The EDM wire-cutting machine is used for the accurate execution of holes in metals of various densities. The movement of the tool occurs with high precision and smoothness. Engines for it are produced at the enterprise - the manufacturer of machine tools - using a unique technology.

Design

The EDM wire-cutting machine is equipped with plane-parallel motors. To do this, manufacturers create their own neodymium magnets (NdFeB - neodymium-iron-boron). In addition to them, a unique K-SMS control system was also required.

The classic EDM wire cutter is capable of processing only electrically conductive workpieces. Metals are burned by an arc to a considerable depth. A smooth surface remains at the cut site, often not requiring additional processing.

EDM wire-cutting machine helps to obtain complex products: molds, strains, conical and cylindrical surfaces, ledges and bevels. On sale you can find two-coordinate assemblies used for simple operations. More complex products are obtained using five-axis machines.

Principle of operation

In the process of using a wire-cutting machine, brass wire is most often used as a cutting tool. It is performed using a unique technology, and the speed and accuracy of processing depend on its quality.

If high-power pulses are used, which are built into the described machine, the brass wire is equipped with a special coating. Its structure has several layers:

- Base - CuZn40 or brass. Molybdenum, copper can also be used.

- Thermal diffusion layer - zinc concentration over 50%.

- The top layer is pure zinc.

Due to this structure, the wire has a number of advantages:

- Withstands high temperatures.

- The arc during processing is stable, the formation of sagging at the cut site is excluded.

- Reduced wire consumption per cut length.

CNC wire EDM machines are mainly used in serial production. Single products do not justify the purchase of expensive equipment, but some parts can only be obtained with this type of cut. Zinc coating ensures the continuity of the automatic process due to the elimination of shedding of brass from high-frequency currents.

processing process

Electroerosive machining of materials is based on the formation of a spark by passing a high-frequency current through a minimum air or water gap. This process is most active with the participation of brass.

There are several types of metal processing on the above equipment:

- Copying and stitching technologies.

- Profile-cut.

- Firmware.

More often, wire for EDM machines is attached to a movable assembly. The workpiece is placed on a fixed table. The cutting process is controlled by the CNC system controller, which simultaneously controls several axes.

The essence of technology

An electrical discharge between the wire and the workpiece results in the removal of some of the metal. The separated particles are discharged into the volume of the working fluid. The sludge (crystallizing particles) is filtered out and removed at the end of the cut. The processing speed is regulated by the current strength. But the optimal modes must be selected in which no sagging is formed during the cutting process.

Electroerosion helps to produce products with very thin walls, process soft metals without mechanical damage. This cutting method is used for piercing to a greater depth. The thickness of the wire is minimal, only this parameter limits the diameter of the resulting holes.

Additional processing is not required, since after cutting with current pulses, no burrs remain. It also does not require expensive tools used in classical milling methods. This becomes relevant for workpieces made of viscous materials.

Equipment parameters

CNC process control expands the possibilities of electroerosion metal processing. Deviations of perpendicularity and straightness of movement of the axes are not more than 0.01 microns.

The mechanical accuracy is declared by the manufacturers and no further adjustments are required. The machine is completely ready to start the automatic cycle, you just need to load the model of the part in the standard code.

Modern electronics provide movement accuracy due to angular and linear sensors, the resolution of which is 1.5 microns. The accuracy of the resulting contours varies from ± 1.5 to ± 5 µm over a length of 300 mm.

Characteristics are selected individually according to the needs of production. Based on this, the cost of equipment is formed, focused on a suitable model.

Additional options

The buyer of the machine with electroerosion can retrofit the equipment with the presented options:

- Controlled position of the C axis. More often required for milling cylindrical workpieces.

- Turret with additional degrees of freedom of the tool. With the help of such a model, geometrically complex parts are obtained.

- The table may have additional axes. This option is used when processing case products or several workpieces in one cycle.

The standard package includes systems for cleaning the working fluid, allowing filtration with a quality of up to 3 microns. Dirty cartridges have standard sizes and change fairly quickly.

EDM conductive materials ranging from aluminum and copper to graphite and PCD. EDM technology achieves extreme precision in the production of extremely critical parts at relatively high cutting speeds. At the same time, the capabilities of the machine are not limited to the manufacture of dies and molds. With only one tool required to get the job done, this machine is your affordable alternative to milling, turning, grinding or broaching equipment. What’s more, a whole range of other processes can be carried out with the EDM – even in automatic mode.Contact us right now.

