A curved opening or arch is a bright architectural and design element, which is a decorative connection of the upper part of a window or door opening. The design in the form of an arch of openings between two load-bearing beams is very popular. With the help of an arch made of bricks, you can decorate the appearance of the house outside and inside, which is why many owners who are busy ennobling their own homes are interested in how to make a brick arch.

Types of arches and their characteristics

There are a huge variety of forms of arches, therefore, before starting work, you need to decide what form of construction you need.

There are the following main types of structures of this kind:

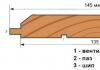

Arched (beam) jumper: 1-heel, 2-pin seams, 3-castle brick.

- Wedge-shaped. To create arches in the form of wedges, the brick is laid in an appropriate way and the uppermost sharp point is fixed with a specialized building element. Such design solutions are most often found in Gothic style interiors.

- Luchkovye. Such an arch has the shape of a truncated cone. You can meet with similar openings in rooms with oriental-style decor.

- The correct semicircle or the classic form of arches. To create such a design, it is necessary that the size of the semicircle be equal to half the width of the decorated opening.

- Modern. This shape is an arc that repeats the dimensions of a truncated cone.

- Romance. Such an opening is rectangular, but its corners are rounded, which gives the opening a softer and more delicate appearance.

- Ellipse. This form is a prominent representative of such styles as postmodern and new wave.

- The portal is the simplest rectangular structure.

All presented forms have both advantages and disadvantages, which must be taken into account when making your choice. So, for example, a Gothic pointed arch made of brick suggests that the height of the ceilings in the building reaches 3 meters or more.

So, if you have decided on the appearance of the structure, it's time to talk about materials, tools and stages of work.

Back to index

We create a high-quality brick arch

1-lock.

The process of laying arches from a material such as brick can be divided into the following stages:

- Creation of a drawing of the planned structure and work on the calculations of its parameters.

- Works related to the installation of a chipboard template of the upper form in the opening.

- Laying out jumpers of the opening.

- Fixing masonry building material and fixing it.

- Removing a template element.

- Finishing the created opening.

Back to index

Creating a template and some calculations

To make an arch, you will certainly need a template. It serves to determine and maintain the shape of the future opening. Before you build something, you should make all the necessary calculations and for the construction of arches, you need to measure such quantities as:

- thickness of load-bearing structures;

- ceiling level;

- required opening width.

Having measured these values, you can begin work on the calculations. To begin with, we create on paper a sketch drawing of the future chipboard template:

- We set the desired radius of the future arch based on the width of the opening under it.

- Using a compass, draw an optimally curved arc on the sketch.

If it is planned to build a complex arched span with ornate bends or with several levels with different arc radii, each element must be calculated separately.

According to the created sketch, it is possible to make a template part from chipboard. It should be noted that this product is cut a couple of centimeters less in width and height. This discrepancy in size is necessary so that the template can be easily removed from the opening.

Back to index

How to make a brick arch: the nuances

Now that you know exactly the dimensions of the future opening, you should figure out how to make an arch. This process should begin with the installation of the template and laying bricks:

- In the very center of the upper arc, they place, or rather drive in, the final castle brick, which serves to fix the shape.

- Next, the side parts of the opening are laid out, and at the same time, you need to know that the number of building elements on each side should be odd.

- After the brick laying is completed, a retaining beam will be laid on both sides of the arch.

- On the side surfaces of the opening, strobes are placed.

- To make an arch, first you need to install a structure that will support the future masonry until it hardens. The template is made of chipboard with a sheet thickness of at least 10 mm. The rounded parts of the product are cut out in accordance with the prepared sketch.

- The made template is attached to the opening with the help of spacer bars and ordinary self-tapping screws.

- Brick laying is carried out from the sides of the opening at the same time on the right and left.

- Between the rounded parts of chipboard and the beams there are special wedges that will be needed to align the frame. In addition, these wedges will allow you to easily remove the template in the future.

- It is necessary to check that all gaps and seams are tightly filled without bubbles and voids.

- As soon as the work with the brick is completed and the mortar dries, the template can be removed.

Depending on the desired result, you can cover the structure with a finishing finishing material.

The article contains a detailed description of the brick arch construction technology. A step-by-step instruction with video tutorials will help you understand the main points of calculating, preparing and laying the vault. You will learn how to correctly assemble the formwork and avoid mistakes during its installation.

