To begin with, we will take into account the fact that work on CNC machines is performed with general-purpose cutting tools (i.e., such a tool is used on machines that have manual control). But everything is not so simple, because if the tool is used on CNC machines, then it must meet the following requirements: it must have a high quality of sharpening, be interchangeable, and must meet increased requirements for rigidity and wear resistance.

One type of cutting tool is a cutter. So, with a turning tool, you can perform many operations, including on CNC machines. And, of course, turning tools differ in purpose.

Therefore, the following subsystems were identified:

Turning cutters performing such operations as turning, threading, boring, grooving, cutting on machines of medium and light series;

Turning cutters that perform special work (for example, a shaped cutter or a cutter for plasma machining);

Turning cutters that are installed on heavy, rotary and large machines;

Turning cutters mounted on TPM and multi-purpose machines.

Cutter subsystem for CNC machines.

Let's take a closer look at the cutter subsystem for CNC machines. So, for example, a cutter with a modernized SMP wedge fastening - a wedge-tack, serves to carry out preliminary and final operations on universal machines. The bottom line is to press the SMP wedge to the pin and to the base plate. Having such a fastening, we can observe an open auxiliary cutting edge.

And now, consider the cutter subsystems that make up the grooving cutters and turning cutoff cutters.

So, based on the structural features, the cutter can be:

1. Cutting-off holder, in which replaceable non-regrindable carbide cutting inserts are mechanically fastened.

This cutter has in its structure: a spring-loaded clamp, a non-regrinding single-edged cutting plate, a holder.

In order to install the cutting insert in the V - shaped groove of the socket of the holder, a V - shaped protrusion is needed directly on the supporting surface of this very insert.

I would also like to note that if the cutting inserts are made of hard alloys with a wear-resistant coating, then the durability increases by 2-3 times.

2. Cut-off, having soldered hard-alloy plates.

Here, new (including three-layer) brands of solders are already used for manufacturing. And the holder can be made of steel 35KhGSA or 30KhGSA, which significantly reduces, or rather, virtually eliminates cracking during soldering. thus, there is a reduction in the consumption of incisors by 3-4 times.

Very good quality and accuracy of sharpening leads to a reduction in the cost of primary sharpening (by about 0.3 - 0.4 rubles).

3. Groove holder, in which replaceable regrindable carbide cutting inserts are mechanically fastened.

By name it is clear that such a cutter must be used to cut a groove (with exact dimensions). The cutting element is nothing more than a carbide plate made in accordance with GOST 2209-83. The structure of this cutter includes: a holder, a cutting plate (which has a prismatic shape), a thrust element (looking like a cracker), an adjusting screw and a clamp.

To prevent transverse displacement of the supporting surface of the cutting plate, it (the plate) is made at an angle to the side, and fixation occurs with a clamp. The adjusting screw ensures that the cutting insert extends after regrinding, and subsequently fixes this very insert, thereby preventing longitudinal displacement.

The basis of this design was the production of grooving cutters, which allow the processing of internal threaded, angular, straight grooves and external angular and straight grooves.

Well, it is worth noting that rational operation involves at least 20 regrinding.

4. Cut-off lamellar having replaceable hard-alloy cutting plates.

(But, such a cutter is primarily applicable for universal machines with manual control)

Such a cutter has in its structure: a block (which is fixed in the tool holder), a non-regrinding two-edged cutting plate, which is fixed by an elastic blade of the holder, and a lamellar holder.

The cutter becomes more versatile because the plate holder allows you to adjust the indicators of its departure from the block to a given size.

5. Grooving, in which replaceable non-regrindable carbide cutting inserts are mechanically fastened.

This type of cutter has in its structure: a holder, a clamping screw with a washer, a two-edged cutting plate. The cutting plate is secured with a screw. With regards to the presence of two cutting edges, this allows you to save hard alloy.

Further, it is worth noting the subsystem of multi-purpose cutters, consisting of prefabricated cutters, which allow for rough, semi-finishing and finishing turning of workpieces made of cast iron and steel.

Thus, workpieces can be subjected to turning, trimming, processing, slotting, boring.

The subsystem includes a small number of groups:

TTO

The cutter of this group is installed on heavy lathes (blank diameter 1250 - 4000 millimeters) and on rotary machines (blank diameter 3200 - 12000 millimeters), which have conventional tool holders.

CCI

The cutter of this group is installed on heavy lathes with lamellar toolholders of CNC machines.

WHO

The cutter of this group is installed on large lathes (blank diameter 800 - 1000 mm) with standard tool holders, and rotary machines (blank diameter 1600 - 2800 mm).

It is necessary to improve the quality of the cutting tool in all possible ways, including, using the experience of inventors, to develop new methods of fastening and changing plates, to use advanced technologies to increase labor productivity.

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted on http://www.allbest.ru/

CNC cutters

Introduction

Turning cutters are designed to perform the whole variety of different operations on CNC machines, on GPM and GPS, as well as on manual turning machines.

Differences of turning tools according to their purpose.

By purpose, the system of turning cutters is divided into the following subsystems: cutter lathe sharpening

For external turning, boring, threading, grooving cutting off on machines of light and medium series;

For work on heavy, large lathes and rotary machines;

For work on GPM, multi-purpose machines with built-in robotic complexes for automatic tool change;

For special work (cutters for plasma-machining, shaped).

Each of the subsystems has its own specific features, due to many factors, primarily the design of the equipment, its technological purpose, etc. The incisor system is based on general methodological principles and provides for:

Development (selection) and unification of reliable methods for fixing replaceable inserts in the holder (including solid and compound cutters, with soldered inserts, prefabricated);

Ensuring satisfactory crushing and removal of chips from the cutting zone;

Sufficiently high positioning accuracy of the tops of the replaceable plates (due to the creation of accurate socket bases);

Quick-change and ease of removal and replacement of interchangeable plates, cutting element or cassette (block);

Unification and the maximum allowable reduction (reduction to the optimal value of technical and economic indicators of industrial production and use) of the number of methods for fixing inserts in a holder;

The possibility of using the whole range and sizes of replaceable plates of domestic and foreign production;

Compliance of precision parameters of cutters with international standards;

Compulsory use of special fasteners (screws, pins, etc.) of increased accuracy and reliability; development of new shapes and sizes of cutting inserts, shapes of their front surfaces, providing satisfactory crushing and chip removal;

Using the experience of innovators and inventors;

The use of progressive resource-saving technologies for the manufacture of fasteners, keys; manufacturability and cost-effectiveness of manufacturing (saving materials and labor resources);

The possibility of using composite (found, solid, glued and other similar connections) carbide inserts with tool blocks (holders) in cases of their undoubted technical and economic efficiency or the impossibility of designing a cutter in an assembled version (primarily for small sections of holders, some boring and cutting operations, etc.).