DISCOVER FANUC ROBOCUT OPTIONS

Advantages of EDM cutting machines

![]()

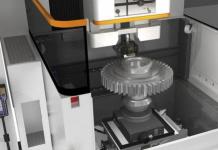

EDM cutting machine: eight steps in one

EDM technology eliminates up to eight production steps, including pre-machining, hardening, finishing and texturing, required in traditional machining processes such as milling, drilling and turning. The impeller (left) was made using this technology. This is a highly economical cutting method.

Your possibilities with a wire-cutting machine:

AgieCharmilles CUT P EDM was announced in April 2017. This flagship series has no equal on the market in terms of its capabilities and the number of unique technical solutions.

The combination of the IPG-DPS digital generator with Quadrax mechanical design, together with additional automation modules, has once again raised the bar for EDM wire cutting machines to new heights.

This series includes four models with X-axis travels from 350 mm to 1250 mm, while the mass of the workpiece is practically unlimited.

Quadrax designs are capable of cornering up to 45˚ over the entire height of the workpiece. No line of wire-cutting machines in the world has such capabilities.

The use of a new version of the IPG-DPS generator made it possible to increase the processing speed by 15-20%, while the accuracy of manufacturing small contour elements increased significantly. The surface roughness has also improved.

The thermal stabilization system, which maintains the temperature of the dielectric, the machine bed and all axes within the specified range, guarantees high accuracy characteristics even when working in non-thermostated rooms.

The OMS optical measuring system makes it easy to tie the workpiece, find the center of starting holes and control the dimensions of finished parts - this facilitates the operator's work and saves working time.

A similar function is performed by the Renishaw stylus, which is integrated into the design of the wire cutter. Its use is especially important in combination with a pallet changer - in automatic mode, it will control the position of the workpiece, including the slope of the upper surface and make the necessary corrections to the program.

Also, the AWS and AMS modules are aimed at increasing the efficiency of the EDM wire-cutting machine in autonomous mode. Which fix and automatically remove the falling parts of the workpiece.

When you look at the Progress VP EDM wire cutter, the words about the “imperishable classic” come to mind - outwardly these wire cutters have remained unchanged for 20 years. This impression is deceptive - the element base of the generator has repeatedly changed, new modules have appeared, the control system has been completely rewritten.

The level of technical solutions used in the design of machines is respected. A comparable level of thermal stability, which demonstrates Progress VP during operation, modern EDM machines achieve through additional heat sinks, cooling circuits and tracking sensors. Here everything is decided due to the cabinet-type design and carefully thought-out placement of heat-generating elements.

A whole bunch of unique possibilities are provided by the use of patented prismatic wire guides:

- service life - 100 thousand hours

- ability to work with wire diameters ranging from 0.05 mm to 0.33 mm

- using wires of different diameters and/or types in one program.

| Features and Specifications | Travel dimensions X, Y, Z | Price in rubles: on request | Availability of equipment | |

| AC Progress VP2 | 750 x 550 x 250 mm | 350 x 250 x 256 mm | On order | |

| AC Progress VP3 | 1050 x 650 x 420 mm | 500 x 350 x 426 mm | On order | |

| AC Progress VP4 | 1300 x 1000 x 510 mm | 800 x 550 x 525 mm | On order | |

| CUT P 350 | 1000 x 550 x 220 mm | 350 x 220 x 220 mm | On order | |

| CUT P 550 | 1200 x 700 x 400 mm | 550 x 350 x 400 mm | On order | |

| CUT P 800 | 1300 x 1000 x 510 mm | 800 x 550 x 510 mm | On order | |

| CUT 200 Dedicated | Ø150…Ø500 mm | 350 x 220 x 220 mm | On order |

Ultra Precision Wire Cutting Machines

CNC EDM machines from the Swiss company AgieCharmilles are designed for the automatic production of precision parts in the instrument-making, watch, and medical industries. This involves the operation of a wire-cutting machine as part of robotic lines 24/7, and everything necessary for this is provided for in the design of the machines.

The design of these wire-cut EDM machines, in addition to the technical solutions implemented in Progress VP, is based on a number of unique features:

The IWC module adds a second wire path and an automatic changer. You can choose to use different types of wire in one processing program, or two coils of 25 kg each will allow the machine to work autonomously for more than 170 hours.

