Wood is one of the main building materials worldwide. But it must be pre-treated in such a way that it can maintain its state for a long period of time.

Particular care must be taken to protect wooden supports, fence posts, in order to effectively avoid the onslaught of bacteria, fungi and insects that feed on cellulose. In addition, the effect of moisture on wood is very harmful, and can compromise its strength and reliability.

Which pillars require antiseptic and impregnation?

Wooden poles - can be used in a number of industries, in electrical, distribution, telecommunications, household.

Wood has high performance in terms of handling workloads. As a result, the number of wooden supports is required less than concrete ones, for example.

Wooden poles, due to their light weight, are easier to install into the ground without a special foundation or grounding, no specialized fixtures or accessories are needed.

In the photo: excellent and the best impregnation for wooden poles - logs and timber. Wooden supports of log cabins, wooden houses made of rounded logs and various wooden fence posts with the use of Neomid 430 eco impregnation acquire exceptional anti-rotten properties and better protection against destruction from all types of biological pests of wood! Leading experts in the field of wood protection recommend buying this product for impregnating and processing pillars with it!

The service life of wooden poles impregnated with the protective compound Neomid 430 eco from rotting and other biological influences is longer than that of steel or concrete poles, and can last 30-60 years.

Which pole protection technology is considered the best?

To avoid many devastating problems, industrial pressure impregnation treatment of poles is the best choice for all kinds of building projects. The degree of protection provided by the preservative Neomid 430 eco depends on how much of the chemical agent the tree has absorbed. During impregnation under pressure, the protective composition penetrates deep into the structure of the wood.

But the wood from which the poles or supports for the fence are made can also be processed manually by applying the product in 2-3 layers with a synthetic roller or brush, as well as by immersion.

Photo: Neomid 430 eco in a 5 liter concentrate package. From this amount, 50 liters of the strongest antiseptic for impregnating wooden poles will be obtained.

Environmentally friendly product Neomid 430 eco, approved by the Ministry of Environmental Protection, using the unique technique of Neomid, with strict compliance with European product quality standards. The class of wood treated by him is intended for use in contact with earth, water and concrete.

Enhanced protection of pillars and supports is provided by the fact that the product chemically binds to wood, strengthening its physical and chemical properties, pushing oxygen and water out of the pores, sealing them, and making it almost impossible for destructive fungi, mold or insects to penetrate.

Processing and drying of wooden supports and fence posts should be carried out in dry weather, at temperatures above 10 degrees or in a ventilated room. Surfaces must be free of paint, grease, dirt, and rot. If necessary, the posts should be treated with NEOMID 500. It dries completely in two days.

Photo: impregnation of wooden poles and a wooden fence with an indelible antiseptic Procept Ultra will help you avoid infection of a wooden structure with pest fungi. We recommend that the processing of pillars buried in the ground be carried out with this tool at least three times with an interval of 2-3 hours. Such repeated impregnation will help the wooden pole to be reliably preserved from the penetration of pests into the wood structure of the pole. The fence itself from the boards is best processed at least 2 times. This will also create conditions for reliable preservation of the fence boards.

Photo: we have repeatedly carried out real experiments on the conservation of old lumber, logs and timber from the effects of various biological pests. Real experiments have shown good performance in terms of the safety of wooden products and structures in adverse environmental conditions.

The procedure for applying impregnation

Before work, Neomid 430 eco should be diluted in the required proportions - as it is a concentrate. When working, use personal protective equipment.

Photo: it is best to process the wooden surface of the pillars and the wooden fence itself with an ordinary high-quality paint brush.

Watch a thematic video about Neomid 430 impregnation

Watch a thematic video about Procept Ultra impregnation

Where to buy in Moscow and the Moscow region?

Photo: high-quality and powerful impregnations for wooden structures Neomid 430 eco and Neomid 440 eco.

Photo: these effective impregnations (Procept Ultra and Neomid 430) are best suited for treating poles before burying the ends of the poles in the ground.

You can buy this effective protective agent for impregnating wooden poles in our company from a warehouse in Moscow. Our partners are clients of the cities of Balashikha, Reutov, Zheleznodorozhny, Schelkovo, Noginsk.

