The rocking chair is rightfully one of the most popular pieces of furniture. It is gaining even more popularity in the presence of a country house. It can be different models made of different materials. But more preference is given to wooden products. You can buy ready-made, or you can make it yourself. How to make a rocking chair with your own hands and what materials to give preference to, read further in the article.

Advantages and disadvantages of wooden structures

Wood is the most common material for making furniture. The wooden rocking chair is no exception, thanks to its many benefits:

- Environmentally friendly material that emits a pleasant forest smell.

- Significant strength.

- Long period of operation.

- The possibility of implementing design solutions.

- Ease of processing, including manual.

- A wide choice of wood of any brand and in any place.

- Large color spectrum of the material.

The finished rocking chair fits well into any architectural ensemble of the building. It can be installed at any time in a convenient place: in a clearing, by the pool, by the fireplace, near the barbecue, etc. Rocking in a chair is relaxing, comfortable for the body, and beneficial for the body. It is a comfortable and safe swing for children.

Photo: rocking chair in interior design

Along with numerous advantages, there are a number of disadvantages, the main of which is the significant cost of any rocking chair. In addition, structures are characterized by the loss of their qualities and characteristics if it is affected by rain, fog, and other precipitation. Undesirable will be a long stay of a rocking chair under the influence of the sun.

Material and its characteristics

For the manufacture of rocking chairs from solid wood, conifers are preferably selected. It can be pine, spruce, alder or larch. These rocks are characterized by low mass and low density. Home-made structures with a significant mass will be inconvenient to move. The high density of the material will create difficulties in work.

Coniferous trees have a light gray structure. Easily processed. A significant disadvantage of such wood is that with an increase in the level of humidity, it increases in size. Despite this, conifers are a budget option, are widely distributed in the distribution network and have a low cost.

The chair can be made from more expensive types of wood. It can be oak, ash or beech. These types of wood have almost no pores, resulting in a high level of strength. Finished structures are reliable and durable, but have a high cost. Tree species have a light or light yellow color.

For the manufacture of a chair that sways, high-quality wooden blanks of the first grade are used. The humidity of these blanks by the beginning of work should not exceed 10%. If this figure is higher, then wood is not recommended. It is better to let it dry, as a structure made of wet wood will subsequently dry out and undergo deformation. The consequence will be its nondescript appearance or complete destruction.

Blueprints

For the manufacture of a wooden swinging structure, it is necessary to draw up a drawing of the chair. It is better to perform it on graph paper, drawing all the structural elements with dimensions. To make a simple rocking chair with your own hands from wood, it is recommended to take an ordinary chair as a basis.

Drawing of a rocking chair made of wood

The simplicity of the design lies in the fact that all elements are attached at a right angle and there is no need to cut additional parts. The basis for the whole structure is the size of the seat and the height of the legs. Under these dimensions, connecting elements will be cut. The next step in the manufacture of rocking chairs, according to the drawing and the required dimensions, we cut wood parts.

A square seat with a side length of 53-56 cm can be made of plywood or a solid piece of wood. The thickness of the seat should be 1.0-1.5 cm. For the rear and front legs, a bar with a section of 4.5x4.5 cm is used. The rear legs are cut with a height of 105-110 cm, the front ones - 55-60 cm. length, height and thickness 57x4x1.5 cm, respectively.

This design and dimensions are not a dogma. Based on preferences, the shape and size of parts may vary.

Another drawing example

Tool

Making a chair requires a tool. To complete the work you will need:

- fine-toothed wood saw or electric jigsaw for cutting blanks;

- a simple or electric planer for processing structural details;

- grinding or belt machine for grinding parts;

- manual milling machine for grooving and processing connecting rails;

- right angle or building plumb;

- screwdriver;

- a hammer;

- tape measure and pencil;

- clamp or rubber band;

- brush or spatula to fill the mounting holes.

Given that the structural elements will not be attached to nails, a hammer will be needed to fit the parts to each other.

Connection of parts

To attach the seat and legs to each other, you can use two options:

- spike fastening;

- connection with glue.

When fastening into a spike, markings are applied to the wooden elements of the rocking chair. According to it, grooves are cut out in the legs, 2.0x1.5 cm in size, 2 cm deep. The shape of the connecting rails is prepared for the grooves. Before fastening the parts, the groove and ends of the rails are treated with building glue.

Users often search:

In the second version, the attachment points are treated with glue and interconnected. For reliability, epoxy glue is often used. The joints are reinforced with self-tapping screws. The seat is mounted on transverse rails and is also fixed with self-tapping screws.

In both versions, a clamp and gaskets are used to finally fasten all elements of a rocking chair made of wood. The gasket material is installed between the clamp and the rocking chair. After installation, the clamp is tightened and the swinging chair is left for 24 hours for the glue to completely harden. In the absence of a clamp, the screed is carried out using a hard rubber band.