The scope imposes additional requirements on the accuracy of machined parts. The integrated optical measurement system IVU is responsible for the 1 µm result. In addition to controlling dimensions and binding cycles, she has the right to make changes to the control program so that the profile of the resulting parts is as close as possible to the specified one.

The AgieCharmilles OilTEch series EDM wire-cutting machines do not use traditional water as a working medium, but a hydrocarbon dielectric, as in piercing machines. This decision is dictated by the scope for which they are designed. The use of hydrocarbons provides both undeniable advantages and imposes certain restrictions on wire-cut technologies.

Three main groups of tasks in which machines of this type are unrivaled:

- processing of materials with high corrosive activity;

- surface roughness requirement is higher than Ra 0.05um;

- production of carbide tools;

Manufacturers of EDM wire-cutting machines are silent about the fact that during the processing of a hard alloy in an aqueous dielectric, the cobalt bond is washed out. Progress in this area is significant, but the tool life of a carbide tool machined on a traditional wire cut machine is lower than the tool life of the same tool machined, for example, by grinding.

The use of a hydrocarbon (oily) dielectric solves this problem, and the durability of a tool processed on a wire-cutting machine is not inferior to a tool obtained using other technologies. In this case, the surface roughness reaches Ra 0.3 µm.

| Features and Specifications | Workpiece dimensions (L x D x H) | Travel dimensions X, Y, Z | Price in rubles: on request | Availability of equipment |

| CUT 1000 | 300 x 200 x 80 mm | 220 x 160 x 100 mm | On order | |

| CUT 1000 | 300 x 200 x 80mm | 220 x 160 x 100 mm | On order | |

| CUT 2000 | 750 x 550 x 250 mm | 350 x 250 x 256 mm | On order | |

| CUT 2000 | 750 x 550 x 250 mm | 350 x 250 x 256 mm | On order | |

| CUT 3000 | 1050 x 650 x 250 mm | 500 x 350 x 256 mm | On order |

| On video: AgieCharmilles CUT 2000 X, CUT 3000 X |

Universal CNC wire cutters

Introduced in 2016, CNC EDM CUT E is the first family of AgieCharmilles wire cutters based on a new innovative platform. Main innovations:

- digital generator IPG-DPS;

- motor controllers and industrial computer from BECKHOFF;

- AC HMI 2 control system.

Electroerosion is the destruction of metal surfaces under the influence of electric charges on them. This technology is based on the work of Soviet scientists N. I. Lazarenko and B. R. Lazarenko. Using this method, you can easily change the dimensions of metal products, get holes in them of various shapes and depths. Excellent results are obtained by electroerosive machining of profile grooves and grooves, shaped cavities in machine parts and mechanisms. Such equipment is especially in demand for the manufacture of hard alloy parts, where conventional machining is difficult.

Machine tools of the electroerosion type have universal capabilities in the processing of materials with a dense surface structure. This type of material processing compares favorably with other methods of changing the shape and size of parts, since the labor intensity of operations is sharply reduced due to electroerosive technology.

The principle of operation of the EDM machine is shown in the diagram below. Under the action of a pulsed electrical generator, sparks or other electrical interactions are formed in the gap between the electrode and the surface of the part. The space of the spark gap is continuously washed by the coolant flow, due to which the destroyed metal is removed from the treated surface. Under the control of the CNC unit, the process proceeds in a given direction and in the required quantity. Brass wire is most often used as an electrode, which, as it is consumed, is fed into the EDM zone. A more modern consumable for electroerosion is molybdenum wire, the consumption of which for processing one part is negligible. However, these machines also have significant limitations compared to machines for machining parts. After all, they are suitable for processing only conductive metals and their alloys.

It is possible to influence the metal in an electroerosive way in various ways: by applying both electric discharges and parametric pulses to the spark gap. Depending on the desired processing result, a more suitable way of its implementation is selected. A very important element of this effect on metal surfaces is that with it it is possible to process the workpiece in different directions at the same time.

Among the methods of electroerosive processing of products, there are:

- electropulse;

- electrospark;

- electrocontact;

- anodomechanical.

Technological operations that are performed by electroerosion include:

- structural strengthening;

- grinding;

- marking;

- cutting;

- fine-tuning;

- bulk copying;

- fine-tuning.

