This is for those who have trouble sharpening knives for wood planers.

The quality of wood processing (and not only wood) depends on the "sharpness" of the knives and not only the quality of processing, but also the safety of work on such machines. In my "arsenal" there are seven such machines. Every time "search" where to sharpen tired. And you won't find much. The sharpening process itself does not tolerate "speed", the knife can simply be "burned". It takes a lot of time to do this and it is advisable to do it at home. The machine must be automatic or at least semi-automatic. In order to remove the maximum tedious work from the machine operator.

As always in my practice, I apply, first of all, to make from "what is." To minimize costs, while the quality of work, the future manufactured product, should not suffer.

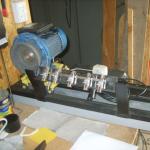

As a result, we got such a "unit". I am satisfied with the work of the machine, the problem of sharpening knives has been removed.

The power engine borrowed from an unnecessary pumping station, about this modification.

Its parameters are quite acceptable for this machine.

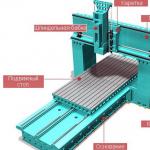

The frame of the machine was welded from a profile pipe (20x40) and screwed with screws to a wooden base, thereby increasing the rigidity of the structure. Which is very important. I welded a guide profile of the same size in the center. It serves to guide the movement of the carriage of the grinding unit.

The basis of the sharpening unit is made of powerful metal from railway linings for rails. Found on the farm.

To him, after appropriate processing, he installed a guide plate, on which he fixed the electric motor at three points. One of them is adjustable. The guide plate, relative to the base plate, is movably fixed on two piston pins from the Muscovite, the rollers (guide shafts) exactly fit from the UAZ gearbox. To feed the grinding stone to the part (knife), there is a screw with a fine thread.

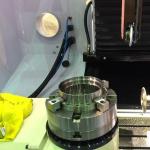

The whole unit moves along the guides on closed ball bearings, 4 support and 4 guides. This must be done very accurately, since backlash is not acceptable here.

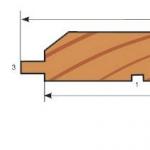

The emery (stone) itself is plate-shaped, which allows sharpening according to the rules for sharpening such knives.

The knife is fixed in a special device that can change the angle of sharpening. For a planer sheath, it should be 45-60 degrees. To attach the knife to the device, I used canopies from a furniture set.

Below are two adjusting screws for adjusting the knife, when sharpening, along the gap between the knife plate and the grinding stone.

Fasteners turned out reliable and not expensive.

After the adjustments, turn on the emery and begin to move the unit along the guides, from one end to the other bed. At the same time, gradually tighten the feed screw. But do not overdo it, otherwise you can burn the knife.

Naturally, this process takes a lot of time and this part of the manual work had to be automated. Found in stocks (already three) electric motor with the desired number of revolutions. He came up with a "power supply" from the 220th century. (there he has 127 v.) and most importantly, reverse switching of the engine. Installed limit switches and relay,

Shaft, to move the carriage, I had to write out a set from the Chinese, which suited me perfectly. The set consists of a shaft (60 cm), bearings, a self-centering coupling, a guide sleeve.

Owners of planers and electric planers periodically face the problem of sharpening cutting edges. A well-sharpened tool will ensure clean woodworking even at non-ideal angles and speeds. The easiest way to sharpen knives and knife heads with your own hands using specialized equipment.

Sharpening of knives is necessary

planer knife sharpeningPlaner knives require timely maintenance because:

- dull surfaces do not process wood well;

- when processing soft rocks with blunt knives, the surface is covered with pile and irregularities;

- worn edges crumble;

- during planing with blunt edges, the engine and power units are overloaded.

Attempts to sharpen blades with your own hands using diamond stones, as a rule, give a short-term result. Due to poor-quality editing, the blades have to be sharpened soon. Therefore, professional carpenters use only mechanical sharpening.

Types and designs of machines

The machines on the market are distinguished by the knife feed mechanism:

The machine for sharpening planer knives with manual feed consists of:

- grounds;

- abrasive stone;

- carriages for fixing the knife.

During processing, the cutter moves progressively with the help of a handle. The lateral movement of the cutter is provided by a flywheel.