An arched vault or lintel is a spectacular solution for the appearance and a reliable construction of the top of any opening. Due to its greater length (compared to a straight lintel), it distributes the load better, which makes it possible to dispense with the use of metal or concrete in the construction of walls or cladding. Scope of the arched brick structure:

- Load-bearing wall openings.

- Brick cladding.

- Fireplaces, stoves (hearth or firebox).

- Outdoor barbecues and barbecues.

- Separately standing portals (gate, gate).

To build an arch, you will need developed skills as a mason and carpenter. If there is no self-confidence, it is better to lay out a trial design, evaluating its stability. We will consider the option of creating an arch using an abstract example.

To work, you will need the following tool:

- Bricklayer's set - pick, cord, trowel, buckets.

- Power tools - grinder, screwdriver, electric jigsaw.

- Carpentry measuring and marking tool.

Preparation for work

For laying the arch, it is necessary to assemble a temporary load-bearing formwork from wood (bar, rail, sheet material). This is a wooden support that repeats the shape and dimensions of the inner plane of the arch. In order to do it, you need to know the following parameters of the future design:

- Vault form. In total, there are two types of arched vaults - the correct arch and the bow lintel. You can read more about them in the article "Window lintel". In the work itself, the chosen form does not play a big role, so here you should be guided more by the combination of appearance with other architectural elements.

- arch radius. In a regular arch, the radius of a semicircle (arch) is equal to half the distance between the supports (along the inner plane). The radius of the arch of the beam bridge is determined arbitrarily (individually) for reasons of appearance.

- The distance between the inner planes of the supports. Determined by location. The circle should pass freely between the supports.

- Wall thickness. The arch can be of any thickness, even a continuous tunnel. To begin with, we recommend building a structure with a thickness of 1 brick (250 mm).

- Advance paynemt. The main condition for the stability of a brick lintel is an odd number of bricks. That is, the central (“castle”) stone should be at an equal distance from the supports or their projections. If it is slightly smaller than the standard, you can cut it with a grinder. In this case, the thickness of the seam in the lower part of the masonry should be at least 5-6 mm, in the upper part no more than 30 mm.

When all dimensions are taken and there is complete clarity of the desired result, you can start assembling the formwork.

Formwork assembly

Progress:

- From sheet material (OSB, plywood, chipboard), cut out two identical semicircles or a segment according to the size of the future arch (the craftsmen call these segments “circled”).

- Screw the bars to the circles for reinforcement - along the bottom and in the upper third (horizontally, in parallel).

- Fix the walls at the required distance (250 mm) with a bar.

- Distribute the slats in 200 mm increments along the edge of the circle so that they form a supporting frame. Fix them with screws.

- Thin sheet material (plywood, OSB 4-6 mm, galvanized, fiberboard) cover the working plane of the formwork (brick laying place). The wooden plane can be lubricated with oil or diesel fuel so that it does not deteriorate from the solution, and it is easier to remove the formwork.

The formwork is ready. Now you need to install it directly into the opening.

Formwork installation

Even if the weight of the bricks is assumed to be small, and the arch is at a height, we strongly recommend installing the formwork on vertical posts. They can be fixed to the supports with dowels in the seam, and an additional support can be placed in the middle. Be sure to make spacers racks.

As a rule, the arch is laid out simultaneously with the plane, so the place of the “heel” (the supporting platform of the arch arch) is determined by the level of the masonry row. Its height must be known in advance (within tolerance).

If you decide to make a bow (segment) jumper, you will have to additionally lay out the heel stops. To do this, the brick is cut in place. The shape of the trimming is according to the position of the first brick of the vault. At the same time, the formwork is installed so that the beginning of the arch falls on the plane of the heel.

Arch masonry and heel trimming, video

The vaults of a regular arch begin with a brick lying horizontally, then rise, gradually changing the angle of inclination. Therefore, the formwork should be installed after laying the first brick in the support. The beginning of the vault will fall on it (on the first brick).

Bricklaying

The arch is not much different from ordinary masonry - the main difficulties are associated with the correct calculation and manufacture of even formwork. If you are making an arch of a "cold" design, use an increased proportion of cement mortar (1 part cement, 2.5 parts sand). If it is a stove or barbecue, a special clay solution should be used.