Mounting skids

The manufacture and installation of skids can be done in two ways.

First way

Differs in simplicity and speed of execution. It is as follows:

- For the manufacture of skids, a sheet of plywood, 1.5 cm thick, is used.

- According to the template, two blanks of the same curvature are cut out of plywood, about 1 m long.

- Slots are made in the legs of the chair, 1.5 cm wide under the thickness of the plywood skids. The depth of the slots can be 7-10 cm.

- The runners are ground along the edge and installed in the slot. During installation, it is necessary to achieve the most uniform level of their installation.

- At the landing sites of the skids, a through hole is made, with a diameter of 2 cm.

- The hole is treated with glue and a wooden spike is inserted into it.

Second way

More labor intensive. A block of wood is used as a ski. To equip a rocking chair with skis, you must:

- In a wooden bar, with a section of 4.5x4.5 cm and a length of about 1 meter, cut grooves.

- Process the ends of the legs of the chairs for landing in the grooves of the runners.

- Place the skid bars in boiling or hot water until the wood is pliable.

- Using a tool, bend the skis to a certain radius and leave in this state until completely dry.

- Install the dried runners on the legs, pre-treating the grooves with glue.

In order for the runners to serve for a long time, it is necessary to use wood with high wear resistance.

Balance check

Rocking chair made of wood, can cause inconvenience when landing or getting up. This arises as a result of the difference in the weight of the structural elements that are in its front and rear parts. To avoid discomfort, it is necessary to balance the swinging structure.

With a significant inclination of the structure forward, cross bars can be mounted on the skids behind the back. If necessary, the weight on the slats can be increased by installing decorative elements.

Balanced Rocking Chair

When tilting back, the same counterweight must be equipped in front of the rocking chair. It can be an additional shelf for legs. If this weight is not enough, then you can equip a niche under the shelf for an additional counterweight.

Treatment

The finished structure will be used in different places at different temperatures. Operation in winter and summer, under the sun and in the cold, indoors and outdoors can lead to rapid aging of the tree and various diseases. This will save the processing of the material.

Before assembling the structure, the tree can be stained. Due to its concentration, the rocking chair can take on any shade.

Armchair varnished in 3 layers

To prevent diseases, the tree must be covered with a special antifungal liquid, as well as an agent against wood insects and pests.

To protect the wood from getting wet, it is recommended to treat it with a special water-repellent liquid.

Users often search:

At the end, the entire structure must be covered with two layers of varnish.

Conclusion

The presented version of the manufacture of a rocking chair is the simplest and fastest. If you follow the rules and technology of work, you can make a chair of any complexity and design.

The finished chair will serve not only as a piece of furniture, but also as a separate design element that will always attract everyone's attention.

A do-it-yourself rocking chair made by many craftsmen will cost less than a store product. Self-made furniture will be better and more environmentally friendly, you can think over your design and design concept. The rocking chair will be a good addition to the interior design of the room, a device that will calm you down, give you the mood to work, and relax. Such a product will become indispensable when rocking a child. For the baby himself, such a chair is a real swing.

If a person is not related to carpentry, then a natural question arises: how to make a rocking chair with your own hands? Initially, it is worth deciding on the type of rocking chair, there are several of them. There are types according to the design features:

- Rocking chair, which has radius skids. This model is classic and most popular. It has a low landing, as it is very difficult to keep balance when swinging on rounded "radii".

- Armchair with runners of variable curvature. In this case, the "radii" do not represent part of the roundness, which means that the wobble can have a large amplitude. In this case, the use will be safer and more comfortable.

- Armchair nirvana. There are two subtypes: elliptical and spring. The former is considered unsafe, as tipping over often occurs, but the swing is soft and smooth. Spring models are more adapted to widespread use, but making a rocking chair with your own hands for such an upgrade requires skills and experience.

- Rocking chairs 3 in 1. All three modes are presented here: chair, rocking chair, sunbed. Depending on the degree of reclining on the back of the structure, the position of the body is determined. Multifunctional furniture, but oversized.

The presented design options can be made from almost any material: wood, metal, wicker, rattan. The seat can be hard, soft or a combination. Materials can be combined, and in some models even necessary. Thanks to the photo on the Internet, you can choose your favorite model of the product.