Subsystems of cutter designs are created on the basis of the generally accepted world practice of the system of forms of holders and angles in the plan to ensure all turning operations. For example, for the subsystem of external turning and boring of the shape of holders, which ensure the implementation of the whole variety of turning transitions, international (ISO 5910, 5909, etc.) and domestic standards are provided.

1. Basic schemes of incisors

At present, despite the huge variety of designs and schemes of attachment points for replaceable polyhedral inserts in holders, leading foreign manufacturers of cutters use a very limited number of clamping methods in mass production. Their number is also limited in domestic cutter subsystems. For example, in subsystems for external turning and boring on machine tools of light and medium series, four basic schemes for the design of SMP fastening units are adopted (fastening designation according to GOST 26476-85):

Without hole - by clamping (type C);

With a cylindrical hole - a lever mechanism (type P);

Pin and clamp (type M);

With toroidal hole - screw mechanism (type S).

Plates without a hole are fixed according to method C. The design widely used in automobile plants is taken as the basis. With this method of fastening, the cutting inserts are based in a closed seat of the holder along two base surfaces and are pressed from above to the supporting surface with a clamp. Fast plate removal is provided by a differential screw. The base carbide plate is fixed with a screw on the cutter holder or a split spring sleeve.

Cutters with SMP fastening according to the C method have various designs: for cutting inserts with and without a positive angle; with base plates; without base plates.

It should be noted that positive angle SMPs have 2 times more cutting edges than positive angle SMPs. Chip-breaking grooves are made on the front surface of the SMP with a rear angle for crushing and removing drain chips. When using SMP without a clearance angle, overhead chipbreakers are used.

Cutters with a base plate are widely used in turning and boring; cutters without a base plate - when boring small holes and turning on machines of light series (section h [ b of the cutter holder 12 x 12 ... 16 x 16 mm). The operation of the cutters has shown that when working on universal and special machines in large-scale and mass production, cutters with carbide chipbreakers have proven themselves well.

In such cutters, it is possible to use SMP made of hard alloy, ceramics, etc.

Positive SMP cutters provide a reduction in cutting forces, so they are recommended for use when machining non-rigid parts. These cutters can also be used with overhead chipbreakers. For external turning and boring in cutters with method C clamping, square, trihedral, rhombic SMPs are used, as well as parallelogram inserts of the KNUX type with fastening with a special curly tack. SMP with a central cylindrical hole is fixed with a lever mechanism according to the P method and a modernized wedge mount (wedge-intercept) according to the M method. Fastening by a lever mechanism is the most rational for cutters with a section of holders from 20 x 20 to 40 x 40 mm. This design is effectively used on CNC machines. A domestic original design of the lever mechanism has been developed, which corresponds to the best world standards, and for its intended purpose is completely unified with the designs of cutters produced at some large machine-building plants of the domestic industry, and with tools manufactured abroad.

SMP is based in the closed socket of the holder, and the lever, driven by the screw, pulls it up to the two side walls of the socket and securely presses it to the support. The base plate is fixed with a split sleeve.

The design of the mount provides the ability to quickly and accurately rotate or change the SMP and securely fasten it. It allows the whole range of new progressive domestic and foreign inserts, as well as SMP with a complex shape of the front surface, providing good chip breaking in a wide range of feeds and depths of cut.

For contouring on CNC, GPM and HPS machines, which allows turning several surfaces of a part in one stroke, cutters are used with rhombic SMP ((= 80 (and 55 (). Industrial batches of cutters with an L-shaped lever for external turning and boring widely mastered in serial production by tool factories of the Minstankprom, they are produced according to TU2-035-892 and GOST 26613-85.

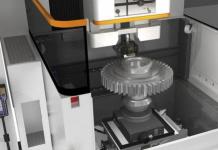

2. Subsystem of cutters for CNC machines

To perform preliminary and final operations with one cutter, primarily on universal machines with manual control, a range of cutters with a modernized SMP wedge fastening with a wedge-tack (M method) has been developed. The wedge presses the SMP not only to the pin on which it is installed with a central hole, but also to the base plate. With this fastening of the SMP, the auxiliary cutting edge remains open. A subsystem of turning cutting and grooving cutters for CNC and GPM machines has also been developed, which includes the following cutters.1. Cut-off cutters of increased reliability with brazed carbide inserts. They are distinguished from cut-off cutters manufactured in accordance with GOST 18884-73 by:

Increased manufacturing accuracy and relative position of the holder surfaces, which ensures their use on CNC machines;

The use of new, including three-layer, grades of solders and the replacement of the holder material with steel 35KhGSA or 30KhGSA practically eliminates cracking during soldering, which will reduce the consumption of cutters by about 3-4 times;

The increased quality and accuracy of sharpening the cutter reduce the cost of the consumer for primary sharpening by 0.3-0.4 r;

Improved appearance.

The main dimensional parameters of the cutters fully comply with the ISO243-1975 (E) standard.

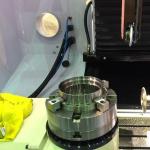

2. Cut-off toolholders with mechanical fastening of replaceable non-regrindable hard-alloy cutting inserts.

The cutter consists of a holder, a non-sharpenable single-edged cutting insert, and a spring-loaded clamp. On the supporting surface of the cutting insert, a V-shaped protrusion is made, with which it is installed in the V-shaped groove of the socket of the holder. When fastening, the pressing of the cutting plate is guaranteed from the side of the thrust surface of the socket. The geometrical parameters of the cutting part provide good chip removal from the cutting zone, which is especially important when machining workpieces made of viscous materials.

The use of hard alloy cutting inserts with a wear-resistant coating provides a 2-4 times increase in tool life.

3. Cut-off lamellar cutters with mechanical fastening of replaceable non-regrindable carbide cutting inserts are designed to perform cut-off operations primarily on universal machines with manual control. The cutter consists of a block fixed in the tool holder of the machine, a lamellar holder and a non-regrinding two-edged cutting plate, which is fixed with an elastic blade of the holder. The supporting surfaces of the cutting insert are made in the form of V-shaped grooves, with which it interacts with the V-shaped protrusions of the socket and the elastic tab of the holder.