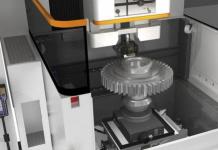

Automatic machines differ in size and set of options. Mechanisms for industrial use are installed on a powerful cast-iron bed. The carriage is equipped with a support. You can set the speed of movement of the blade and the thickness of the removed metal layer. Industrial machines allow you to sharpen several planer blades at the same time without changing the settings.

| Corvette K-470 | WTG-163 | GA-630 | GA-850 | ZX-1000 | |

| Maximum length of knives, mm | 630 | 630 | 640 | 850 | 1000 |

| Abrasive disc diameter, mm | 100 | 150 | 125 | 125 | |

| Sharpening angle, hail | 35…55 | up to 30 | 35…45 | 35…45 | up to 30 |

| Engine power, W | 550 | 550 | 850 | 850 | 1500 |

| Dimensions, cm | 90 x 48 x 42 | 100 x 60 x 65 | 100 x 54 x 120 | 120 x 54 x 120 | 190 x 56 x 150 |

| Weight, kg | 75 | 60 | 112 | 125 | 250 |

| Add. intelligence | Equipped with asynchronous motor wet sharpening possible | Processes milling cutters, circular saws | Wet sharpening possible | Can sharpen up to 4 blades, wet | Wet method available, cup type sanding disc, controlled via remote control |

Table 1. Characteristics of some models of machines for sharpening planer knives

Compact automatic machines for home and small workshops are designed to process one torch at a time. They also provide speed control and automatic tool feed.

Before starting work on any sharpening equipment, you should make sure that the bed is firmly attached. The vibration of the machine worsens the quality of sharpening and can lead to injury to the master.

Basic rules for using manual feed equipment

machine for sharpening planer knives Corvette-470

machine for sharpening planer knives Corvette-470 Such machines are used for one-time work and do-it-yourself sharpening of small batches of blades, since the processing process is quite long.

- Before starting work, make sure that the grinding surface is clean, free of stains and streaks.

- The movement of the carriage should be smooth, without jerks and jerks. It is forbidden to stop it at the moment the cutter approaches the grindstone.

- The faster the carriage moves, the lower the quality of sharpening. The optimal speed of movement is 5 - 6 m / minute.

- For proper sharpening, the amplitude of the movement of the carriage is important. For the passage in each direction, it should move 10 - 13 cm beyond the end of the knife. This ensures optimum contact between cutter and sharpener, which must be interrupted before moving in the opposite direction.

Basic rules for working on automatic machines

- Planer knives can be sharpened dry or wet. In the second case, the blade is constantly washed by a jet of water. The wet method is more gentle on the blade and more efficient;

- Before starting processing, it is necessary to set the parameters: sharpening angle, carriage movement amplitude. The amplitude should be 15 cm more than the length of the knife;

- Do-it-yourself blades are carefully fixed in a mobile carriage.

Homemade machine for sharpening planer knives

machine for sharpening planer knives Kraton-630The design, made at home with your own hands, allows you to quickly and accurately sharpen knives at one set angle. The factory angle will change, so all blades will need to be resharpened. The quality of planing will not deteriorate, but may improve.

To make a device for sharpening straight blades of planers, planers and thicknessers with your own hands, you need:

- metal corner No. 50;

- round pipe with a diameter of not more than 50 mm;

- an electric motor from a washing machine;

- powerful spring;

- bolt with nut;

- plastic handle (knob);

- Bulgarian;

- welding machine.

Making a machine with your own hands.

- Cut off a corner about 50 cm long.

- We bend two pieces of the pipe in such a way that we get a stable stand for the corner, weld the legs. The corner should be located vertically to the master.

- At the left end, around the corner, we attach the electric motor. It is placed on two points: a rigid axis and a powerful spring; The spring is tightened and released with the adjusting screw, moving the motor closer or further away from the guide-corner.

- We put an abrasive wheel on the motor shaft.

- The engine is started by a switch placed on the frame in a convenient place.

- We feed the tool with the help of home-made vices from a piece of pipe 25 cm long, a pressure plate, a bolt with a nut and a knob. We clamp the knife in a vice and move it along the guide, holding the knob.

Video review of this machine model:

stanokgid.ru

Articles

Dedicated to the owners of planers, jointers and electric planers.....

Each owner of planers, planers and electric planers faced the need to sharpen knives for their equipment. Having a specialized small machine for sharpening planer knives will not be difficult for you to do this. It will also be true to turn to a sharpening workshop where your planer knives will be sharpened quickly and inexpensively.

Is it possible to sharpen planer and planer knives at home?