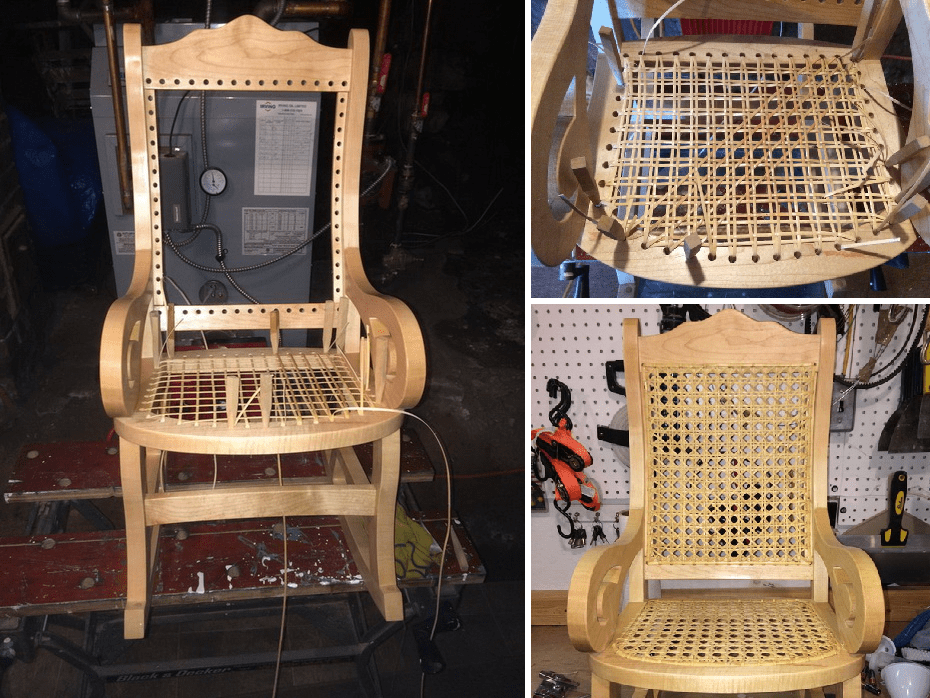

braided pattern

It is quite difficult to make furniture from a wicker or rattan with your own hands. Rattan is an expensive material, but a product made from it has a long service life, and the body is more resistant to mechanical stress. The same cannot be said about the vine, but it is more accessible and malleable in work.

To create original wicker furniture, you can view the master class. Such instructions will be quite enough to implement the project. First, the material is prepared:

1. Rattan cannot be assembled on your own - it is a tough liana that grows in certain areas of America. The vine is harvested independently: the branches are harvested throughout the year. Length and thickness may vary. When the vine is harvested, it is placed vertically outside to dry.

2. Processing of rods consists in stripping. The branches are placed in a bath of warm water, where the material should spend about 12 hours. The branches will become elastic. When each twig begins to bend well, then you can remove the bark from them.

3. To continue working, you need to give each element the appropriate form. Thick branches are fixed in clamps in the appropriate position, and thin branches are divided into several parts, which are called taverns, with the help of a splitter.

4. Each shank must be passed through a press so that they become flat and fit for weaving.

5. The prepared vine is placed in a dryer for three days, where the shape of each element of the future product is fixed. Only from such a vine can a rocking chair be made.

The next step will be the production itself:

1. First, a frame is made from thick branches or wooden planks. The sizes are determined independently. All parts are fixed with nails or wire. The item is placed in the dryer for several days.

Frame is being made

Frame is being made 2. The braid consists in pasting the back and seat with tatters. Furniture glue is applied to the body, which will serve as an additional connection. The taverns themselves braid the bars of the crate in a checkerboard pattern.

Weave the back and seat

Weave the back and seat 3. When the body is ready, the skids are attached and the product is tested. The chair needs to be slightly rocked, if this process proceeds easily, and it does not tip over during swinging, then the center of gravity is determined correctly.

4. The last step is to open the vines with furniture varnish.

The made rocking chair can be used in the country house, veranda, balcony, garden, hallway. In addition to positive feelings during the use of this piece of furniture, this element will become a wonderful authentic design.

On video: making a fully wicker rocking chair

Wooden rocking chair

Making a rocking chair with your own hands from wood is quite simple, the main thing is to make the appropriate preparation. If such work is done for the first time, then a master class will help in this. . First, prepare the tools:

- wood saws, jigsaw;

- grinder or sandpaper;

- screwdriver;

- set of drills;

- measuring tape;

- a hammer;

- putty knife;

- level;

- construction angle;

- brushes, pencil.

Material preparation is also important. The wooden rocking chair is made partly from plywood. The remaining wooden parts are best selected from an elastic material. It's great if it's flannel.