Bricks are laid on the formwork from both sides at the same time. Use the bottom layer thickness gauges and check for flatness. It must coincide with the plane of the supports, and the seams are filled with mortar. It is possible to dismantle the circle not earlier than 21 days from the moment of laying.

Outdoor fireplace - video masonry walls and arches

Having mastered the main principles of calculation, formwork creation and the general approach, the novice master develops his own techniques and know-how. The more practice, the better the result will be. Based on the data in this article, you will be able to master the laying of any kind of stone lintels.

Firebox in the form of an arch. Step by step video with comments

A beautiful brick window or door arch will decorate any interior space. Masonry technology is simple, but still requires certain skills. Therefore, it is better that the arched opening be designed and overlaid by the master. However, if you carefully study the instructions and take into account all the important nuances, draw up a project, then lay out the arch in a semicircle with your own hands.

Types of brick arches

The brick arch is a decorative element, so it is often used to decorate openings in residential premises. But before building beautiful arched openings in houses and apartments, it is useful to study information about what types of arches exist. The most common varieties are:

- wedge-shaped. Fans of gothic-style interiors often resort to the wedge shape. Brick laying in this case should form a wedge arched vault, the upper point of the tip is fixed with a special building element.

- Romance. In this situation, the opening must be laid out in a rectangular shape, and the corner part is semicircular.

- Luchkovye. At home, this type of arch can be made by an admirer of oriental-themed interiors. In this case, the bricks are laid out in such a way that a truncated cone arch is formed.

- Classic. This arch is semicircular, if desired, can be framed with decorative pillars. To make the design look harmonious, it is important to adjust the size of the semicircle to ½ the width of the main opening.

- Modern. Externally, the opening looks like an arc.

- Port. A simple design, laid out in the shape of a rectangle.

- Ellipse. Such an arch is round on the vault and can have different widths.

Advantages and disadvantages

Category: Doors, openings, archesDespite the fact that semicircular arched window and door ceilings are considered an interesting interior solution, they have their pros and cons, which are important to consider before proceeding with construction.

This decor is used for window openings.

The main advantages of such structures are as follows:

- Unique atmosphere in the house. The vaults of the entrance or interior door laid out in a semicircle create a special, pleasant atmosphere that the owners of the premises and their guests will feel.

- Easy design and installation. Even without building experience, having carefully studied the construction scheme, it will be possible to build a red brick door arch in your house on your own.

- Design reliability. The arch is a monolithic structure capable of withstanding increased loads.

- Versatility. You can fold the arch not only inside the house. She is often framed by entrance gates, gates, window openings. Even the hole in the stove can be overlaid with bricks in the form of an arched arc, which is also an original solution and a beautiful addition to the overall interior of the room.

However, this structure also has disadvantages, for example, the following:

- A semicircular arch requires the creation of a single interior style, which includes specific wall, window, and floor cladding. The implementation of these ideas will require significant costs of labor, materials and finances, which not everyone can afford.

- Strict, step-by-step adherence to masonry technology. If it is incorrect to calculate the dimensions or not to form a brick vault according to the project, there is a high risk that the structure will not withstand and fall apart.

Step-by-step instructions for building an arched opening

Drafting and drawings

To make a design project, you need to measure the height of the wall.

If the decision to lay a brick arch is final, first of all, you need to draw up a template with which you can evaluate the shape and dimensions of the future structure. To draw up a template, it is recommended to measure:

- thickness of supporting structures;

- the distance of the top point relative to the ceiling;

- wall height;

- desired opening width.

When these parameters become known, an initial sketch of the future template is created, which is made from chipboard. For drawing:

- an arc is drawn with an optimal bend;

- the optimal radius of the structure is set, taking into account the width of the opening under it.

If the laying of a brick arch is complicated, while the number of bends and levels is non-standard, each element should be calculated and drawn separately. After, when making a sketch, all the elements add up. It is important to pay attention to the fact that the template should be smaller in size than the actual parameters of the arch. This will help remove the layout from the opening without additional effort.

Calculation of material and design parameters

The parameters of the finished structure must be calculated.

Before proceeding with the sketch modeling, it is worth measuring the wall, the height of the ceiling and the desired width of the opening. The calculation of a brick arch is carried out as follows:

- the radius of the semicircle is determined, as well as the width;

- using a compass, the required radius is drawn.