At the same time, we draw your attention to the availability of the best sealant for a wooden house and other wooden structures in our warehouse. Its price does not bite at all, unlike its American counterparts.

Wood has long been considered one of the main building materials. Wood was used both for building houses and for the construction of the surrounding infrastructure (fences, sheds, poles, etc.). But how to treat a wooden fence if it is so endangered by the environment?

With the development of technology, new building materials have appeared that have pushed the position of wooden structures in housing construction. But wood is still on the list of the most popular building materials in the private sector. This is especially true for the construction of various fences and fences.

Wooden fences are quite popular due to various objective and subjective reasons. The advantages of such structures include:

- Availability and cheapness. Today there is no problem to buy ready-made processed material for the fence, unedged board or untreated wood. The cost of wood is less than metal or stone.

- Environmental friendliness and naturalness. Wood is a natural material that will organically fit into any exterior of a country estate or cottage.

- Ease of processing. The impregnated wood is easily amenable to external processing, which makes it possible to make the most intricate designs from it.

- Ease of installation. To build a wooden fence, you do not need to have special building skills. It is enough to be able to use standard tools: a hacksaw, a hammer, etc.

The only significant drawback of a wooden fence is its susceptibility to an external aggressive environment (moisture, temperature changes, harmful insects).

That is why the question always arises of how to process the fence so that it retains its beautiful appearance for a long time and lasts as long as possible? It's actually not that hard to do. The main thing is to follow certain recommendations when processing wooden poles from decay.

Wood preparation

The future strength and reliability of your wooden fence should be laid already at the stage of wood preparation. Many believe that for protection it will be enough to process a wooden fence after construction. But preliminary preparation will make it possible to lay a certain margin of safety and facilitate the search for an answer to the question of how to protect your hedge from the influence of external factors.

Following simple tips will allow you to prepare and process the tree correctly and protect the wood from rotting and other adverse factors in the future:

- Logs need to be debarked to protect against the bark beetle. The same applies to unedged boards. After that, the tree needs to be allowed to dry a little.

- Then a beam of rectangular or square shape is cut out of the log. It will become the starting material for fence boards and poles. Many people use round logs as pillars.

- Next, you need to plan the beam (for poles) and boards for the fence span. This will help "clog" the pores of the wood.

- It will be useful to impregnate all the wood with iron (copper) vitriol. Proved its effectiveness and folk way - impregnation with hot "development". Such processing just before installation makes it possible to process the entire wood as a whole.

- Also, a part of the column, which will be placed in the ground, is additionally treated with melted tar.

Often people mistakenly lower the pole butt down. This is categorically wrong, since such an arrangement allows moisture to spread faster through the wood capillaries. The column must be placed butt up.

Simple preparatory procedures will allow you to get a really reliable fence in the future, protecting the tree from rotting.

How to process a wooden fence?

Due to its composition and structure, wood is particularly susceptible to external damage from three sources: fire, insect pests and damp environments.

Fire protection for a wooden fence is not as relevant as for permanent buildings. Nevertheless, many are trying to protect the fence from a possible fire entirely, or at least process those areas that are located next to the buildings.

To do this, you can treat the fence with flame retardants. But such treatment will be effective if it is done by first placing the material in baths with a solution. Applying a layer on an already installed fence will not give a special effect.

Protecting wood from insects is important at the preparatory stage. Timely removal of the bark from the surface of the tree will save you from grinders and bark beetles.

Moisture is the main enemy of a wooden fence. High humidity becomes a favorable environment for the spread of rot and mold. This is especially true for the bases of pillars dug into the ground. Outside, the fence is also exposed to rain and moist air, which causes it to rot. An additional problem is the penetration of moisture into the wood and freezing in winter, which further leads to cracking.

That is why the protection of a wooden fence from moisture in general and rotting in particular is an important element in its construction. At the same time, it is necessary to protect not only the pillars (them in the first place), but also the fence spans.

On the video: types of wood processing from decay.

Decay protection

Proper preparation and processing of a wooden fence will allow it to delight the owner’s eye with a well-groomed appearance for a long time. To do this, the tree is thoroughly impregnated. Constant contact with the soil predetermines an aggressive external environment. That is why the processing of wooden fence posts should be given special, priority attention so that there is no situation when all such a beautiful fence also beautifully falls in whole spans due to the rotten base of the pillar.