After collecting the tools and material, you can get to work. Initially, a drawing of a rocking chair is made, performed in accordance with the parameters of the future product. The diagram is an exact copy, but on a reduced scale:

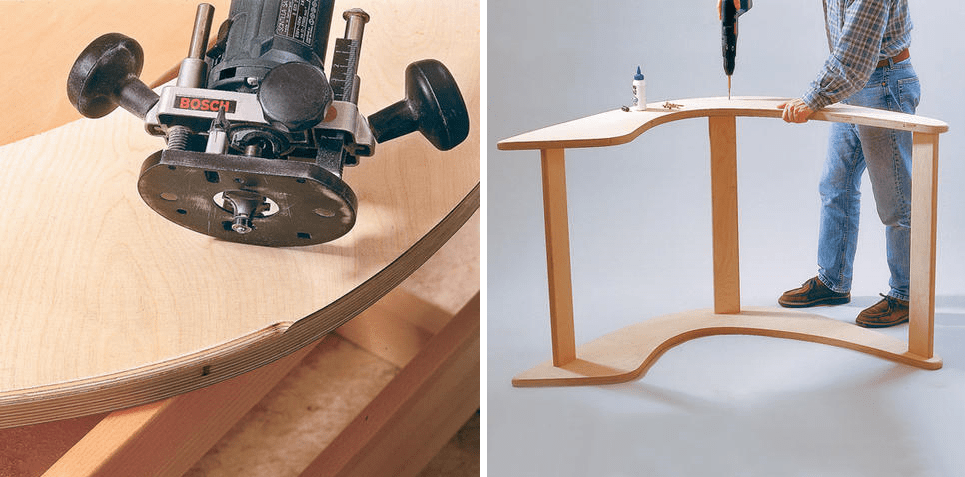

1. From plywood with your own hands, you need to cut out the side elements, which are semicircular bases with grooves for flannels. A jigsaw, wood saws and a grinder will come in handy here.

Making sidewalls

Making sidewalls 2. Flannels are being prepared, you can make them from plywood with your own hands, but on condition that the plywood is at least 30 millimeters thick and flexible in nature.

We make flannels

We make flannels 3. The plywood side parts are interconnected using 30x50x600 mm bars. Crossbars (flanels) are attached to the frame from above with a screwdriver at a distance of 2-3 cm from each other.

Assembling the structure

Assembling the structure 4. We attach flannels to the frame, for this we use a screwdriver.

We fasten the flannels to the frame

We fasten the flannels to the frame 5. A plywood rocking chair is waiting for finishing. Places where there is an attachment of flannels to the sidewalls are covered with putty. When the putty dries, you can varnish the product on wood.

Finishing

Finishing A plywood rocking chair can be additionally equipped with other elements. For example, you can make the seat soft. To do this, a foam base is laid on a wooden base, on top of which a fabric is laid.

On video: how to make a rocking chair out of wood.

Metal armchair

There is another class of product - these are metal rocking chairs. Not every master will be able to make such a design, since this requires more serious equipment and skill. Although, it is worth trying to make a rocking chair out of metal with your own hands. This can be done by focusing on the pictures, or by viewing the master class.

For work we need the following components:

- steel bars;

- galvanization;

- steel corners;

- apparatus for welding;

- drill with special drills;

- Bulgarian.

Often, arcs for skids are made from a profile pipe, and corners are cut out of the profile itself, which will serve as fasteners. From a profiled metal sheet, you can make all the necessary elements to create such a design:

1. First, drawings are made according to product design. To do this, you can take a finished chair and transfer this sketch, but besides this, think about how to attach the rounded skids.

2. Steel bars are cut to a length of 1 meter. After that, the frame is welded, to which the rods will be welded. The distance between them is about 1 centimeter. The metal is twisted into an oval.

3. After that, the master must attach the seat to the oval base. The seat itself is made of galvanized steel. Fastening is carried out using bolts, and the holes for them are made using a drill.

4. The final step will be painting and sanding sharp parts.

If we compare the operating conditions of wicker, metal and wooden furniture, then the most versatile option is wicker. It does not damage the floor surface, is easy to move, can be used in any room and on the street.

You can decorate such an element of furniture with textiles, in particular decorative pillows, quilted bedspreads, warm blankets. Thus, a note of comfort and coziness is introduced into the overall idea.

Reading time ≈ 10 minutes

Comfortable furniture is one of the important components of home interior. Everyone associates a rocking chair with comfort, because it is so nice to sit by the fireplace with a cup of tea and relax in it. This piece of furniture is able to fit into any style, as well as serve as an independent decor. You can make a rocking chair with your own hands from wood, for this we will consider photo examples with drawings and the progress of work.

Design feature

On the chair, you can swing anywhere, calming your nerves and relieving stress. This is one of the simplest and most affordable means for relaxation. You can buy it in furniture stores, order it on the website or make it yourself in your home workshop.

Why is the rocking chair so popular:

At the same time, you can put an armchair everywhere: in the bedroom, in the home office, and on the terrace of the country house, and even in the office. How to make a rocking chair with your own hands from wood according to photos and drawings, a video with the progress of work and detailed instructions will tell.

The wooden structure has its advantages:

The main part of the rocking chair is skis or arched skids, due to which rhythmic rocking occurs. If the runners are made long, the amplitude and depth of the swing will be large, it is possible to smoothly move from a sitting position to a recumbent one. And if you assemble with short skids, the swings will be slight, soft and smooth. These chairs are more suitable for older people.