Maybe. And you can sharpen planer knives on a sharpener. Yes, on the grinder. But only for this you need a modern low-speed grinder (or rather, even a grinding machine) with water cooling. The best option is to use Tormek T7. Naturally, such knives are not sharpened by hand. For their sharpening, we use a special tool Tormek SVH 320.

Maybe. And you can sharpen planer knives on a sharpener. Yes, on the grinder. But only for this you need a modern low-speed grinder (or rather, even a grinding machine) with water cooling. The best option is to use Tormek T7. Naturally, such knives are not sharpened by hand. For their sharpening, we use a special tool Tormek SVH 320.  For high-quality sharpening of planer knives, a smooth and not greasy grinding stone is required. Align the Tormek SG 250 grinding stone with the Tormek TT-50 grinding stone alignment and straightening tool that comes with the Tormek T7.

For high-quality sharpening of planer knives, a smooth and not greasy grinding stone is required. Align the Tormek SG 250 grinding stone with the Tormek TT-50 grinding stone alignment and straightening tool that comes with the Tormek T7.  After dressing, we smooth the grinding stone with a Tormek SP-650 sharpening stone cleaning and leveling bar. Having prepared the grinding stone, let's start sharpening the planer knives. We remove the universal stop and install the special stop that comes with Tormek SVH 320.

After dressing, we smooth the grinding stone with a Tormek SP-650 sharpening stone cleaning and leveling bar. Having prepared the grinding stone, let's start sharpening the planer knives. We remove the universal stop and install the special stop that comes with Tormek SVH 320.

We screw into it a screw that regulates the angle of inclination of the knife to be sharpened relative to the grinding stone. With this screw, we will be able to set the required sharpening angle in the future.

We take the blade holder supplied with the SVH 320 and install our planer knife into it.

Tormek recommends sharpening blades and knives with a width of at least 13 mm. The length of the knife is not so important, because. it is possible to rearrange the long knife in the holder. However, this can be argued, because. I have doubts about the convenience and quality of sharpening long knives with rearrangement. It is very important to correctly install the knife in the holder, because. otherwise it will be sharpened with a warp. When installing the knife in the holder, we rest the back of the knife against the stop and clamp it with the screws of the holder. For precise setting and control of the set sharpening angle with a marker, paint over the sharpened chamfer of the knife.

Now, by the nature of the sharpening stone marks on the painted blade, we can estimate the angle of inclination and correct it in the required proportions. We install the holder with a knife on the stop fixed on Tormek. Lower the holder with the knife with the adjusting screws of the stop until it touches the grinding stone.

With the adjusting screw for setting the angle, we set the angle of the knife relative to the stone. Manually rotating the sharpening stone, by the nature of the marks on the painted blade, we determine whether it is necessary to adjust the angle of inclination of the holder with the knife. We make adjustments if necessary.

So, having set the required angle, we proceed directly to sharpening. For a fixed removal of metal from a knife being sharpened, there are two sliders on the stop with a scale division of 0.1 mm. It is assumed that the sharpener can adjust the amount of removal in exact proportions. Be sure to securely fix the fence after each feed with two clamping screws so that there is no oscillation of the fence during sharpening. Sharpening of the knife is carried out by moving the holder with the knife to the right to the left relative to the grinding stone.

It is not permissible for the knife to be sharpened to go beyond the edge of the grinding stone. It is recommended to stop the holder 12 mm before the edge of the circle. To eliminate errors, stops are provided that can be moved and set the required holder stroke. We did not use these stops, relying on our experience. It should be noted that during the sharpening of a planer knife, water accumulates and distributes on the knife blade from the grinding stone, which leads to water runoff onto the body of the sharpening machine and onto the floor. And there is a lot of this water. Therefore, it is necessary to regularly add water to the Tormek water tank. To reduce water spillage on the body, it is recommended to place a 6 mm high pad under the right leg of the machine (under the honing leather wheel).

However, this measure does not completely eliminate the ingress of water on the body of the Tormek T7. However, the Tormek T7 has good protection and is not afraid of such water baths.

Another annoyance when sharpening a planer knife was that the SG 250 stone was constantly clogged, which reduced sharpening efficiency and increased sharpening time. I had to clean it regularly with an SP-650 sharpening stone cleaning and leveling stone. Of course, what material the knife is made of is of great importance. In our case, a knife made of HSS steel was sharpened and this stone had to be edited constantly. When sharpening knives made of tool (softer steel), there is a more intensive removal of chalk and sharpening is faster. To sharpen HSS knives, it is recommended to use another Tormek SB 250 stone.

