve also have disadvantages. These shortcomings are connected with the fact that for the normal functioning of the fittings it is necessary that in the water supply network there is a more or less constant pressure of at least 0.05-0.1 MPa (0.5-1 atmosphere) and not more than 1-2 MPa, and in addition to pressure, membrane valves need pure water. It is clear that it is not always realistic to fulfill both of these conditions in private houses, villages, and summer cottages. In addition, the reliability of the functioning of membrane fittings is also affected by the quality of workmanship and the quality of materials used for the manufacture of fittings. Therefore, fittings with a membrane valve have to be repaired every few years, but more often just change, like a used razor, you cannot cut a new membrane from an old tire for such fittings. We'll have to figure out what kind of fittings this is and how it works.

For owners of Jika toilet bowls, as well as toilet bowls equipped with Slovenian inlet fittings, I can offer the following schemes for inlet fittings with a membrane valve:

Well, for everyone else, I present the following, in my opinion, more illustrative model of the operation of the inlet fittings with a membrane valve. But first, it is better to look at the membrane, what it is. After watching the video, it will be a little easier to understand what is at stake:

Phase 1. The valve is in the open position, water is drawn into the tank.

The membrane moves away under the pressure of water and does not interfere with water intake (it does not interfere so much that it is not even shown on the diagram, yet). Water enters the hole (1) and fills the pre-chamber. In order for water to enter the toilet bowl, there is a hole in the preliminary chamber (2), this is where the water passes. For this moment, everything is very similar to a conventional stem valve, but here the valve is diaphragm, which means that the valve has a diaphragm (3) put on the piston (4):

There is a hole in the membrane, through which a rod with a hole (5) with a diameter of about 1 mm is passed, the exact diameter of the hole is the result of rigorous calculations, which is why a plastic rod is used. Through this hole, part of the water passes into the filling chamber formed by the piston (4) and the membrane (3). When the float is lowered, the hole (6) with a diameter of about 0.5 mm in the piston (4) is open, through which part of the water flows into the tank. Thus, the water pressure in the preliminary chamber, in the filling chamber and behind the filling chamber is approximately the same, and this is the main difference between the principle of operation of a membrane valve and the principle of operation of a simple stem valve.

Phase 2. Water, gathering in the tank, raises the float.

When filling the toilet bowl with water, the float rises and pushes the rod with a rubber seal to the hole (6), the hole closes. The rod, moving further, presses the piston (4) with the membrane (3) to the large seat, while the filling chamber becomes sealed, and to the small seat, for clarity, marked in orange in the figure. The pressure of the water in the filling chamber plus the pressure from the rising float firmly presses the membrane against the seats, and water intake stops. I didn’t draw how the rising float pushes the stem, I hope it’s clear, and you can always see it, just remove the tank lid.

Repair of built-in toilets or installations is more difficult, due to incomplete access to the installation mechanisms.

We repair Swedish toilets Gustasvberg, IFO. Spare parts from the manufacturer and high reliability will please you for a long time. According to many, the Gustavberg toilet is the most suitable for our operating conditions. Spare parts are not difficult to find, so it is popular and loved by the people.

We carry out maintenance and installation of all types, from simple to built-in, suspended and floor, licensed, branded, German, Italian, French, Spanish, American, Czech, Romanian, Bulgarian manufacturers. All plumbing and other works and services are guaranteed! Learn about us

How to change the diaphragm valve.

Description:

Details at http://doctorlom.com/item99

Not that there is a great need for this, in 90% of cases it is much faster and more efficient to completely change the float membrane fittings like a cartridge in a printer, especially if the water supply is on the side. But I can’t refuse those who want to dig deeper into the fittings.

The toilet flush system is a mechanism that is mounted inside the tank. To use the toilet was convenient, the drain mechanism must be properly selected, installed and configured. It is these questions that the article will be devoted to.

System description

Principle of operation

The device of the drain tank is not difficult. The tank is a container inside which there is a mechanical locking system.

This system performs the following functions:

- controlled draining of water from the tank;

- filling the tank with water after draining;

- stopping the flow of water into the tank after it is filled at a certain level.