Reducing the width of one of the two cutting edges by 0.3-0.4 mm ensures the performance of each cutting edge within the normative average life period, but for this, the worn, spent edge must be resharpened by 0.3-0.4 mm. This technical solution provides savings in hard alloy.

The plate holder allows you to adjust the value of its overhang from the block to the required size, which makes the cutter more versatile. The shape of the front surface of the cutting inserts provides satisfactory chip formation and good chip removal when machining workpieces from various steels in a wide range of feeds.

4. Grooving toolholders with mechanical fastening of replaceable regrindable carbide cutting inserts are designed to work on universal and CNC machines. They are used primarily for cutting grooves of precise dimensions. Carbide plates produced in accordance with GOST 2209-83 are used as a cutting element.

The outer shape of the cutting part and the required size are provided by sharpening. The maximum width of the cutting edge is 4.8 mm. The cutter consists of a holder, a prismatic cutting insert, a clamp and a thrust element in the form of a cracker and an adjusting screw. The supporting surface of the cutting plate is made at an angle to the side, which ensures its fixation from transverse displacements when fastened with a tack. Departure of the cutting plate after regrinding and its fixation from longitudinal displacement are provided by an adjusting screw.

On the basis of this design, grooving cutters for processing external straight and angular grooves have been mastered and mass-produced; for internal straight, angular and threaded grooves. With rational operation, the permissible number of regrindings is at least 20.

5. Mechanically held grooving cutters with replaceable non-regrindable carbide cutting inserts consist of a holder, a two-edged cutting insert and a clamping screw with a washer. The supporting surfaces of the cutting insert are made in the form of V-shaped grooves, with which it interacts with the V-shaped protrusions of the socket. The cutting insert is fixed with a screw interacting with the upper part of the socket formed by a slot in the holder.

The accuracy of basing and the fixation of the cutting insert against longitudinal displacement is ensured by the presence of a persistent base surface in the socket.

The ratio of the depth of the cut groove to its width is in the range from 1.0 to 2.0, depending on the width of the cutting part.

The presence of two cutting edges on the cutting insert provides savings in hard alloy. The shape of the rake face of the cutting inserts ensures satisfactory chip formation and good chip evacuation over a wide feed range.

The presented range of cutters provides the ability to perform all types of cutting and grooving operations.

For threading on lathes, cutters with brazed carbide inserts according to GOST 18885-73 are used, with mechanical fastening of carbide inserts.

The design of the cutter with mechanical fastening of regrindable inserts is similar to the design of the grooving cutter for cutting straight grooves, the only difference is in sharpening the cutting insert with a profile angle at the top equal to 59(30). With the accepted width of the plate used, the pitch of the thread being cut is lt 0.8 to 3.5 mm. Precise grinding (sharpening) of the profile of the cutting part provides a cut thread with an average degree of accuracy.

In cutters with a mechanical fastening of a non-regrindable rhombic cutting insert, the required geometry of the cutting part of the insert is provided by pressing and sintering. For reliable fastening of the cutting insert in the blind socket of the holder, on its front surface there is a V-shaped groove designed for connection with a clamp. The pitch of the threads to be cut is in the range from 2.5 to 6.0 mm.

Threads of a special profile on pipes, couplings, nipples and locks of oil and geological exploration equipment, depending on the thread profile, are cut with the following cutters:

Preliminary - with cutters equipped with trihedral SMP according to GOST 19043-80 and GOST 19044-80;

The final one is cutters equipped with square or trihedral plates with a cutting part, the profile of which is obtained by grinding.

Plates without a hole are fixed according to method C, and plates with a hole

Pulling grip. The profile of the cutting part can be multi-toothed (up to five) on one cutting edge; the range of pitches of threads to be cut is in the range from 2.54 to 6.35 mm. The number of working strokes, depending on the step, from 2 to 12.

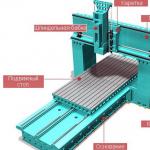

Let's consider a subsystem of multi-purpose cutters for processing on heavy and large lathes, vertical lathes and roll lathes, including CNC machines. Such cutters can also be used for other heavy metal cutting equipment. The subsystem includes prefabricated cutters for rough, semi-finishing and finishing turning of workpieces made of steel, cast iron and other materials of any hardness with a cutting depth when peeling up to 50 mm and a feed rate of up to 10 mm/rev. Cutters perform turning, trimming, boring of large diameters, cutting and cutting, processing of transitional surfaces.

The subsystem consists of several groups:

TTO - for heavy lathes with the largest diameter of the installed workpiece 1250-4000 mm and for rotary machines with the largest diameter of the installed workpiece 3200-12000 mm, having conventional tool holders;

TTP - for heavy lathes with lamellar toolholders of CNC machines;

KTO - for large lathes with the largest diameter of the installed workpiece 800-1000 mm, having standard turning tool holders, and rotary machines with the largest diameter of the installed workpiece 1600-2800 mm.

In the TTO group, two types of cutter are provided up to its supporting surface.

On the main body K1, a set of quick-change blocks B1 is fixed (right and left through, thrust through, scoring, etc.). These blocks are designed for processing with large depths of cut (t= 12…40 mm), including roughing and interrupted cutting. Auxiliary housing K2 is provided for mounting cutters of the KTO group (t = 10 ... 20 mm), as well as standard ones (t (8 mm).

In the TTP group, there are three types of L-shaped tool bodies of various widths for lamellar tool holders, which provide a minimum overhang of the tool head and high rigidity of the support with the tool holder. Blocks B1 are mounted on the body K4 for large depths of cut, on the body K5 - cutters of the KTO group for medium depths of cut and on the body K6 - blocks B "for small depths of cut.

Various articulations of bodies, blocks, cutters and plates allow obtaining more than 200 types of tools for various transitions with different leading angles and blade lengths l for only a part of the subsystem.

In the developed subsystem for especially difficult cutting conditions, inserts with a ledge P1 (TU 48-19-373-83) are used. The inserts are characterized by a slight increase in thickness with a corresponding decrease in width, which leads to a further increase in the strength of the tool.

The use of cutters with shouldered inserts, with their rational fastening and basing, provides an increase in feed by 20-40% compared to the feed when machining with cutters with a brazed insert (which is 10-15% higher compared to the best prefabricated cutters of foreign companies).

For semi-finishing with smaller depths of cut, a thickened polyhedral plate P3 with a hole is used. The new design of the fastening unit provides a reliable clamping of this plate to the supporting and thrust surfaces.

3. Tool materials

Cutting tools are made wholly or partly from tool steels and hard alloys.