The calculation of the arch and its dimensions is carried out according to the following formula:

- R=L2+H2/2H, where R is the radius, L is ½ chord, H is the height.

Archway masonry

When all the parameters become known, the installation of a wooden sketch is carried out, after which the brickwork follows directly. The distribution of bricks is carried out from below, while the laying is carried out on both sides of the future arch. In order not to violate the distance between the supports, a board of the required length is placed, which rests on the pillars and moves as they increase. After that, it is necessary to install a beam on both sides of the structure, which will serve as a support.

When laying out columns, it is worth considering that the number of rows laid out to form an arch should not be even. It is important to carefully fill all the seams and lintels with mortar, otherwise the design will be unreliable. Having reached the central vault, you need to install a “castle” brick, with which you can fix the entire lintel of the opening. When the structure is completely laid out, the wooden template is removed. To finish the arch, you can use decorative plaster imitating red brick. If the arched structure is erected on the street, for example, above the gate, plaster for outdoor use is selected for cladding.

It's no secret that an arched doorway looks aesthetically much more attractive than a standard rectangular one. Thanks to the arched vaults, non-standard design solutions can be used. One of these options in interior design can be in your home.

Arched forms have certain difficulties, so you need sufficient skill to make such an architectural structure yourself. This tutorial will show you how to properly lay a brick arch on your own with minimal building skills.

Varieties of brick arches

The arch is a jumper in the form of a semicircle, which connects two vertical supports to each other. The strength of the arch is ensured by distributing the load to the sides (thrust). Usually arches are laid out above window or doorways. Arches are also made near stoves and barbecues.

In the existing construction practice, there are 3 forms of brick arches:

- Normal (full) arch. When it is erected, the semicircle of the arch is made half the diameter of the circle. Any home master can make such an arch.

- Wedge (rectangular) arch. This type of arch is shaped like the letter "P". The arched vault is equal to the radius of the circle. Such a brick arch is the most difficult in construction.

- Bow (truncated or incomplete) arch. In such an arch, the arched vault is made low, less than half the diameter of the circle. In this case, the laying of bricks is carried out along a truncated arc. In terms of complexity of execution, the arch arch occupies an intermediate position between the usual and wedge-shaped arches.

The bricklaying technology of the above types of arches practically differ little. It remains only to prepare the necessary tools and materials to fold a brick arch with your own hands, which will become part of your interior design.

At the initial stage, when the shape of the future brick arch is already known, it is necessary to develop and make a template for the vaulted element. As a material for the manufacture of the template, wooden blocks and chipboard sheets are used.

The template is easy to make with your own hands. A horizontal line is drawn on the chipboard sheet, which is equal to the width of the opening, the center of the arched vault is marked, as well as its extreme lower and upper points, which are then also connected by lines to each other. The result should be a truncated semicircle (circling) of the future arch.

Next, with a hacksaw or a jigsaw, two circles are cut along the marked lines, which must be connected to each other using self-tapping screws and bars. Then the resulting template of the future arch must be installed in the opening and fixed in it with the help of spacers and supports.

Before the start of the laying out, on both sides of the arch, at the level of its lower border, fines are installed, which will allow the structure to be clamped, ensuring its stability and strength.

Do-it-yourself brick arch should be made without interruption in work in one go. Laying is done by moving along the arc of the template from the bottom up while laying bricks on both sides. At the end of the set, a brick (lock) is tightly driven into the top of the masonry, the main function of which is to fix the entire arched structure. After that, the template is removed, and the surface of the brickwork is cleaned from the remnants of the mortar.

To lay out the arched structure, a special wedge-shaped brick is used, which has the shape of a trapezoid, which provides better fixation of the brick arch. It is not a problem to buy such a brick. It is sold in specialized hardware stores, but you can make it yourself by processing it with a grinder to the desired shape.

A properly mounted brick arch with your own hands can last a very long time, giving your home an original look and filling it with homely warmth and comfort. You will find additional information for the lesson by watching a do-it-yourself brick arch video.

Photo of brick arches

In order to decorate the facade of a house, decorative components of architecture are often used, which can give it a special brilliance and originality.

Today it is considered fashionable to build brick arches. In the form of arches, you can make both gates and interior doors.