The mechanism of the toilet cistern functions as follows:

- Through the filling valve in the bottom or wall of the tank, water enters the tank.

- As the tank fills, control devices (floats, valves, etc.) are activated. As soon as the water level in the tank reaches the set value, the flow stops. To do this, the filling valve is blocked.

- When we need to drain, we press the button on the tank or pull the lever. As a result, the drain valve in the bottom opens, and water flows into the toilet bowl.

- Tanks with two buttons work similarly. By clicking on the smaller one, we release only part of the water from the tank, and by clicking on the larger one, we ensure a complete drain. This helps to save fluid, because most modern models are equipped with just such two-button mechanisms.

- After draining, the water level drops, the control devices are activated and the inlet valve opens again.

By and large, this is how all drain / water intake systems work, regardless of their design. Of course, there are nuances, but if you understand the general principle, you will most likely be able to deal with unfamiliar fittings quite quickly.

Essential elements

In order for the entire water supply system to function as I described above, several parts must interact. They may look different for different mechanisms, but in general the set is quite typical.

It includes:

- Filling (inlet) valve. It is a threaded pipe that is inserted into the hole in the bottom or side wall of the tank. The presence of a thread allows you to press the pipe against the wall of the container with nuts, providing. For opening / closing the gap through which water enters, the locking mechanism associated with the rocker is responsible.

- A rocker arm is a lever that drives the intake valve mechanism. The free end of the rocker is attached either to the float (plastic sealed container) or to the control valve. When this valve is activated or the float floats up, the rocker rises and closes the gap in the filling valve, and vice versa.

- The drain hole is normally blocked by a drain valve. It is a flat or hemispherical elastic gasket, hinged to the bearing part.

- On top is a push-button or lever mechanism that controls the operation of the drain valve. When used, its bearing part rises (either a chain, or a lever, or a plastic frame is used as a thrust), opening a hole. Water enters the bowl at a sufficiently high speed, and all the contents are washed down the drain.

These elements can be arranged in different ways. In older models, water collection systems with overflow control and flush systems with control levers / buttons were mounted separately. Modern fittings are usually produced in a single complex. On the one hand, it is easier to install and configure it, but on the other hand, repairs are seriously complicated.

Varieties and their choice

A convenient toilet drain is very important for the comfortable use of the device, so it is advisable to choose a model quite meticulously. There are several factors worth paying attention to.

The first factor is the placement of the filling valve:

- bottom - the pipe is located in the bottom of the drain tank. A pair of gaskets is responsible for sealing;

- lateral - a branch pipe with a valve is inserted into the tank through a hole in the side wall, located almost under the lid. At the same time, the entry point is made conditionally airtight, because water usually does not reach it.

In terms of efficiency and comfort, I would recommend models with a bottom connection. They do not make as much noise when filling, in addition, shut-off valves of this configuration are more reliable. The weak point is the gasket, so tightness must be monitored very carefully.

- older models are equipped with a lever, to which a chain or cord with a handle is usually attached. Among modern products, such an arrangement is found only in antique-styled toilet bowls;

- button - a universal solution for all mass-produced tanks. The advantage is a relatively small stroke, which at the same time allows you to control the volume of drained water;

- the dual-mode tank is completed with a two-button system. In it, one button is responsible for emptying part of the tank, the second for a hollow drain. The system is more economical, but also more capricious - and it is more difficult to set up and repair it.

Here the choice is quite obvious - push-button or two-button option.

Finally, we pay attention to the overflow control mechanism.

Here the choice is much more extensive, but from the point of view of a simple “user”, two options can be distinguished:

- float system - a shut-off valve is controlled by a rocker or lever connected to the float.

- membrane system - when filling the tank, water acts on the membrane assembly, which activates the locking mechanism.

Despite the fact that many plumbing manufacturers have recently installed a membrane system, I would recommend abandoning it.

Yes, it works well, but there are two nuances:

- The membrane fails unpredictably, therefore, at one “perfect” moment, the overflow blocking can simply turn off. If you have good sound insulation and you don’t hear the murmur, then the consequences will be serious.

- If the mechanism fails, it is quite difficult to repair it even with a new membrane. After replacing a worn element, the adjustment takes a very long time, but this does not guarantee that the diaphragm valve will work in 100% of cases.