Wooden chair on skids

Types of armchairs

Today you can find a huge number of models of wooden rocking chairs of various shapes, sizes, breeds, styles and purposes.

Rocking chairs are:

To make a do-it-yourself rocking chair from plywood, you will need drawings and instructions from experienced craftsmen, as in the video below.

According to the type of chair design are:

How swinging happens

Many people assemble rocking chairs according to ready-made drawings, however, products may not always fit a particular person in size. Therefore, before starting manufacturing, you should understand the kinematics of this product:

- If a person is standing straight, the center of gravity (CG) of the body is between the lower back and the sacrum inside the spinal column. If a person is in a sitting position, the CG shifts slightly forward and down. In rocking products, the general CG is always shifted back and down to its original position. In this case, there is a small error in the projection of the main center of gravity in relation to the supporting surface (floor, ground, etc.), which can be corrected at the end when balancing.

- Most of all, the stability of the structure is affected by the displacement of the common CG with respect to the vertical central axis (CO). If the CO coincides with the CO, this is a state of free balance, which cannot be achieved in a rocking chair. If the CG is larger than the CG, the probability of tipping back is high. It is necessary that the central heating is 450 mm or more higher than the central heating (recommended excess is 600-700 mm).

In other words, the general center of gravity of the rocking chair should be shifted from the seat to an angle intermediate between the back and the seat. Support legs - two arcuate strips, thanks to which smooth rocking is possible. The amplitude in this case depends on the length of the runners.

How to choose material and design

Modern models of rocking chairs are made from various materials, each of which has its own characteristics:

To make a rocking chair from solid wood, it is best to use conifers: larch, pine, alder or spruce. The density and weight of such wood are small, which is very convenient when working with the material.

Masters Tips:

Assembly steps

Modern furniture manufacturers are ready to offer a huge range of models of various shapes, colors, styles and materials. However, if there is time and desire for self-assembly of a home rocking chair, you need to safely purchase all the necessary materials and get to work.

The simplest model

Tools and materials:

- Screwdriver or drill.

- Roulette for measurements.

- Self-tapping screws.

- Special wood glue.

- Electric jigsaw.

- Thick cardboard for patterns.

- Sandpaper for grinding.

- Plywood sheet.

Step-by-step instruction:

How to make a rocking chair with your own hands is shown in the video master class with detailed step-by-step instructions.

Rocking chair with curved skis

For assembly you will need:

- Roulette for measurements.

- Simple pencil.

- Graph paper.

- Screwdriver.

- Electric jigsaw for woodworking.

- Sander.

- Metal confirmers.

- Wood cutting board for skis 300/20/4 centimeters.

- Board for the frame 300/10/2 cm.

Country chair with curved skis

Step by step assembly instructions:

In most cases, additional balancing of the product will be required so that the chair does not cause inconvenience when swinging, landing and getting up.

How to balance a rocking structure:

A rocking chair will always remain a desirable piece of furniture, because it is so nice to sit in it and forget about all the problems. It is not at all necessary to spend a lot of money on a purchase, such a product can be made independently. Ready-made instructions and drawings will help with this.

The rocking chair in most people is associated with home comfort, rest, relaxation. Sitting in it, it's nice to have a cup of coffee, read a book or dream by the fireplace, covered with a blanket, on a long winter evening. Measured swaying soothes, relaxes, gives peace. No wonder everyone loves to swing so much even on ordinary chairs, often breaking them. But it is not always possible to purchase rocking chairs - they are not cheap. In this case, you can make a thing with your own hands.

Types of rocking chairs

There are many types of rocking chairs. They differ in design, scope, material of manufacture and upholstery, design.

Design variation

Rocking chairs according to the type of structure can be divided into the following types.

- On simple radius skids - skis, rocker arms, arcs. Such chairs were the first to appear and are still used today. They are easy to manufacture, but have the disadvantage of tipping over with strong rocking. In this regard, they are made with a low fit for a greater excess of the center of the generatrix of the circle over the center of gravity. There are also varieties with a closing horizontal arc. This model requires the construction of individual drawings, taking into account the height and weight of the person for whom it is intended.

- On skids of variable curvature. They have no risk of tipping over. Due to their length, when tilted back, they do not allow the chair to fall, and when tilted forward, they simply push the person out of the seat. When making this model, it is better to use a ready-made drawing, since the process of building it is quite complicated.

- On elliptical skids. They roll very softly. They are often equipped with bumpers at the back, a footboard at the front, or springs. At home, a model on springs cannot be made, for this you need special types of wood or a rubberized metal strip.