So, after 20 minutes of sharpening, we have an even, smooth, beautiful bevel of the knife with a stable, even burr on the cutting edge.

The knife needs finishing. We finish the planer knife on a Tormek T7 leather wheel using Tormek PA-70 finishing and polishing paste.

First, we bring the working plane of the knife, then its chamfer. We make sure that there is no burr on the cutting edge of the knife. Once the burr is removed, the knife is sharpened and ready to go. After sharpening, we checked the geometry of the knife. The knife had a strict parallelism of the cutting edge and back. Even despite the rather large sharpening angle, the knife sharpened by us perfectly cut a sheet of paper.

First, we bring the working plane of the knife, then its chamfer. We make sure that there is no burr on the cutting edge of the knife. Once the burr is removed, the knife is sharpened and ready to go. After sharpening, we checked the geometry of the knife. The knife had a strict parallelism of the cutting edge and back. Even despite the rather large sharpening angle, the knife sharpened by us perfectly cut a sheet of paper.

Let's summarize:

1. To sharpen planer knives, you do not need to have complex and expensive machines. It is enough to have a Tormek T7 and a special attachment Tormek SVH 320 2. After sharpening on the Tormek T7, you get a well-sharpened planer knife with an unchanged geometry.

Identified shortcomings:

1. At the entrance of sharpening from the knife being sharpened, water pours abundantly on the desktop and machine body, which causes some discomfort. Even resorting to certain tricks, it is not possible to completely get rid of this inconvenience.

2. The Tormek SG 250 sharpening stone is regularly oiled and needs to be cleaned and leveled with a Tormek SP-650 whetstone. There is an assumption that if you use a Tormek SB 250 stone, this trouble will be eliminated.

www.grinding.ru

Description of sharpening knives for woodworking machines

Sharpening knives for woodworking machines is a mandatory process that you can do yourself with the help of special tools. Sharpening is the restoration of the previous cutting capabilities of hacksaws, scissor shafts, planers, planers and other devices for woodworking.

- 1 General information

- 2 Preparations

Photo of sharpened knives

- To sharpen the knife shaft of a planer, jointer, you will need the appropriate tool;

- Sharpening work is done by hand;

- Craftsmen learned how to assemble grinding devices;

- When restoring hacksaws, planers, sharpening knife shafts, be sure to follow a few recommendations, strictly follow the technology;

- If the teeth of the hacksaws, the knife shafts are not sharpened correctly, the quality of wood processing with tools will deteriorate significantly;

- Grindstones are a good alternative to a grinder. But if it is possible to assemble with your own hands or purchase a grinding machine, be sure to use it.

Scheme of the device of the machine for sharpening knives of woodworking machines

If you need to sharpen knives for a woodworking machine, you should start with the mandatory preparation steps. It is not so important what parameters the knife shaft or cutting sheets of hacksaws have 13 mm, 20 mm or all 200 mm, they will definitely need sharpening.

Some prefer to give blunted shafts to special workshops, where they can easily restore the former sharpness of a 200 mm knife or a small cutter of a lathe. But both ordering sharpening and buying new knife shafts is a financially costly business.

Preparation for sharpening begins with an acquaintance with the available means of restoring the surfaces of cutting tools and some recommendations.

- To keep jointers, planers, and hacksaws in working order, assemble or purchase an appropriate sharpening tool.

- The simplest, budget option is a grindstone. But the quality of processing directly depends on your ability to work with a stone. If there are none, it is extremely difficult to achieve the desired level of sharpening. Plus, stones are not able to cope with all types of cutting tools that modern woodworking machines are equipped with.

- Choose a machine that can sharpen at low speeds, as this has a positive effect on the quality of processing.

- The recommended element of equipment of the grinding machine is a water cooling system.

- Carefully study the complete set of household woodworking machines. Often there is already a whetstone, which is optimally suited in terms of parameters for processing the knives used.

- If the stone is not provided in the package, it will have to be purchased separately, aligned with a special tool, and smoothed. Only in this way can you sharpen the knife shafts of planers with high quality.

- On machines there is a function of setting the angle of inclination, adjustable with a special screw. By turning the screw and changing the position of the sharpener, you will be able to correctly fix the tool relative to the stone.

- The next preparatory stage is the holder in which the knife shaft is installed.