Tool steels are divided into carbon, alloy and high-speed. Carbon tool steels are used for the manufacture of tools operating at low cutting speeds. From carbon steel grades U9 and U10A, knives, scissors, saws are made, from U11, U11F, U12 - locksmith taps, files, etc. The letter U in the steel grade indicates that the steel is carbon, the number after the letter indicates the carbon content in the steel in tenths fractions of a percent, and the letter A - that the steel is high-quality carbon, since it contains sulfur and phosphorus no more than 0.03% each.

The main properties of these steels are high hardness (HRC 62-65) and low heat resistance. Heat resistance is defined as the temperature at which the tool material retains its high hardness (HRC 60) when subjected to repeated heating. For steels U10A - U13A, the heat resistance is 220 (C), therefore, the recommended cutting speed for a tool made of these steels should be no more than 8-10 m / min.

Alloyed tool steels are chromium (X), chromium-silicon (XS) and chromium-tungsten-manganese (CVG), etc.

The numbers in the steel grade indicate the composition (in percent) of the incoming components. The first digit to the left of the letter specifies the carbon content in tenths of a percent. The numbers to the right of the letter indicate the average content of the alloying element in percent. If the content of the alloying element or carbon is close to 1%, the figure is not put.

Taps, dies, cutters are made from grade X steel; made of steel 9XC, HGS

Drills, reamers, taps and dies; from steel ХВ4, ХВ5 - drills, taps, reamers; from KhVG steel - long taps and reamers, dies, shaped cutters.

The heat resistance of alloyed tool steels reaches 250-260 (C) and therefore the permissible cutting speeds for them are 1.2-1.5 times higher than for carbon steels.

High-speed (high-alloy) steels are used for the manufacture of various tools, but more often drills, countersinks, and taps.

High-speed steels are denoted by letters and numbers, for example, P9, P6M3, etc. The first P (rapid) means that the steel is high-speed. The numbers after it indicate the average content of tungsten in percent. The remaining letters and numbers indicate the same as in alloy steel grades.

These groups of high-speed steels differ in properties and applications. Steels of normal productivity, having hardness up to HRC65, heat resistance up to 620 (C) and bending strength of 3000-4000 MPa, are intended for processing carbon and low-alloy steels with a tensile strength of up to 1000 MPa, gray cast iron and non-ferrous metals. Tungsten grades are referred to steels of normal productivity R18, R12, R9, R9F5 and tungsten-molybdenum grades R6M3, R6M5, retaining a hardness of at least HRC 62 up to a temperature of 620.

High-speed steels of increased productivity, alloyed with cobalt or vanadium, with hardness up to YRC 73-70 with heat resistance of 730-650 (C and bending strength of 250-280 MPa) etc. Improving the cutting properties of steel is achieved by increasing the carbon content in it from 0.8 to 1%, as well as additional alloying with zirconium, nitrogen, vanadium, silicon and other elements. , R9M4EV, R9K5, R9K10, R10K5F5, R18K5F2, maintaining hardness HRC 64 up to a temperature of 630-640.

Hard alloys are divided into metal-ceramic and mineral-ceramic, they are produced in the form of plates of various shapes. Tools equipped with carbide inserts allow higher cutting speeds than HSS tools.

Metal-ceramic hard alloys are divided into tungsten, titanium-tungsten, titanium-tantalum-tungsten.

Tungsten alloys of the VK group consist of tungsten and cobalt carbides. Alloys of grades VK3, VK3M, VK4, VK6, VK60M, VK8, VK10M are used. The letter B means tungsten carbide, K - cobalt, the number - the percentage of cobalt (the rest is tungsten carbide). The letter M, given at the end of some grades, means that the alloy is fine-grained. This alloy structure increases tool wear resistance, but reduces impact resistance. Tungsten alloys are used for processing cast iron, non-ferrous metals and their alloys and non-metallic materials (rubber, plastic, fiber, glass, etc.).

Titanium-tungsten alloys of the TK group consist of tungsten, titanium and cobalt carbides. This group includes alloys of grades T5K10, T5K12, T14K8, T15K6, T30K4. The letter T and the number it indicates the percentage of titanium carbide, the letter K and the number behind it indicate the percentage of cobalt carbide, the rest in this alloy is tungsten carbide. These alloys are used for processing all types of steels.

Titanium-tantalum-tungsten alloys of the TTK group consist of tungsten, titanium, tantalum and cobalt carbides. This group includes alloys of grades TT7K12 and TT10KV-B, containing respectively 7 and 10% titanium and tantalum carbides, 12 and 8% cobalt, the rest is tungsten carbide. These alloys work in particularly difficult machining conditions, when the use of other tool materials is not effective.

Alloys with a lower percentage of cobalt, grades VK3, VK4 have a lower viscosity; used for processing with the removal of thin chips in finishing operations. Alloys with a higher cobalt content grades VK8, T14K8, T5K10 have a higher viscosity, they are used for processing with thick chip removal in roughing operations.

Fine-grained hard alloys of the VK3M, VK6M, VK10M grades and coarse-grained alloys of the VK4 and T5K12 grades are used under conditions of pulsating loads and in the processing of difficult-to-machine stainless, heat-resistant and titanium alloys.

Hard alloys have high heat resistance. Tungsten and titanium-tungsten hard alloys retain their hardness at a temperature in the processing zone of 800-950 (C), which allows you to work at high cutting speeds (up to 500 m/min when machining steels and 2700 m/min when machining aluminum).

Especially fine-grained tungsten-cobalt alloys of the OM group are intended for machining parts made of stainless, heat-resistant and other hard-to-cut steels and alloys: VK60OM for finishing, and VK10-OM and VK15-OM alloys for semi-finishing and roughing. Further development and improvement of alloys for processing hard-to-cut materials caused the appearance of alloys of the VK10-HOM and VK15-HOM grades, in which tantalum carbide was replaced by chromium carbide. Alloying alloys with chromium carbide increases their hardness and strength at elevated temperatures.

To increase the strength of hard alloy plates, cladding with protective films is used. Widely used wear-resistant coatings of titanium carbides deposited on the surface of carbide in the form of a thin layer 5-10 mm thick. In this case, a fine-grained layer of titanium carbide is formed on the surface of the hard-alloy plates, which has high hardness, wear resistance and chemical resistance at high temperatures. The wear resistance of coated carbide inserts is on average 1.5-3 times higher than that of conventional inserts, and the cutting speed can be increased by 25-80%. Under severe cutting conditions, where chipping and chipping occur on conventional inserts, the performance of coated inserts is reduced.