It is not news to anyone that the water loss device is capable of breaking. For such a situation, there is an overflow in the design of the toilet cistern flush mechanism. As soon as the water exceeds the indicated level, it will begin to flow into the appropriate tube and go directly through the bowl into the sewer. The device is thought out so that the liquid cannot flow out of the tank. If this transfusion works, it will lead to an increase in the data of the cold water counter, but most importantly, it will prevent the flood. Descent of water of a toilet bowl according to the design is subdivided into horizontal and circular.

Horizontal implies the supply of water in a single stream along one side of the bowl and is a classic version.

Round descent involves the formation of a jet in a circle, starting from the bypass of the bowl and is considered the best in all user characteristics.

The best way out in such a situation is to change not the membrane, but the entire armature, albeit to a cheaper float one.

Tank maintenance

Installing the mechanism

If necessary, the drain mechanism can be installed in the tank with your own hands. This is done either when replacing a failed system, or when buying a separate tank and separately fittings.

Work in this case is performed according to the following algorithm:

- For replacement, we purchase fittings suitable for our tank model. The most important parameters are the location of the inlets (top or side), their dimensions, the size of the drain hole and the overall dimensions. Ideally, it is desirable to take a mechanism for the same model - it will definitely work.

- Now turn off the water and press the drain button to remove everything that remains in the tank.

- The flush button for the toilet is gently unscrewed, after which we get the opportunity to remove the lid.

- Disconnect the water supply hose.

- Unscrew the nuts securing the filler pipe. We take out the part itself from the hole.

For structures with a lower water supply, it is advisable to substitute a small container under the hole. Liquid will drain into it, which collects at the bottom of the tank and does not go into the drain.

- We dismantle the inner part of the armature, removing it from the tank.

- We unscrew the bolts with which the tank is attached to the toilet bowl and remove it. We dismantle the lower part of the drain system and sealing gaskets.

This completes the disassembly. Now you can wipe the inside of the tank and the holes in the bowl to remove plaque. At the same time, it is worth cleaning the channels in the sides of the bowl, which ensure the distribution of the drained water - they can become clogged with debris and lime deposits. Usually you can’t get to these places, but here is such an opportunity!

The installation instructions for the drain mechanism require the work to be performed in the reverse order:

- In the hole we install the lower part of the drain system with sealing gaskets.

- We put the tank in place, align it and fix it with fixing bolts.

Poor-quality bolts can rust during long-term operation. Parts with signs of corrosion should be replaced with new ones.

- We install the inner part of the drain mechanism, fixing it on the drain hole.

- We insert the filling valve into the hole in the side wall or the bottom of the tank and fix it with a nut with sealing gaskets.

- We connect the water supply hose to the outlet pipe of the inlet valve. We turn on the water and check how the system works.

- We adjust the operation of the mechanism, if necessary, adjusting the height of the overflow (about 20 mm below the top hole) and the length of the rod connecting the drain to the button.

- If the drain, set and overflow control function correctly, and there are no leaks at the attachment points, put the cover back in place. We fix the lid on the tank by screwing the button.

Of course, differences in models may cause deviations from this algorithm. But, at the same time, most cisterns are arranged exactly according to this scheme, therefore, in 95% of cases, this is how the toilet fittings are installed.

The exception is built-in models, in which the drain mechanism with a tank is located in the wall. If you have such a device, and it shows signs of a malfunction, the best solution would be to contact a specialist!

Trouble-shooting

Despite the fact that the price of fittings for a drain tank is relatively low, in some cases it is possible to do without replacing it. To do this, it is enough to perform relatively simple repair measures or get by with the purchase of one or two parts.

When identifying a malfunction, the easiest way is to open the tank lid, gaining access to its insides, and see what, in fact, does not work as it should. If the system is at least approximately familiar to you, then to understand the reasons, it is enough to drain and fill water a couple of times.

In addition, for quick diagnosis and troubleshooting, you can use the table:

| Malfunction | What to do |

| Overflow control not working |

|

| Fill valve leaks |

|

| Drain button doesn't work |

|

| Weak water pressure when filling |

|

Conclusion

The mechanism for draining water in the toilet is not the most complicated design. The tips and illustrations in this article will help you figure out how it works, how to install it and, if necessary, repair it. The video in this article contains more visual information, and you can ask questions in the comments.