- If you are a beginner, it is not recommended to start the first job with 200 mm knives. Start literally with 13-15 mm, and gradually you will learn how to process 200 mm and even 2 mm. To do this, you need to accumulate some experience.

- The length of the knife is not a fundamental parameter, since the knife in the holder can move to the distance you need.

- Make sure to keep firmly fixed the shaft. Otherwise, you will get a significant distortion, due to which the quality of woodworking will suffer.

- Read the instruction manual of the purchased grinder in detail. If this is a do-it-yourself tool, you will have to rely on the drawings and available information on the network about a specific sharpening project.

sharpening

In order for the sharpening of knives for a woodworking machine to give a positive result, you can resume working with equipment at the same quality level, you need to follow a few fairly simple rules.

- The sharpener holder can move left and right relative to the knife sharpening stone.

- Don't let the blade go over the edge.

- Immediately fix the holder at a distance of 12 mm from the edge of the grinding wheel.

- When sharpening knives of 200 mm or smaller, make sure that the water cooling function is activated on the machine.

- The cooling system requires constant monitoring. The tank usually has a small volume, so water needs to be topped up periodically. If it ends, and the sharpening process continues without cooling, you risk ruining a rather expensive knife.

- As the knives are processed, water from the cooling system may accumulate on the floor. Since grinders are electrical appliances, be sure to keep water away from your feet by wearing rubber boots. In any case, standing in a puddle of water while working with an electric machine is always dangerous. Adhere to safety regulations.

- Keep the grindstone clean. It gets dirty quite quickly with active use.

- The grinding wheels of machine tools are cleaned using a special tool. Machines should be equipped with this cleaning bar, but if it is not in the set, then you will have to purchase it separately.

- Each subsequent sharpening, according to the rules of operation, is carried out only on condition that the stone is cleaned. Therefore, after each sharpening, arm yourself with a cleaning bar, processing the machine with it.

- On average, sharpening with a special machine takes about 10-20 minutes. It all depends on the type and size of the tool that has become dull as a result of woodworking operations.

- After sharpening the tools of woodworking machines, do not rush to return them to their place and continue working. After processing on the machine, the tool needs to be fine-tuned.

- Finishing consists in applying a special paste to the surface of the cutting element. Proceed according to the instructions provided by the manufacturer of finishing paste on the package. Different pastes may differ slightly in application methods.

If you did everything right, then the knife should turn out to be perfectly even, sharply sharpened, devoid of any irregularities, burrs. Do not worry when the first time the result does not live up to expectations. This takes some time and some experience. That's why it's worth starting with simple and inexpensive knives that you don't mind ruining.

tvoistanok.ru

What you need to know about sharpening jointer knives

Jointer and jointer have long been one of the most popular carpentry tools, they have not lost their relevance today. The question of how to sharpen jointer knives is of interest to many specialized specialists, since a fully prepared tool for work allows you to achieve the best quality of work. The first thing to do is to remove the knife and chipbreaker, which must be unscrewed before work. A used tool must be cleaned of contaminants, such as resin, it is best removed with gasoline.

To sharpen a knife of a planing and jointing type, it is better to use specialized devices. The procedure is also carried out manually, in addition, the device for sharpening jointer knives can be assembled independently. When working, you need to follow a number of rules, you can use several technologies. Regardless of which sharpening option you use, you need to follow the instructions as accurately as possible. Otherwise, you can achieve poor-quality work of the tool, the functions of which the carpenter will not be able to use 100%. If you're wondering how to sharpen planer knives at home, then use regular whetstones, although choosing a professional grinder with a cooling function would be ideal.

Preparation for sharpening knives

Sharpening of jointer knives can be done better if you choose a fixture with low speed and high quality. If you want to use a grindstone, then it must be leveled initially. After editing the device, the stone must be smoothed with a bar.

Now set the appropriate angle of inclination, this is done by rotating the screw that secures the canvas. Next, you need to use the holder, which is included in the standard equipment of the machine, where the planer knife is fixed. Work should begin with knives no wider than 13 mm. The length is not important, since the tool is fixed in a convenient position in the holder.

In order to fix the knife well, hold it in the selected position and tighten the screws tightly.

To control the angle of sharpening the jointer knives, a marker is used to mark the chamfer of the knife. You can understand the accuracy of adjustment by turning the stone manually.