Among these elements, arches can be distinguished, which are quite often used in modern construction of both industrial buildings and country houses.

The arch is a lintel of a figured type, which can be mounted both above window and above doorways.

Brick arch classification

A bow arch is an arch shape that is only part of a circle.

Types of brick arches:

- Bow arch (another name is truncated or incomplete; it is an arc, the height of which is less than the radius).

- Full arch (regular, half a circle, that is, its height is equal to the radius).

- Wedge type of arches (bricks above a rectangular window are placed in a wedge, while they fix themselves, leaning against each other).

Each of the above types of arches has advantages and disadvantages.

Brick masonry

This technology may include several stages:

- Create a template.

- Template mounting.

- Kit .

- Arch compression.

- Template disassembly.

- Clean finish.

High-quality masonry of a brick arch involves the use of the following building tools:

- trowel (leveling the solution, trimming excess mortar at the seams and high-quality filling of vertical seams);

- bucket-shovel (used for supplying, shoveling the solution and spreading it);

- instrumentation to determine the current quality of the structure (m, plumb, level, rule, triangle);

- pick hammer;

- roulette;

- mortar shovel;

- mooring twisted cord.

Risk of breakage

There are several reasons why a brick arch may burst:

- A small radius (height) of the structure with a sufficiently large width. Such a structure perceives large loads, but does not distribute them. As a result, the formation of cracks is possible, but the array will not collapse. To create a template, you can use corners or metal bases. They are used in order to additionally attach the structure, but sometimes this can lead to very adverse consequences. Indeed, when using a template made of wood and after its dismantling, the brickwork shrinks and compacts. However, in the case of a metal base, the masonry does not sag. Thus, the structure will come out very strong, but with some cracks.

- The template remained in the arch for quite a long time after its creation. For example, they could not pick it up immediately, but leave it overnight. During this time, the tree absorbed moisture, swelled, and the masonry of the arch could not withstand the stress. Although such cases are rare, it is still recommended to be careful at this stage. It is better to cover the arch with polyethylene.

- Subsidence of the base. The formation of cracks near the window openings is one of the signs of an improperly constructed foundation. At the same time, cracks in the design of the arch are no exception. In this situation, it is necessary to strengthen the foundation.

Arched opening calculations

1. rotating rail or cord;

2. a board located at the level of the center of the arch circle.

The first step is to create a template using a chipboard sheet. It uses wooden bars and fiberboard. At the same time, the quality of the template, the correspondence of its size and shape to specific parameters largely determine the future quality of the arch.

The first step is to determine the size of the template. To do this, it is necessary to calculate the width of the opening (as an example, a window with a width of 1500 mm). The width of the template is taken 5 mm less, that is, 1495 mm. Subsequently, it is possible to dismantle the template without much difficulty in the final stages, even if it swells from moisture. The height of the template must match the selected arch height (eg 168 mm). It is advisable to lay a whole facing brick in the upper area of the arch. Thus, to determine the height, you need to calculate the number of bricks. The height of one row should be around 72 mm (the height of the seam and brick), and the total number of rows should be 4. That is, the arched height: 72 * 4-120 = 168 mm. Hence 120 mm - the height of the shaped brick laid on the edge.

Calculation of arch parameters: Ha - Arch height, lpr - Span width

The height can be less or more, but it must be borne in mind that if the arch is too low and the width is too large, then there is a risk of subsidence of the brickwork under the influence of the load.

The thickness of the template is selected based on the thickness of the wall. It should be specific so that you don't have to create a helper template. After all, there are only two arches: backing and front. The acceptable thickness here is 200 mm, which is half the thickness of the cinder block. A larger template will be heavier, which is naturally undesirable.

The characteristics of the template may be as follows:

- height - 168 mm;

- thickness - 200 mm;

- width - 1495 mm.

Accordingly, after the calculation, you can start creating the actual template. A chipboard sheet serves to mark the center of the arch, the lower and upper points. In order to get a truncated semicircle, the lower and upper points are connected to each other with an arc. You can use a thread for this, or a wire with a metal peg attached to it on one side and a pencil on the other (this way you get a kind of compass, the radius of which will be many times greater than the standard one).

For more efficient and convenient installation of the template, it is necessary to deviate from the extreme lower points of the arc by about 100 mm. This is done so that the arch includes supports for fastening the bars. Use the resulting outline to cut out the circle. This operation is performed using a jigsaw.