For various models of toilet bowls, the cistern device is almost the same and consists of a body with a lid, a button for draining water, an inlet (filler) valve, a plug and a drain valve.

One of the most important components of this design is the intake valve, which regulates the amount of water in the tank.

Purpose

This mechanism:

- regulates the flow of water into the tank to a certain level,

- releases water into the toilet when the trigger is pressed,

- ensures the presence of a constant amount of liquid during pressure drops in the water supply.

The operation of the valve begins due to a decrease in the pressure of the water that flows into the tank with the simultaneous ascent of the float. When a critical level is reached, the lever closes the valve, and the liquid stops flowing into the tank.

Classification

Inlet mechanisms can be divided into groups according to three criteria:

- material composition,

- location,

- construction type.

By material

- brass or bronze. Products made from these alloys are practical, durable, reliable and completely resistant to corrosion. But such metal valves have a rather high cost.

- Plastic. Plastic products are very popular, because, along with a long service life, they are quite inexpensive.

By location

It is necessary to choose inlet units depending on the design of the toilet bowl. Also, when choosing, you must adhere to the following rules:

- The complete set of goods should include the valve itself, the float, o-rings and the fixing nut.

- O-rings must be elastic, of correct shape and without defects.

- The plastic element should not have visible scratches and notches.

- The movement of the float should be smooth, without sudden jumps.

By type of construction

Once the valves were ball valves, the device had the form of a ball, which was used in all tanks. The modern device is called an inlet, as it has no resemblance to the design of ball mechanisms, but is used together with a float. There are several types of float devices for the toilet cistern:

- Croydon valves consist of a shell, a float with a lever and a piston with a seat. In this mechanism, the movement of the lever is perpendicular to the operation of the piston. Such a system is used in old tanks and has a fairly low price.

- Piston equipped with a bifurcated hairpin with a lever axle. Here, the water is adjusted by horizontally raising the lever that drives the piston, at the end of which there is a special seal that comes into contact with the seat and blocks the flow of fluid. This is a fairly common model and is included in the middle price category.

- Membrane instead of a gasket, the valves have a rubber or silicone membrane that moves when the piston moves. This is the latest device that is used only in the latest models of toilet bowls. The advantages of this valve include a quick intake of water, instant shutoff of the liquid intake and, depending on the quality of the fittings, silent filling of the tank. Among the shortcomings, one should take into account the presence of a constant pressure of water in the system (0.05-0.1 MPa) and the purity of the liquid, since if the membrane is damaged, it is impossible to replace it on its own. In this case, you will have to purchase the entire intake mechanism.

Possible malfunctions and their elimination

Before you figure out the possible reasons for the breakdown of the inlet valve, you need to turn off the tap of the water supply system, open the tank lid and drain the remaining water from the tank. If necessary, pull out the device itself.

No water in the tank

- Reason #1: clogged holes. In this case, you should disassemble the device, clean and rinse its elements.

- Reason number 2: low water pressure or its jumps. In this problem, it must be taken into account that with a weak flow of water and a high location of the tank, the liquid will not approach the filling chamber, the float will pop up, but the water will not shut off. You can try to increase the inlets by 3 mm, and in the case of constant surge pressure, it is better to purchase a stem valve.

Constant flow of water into the toilet

- Reason #1: skewed float. Repair consists only in fixing the intake valve in place.

- Reason number 2: violation of the tightness of the gasket (damage to the membrane or stem). In this case, a complete replacement of the mechanism is necessary.

Noisy filling of water in the tank

- Reason #1: Disconnecting the water silencer. To correct the situation, the muffler should be adjusted to a special fitting.

Conclusion

For urban environments, a low outlet float inlet valve with a silicone membrane and a full and small drain button is well suited. For country houses with untreated water, it is better to purchase a piston version.

It is necessary to buy a filling mechanism according to the parameters of the tank. If there are none, then you can take universal ones with a side supply, suitable for any type of toilet tank. And it is better to entrust the repair and installation of the device to specialists.