The industry has mastered economical tungsten-free hard alloys based on titanium and niobium carbide, titanium carbonitrides on a nickel-molybdenum bond. Tungsten-free hard alloys of grades TM1, TM3, TN-20, TN-30, KNT-16 are used. They have high scale resistance, exceeding the resistance of alloys based on titanium carbide (T15K6, T15K10) by more than 5-10 times. When machining at high cutting speeds, a thin oxide film is formed on the surface of the alloy, which acts as a solid lubricant, which increases wear resistance and reduces the roughness of the machined surface. At the same time, tungsten-free hard alloys have lower impact strength and thermal conductivity, as well as resistance to impact loads, than alloys of the TK group. This allows them to be used for finishing and semi-finishing of structural and low-alloy steels and non-ferrous metals.

From mineral-ceramic materials, the main part of which is aluminum oxide with the addition of relatively rare elements: tungsten, titanium, tantalum and cobalt, oxide (white) ceramics of grades TsM-332, VO13 and VSh-75 are common. It is distinguished by high heat resistance (up to 1200 (C) and wear resistance, which makes it possible to process metal at high cutting speeds (up to 3700 m/min when finishing turning cast iron), which are 2 times higher than for hard alloys. Currently, for the manufacture cutting tools use cutting (black) ceramic grades B3, VOK-60, VOK-63, VOK-71.

Cutting ceramics (cermet) is an oxide-carbide compound of aluminum oxides and 30-40% tungsten and molybdenum or molybdenum and chromium carbides and refractory bonds. The introduction of metals or metal carbides into the composition of mineral ceramics improves its physical and mechanical properties, and also reduces brittleness. This allows you to increase the productivity of processing by increasing the cutting speed. Semi-finishing and finishing of parts made of gray, malleable cast irons, hard-to-cut steels, some non-ferrous alloys is performed at a cutting speed of 435-1000 m/min without cutting fluid. The cutting ceramic is characterized by high heat resistance.

Oxide-nitride ceramics consist of silicon nitrides and refractory materials with the inclusion of aluminum oxide and other components (silinite-R and cortinite ONT-20).

Silinit-R is not inferior in strength to oxide-carbide mineral ceramics, but has greater hardness (HRA 94-96) and stability of properties at high temperatures.

Hardened and case-hardened steels (HRC 40-67), high-strength cast irons, hard alloys of the VK25 and VK15 types, fiberglass and other materials are processed with a tool, the cutting part of which is made of large polycrystals with a diameter of 3-6 mm and a length of 4-5 mm based on cubic nitride boron (elbor-R, cubonite-R, hexanit-R). In terms of hardness, Elbor-R approaches diamond (86,000 MPa), and its heat resistance is 2 times higher than that of diamond. Elbor-R is chemically inert to iron-based materials. The strength of polycrystals in compression reaches 4000-5000 MPa, in bending 700 MPa, heat resistance - 1350-1450 (C. The abrasive materials include normal electrocorundum grades 14A, 15A and 16A, white electrocorundum grades 23A, 24A and 25A, monocorundum grades 43A, 44A and 45A. Green silicon carbide grades 63C and 64C and black grades 53C and 54C, boron carbide, elbor, synthetic diamond, etc.

Powders are made from abrasive materials, which are intended for cutting in a free and bound state in the form of an abrasive tool (grinding wheels, bars, skins, tapes, etc.) and pastes.

4. Sharpening of cutters

At machine-building enterprises, the tool, as a rule, is sharpened centrally. However, sometimes it is necessary to sharpen the tool manually.

For manual sharpening of tools, grinding and grinding machines are used, for example, a model 3B633 machine, consisting of a grinding head and a bed. The grinding head has a built-in two-speed electric motor. At the outgoing ends of the rotor shaft, grinding wheels are attached, which are closed by covers with protective screens. The machine is equipped with a turntable or a handpiece for installing the cutter. The frame houses the electrical cabinet and control panel.

Grinding machines, depending on the purpose and size of the grinding wheels, can be divided into three groups: small machines with a circle with a diameter of 100-175 mm for sharpening small tools, medium machines with a circle with a diameter of 200-350 mm for sharpening the main types of cutter and other tools, large machines with a circle with a diameter of 400 mm or more for grinding parts and roughing and cleaning work.

The cutters, depending on their design and the nature of wear, are sharpened on the front, back, or both surfaces. Standard cutters with carbide or high speed steel blades are most often sharpened on all cutting surfaces. In some cases, with a slight wear of the cutters on the front surface, they are sharpened only on the back surface.

When sharpening on grinding and grinding machines, the cutter is placed on a turntable or handpiece and manually pressed by the work surface to the grinding wheel. For uniform wear of the circle, the cutter must be moved along the table or handpiece relative to the working surface of the circle.

When sharpening the cutter along the back surfaces, the table or handpiece is turned to a given rear angle and fixed in close proximity to the circle. The cutter is mounted on a table or handpiece so that the cutting edge is parallel to the working surface of the circle. The front surface of the cutter is most often sharpened by the side surface of the circle, while the cutter is mounted on the side surface handpiece. The front surface can also be sharpened with the periphery of the circle, but this method is less convenient. HSS cutters are sharpened first along the front, then along the main and auxiliary rear surfaces. When sharpening carbide cutters, the same procedure is used, but the back surfaces of the rod are pre-treated at an angle 2-3 greater than the angle of sharpening on a hard alloy plate.

The quality of sharpening depends on the qualifications of the sharpening worker and the characteristics of the grinding wheels. With an increase in the pressing force of the tool to the grinding wheel, labor productivity increases, but at the same time, burns and cracks can occur. Usually, the clamping force does not exceed 20-30 N. With an increase in the longitudinal feed, the probability of crack formation decreases.

Usually, grinding wheels of different characteristics are installed on a grinding and grinding machine, which allows for preliminary and final sharpening of the tool. For preliminary sharpening of a carbide tool, circles of carbide, silicon (24A) with a grain size of 40, 25, 16 and a hardness of CM2 and C1 on a ceramic bond (K5) are used; final sharpening (with an allowance of 0.1-0.3 mm) is performed on diamond, elbor and fine-grained abrasive wheels with a bakelite bond.