With the help of electrical erosion on these machines, it is possible to make various blind openings, recesses and holes of non-geometric configuration. It is also possible to make threads of any profile on the surface of holes. Machine tools are able to sample metal from the inner surface of products to a given depth, thereby performing operations that replace milling and turning. The technology of electrical erosion is used in the processing of metals that are difficult to classical mechanical machine action. These include, in particular, titanium and its alloys.

To choose which EDM machine to buy, you need to accurately determine the tasks that will be set for this equipment at the enterprise and what operating parameters of the machine will be required to solve these problems. It is quite acceptable to buy a used machine to perform certain technological operations in the workshop, having previously checked its performance. Practice shows that even with a large number of operating hours, EDM equipment is almost not subject to wear.

EDM machines

The methods of electrical discharge machining implemented in production can vary greatly depending on the design of the machines, but the principle of operation of the equipment remains the same. Consider the main types of EDM machines used for processing metal blanks.

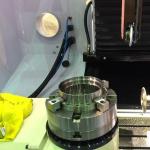

Wire cutting machine

This machine tool is used for contouring products with high precision and low surface roughness. The workpiece is exposed to an electrode in the form of a molybdenum wire with a diameter of 0.18 mm. The operating costs of this equipment are quite low, since the wire itself is used many times. The traditional EDM wire-cutting machine, which cannot reuse the wire, significantly loses in the cost of similar work operations.

The role of the electrolyte in the working area of the machine is played by the coolant, the flow of which flushes out the erosive products and protects the machined surface of the part from air oxidation. A water-soluble concentrate of a special composition is used as a coolant.

The price of an EDM copier is not very high compared to similar traditional type machines, but its maintenance is very convenient due to the use of a CNC unit. It will take no more than two days to train the operator in the basic methods of working on it.

With this machine you can make:

- various molds;

- stamps;

- gear wheels;

- slotted holes;

- keyways;

- recesses of a complex profile with a depth of up to 20 cm.

The figure above shows a high-speed CNC EDM cutter, which is a jet type and is used for contouring parts. Machines of this type can be used both in the workshops of a small enterprise with piece production of products, and in large enterprises in mass production. The DK 7720 wire EDM machine can currently be purchased for 850 thousand rubles.

piercing machine

The electroerosive copy-piercing machine in a modern version is equipped with a CNC unit, in which the functions of automatic positioning, the orbitality of the movement of parts and the possibility of burning side surfaces are built-in. Also, the machine is equipped with the functions of automatic edge search and search for the center point of the processing zone. Along with this, the programs of the CNC block include the determination of the depth of the cavity and the automatic exit of the tool head to the zero point.

The EDM piercing machine is designed to process both internal and external spherical elements, working along a 3-dimensional linear path. Along with the possible surface treatment along a 2-dimensional arc, it can perform electro-erosion piercing, using the original matrix of the product as an original for copying.

At present, the price of an electroerosive machine of this type fluctuates around 1 million 800 thousand rubles.

Electroerosive machine for cutting metals

EDM wire cutting is used when it is impossible to perform the required cut of a metal part or workpiece using classical traditional processing, when both the cutter and the cutter of the lathe are powerless before the strength of the workpiece. Mechanical cutting is not beneficial or even impossible when it is required to obtain sharp corners with ultra-small radii of curvature inside or outside the part. This situation occurs when machining parts that have undergone hardening or carbide metal joints. Sometimes they also resort to electroerosive cutting of metal if, due to the depth or complex structure of the cavity, it is impossible to perform a simple mechanical operation on a milling machine. Wire-cutting machines complement the set of operations in the manufacture of complex parts of modern engineering.

Electric discharge cutting is an intensive electroerosion of metal in the desired section of the part. The high-frequency pulses generated by the generator are fed to the electrode, which is a molybdenum wire. When the generator is running, the part itself moves in the right direction with the help of an electric drive of the guides of the machine plate. The metal is burned out by electric sparks, and then the destroyed layer is washed off with a coolant of a special composition, which is continuously supplied to the cutting zone. The movement of wire for EDM machines always occurs in the direction perpendicular to the axis of the winding drum.

It is possible to distinguish those technological operations where the operation of electroerosive cutting machines compares favorably with the mechanical processing of metals:

- processing of superhard metals and alloys;

- making cuts in workpieces with angular sharp edges having ultra-small rounding radii;

- processing of cylindrical and shaped surfaces of great depth;

- surface treatment with very high precision.