Tool sharpening

Sharpening jointer knives is a simple process, you only need to move the holder from side to side relative to the whetstone. Try not to let the blade go over the edges of the stone. Fix the holder 12 mm from the end of the circle. When carrying out work, it is necessary to establish the supply of water cooling. Be prepared for the fact that you will need to regularly replenish the supply of fluid in the reservoir and prevent the reservoir from draining. To secure the work, you need to ensure that moisture does not flow onto the floor under your feet.

Sharpening planer knives is a rather lengthy procedure. Periodically check the cleanliness of the grindstone, as it can quickly become clogged. To clean it, you need to use a special bar as soon as contamination is detected. By the way, the choice of stone largely depends on the type of instrument. A planer can include blades in a variety of hardnesses, so choose your whetstone carefully.

Usually knives for a planer are sharpened within 20 minutes, after which it is necessary to perform finishing. This procedure is carried out using a special paste. Polishing is carried out so that the blade does not have the slightest roughness, burrs, otherwise work with such a knife will not be complete. Check the effectiveness of sharpening by cutting a piece of paper with it. If the cut is made neatly, then the knife is completely ready for work.

Other materials for sharpening tools: * Sharpening a hacksaw for wood. * Sharpening a chisel with your own hands.

Almost every person in life is faced with the question of sharpening knives. After all, any knife, regardless of its quality, sooner or later becomes dull. Therefore, the blade must be carefully looked after.

In stores today you can choose any sharpener among a huge variety.

What are sharpening stones?

In general, there are several main types of such devices. Namely:

Oil, on the surface of which there is oil, especially to save material.

Water, similar to the previous one, but water is used here.

Natural, industrially processed.

Artificial, made from non-natural materials.

Rubber, extremely rare. Completely inconvenient to use.

Nuances in the issue of sharpening

There are moments in sharpening every knife.

For example, a Japanese self-sharpening type requires special attention from a rather experienced specialist, since the Japanese type of steel is quite fragile. To sharpen them, manufacturers give a recommendation to use different water stones, endowed with a variety of grain sizes.

Mistresses use sharpeners bought in the store for sharpening. When using several knives, their sharpness lasts longer.

But this is very important, even though it takes a lot of time and effort.

How to sharpen knives properly?

For this, special conditions must be created. Thanks to them, the knife will remain sharp for a very long time.

Therefore, it is important to choose the right angle at which you will sharpen your knives. According to the basic rule in this matter, the smaller the angle at which the knife is sharpened, the stronger the cutting edge will be.

It is important not to forget that the next sharpening depends on the maximum sharpness. The sharper the knife, the faster it will need to be sharpened. At the same time, it will be much more difficult to make it “workable” again.

Why sharpen knives?

The purpose of sharpening is to restore the sharpness of the blade. To do this, take care of the correct sharpening angle. That is, it is necessary to restore the previously set angle that meets the standards from a technological point of view.

To check how well the sharpening is done, cut the material that is cut with the blade of this particular knife. If the material is cut elementarily, you will do everything absolutely right.

Possible problems during the sharpening process

In order to choose the right angle correctly, it is important to have some experience, without which it is quite difficult to cope with this issue. And even more so if there is no special equipment for this.

After all, if you hold the knife with your hands during the sharpening process, it is quite difficult to achieve its ideal “sharpness” as a result.

How do you sharpen knives at home?

Sometimes it happens that the knife needs to be sharpened quickly. A block of wood, a hacksaw, sandpaper, a ceramic plate, a chisel, etc. can come in handy here.

And there are even those who can sharpen on the foundation of cement with sand. But, this method is not recommended at all. After all, there are many other and more proven ones!

The best of all is to make a homemade device. It is not only convenient, but also indistinguishable from the factory.

How to sharpen a planer knife

An experienced professional master who has not only knowledge, but also skills in this matter can handle knives of such a plan. The process is quite complicated actually.

At the same time, in a simple store, equipment for sharpening such a knife is quite difficult to find. You should know that a modern tool will help here, in which you can set low speeds with water cooling.

It is necessary to apply a new stone on which a flat surface. The best will be exactly the water type of stone.

In addition, without having certain experience and skills in sharpening planing knives, you can also contact the service station, where you probably have equipment such as a sharpener.

Owners of planers and electric planers periodically face the problem of sharpening cutting edges. A well-sharpened tool will ensure clean woodworking even at non-ideal angles and speeds. The easiest way to sharpen knives and knife heads with your own hands using specialized equipment.

Sharpening of knives is necessary

Planer knives require timely maintenance because:

- dull surfaces do not process wood well;

- when processing soft rocks with blunt knives, the surface is covered with pile and irregularities;

- worn edges crumble;

- during planing with blunt edges, the engine and power units are overloaded.