- Glider is a sliding rocking chair. Unlike previous designs, its base remains motionless. It swings due to the installed pendulum mechanism. This piece of furniture is a difficult option for a novice master.

- Vanka-vstanka - a garden roly-poly chair. Does not lose stability in any position. This is due to the fact that the seat is also a skid. If you lean back strongly, the chair will move to an almost horizontal position, but will not roll over, and with a little effort will return to its original position. It is not easy to build a drawing of such a chair, but you can use the finished one.

Options for rocking chairs depending on the structure - photo gallery

The classic rocking chair has the main drawback - the risk of tipping over with strong rocking.  Elliptical arms provide a smooth swing

Elliptical arms provide a smooth swing  On skids of variable curvature, the risk of tipping over is excluded

On skids of variable curvature, the risk of tipping over is excluded  The glider chair will not leave scuff marks on the floor in your home

The glider chair will not leave scuff marks on the floor in your home  The rocking chair does not lose stability in any position, and on the side it resembles a recumbent person

The rocking chair does not lose stability in any position, and on the side it resembles a recumbent person

Glider - the perfect chair for new mothers - video

Variety of materials

In the manufacture of rocking chairs, the following materials can be used.

- Wood. Conifers, oak and larch are suitable for this. The master will need experience in woodworking, knowledge of how to connect parts.

- Plywood. The best option for a novice craftsman would be plywood. Working with it will require a minimum of skills and tools, all the details can be cut with electric jigsaws.

- Vine and rattan. Without the skills to work with these materials, it is better not to take on the job. You will need skills in the field of proper harvesting, drying and processing of vines, as well as weaving skills. In addition, it is worth considering that the rattan palm does not grow in Russia, its homeland is Indonesia and the Philippines.

- Metal. Products from it are durable, strong, but have a lot of weight. To work with this material, special welding or forging skills are required, as well as pipe bending equipment if the chair is made from pipes. As a rule, the frame is made of metal, and the seat is made of wood. Such a chair in an apartment can damage the floor, and it looks more appropriate in a country house or a country house.

- profile pipes. Suitable for making elliptical arches. This material, like any metal, also requires welding skills.

- Plastic pipes. Lightweight, durable and easy to work with. All you need is fittings and a blowtorch. Moreover, the cost of such a product is low.

Types of materials for the manufacture of rocking chairs - gallery

Plywood is suitable for making a chair by a novice craftsman

Plywood is suitable for making a chair by a novice craftsman  The rattan palm does not grow in our country, its homeland is Indonesia and the Philippines

The rattan palm does not grow in our country, its homeland is Indonesia and the Philippines  Working with metal requires skills in welding or forging.

Working with metal requires skills in welding or forging.  Polypropylene pipes are light, durable, easy to work with

Polypropylene pipes are light, durable, easy to work with  Softwood, oak and larch are the most popular materials for making rocking chairs

Softwood, oak and larch are the most popular materials for making rocking chairs  For the manufacture of products from the vine, you will need special skills

For the manufacture of products from the vine, you will need special skills

Applications

Depending on the place of use, rocking chairs are divided into items for home or outdoor use. If you plan to use the product outdoors (dacha, garden plot), keep in mind that the material will be affected by sunlight, precipitation, air temperature.

The metal is not afraid of moisture changes. It only needs to be treated with an anti-corrosion compound. Due to the large weight, it is better to put such a chair on a stone base. It will push through loose earth or a wooden podium. The best option for the street is a metal product with a wooden seat or with removable cushions.

Chairs made of wood must be treated with a waterproof coating. This must be done especially carefully if the product is made of plywood. Before assembly, hot drying oil is applied to the ends of the parts, and then they are slightly flattened with a hammer so that moisture does not penetrate inside. After this procedure, the elements are coated twice with waterproof varnish.

Wooden rocking chairs should not be kept outdoors all the time. Otherwise, the product may lose its original appearance.

The most successful street option are plastic chairs. They do not rot, are not afraid of the sun and wind, do not require a protective coating. Such products are durable and lightweight, they can be moved to any place if necessary.

You should not use chairs with soft upholstery on the street, it is better to cover them with a blanket or put removable pillows. The upholstery will get wet in the rain and deteriorate.

"Street" seating options - gallery

An armchair made of plywood and wooden planks is the easiest option for a novice master

An armchair made of plywood and wooden planks is the easiest option for a novice master  A chair made of plywood with a roof will save you from sunburn

A chair made of plywood with a roof will save you from sunburn  The rocking chair can accommodate several people at once

The rocking chair can accommodate several people at once  Plastic pipes are quite inexpensive material, even a beginner can make a rocking chair out of it.

Plastic pipes are quite inexpensive material, even a beginner can make a rocking chair out of it.

How to make a rocking chair with your own hands

Do-it-yourself things carry a completely different energy than purchased ones. With their manufacture, you can realize any of your wishes. It is not difficult to make a rocking chair, even a beginner can cope with this task. You need to be patient and follow the step-by-step instructions exactly.