One of the most unpleasant situations that happen at home, in the office, at an enterprise, etc., is the failure of the toilet fittings for a reason. Agree, neither a torn tap nor a burnt out lamp will create so many tangible inconveniences.

This problem can be immediately eliminated if you know how to choose and correctly install a toilet valve. We will tell you in great detail which device is needed to close the flow of water into the tank, and which one to drain it from there.

Here you will find complete information about the types of plumbing valves, the rules for their selection, depending on the design of the tanks and installation methods. The article we have proposed contains reliable information, supplemented by useful diagrams, photos and videos.

The most common type is separate. It is used on all the most popular models of toilet bowls and includes mechanisms for draining and collecting water, which are installed and work autonomously.

Exhaust valves can be divided into types according to the method of actuation:

- pressure. They work by pressing a button.

- exhaust. The drain mechanism is activated by lifting up the rod, which locks the drain hole.

- Lever. The lever itself can be placed on the tank or at the bottom, near the toilet. The device is activated by pressing the lever.

The lever system is used mainly in public restrooms due to the budget price, simple design and maintainability.

Inlet and outlet valves for toilets are elements of the same system, but they perform completely different functions.

Push-type devices, in turn, can also be divided into types:

- outlet valve single level(with single-mode drain) - equipped with one button, when pressed, all contents are drained from the tank;

- single level stop valve- in such a device, the first press leads to the flow of water into the toilet, the second stops the drain;

- exhaust valve two-level (two-mode)- the drain button consists of two keys, one of which drains part of the water, the second completely empties the tank.

Shut-off valve models can be divided according to the method of water supply: for side connection and for bottom water inlet.

As well as structural features:

- piston device. The intake mechanism has a piston, which is driven by a lever. A gasket installed at the end of the piston blocks the flow of water into the tank.

- Diaphragm valve. This is the most modern device. Instead of a piston gasket, a silicone or rubber membrane is installed in it. It allows you to draw water silently and quickly, but is very sensitive to its purity - this is the main drawback, which often leads to malfunctions.

In addition to separate valves, there are also fittings of a combined design, in which two valves - inlet and shutoff - are combined into one system. The performance of one depends on the performance of the other.

Even if the toilet model is outdated, the manufacturer releases a new, but suitable device. It is better, of course, that the tank and valves belong to the same brand.

The valve is installed in the opening of the tank and the nut 15 is tightened from the outside, on which the gasket 16 is then put on. It will ensure the tightness of the connection.

Bolts 13 are installed in the mounting holes in a certain sequence.

Install the cable mechanism. Its end is fixed in the rocker 8 so that the plastic casing is wound up to the stop.

Then the drain valve body 9 is lowered into the base 12 and fixed by turning it to the right. Check if the device does not touch the walls of the tank and the intake valve mechanism.

Before installing the cable mechanism, check the reliability of the cable in the holder. If it is released during transportation or installation, then it must be fixed.

Next, adjust the height of the overflow tube 7. To do this, first turn it clockwise to unlock it. After setting the required height, it is again blocked by turning it counterclockwise.

With a correctly adjusted tube height, the water level must not rise closer than 20 mm to the edge of the overflow tube.

The edge of the overflow tube, in turn, in the presence of a side opening of the tank (for connection to the water supply), must be 10 or more millimeters below it.

Next, fix the push button on the tank lid. There is a special holder for this. Connect the button to the cable so that it does not twist and does not cling to the filling valve. In tanks with a non-standard opening, an adapter ring is used.

If necessary, you can adjust the filling level of water in the toilet flush tank using the inlet valve settings.

In a properly installed device, the valve ring, when the button is pressed and released, should fall freely and tightly close the water drain hole. If this does not happen, then you need to adjust the length of the cable by turning the knob

Water drain adjustment

You can change the amount of water remaining after a complete drain using the regulator 10 on the valve body for the toilet.

To increase the balance, it is raised; to decrease, it is lowered. You can adjust the valve so that the water is completely drained from the tank by lowering the regulator all the way down.

To adjust the full or partial drain, manufacturers provide for an adjustment mechanism that allows you to set the required amount of flushed water.