Attempts to sharpen blades with your own hands using diamond stones, as a rule, give a short-term result. Due to poor-quality editing, the blades have to be sharpened soon. Therefore, professional carpenters use only mechanical sharpening.

Types and designs of machines

The machines on the market are distinguished by the knife feed mechanism:

- manually;

- automatically.

The machine for sharpening planer knives with manual feed consists of:

- grounds;

- abrasive stone;

- carriages for fixing the knife.

During processing, the cutter moves progressively with the help of a handle. The lateral movement of the cutter is provided by a flywheel.

Automatic machines differ in size and set of options. Mechanisms for industrial use are installed on a powerful cast-iron bed. The carriage is equipped with a support. You can set the speed of movement of the blade and the thickness of the removed metal layer. Industrial machines allow you to sharpen several planer blades at the same time without changing the settings.

| Corvette K-470 | WTG-163 | GA-630 | GA-850 | ZX-1000 | |

| Maximum length of knives, mm | 630 | 630 | 640 | 850 | 1000 |

| Abrasive disc diameter, mm | 100 | 150 | 125 | 125 | |

| Sharpening angle, hail | 35…55 | up to 30 | 35…45 | 35…45 | up to 30 |

| Engine power, W | 550 | 550 | 850 | 850 | 1500 |

| Dimensions, cm | 90 x 48 x 42 | 100 x 60 x 65 | 100 x 54 x 120 | 120 x 54 x 120 | 190 x 56 x 150 |

| Weight, kg | 75 | 60 | 112 | 125 | 250 |

| Add. intelligence | Equipped with asynchronous motor wet sharpening possible | Processes cutters, circular saws |

Wet sharpening possible | Can sharpen up to 4 blades, wet | Wet method available, cup type sanding disc, controlled via remote control |

Table 1. Characteristics of some models of machines for sharpening planer knives

Compact automatic machines for home and small workshops are designed to process one torch at a time. They also provide speed control and automatic tool feed.

Before starting work on any sharpening equipment, you should make sure that the bed is firmly attached. The vibration of the machine worsens the quality of sharpening and can lead to injury to the master.

Basic rules for using manual feed equipment

Such machines are used for one-time work and do-it-yourself sharpening of small batches of blades, since the processing process is quite long.

- Before starting work, make sure that the grinding surface is clean, free of stains and streaks.

- The movement of the carriage should be smooth, without jerks and jerks. It is forbidden to stop it at the moment the cutter approaches the grindstone.

- The faster the carriage moves, the lower the quality of sharpening. The optimal speed of movement is 5 - 6 m / minute.

- For proper sharpening, the amplitude of the movement of the carriage is important. For the passage in each direction, it should move 10 - 13 cm beyond the end of the knife. This ensures optimum contact between cutter and sharpener, which must be interrupted before moving in the opposite direction.

Basic rules for working on automatic machines

- Planer knives can be sharpened dry or wet. In the second case, the blade is constantly washed by a jet of water. The wet method is more gentle on the blade and more efficient;

- Before starting processing, it is necessary to set the parameters: sharpening angle, carriage movement amplitude. The amplitude should be 15 cm more than the length of the knife;

- Do-it-yourself blades are carefully fixed in a mobile carriage.

Homemade machine for sharpening planer knives

The design, made at home with your own hands, allows you to quickly and accurately sharpen knives at one set angle. The factory angle will change, so all blades will need to be resharpened. The quality of planing will not deteriorate, but may improve.

To make a device for sharpening straight blades of planers, planers and thicknessers with your own hands, you need:

- metal corner No. 50;

- round pipe with a diameter of not more than 50 mm;

- an electric motor from a washing machine;

- powerful spring;

- bolt with nut;

- plastic handle (knob);

- Bulgarian;

- welding machine.

Making a machine with your own hands.

- Cut off a corner about 50 cm long.

- We bend two pieces of the pipe in such a way that we get a stable stand for the corner, weld the legs. The corner should be located vertically to the master.

- At the left end, around the corner, we attach the electric motor. It is placed on two points: a rigid axis and a powerful spring; The spring is tightened and released with the adjusting screw, moving the motor closer or further away from the guide-corner.

- We put an abrasive wheel on the motor shaft.

- The engine is started by a switch placed on the frame in a convenient place.