Types of handmade chairs from various materials - gallery

From plywood, you can cut a chair of absolutely any shape.

From plywood, you can cut a chair of absolutely any shape.  The presence of a footrest creates a greater relaxing effect.

The presence of a footrest creates a greater relaxing effect.  Armchair covered with threads will surprise your guests

Armchair covered with threads will surprise your guests  Upholstered wooden armchair to help you relax after a hard day's work

Upholstered wooden armchair to help you relax after a hard day's work  An armchair made of natural materials is suitable for an eco-style interior.

An armchair made of natural materials is suitable for an eco-style interior.  Such an original rocking chair will decorate your country house

Such an original rocking chair will decorate your country house  Pipes can serve as the basis for a future chair

Pipes can serve as the basis for a future chair  Forged rocking chair will organically look at your summer cottage

Forged rocking chair will organically look at your summer cottage  Knitted elements in interior items create a homely atmosphere

Knitted elements in interior items create a homely atmosphere  A pipe and a tree will always be found on the farm. From this material you can easily make a country rocking chair

A pipe and a tree will always be found on the farm. From this material you can easily make a country rocking chair

We turn the most ordinary chair into a rocking chair

The easiest option to get a rocking chair quickly and at no cost is to make it from an old but sturdy chair or armchair. You only need to make a couple of skids. For structural stability and to prevent tipping, the center of gravity must be shifted down. To do this, the legs need to be filed under the arcs, on which a chair or armchair will be attached in the future.

How to make skids from an array - video

Instructions for making a vanka-vstanka

To make this chair yourself, it is better to use plywood. A drawing can be built by making calculations with your own hands, or you can use a ready-made scheme.

We prepare tools and materials

Before starting work, it is necessary to prepare materials and tools. You may need:

- electric jigsaw with wood files;

- disc grinder with a set of nozzles of various grain sizes;

- screwdriver or drill;

- a hammer;

- brush;

- plywood sheet 20-30 mm thick;

- bar 50x25 mm for cladding;

- 3 connecting bars 30x50 mm;

- self-tapping screws or confirmants;

- wood glue;

- antiseptic for wood;

- primer or drying oil;

- dye;

- roulette;

- pencil;

- graph paper.

Now you have everything you need. Before proceeding to the next step, treat the plywood sheet with an antiseptic. While you are working on the drawing, it will dry out.

We draw a diagram

The design of the vanka-vstanka does not require taking into account the individual parameters of future users. If you wish, you can amend the finished scheme. For example, if necessary, such a chair can be made double. Thus, we will assume that you have a drawing.

We transfer it to graph paper, and then to thick paper in the full size of the details. We cut out the patterns and draw the sidewalls. We will make them from plywood, fasteners - from bars, sheathing - from rails.

Both sidewalls must be exactly the same, there must be no bulges and bumps on the rocking surface, the line must be smooth!

We make parts

With an electric jigsaw, he cuts sidewalls from plywood, from bars - connecting drawers. The best connection of chair parts is spiked. If it is provided for by the drawing, we make spikes and cuts for them in the sidewalls. We cut the facing plank from the rails. To keep as few scraps as possible, when choosing a rail, observe the multiplicity of their sizes to the finished bar. If there is a remainder, save them, they will be useful to you when the product needs to be repaired.

All parts are sanded, sanded, and then chamfered. We carefully process the ends. We slightly break their fibers with a hammer so that moisture does not penetrate into them. All elements must be primed and painted, the ends - twice.

Chair assembly

We connect the sidewalls with bar-bars. If you have a spiked connection, then insert the spikes into the cuts under them, having previously smeared them with wood glue. If not, then we mark the joints on the sidewalls, make holes with an 8 mm drill, and 5 mm at the ends of the bars. We tighten with the help of confirmants - euro screws.

Now it remains only to attach the facing strips. In order for them to lie flat, they must first be marked. Each board should have 4 marks, that is, 2 on each side. To facilitate the work, you can make a template from trimming the rail by drilling 2 holes in it, then the work will go much faster.

To prevent the strips from cracking during fastening, drill holes along the marks with a thin drill and screw them to the sidewall with self-tapping screws. The distance between the rails should be 15 mm.

Cover the product with primer and paint. The rocking chair is ready, you can enjoy it.

Video on making a plywood rocking chair

Making a rocking sofa

Using the basics of making a roly-poly chair, you can make a rocking chair. In this case, you will need three sidewalls.

This light and comfortable chair is suitable for both home and garden. The seat and back can be braided with leather strips, colored cord, or simply stretched with a durable fabric.