To program the processing of a part with an EDM machine, you need to have a technical task and a layout of the product itself. The format of the presented data can be any, its translation into commands of the CNC block is carried out by the machine operator or programmer.

In EDM cutting, there is no need to use tools that are harder than the material of the workpiece. For cutting carbide joints, non-ferrous alloy wire is used, which is obtained in the usual way. Equipment for cutting is also not very complex, as well as the technological methods of working with it. The speed of the working process does not depend on the hardness and strength of the material being processed. When cutting, no mechanical effort is required, so the processing quality is very high. The number of various operations and transitions to one processing is reduced to a minimum even with a very complex shape of the part. Cutting machines of different technical characteristics have different workflow performance, but they can all perform similar operations, only in different times.

Models of modern machines

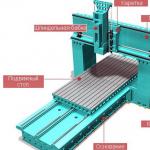

A modern machine for electrical discharge machining of metals consists of the following units:

- electric motors operating independently of each other;

- wire feeder to the erosion zone;

- working bath with coolant;

- desktop for the location of the workpiece in the process of processing;

- machine control unit.

Manufacturers of machines of this type are both Asian and European countries. Having the same purpose, machines from different manufacturers differ greatly in their functionality and price. If Chinese and South Korean equipment is much cheaper than European equipment, then the latter is performed by manufacturers at a higher level with a greater degree of automation of work processes.

ARTA

Russian manufacturers produce ARTA precision equipment for electroerosive machining of metals.

Scientific and industrial corporation "Delta-Test" today is the leader in Russia in the manufacture of equipment of this type. By manufacturing new machines, the company is also engaged in the modernization of equipment of earlier production periods.

Sodick

In the modern equipment market, Sodick is a well-known company that produces wire-cut EDM machines.

Possessing high technological parameters, the equipment of this company is used for processing refractory metals and single crystals. With the help of these machines, perforated plates and pipes, working elements of copying machines, stamps with three-dimensional measurement profiles, metal-ceramic stamps are produced. Specialists using such equipment can easily produce cams and their prototypes, electrodes-tools for machines of the copy-and-pierce group.

The Mitsubishi MV1200S wire-cutting machine at a cost of about 7 million rubles allows you to perform the most complex operations for electroerosive machining of parts of any shape made from a wide variety of conductive materials.

With intensive use of this machine tool in modern production, the cost of its purchase pays off in a short time.

Agie

Agie EDM equipment is made in Switzerland and competes with other models of this machine group.

With small overall dimensions, the Agie machine can automatically perform the most complex work on the processing of carbide products for a wide range of purposes.

As can be seen from the article, there are plenty of equipment for electrical discharge machining of parts on the modern market. It is produced by almost all the leading industrial countries of the world under various brands and at different prices. It is not easy to choose from this proposal exactly what our domestic manufacturer needs. However, having measured your financial capabilities and held substantive negotiations with the managers of the companies presented on the Internet sites of this subject, you can draw the right conclusions, and then make the purchase itself.

The process of electrical discharge machining (EDM) of conductive materials is based on the principle of directed destruction of the anode (workpiece), which is in a liquid dielectric medium, as a result of the passage of a high-power electric discharge between it and the cathode (working tool). Due to the significant technological capabilities of the method, it is implemented on EDM machines of various designs.

Structure and types of equipment for EEE

A typical EDM machine includes:

- several autonomously operating from each other electric motors;

- node for supplying the electrode-tool;

- a bath with a working environment;

- table for placing the workpiece;

- control scheme.

The classification of the equipment in question is carried out according to the following criteria:

- Technological purpose. It is possible to single out universal, specialized and special machines for EEE;

- According to the principle of layout of the main nodes. It can be made horizontal and inclined, but vertical layout is more commonly used;

- By type of table: fixed or coordinate;

- By type of bath - removable or rising;

- According to the degree of accuracy - equipment for work of ordinary accuracy and precision;

- According to the principle of excitation and subsequent regulation of the parameters of the electric discharge.

The size range of types of domestically produced EDM equipment is determined by the requirements of GOST 15954.