For preliminary sharpening of high-speed tools, grinding wheels made of electrocorundum (23A, 24A) with a grain size of 40, 25, 16 and a hardness of CM1, CM2 on a vitrified bond (K5) are used. The final sharpening (with an allowance of 0.1-0.3 mm) is performed with circles of electrocorundum (23A, 24A) or monocorundum (43A, 45A) with a grain size of 25, 16 and 12 and a hardness of M3, CM1, CM2 with a non-ceramic bond (K5). The surface roughness of the tool after preliminary sharpening is 2.5-0.63 microns, after the final sharpening - 0.63-0.1 mm according to Ra.

When sharpening a cutter on a fine-grained wheel, irregularities remain on its cutting edge, which directly affect the wear rate of the cutter. Therefore, after sharpening, the cutter is adjusted on a diamond wheel or on rotating cast-iron disks using abrasive pastes. The speed of rotation of the diamond wheel is up to 25 m/s, the speed of rotation of the disc is 1-1.5 m/s. The cutter is brought along the main back and front surfaces on a chamfer of 1.5-4 mm. The auxiliary rear surface of the cutter is not processed.

To obtain high quality surfaces (Ra = 0.32 (0.08 μm), it is necessary that the runout of the finishing disk or circle does not exceed 0.05 mm, while their rotation should be directed under the cutting edge. Before applying the paste to the disk, it should be lightly wipe with a felt brush dipped in kerosene.The layer of paste applied to the disc should be thin, since a thick layer does not speed up the finishing process.The finishing should be done with light pressure, touching the cutter of the finishing disc without hitting.Strong pressure does not speed up the finishing, but only increases the consumption of paste and accelerates the wear of the disk.

Checking the angles of sharpening the cutter can be done with templates and devices.

Drills are sharpened along the back surface, giving it a curvilinear shape to ensure equal back angles in any section of the cutting teeth. To do this, the drill is pressed against the grinding wheel and simultaneously rotated. First, the surface near the cutting edge is sharpened, and then the surface located at a large rear angle. For carbide drills, the insert is sharpened first, and then the drill body.

Bibliography

1. V.N. Feshchenko, Makhmutov R.Kh. Turning. Publishing House "Higher School". Moscow. 1990.

2. L. Fadyushin, Ya. A. Musician, A. I. Meshcheryakov et al. Tool for CNC machines, multi-purpose machines. M.: Mashinostroenie, 1990.

3. P.I. Yascheritsyn and others. Fundamentals of cutting materials and cutting tools. Mn.: Vysh.shkola, 1981.

Hosted on Allbest.ru

...Similar Documents

The main varieties of turning tools, features of their shape and distinctive features, functional purpose and scope. The design of the turning cutter and its elements Instruments for measuring the angles of the cutter and the technique of their use. Types of shavings.

test, added 01/18/2010

Familiarization with the classification, purpose and use of turning tools, with the sequence of calculation and design of a cutting tool. Classification of turning tools. Appointment and use of a cutting tool. Image of cutoff cutter and geometry.

abstract, added 11/21/2010

Requirements for the materials of the cutting part of the tool. Scope of basic hard alloys. Structural elements of cutters Technological schemes of turning, drilling and milling. Calculation of cutting modes. Kinematics and mechanisms of machine tools.

term paper, added 12/03/2015

Principles of calculation for the strength of a core turning tool. The choice of shape, size of the cutting plate. Choice of brand of tool material, body material and assignment of geometrical parameters. Calculation of the outer and average diameters of thread rolling rollers.

term paper, added 04/15/2011

Description of the object of study - the boring bar cutter: its structure, principle of operation, purpose and main shortcomings. Investigation of the state of the art of the cutting plate, the patentability of the improved object, the patentability of the technical solution.

scientific work, added 07/19/2009

The use of shaped cutters for turning parts from a bar in the form of bodies of revolution with shaped profiles. Graphic profiling of a shaped cutter. Determination of design parameters of round shaped cutters. Analysis of the optimality of geometric parameters.

test, added 05/26/2015

Preparation of initial data for calculating the profile of a shaped cutter. Determination of the geometry of the cutting edges of shaped cutters. The geometry of the cutting edges that process the radially located surfaces of parts. Analytical calculation of the profile of shaped cutters.

term paper, added 12/13/2010

The process of broaching, types of broaches and their purpose. Calculation of a round broach. Designing a round shaped cutter: calculating the values of the rear angle, profile depth for each section, the length of the working part of the cutter, tolerances for the manufacture of shaped cutters.

term paper, added 05/19/2014

Design features of cutters with multifaceted carbide inserts. Advantages and disadvantages of various ways of installing multifaceted replaceable inserts in the cutter holder. Clamping on top for best insert placement accuracy.

laboratory work, added 10/12/2013

Elements of hydraulic systems of lathes. Hydraulic tanks and heat exchangers. Filter elements and filter materials. Contaminants in hydraulic fluids. Filters designed to remove solid contaminants from lubricating oils.

In CNC machines, a general-purpose cutting tool is used, that is, a tool that is used on manual machines. However, tools designed for CNC machines are subject to increased requirements for rigidity, interchangeability, sharpening quality, wear resistance, etc.

Used to fasten the tool tool holders and cutting mandrels. The cutting tool is adjusted by measuring its position in the tool holder. If tool holders are fixed in the machine support or turret, then small-sized tool inserts adjusted to the size are installed in them (Fig. 20.1).

In most modern machines, tool holders (Fig. 20.2) and cutting blocks (Fig. 20.3, a, b) are used to secure the cutting tool, since in this case there is no need for a special cutting tool. The most important requirements for cutting blocks are accurate and stable installation of the block in the caliper.

machine (installation error should be within 0.001 - 0.003 mm) and a small mass of the block.

Rice. 20.1.Cartridges with pre-set sizeA:

H And IN - height and width of the cutter, D- round cutter diameter

Rice. 20.2.

A - for the cutter b- for boring cutter, V- for drill, G - for countersink

Rice. 20.3. Cutter blocks without pre-adjustment to size(a, 6)

Rice. 20.4.

- 1 - carbide plate, 2 - wedge,

- 3 - wedge clamp screw, 4 - locating pin, 5 - body, 6 - carbide pad,

N, N, V - design dimensions of the cutter

The mounting surfaces of the cutting blocks are most often prisms and gear racks.

Often used in CNC machines cutters with mechanical fastening multifaceted non-regrindable hard alloy plates (Fig. 20.4).

The inserts on the holders are fixed with a wedge and a screw. The plates are based on the central hole using a 06 mm pin. Plates are distinguished by material, shape and size. According to the shape of the plate, they are characterized by the diameters of the circles described around the faces.