Photo of manufacturing a chair on radius arcs

Make a drawing first

Make a drawing first  Prepare all the details of the future chair, outline the attachment points for the elements

Prepare all the details of the future chair, outline the attachment points for the elements  Assemble the chair according to the diagram

Assemble the chair according to the diagram

Making a chair out of wood

Wood is a more complex material than plywood. There are several options for drawings of wooden rocking chairs.

The product can be without armrests and have a back that repeats the curves of the back.

If you do not have sufficient skills in working with wood, you can make a chair, the elements of which are straight lines. The only exceptions are arcs.

The order of work in the manufacture of such a chair is the same as that of a plywood model.

- We make drawings and patterns.

- We cut out the material. A board 3000x200x40 mm will go to the runners, 3000x100x20 mm to the rest of the parts.

- Sanding and sanding.

- We process with a primer and paint all the elements.

- We outline the connection points of the parts, drill holes for the bolts.

- We make assembly.

- We put a soft pillow and swing.

How to make a wooden rocking chair for a child - video

We use the pendulum mechanism in the manufacture of the glider

To make such a chair, you need to have good drawings. Although, there are craftsmen who build them on their own, taking measurements from factory products. The pendulum mechanism is assembled on ball bearings. This applies to both metal and wooden structures. The seat should not be attached to the base, but suspended from it. This allows the chair to swing in a horizontal plane.

How to make a metal pendulum chair - video

We make a wicker chair from a vine

Wicker products are very popular. If you know how to weave from a vine, you can make such a chair at home. However, the process of its manufacture is quite long, it requires patience and effort.

It should be noted that the wicker chair should be comfortable and durable. Its flexibility is achieved due to the vine, which is also an environmentally friendly material.

We use plastic pipes to simulate the sound of the sea - video

We make a chair out of metal "under the wicker"

If you know how to forge products, then it will not be difficult for you to make a rocking chair out of metal. It can also be made by welding from a profile pipe, preferably an elliptical section. The seat, backrest and braiding of the armrests can be made from ropes, belts or strips of fabric.

A simple metal chair for a summer cottage - video

If one person managed to create some thing, then another will certainly be able to repeat it. All you need is a desire and strict adherence to the instructions. And it doesn't matter what your chair is made of. If the soul is invested in the work, the result will bring joy.

Everyone associates a rocking chair with comfort and coziness, and you immediately want to sit in it by the fireplace in a country house with a cup of hot coffee. This is a very beautiful and original interior element that fits into almost any style. In addition, swinging on a chair is good for health. So you can relax, relieve stress, gain strength, calmly read your favorite book, listen to music or just take a nap. You can make a rocking chair with your own hands from wood, consider examples with photos, drawings and the progress of work using several technologies.

Features of wood structures

Most often, furniture is made of wood, so the rocking chair is no exception. Why do many people choose this particular material:

What makes this chair attractive?

How to make a rocking chair with your own hands from wood according to the drawings is shown in the video with instructions and work progress.

Types of armchairs

There are many different models of chairs, all of them can differ in their functionality, dimensions, style, materials and the presence of additional gadgets. We always choose furniture based on our preferences and habits, and the rocking chair is no exception.

Consider several options for the design of rocking chairs:

Work technology

To figure out how to make a rocking chair with your own hands from wood according to the drawings and the right dimensions, you need to purchase all the necessary materials and tools:

- Screwdriver.

- Paint brush for filling fastener holes.

- A hammer.

- Straight corner with a ruler.

- Disc grinding machine.

- Self-tapping screws.

- Electric jigsaw for cutting blanks.

- Clamp.

1 way

To create a rocking chair, you can use an ordinary chair by shortening its legs and attaching this structure to the skids. To make the appearance attractive, the chair can be braided with leather or plastic ribbons. If desired, you can also sew a rocking chair cover yourself.

To make the structure more interesting in shape, sidewalls can be cut out of plywood according to a pre-calculated pattern. The edges of the plywood should be well finished.

plywood edges

plywood edges

Then we connect the two resulting parts to each other using three bars (30 * 50 * 600 mm).

To lay out the upper part, we use thin boards and plywood planks (10 * 50 * 600 mm).

In some cases, the length can be increased so that the slats protrude beyond the edges of the sidewalls. After assembling the chair, it can be varnished or painted.

2 way

We begin the process of creating a rocking chair with a drawing. For a quality result, a sketch is required. In addition, we can save ourselves from strong errors in the calculation of the amount of material.

Work technique:

3 way

We will assemble a rocking chair according to the drawing, using high-quality types of wood. As a basis, we use an ordinary wooden chair. All parts will be mounted at right angles, so you do not need to cut out many additional elements.

Now you can create a rocking chair yourself and please your household. The main thing to remember is that the product can be scratched, and the material will quickly age and lose its appearance. Therefore, always treat the chair with varnish so that it pleases you with its beauty for a long time and creates comfort in the house.