Next, you need to cut out an arched template, which consists of two circles, which is why you will need two copies of them. At the same time, you can make your task easier by cutting out the first one for a start (circle it by putting a sheet on the chipboard) and cut out the second one already along the resulting contour.

To add volume to the arch template, it is necessary to fix wooden bars between two circles. After performing this operation, the template design is fastened with nails or self-tapping screws. The upper area of the arch of the template is equipped with a strip of fiberboard using nails (from 20 to 25 mm). The template will take on a smoother and more regular shape, and will also be able to hold the bricks laid in the upper area.

The template is mounted in a window opening, under which supports from boards 20 mm thick are installed. A spacer is attached between the latter to fix them. The template is mounted on the boards at the same level as the shaped brick of the front sample. At the same time, its height should correspond to the frame of the window.

The laying of an arch type arch to the wall involves trimming the window frame and the upper brick with the help of a grinder. Thus, the arch is mounted lower, and the brick moves towards the inner corner.

Usually the front arch protrudes in relation to the wall. The protrusion should be small (less than 60 mm). Otherwise, there is a risk of soaking arched bricks and their gradual destruction. Even small protrusions are recommended to be covered with a certain material, for example, tiles or a metal sheet. Nevertheless, the larger the ledge, the more colorful the future arch will look, so you personally have to make a choice in favor of beauty or practicality.

Laying the front brick to the wall implies some nuances. In the process, due attention must be paid to the fact that the brick includes two front sides. In the case when the material protrudes strongly in relation to the wall, the front and “back” sides are visible, the plane of which is rough and uneven.

masonry construction

Before laying the arch, it is necessary to mount the bars on both sides, which make it possible to clamp it simply and quickly enough.

The creation of arches must begin with the "heels", on which it will continue to rely. After their installation, the height of one row of masonry is calculated, and the number of rows around the arch is also measured. After that, it is necessary to put risks on the template that will mark the positions of the rows.

It is necessary to make a set of brick arches simultaneously from two sides from the bottom up. The final brick, which is called the "key", is mounted right in the center of the upper area of the arches. It fixes other bricks, which can even be two if their total number is even. The driving of the key brick must be carried out tightly enough so that it not only holds on its own, but also holds the entire brick structure of the arches.

After the arch is set, it is clamped with a brick. It is advised to do this on the same day and not postpone until a later time, because otherwise it may burst.

The template can then be immediately removed and the plane cleaned. If the weather is decent and the air temperature is high, the mortar will quickly harden on the same day, which will make it possible to remove it without damaging the masonry. If the solution is left for a day or two, then it will be very difficult to clean the seams from the solution.

During the laying process, the seams do not always turn out to be perfectly clean and even, so it is necessary to clean them. The solution can be squeezed out of the joints and fall on the front plane of the masonry, or fully fill them. The first case involves cleaning the seams with a dry cloth, and the second - an auxiliary overlay of seams in the direction from the bottom up.

After a day, the wall with the arch must be raised by a certain number of brick rows.

Backfill masonry analogue

A backing arch is a structure that is located behind the front of the arch.

After completing all the above steps, you can proceed to the backing arch. To create these arches, the same wood template is used, but with some changes in its design. Since arched windows have a quarter of a 5 cm on the sides, both the arch and the template should include a similar detail. Thus, the template must be grown by this value. In order to do this, the fiberboard sheet is equipped with wooden blocks with a section of 45x45 mm and a length of 200 mm. The distance between them can be approximately 70 mm.

The sheet is very flexible and therefore the resulting tape is easy to bend and fasten at the top area of the arch template.

Features of work

The technique for creating filling arches is an analogy for making facial arches. First you need to mount the "heels", from which you need to reach the top of the arch. Usually, backing single bricks mounted on the edge are used for this.

Before starting the process of creating an arch, it is recommended to prepare all the most necessary building materials and tools, make a template, cut spacers, wood blocks and props. In general, the creation of the arch will take about 8.5-9 hours a day, so it is rational to start work in the morning and finish by evening.

On this, the work on creating a brick arch can be completed. The main thing in the masonry process is to prepare all the necessary construction tools and strictly adhere to the established rules. Thus, you will get a very high-quality and effective result.