A feature of non-regrind plates (Fig. 20.5) is that during operation there is no need to sharpen them. After blunting one cutting edge, the plate is turned and the other edge is put into operation. When the insert is rotated, the top of the cutting edge will shift (up to 0.2 mm) from the previous position. In this case, the adjustment of the initial position of the caliper is entered on the machine control panel. Using position correctors, the dimensions (after processing) of the required quality (tolerance field) are obtained without removing the cutting block from the machine for re-adjustment in the fixture. It is possible to work with one rod, replacing only carbide inserts.

The service life of the cutter plates can be significantly extended if their edges are periodically refined with a diamond file. A change in the size of the cutter after finishing is easily compensated for on a CNC machine using correctors. This makes the use of prefabricated cutters on CNC machines extremely efficient,

Rice. 20.5.

a, b- hexagonal shape with an angle of 80"; V - triangular shape; g-rhombic shape; d ,e - pentahedral shape; f, h- hexagonal shape; And- square shape

For processing holes on CNC machines, drills, countersinks, reamers are used, both of the usual design and with a cylindrical shank, a leash and a screw to set their overhang (Fig. 20.6).

Rice. 20.6.

A - drill, b - countersink

Rice. 20.7.

For finishing holes with a diameter of more than 20 mm, use boring bars with micrometric adjustment (Fig. 20.7). The cutter 1 is mounted in the sleeve 3, in which it can perform translational movement with the help of the limb-nut 2 relative to the mandrel 4

Tool change in CNC machines with turrets is automatic. In accordance with the control program, after the end of cutting, the tool is retracted from the workpiece, replaced, and then brought back to its original position. And first, a quick approach of the tool to the cutting zone is carried out, and then - the feed at the working speed.

To meet the requirements for the stability of the creation and operation of the cutting tool, the following conditions must be observed: to use hard-alloy non-regrindable inserts with mechanical fastening in the tool body as much as possible; apply the most rational forms of plates, providing the possibility of processing a large number of surfaces with one cutter; unify the main and connecting dimensions of the tool (for example, the same connecting dimensions for cutters with the same angles in the plan), which creates convenience for programming technological operations; improve the accuracy of tool manufacturing.

When servicing CNC machines, universal devices for setting the cutting tool to a size outside the machine. The devices have a base surface, on which an adapter for tool blocks and a sighting device are installed, moving relative to the base surface along two mutually perpendicular horizontal coordinates.

CNC TURNING TOOLS

Requirements for cutters for CNC machines.

Maximum use of MNPs with mechanical fastening on tool bodies and holders. This will ensure the constancy of the design and geometric parameters of the cutters during operation.

Use of rational forms of plates. This gives the instrument versatility, i.e. makes it possible to process the maximum number of surfaces of the part with one cutter.

Unification of the main and connecting dimensions of the tool. Cutters with different plan angles must have the same basic coordinates. This creates convenience for programming technological operations.

Ability to work incisors in a straight and inverted position.

Possibility of using incisors in the left version.

Improved tool accuracy, especially for inserts. This is necessary to improve the accuracy of pre-setting and getting the tool into the size after it is fixed on the machine or in the cutter block.

Satisfactory chip formation. It is provided with grooves obtained in the manufacture of hard alloy or grooves sharpened with a diamond wheel on the front surfaces of the inserts.

Nomenclature of turning tools. To perform a variety of operations on CNC lathes, standard designs of prefabricated cutters equipped with multifaceted carbide inserts, cutting ceramics and superhard materials have been developed.

Depending on the model of lathes, the use of cutters with a cross section from 16x16 to 40x40 mm is provided. The nomenclature of cutters should ensure the processing of typical surfaces of parts and includes the following varieties:

through bent cutters with an angle φ = 45° for external turning, end machining, chamfering, recess machining (GOST 21151-75, type 1);

contour cutters with parallelogram plates and angle φ = 95° for turning parts along a cylinder, end face, reverse cone with a slope angle of up to 30°, processing of radius surfaces and grooves (GOST 20872-80, type 1);

copying cutters with parallelogram plates and φ = 63° for processing hemispherical surfaces and cones with a slope angle of up to 57° (GOST 20872-80, type 2);

threaded cutters with rhombic inserts and fastening with a clamp for cutting external threads with a pitch of 2 ... 6 mm (design of the All-Russian Research Institute of the Tool);

cutters for cutting internal threads with a pitch of up to 2 mm and a minimum processing diameter of 35 mm (GOST 22207-76, type 2);

cutters with a rhombic insert and φ = 95° for boring through holes and turning undercuts (GOST 26612-85, type 6);

boring cutters with φ = 92° and a minimum processing diameter of 22 mm (GOST 20874-75, type 3);

cutters through passage with φ = 45° with square inserts, left, for external turning, facing, chamfering, undercuts (GOST 21151-75, type 1);

cutters for turning external straight grooves with a width of 1 ... 6 mm and a depth equal to the width (design of VNIIinstrument);

contour incisors with a trihedral plate and φ = 63° (GOST 20872-80, type 4);

contour incisors with a plate of trihedral regular Shape and φ = 93° (GOST 20872-80, type 3);

threading tools for cutting external threads up to 2 steps mm (GOST 22207-76, type 1);

thrust cutters with a trihedral plate of irregular shape and φ = 93° for processing stepped surfaces, chamfers, ends (GOST 21151-75, type 4).

Cutters are used in three versions:

Cutters are used in three versions:

Full-length. Used on machines with removable blocks, which, assembled with cutters, are adjusted to a size outside the machine.

Shortened with adjustable elements.

Cutters-inserts.

Short cutters and insert cutters are adjusted to size with set screws outside the machine in a special fixture and then installed in the grooves of the tool heads and tool holders. Produced according to OST-23.5.551-82, GOST 23.5.552-82 and OST 21110-1-83.

Specialists who often use lathe cutters when working on metal, as well as those who sell these products or supply machine-building enterprises, are well aware of what types of these tools are. For those who rarely encounter turning tools in their practice, it is quite difficult to understand their types, which are presented on the modern market in a wide variety.

Types of turning tools for metal processing

Turning cutter design

In the design of any cutter used for, two main elements can be distinguished:

- holder, with which the tool is fixed on the machine;

- working head through which metal processing is performed.

The working head of the tool is formed by several planes, as well as cutting edges, the sharpening angle of which depends on the characteristics of the workpiece material and the type of processing. The cutter holder can be made in two versions of its cross section: square and rectangle.