Methods for obtaining an electric discharge in the working circuits of machine tools

Dimensional processing can be performed by spark, pulse and arc discharges. In the first case, a spark discharge of low duty cycle is formed between the cathode and anode, but with precisely specified characteristics of the interelectrode gap. Such machines are compact, they are distinguished by high work accuracy and surface quality after electroerosion, ease of regulation of technological indicators, but at the same time they have low power and, consequently, productivity. The areas of expedient use of such machines are the precise cutting of hard-to-cut materials (in particular, hard alloys), the production of parts with complex contours. They can also be used to retrieve broken tools and the like.

An increase in the energy of an electric discharge is achieved by introducing a pulse generator into the circuit, which increases the interval between adjacent discharges and simultaneously increases the thermal power during a single electroerosive act. As a result, work productivity increases, but accuracy decreases, and the surface of the machined part can have a rather extended heat-affected zone, which is not always acceptable. Electropulse machines are used where more significant metal removal per unit time is required.

If it is necessary to provide an even higher metal removal (and not only to shape the original workpiece, but also to harden it), electric arc machines are used. The productivity of such equipment increases by several tens of times, since the arc, unlike other types of electric discharge, burns continuously. To control the technological parameters of the arc discharge, it is compressed by a transverse flow of the dielectric medium, which is constantly and under high pressure pumped through the arc burning zone by a pumping unit provided in the machine circuit. Electric arc machines can produce large blanks for rolls, hot stamping hammer dies, etc.

The use of electroerosive machines of various types

Of the equipment of the electric spark type, one of the most accurate is the MA4720 copy-stitching machine. It is designed to work with difficult-to-cut workpieces of complex configuration, for example, for hard-alloy die equipment, molds, molds. The productivity of the machine does not exceed 70 mm 3 /min, but it is possible to achieve an accuracy of 0.03 ... 0.04 mm, with a rather low roughness of the final surface (not higher than Rz 0.32 ... 0.4 μm in finishing processing modes). The movement of the desktop is made by the CNC system. The dimensions of the working table and the allowable range of values of the interelectrode gap between the anode and cathode do not allow to obtain products with overall dimensions of more than 120 × 180 × 75 mm on this machine.

An example of an electric pulse machine is the common model 4E723, also equipped with a CNC. Higher values of power density make it possible to achieve the efficiency of EEE up to 1200 m 3 /min, with processing errors in finishing modes within 0.25 ... 0.1 mm. Higher accuracy is achieved with EDM of shaped surfaces. The machine is also used mainly in tool making, however, the surface roughness increases markedly - up to Ra 2.5 µm, so grinding is required after processing in most cases. On the machine, it is possible to perform EDM of parts with overall dimensions of 620 × 380 × 380 mm, as well as cutting shaped grooves.

These types belong to universal electroerosive machines. An example of specialized equipment is the Model 4531 EDM, which profiles complex contours using a non-profiled electrode. The 4531 machine uses brass wire that is continuously rewound across the interelectrode gap, initiating a discharge between the cathode and anode. With a relatively low productivity (not more than 16 ... 18 mm 3 /min for steel; for hard alloy, the productivity is even lower), the 4531 machine, in principle, allows for an error of ± 0.01 mm, so the equipment in question is effective in the production of punching die matrices of a particularly complex configuration and templates. The maximum dimensions of the contour to be cut out are 100 × 60 mm.

Principles for the optimal choice of technology and machine size for EDM

The initial data are the accuracy of the contour, the dimensions (depth) of the thermally modified zone, as well as the desired value of removal per unit of time. For machine tools that work with non-profiled electrodes, it is important to have devices for automatic wire threading, and for pulse machines, generators that allow the use of bimetallic wire, which increases the performance of EDM.

To improve the quality of the process and reduce the erosive wear of the electrode-tool, it is better to use oil as working media (the most common mixture of industrial-20 oil with kerosene). In principle, for products with increased tolerances, it is also possible to use water.

The technological capabilities of electroerosive machines are significantly expanded by the presence of additional devices (for example, to obtain conical surfaces).

For metal removal from 20000 mm 3 /min and above, only electric arc machines should be used. The smallest error in the operation of such equipment is achieved at reverse polarity when graphite electrodes are used. At the same time, a relatively high surface roughness - not lower than Rz 0.8 ... 1.6 μm - makes it necessary to provide for fine grinding of the resulting contour after EEA with an arc discharge. The pumping pressure of the working medium must be at least 50 ... 60 kPa.