- We feed the tool with the help of home-made vices from a piece of pipe 25 cm long, a pressure plate, a bolt with a nut and a knob. We clamp the knife in a vice and move it along the guide, holding the knob.

The sharpness of a knife is one of the main parameters affecting the quality of wood processing. In addition, this characteristic also affects the degree of security.

Often a person does not want to run over and over again in search of a place where he could bring his cutting tools into proper condition. In this case, it is time for him to think about making a home-made grinding machine that would solve the issue of the sharpness of planer knives once and for all.

The development of industrial equipment does not stand still. There is a constant rapid growth in the requirements for speed and, most importantly, for the quality of material processing. In this regard, there is a need to create a cutting tool with high parameters.

One of the main problems that appear in the process of work is the sharpening of knives. This is what determines the main capabilities of the machines and their suitability for operation.

Homemade grinder.

Depending on the tasks to be solved, such devices are divided into two types: universal and special. The first are sharpening devices for the surfaces of most cutting elements. They are equipped with a variety of devices that allow you to fix, install and sharpen knives.

All units are equipped with various equipment, which determines the degree of automation and control of the accuracy of the work performed. are also different. These can be stationary devices or temporary ones that can be placed on any horizontal surfaces.

Despite the wide range of types of equipment offered, in order to save money, a knife sharpening machine can be made by hand.

Homemade units can in some cases even be more convenient than purchased options. This is due to the fact that the master independently decides what characteristics this device should have.

Although, of course, many models of universal devices allow you to choose the most suitable type of equipment that can solve the tasks.

Homemade knife sharpening machine

Most often due to two reasons. The first is the desire to save money. The second is to show your skills and do everything with your own hands exactly as your soul desires.

Drawing of the device of the machine.

For example, very often you may be faced with the need to put in order only certain tools. These can be drills, milling cutters, saws or planer knives.

In each case, a separate approach is required. Self-assembly of the machine will allow you to make a convenient unit for working with certain elements.

Among other things, the presence of sharpening units will significantly save costs for the purchase of new knives or for their restoration in third-party workshops.

If you need to professionally sharpen the tools listed above, then you should still give preference to purchased devices. They are more thoughtful and elaborate.

In addition, buying in a store guarantees that the device will solve the tasks for a long time. You should also remember about the degree of automation. Of course, professional devices use electronics that are simply impossible to make at home without proper experience.

Option 1

For sharpening a planer, you will not only keep the tool in good condition, but also save time on trips to other workshops.

One of the options for creating such a device is to use an engine with an abrasive wheel, emery or a sharpening device with a knife fixed in it.

Homemade machine for sharpening planer knives.

This device can be made partly from aluminum, metal and wood. In this case, bearings and guides are used, made from improvised materials, for example, pipe corners, etc.

If the knives are level, they can be sharpened on a large abrasive block. If this is not available, sandpaper glued to a flat surface should be used.

Depending on the requirements for the final result, you can vary the speed of this process. In the presence of chipping, it is necessary to first use a belt grinder, and at the final stage process the tool with an abrasive bar or homemade sandpaper.

According to the design features, the machines can also differ from each other. The first option is a device with a fixed base. The angle of its inclination can be changed, but otherwise it is in a fixed position.

The bar is attached to a rod, which is inserted into the loop of a movable latch located on another rod. The disadvantage of this design is the "walking" angle due to the lack of rigid fixation.

The knife is installed by means of two steel plates fixed on a fixed platform. After loosening the fasteners, insert the blade and clamp it. Then adjust the height of the bar so that the required angle is set.

Option 2

The second type of design provides for a movable platform, as well as a magnetic holder. This option is devoid of the shortcomings of the previous unit. Fixed in this device is a frame with a bar that determines the angle.

The knife, in turn, is mounted on a movable table. The choice of holder is up to the master. You can use the magnetic type or the usual one, made of metal platinum and "lambs".

An important requirement for such equipment is the movement of the table with the cutting tool on a strictly horizontal surface. As it is best to use a polymer or marble countertop.

The principle of sharpening knives on the machine.

As you can see, sharpening knives is not so difficult. If you have any problems, you can always use the help of training videos from the Internet. With proper observance of all instructions, anyone can make such equipment.

Outcome

A knife sharpener is an essential piece of equipment in the workshop of every woodworker. A timely solution to the problem of sharpening knives will not only speed up the processing of the material, but also save time and money.

Why go to other workshops if you can make the necessary equipment with your own hands?