According to their design, cutters for turning are divided into the following types:

- straight - tools in which the holder together with their working head are located on one axis, or on two, but parallel to each other;

- curved cutters - if you look at such a tool from the side, you can clearly see that its holder is curved;

- bent - the bend of the working head of such tools in relation to the axis of the holder is noticeable if you look at them from above;

- drawn - for such cutters, the width of the working head is less than the width of the holder. The axis of the working head of such a cutter may coincide with the axis of the holder or be offset relative to it.

Classification of cutters for turning

The classification of turning tools is regulated by the requirements of the relevant GOST. According to the provisions of this document, incisors are assigned to one of the following categories:

- one piece tool made entirely of . There are also incisors that are made entirely of, but they are used extremely rarely;

- cutters, on the working part of which a plate made of hard alloy is soldered. Tools of this type are most widely used;

- cutters with removable carbide inserts that are attached to their working head with special screws or clamps. Cutters of this type are used much less frequently compared to tools of other categories.

The incisors also differ in the direction in which the feed movement takes place. So, there are:

- turning tools of the left type - in the process of processing they are fed from left to right. If you put your left hand on top of such a cutter, then its cutting edge will be located on the side of the bent thumb;

- right incisors - the type of tool that has received the greatest distribution, the feed of which is carried out from right to left. To identify such a cutter, you need to put your right hand on it - its cutting edge will be located, respectively, on the side of the bent thumb.

Depending on what work is performed on turning equipment, cutters are divided into the following types:

- to perform finishing work on metal;

- for rough work, which is also called peeling;

- for semi-finishing work;

- to perform fine technological operations.

In the article we will consider the entire spectrum and determine the purpose and features of each of them. An important clarification: no matter what type the cutters are, certain grades of hard alloys are used as the material of their cutting inserts: VK8, T5K10, T15K6, much less often T30K4, etc.

Use a tool with a straight working part to solve the same tasks as the bent type cutters, but it is less convenient for chamfering. Basically, such a tool for (by the way, not widely used) processes the outer surfaces of cylindrical blanks.

The holders of such cutters for a lathe are made in two main sizes:

- rectangular shape - 25x16 mm;

- square shape - 25x25 mm (products with such holders are used to perform special work).

Such types of cutters, the working part of which can be bent to the right or left side, are used for processing the end part of the workpiece on a lathe. With their help, chamfers are also removed.

Tool holders of this type can be made in various sizes (in mm):

- 16x10 (for training machines);

- 20x12 (this size is considered non-standard);

- 25x16 (the most common size);

- 32x20;

- 40x25 (products with a holder of this size are made mainly to order, they are almost impossible to find on the free market).

All requirements for metal cutters for this purpose are specified in GOST 18877-73.

Such tools for a metal lathe can be made with a straight or bent working part, but they do not focus on this design feature, but simply call them through-thrust.

A through thrust cutter, with the help of which the surface of cylindrical metal blanks is machined on a lathe, is the most popular type of cutting tool. The design features of such a cutter, which processes the workpiece along the axis of its rotation, make it possible to remove a significant amount of excess metal from its surface even in one pass.

Holders of products of this type can also be made in various sizes (in mm):

- 16x10;

- 20x12;

- 25x16;

- 32x20;

- 40x25.

This tool for a metal lathe can also be made with a right or left bend of the working part.

Outwardly, such a scoring cutter is very similar to a through cutter, but it has a different shape of the cutting plate - triangular. With the help of such tools, workpieces are processed in a direction perpendicular to their axis of rotation. In addition to bent, there are also persistent types of such turning tools, but their scope is very limited.

This type of cutter can be produced with the following holder sizes (in mm):

- 16x10;

- 25x16;

- 32x20.

The cut-off tool is considered the most common type of tool for a metal lathe. In full accordance with its name, such a cutter is used for cutting workpieces at a right angle. It also cuts grooves of various depths on the surface of a metal part. It is quite simple to determine that it is a cutting tool for a lathe that is in front of you. Its characteristic feature is a thin leg, on which a hard alloy plate is soldered.

Depending on the design, right- and left-handed types of cut-off cutters for a metal lathe are distinguished. It is very easy to tell them apart. To do this, you need to turn the cutter with the cutting plate down and see which side its leg is located on. If on the right, then it is right-handed, and if on the left, then, respectively, left-handed.

Such tools for a lathe for metal also differ in the size of the holder (in mm):

- 16x10 (for small training machines);

- 20x12;

- 20x16 (the most common size);

- 40x25 (such massive turning tools are hard to find on the free market, they are mostly made to order).

Thread cutters for external threads

The purpose of such cutters for a metal lathe is to cut threads on the outer surface of the workpiece. These serial tools cut metric threads, but you can change their sharpening and cut other types of threads with them.

The cutting insert mounted on such turning tools has a spear-shaped shape; it is made from the alloys that were mentioned above.

Such cutters are made in the following sizes (in mm):

- 16x10;

- 25x16;

- 32x20 (used very rarely).

Such cutters for a lathe can only cut threads in a large diameter hole, which is explained by their design features. Outwardly, they resemble boring cutters for processing blind holes, but you should not confuse them, since they are fundamentally different from each other.

Such cutters for metal are produced in the following sizes (in mm):

- 16x16x150;

- 20x20x200;

- 25x25x300.

The holder of these tools for a metal lathe has a square section, the dimensions of the sides of which can be determined by the first two digits in the designation. The third number is the length of the holder. This parameter determines the depth to which a thread can be cut in the inner hole of a metal workpiece.

Such cutters can only be used on those lathes that are equipped with a device called a guitar.

Boring cutters for blind holes

Boring cutters, the cutting plate of which has a triangular shape (as with scoring cutters), perform the processing of blind holes. The working part of tools of this type is made with a bend.

The holders of such cutters can have the following dimensions (in mm):

- 16x16x170;

- 20x20x200;

- 25x25x300.

The maximum hole diameter that can be machined with such a turning tool depends on the size of its holder.

Boring cutters for through holes

With such cutters, the working part of which is made with a bend, through holes are processed, previously obtained by drilling. The depth of the hole that can be machined with a tool of this type depends on the length of its holder. The layer of metal that is removed in this case is approximately equal to the value of the bend of its working part.

On the modern market there are boring cutters of the following sizes, the requirements for which are specified in GOST 18882-73 (in mm):

- 16x16x170;

- 20x20x200;

- 25x25x300.

Prefabricated cutters for lathes

Considering the main types of turning tools, it is impossible not to mention tools with a prefabricated structure, which are universal, as they can be equipped with cutting inserts for various purposes. For example, by fixing different types of cutting inserts on the same holder, you can get cutters for different angles.