This will not happen if everything is done correctly and in a timely manner. Remember that the base of the pillars is the first to rot.

For the processing of pillars, you can use both folk remedies and special factory substances. Everyone chooses the most suitable method, the main thing is that the processing is carried out in principle, since an untreated pole will last a maximum of 2-3 seasons.

Treating wood from rotting in the ground is often done using folk methods. The following methods can be distinguished:

- Tar from birch bark or resin (pine or spruce). The base of the beam is carefully smeared to a height above ground level. One of the oldest and most proven methods, which is still used to produce copies of sailing ships.

- Waste engine oil. This method is the most accessible, easy and cheap. The oil should be well heated. It is necessary to process wooden poles for the fence in several stages. First, the first layer is applied, covering up all kinds of cracks and paying special attention to the end parts of the timber.

- Roasting on fire and processing with melted bitumen. The base of the timber is cleaned and fired over an open fire (regular fire or burner). The top "coal" layer is created. Then the burnt part is treated with melted bitumen or tar.

Experts do not advise using the method of wrapping a part of a post placed in the ground with roofing material, so beloved by many homeowners. The penetration of water into the space between the post and the roofing material will lead to a constant exposure to moisture on the surface of the tree.

Synthetic compounds for wood processing are presented on the market in huge quantities. These are various mastics, liquid and oil solutions, pastes, etc. Some of them are presented in the form of bituminous mixtures, others in the form of antiseptic solutions. Often you can find combined solutions that not only protect against moisture, but also have refractory and antifungal properties.

The above-ground part of the column also needs to be processed. Processing is carried out by analogy with the fence spans. For this, factory-made substances are usually used, which are presented on the market in large quantities.

Painting the fence as a way to protect

One of the main ways to protect the top of posts and fence bays from decay is to paint them. Most often, painting is carried out with oil paints or special varnishes. The advantage of lacquer is that it allows you to preserve the natural external texture of wood. The paint covers the fence completely.

For proper painting, it is necessary to perform certain preparatory and basic work:

- Clean the surface of foreign debris.

- Prime the fence and the top of the posts. This stage is best not to be ignored, as a good primer will allow the outer coating to last longer.

- Painting directly. It is best to carry out in two layers.

How to properly process a wooden fence? (2 videos)

Foreword. Let's consider in this material how to make waterproofing fence posts made of metal or wood with your own hands. Often wooden beams, logs, metal profiles or used tubing pipes are used for poles - all of these materials require additional processing to protect against moisture, sunlight and precipitation. Mastics, primers, paints and antiseptics are used to protect the pillars.

Wood is the most common material used for the construction of fences on the site. A beautiful wooden fence will harmoniously look between beds, around flower beds and around a country cottage. But unprotected wooden fence posts are susceptible to decay and quickly lose their original appearance due to the constant exposure to precipitation, wind and sun.

The correct technology for mounting fence posts determines the life of the entire structure. In order to correctly waterproof the fence posts, it is necessary to take into account the material of the posts, the type of soil on the site and take into account how they are installed. Taking into account all these factors, one should choose the optimal method for waterproofing underground and external fence elements installed in the ground.

Choosing waterproofing for fence posts

Bituminous mastic insulation

Mastic coating consists of bitumen, polymers and various additives. The insulating properties of technonicol mastic are high, and everyone can apply the composition to the surface, which is important. Bitumen-mastic protection lasts for 10-15 years. When the temperature drops, the mastic becomes brittle and collapses over time from small impacts of the soil during movements in the spring-autumn period.

Rubber bitumen insulation

Before applying the rubber-bitumen material, the surface of the posts is cleaned of rust and degreased. Surface treatment requires an air temperature of +15°C and above, the material is applied with a brush or roller. Rubber-bitumen insulation consists of a primer and mastic. Fence posts and basement walls protected in this way can be used over a wide temperature range.

Polymer waterproofing

Polymer insulation is used most often for gas pipelines and for waterproofing pools. Installing metal fence posts with such protection is relatively easy and can be done on your own. Among the significant disadvantages of polymer coating waterproofing is the poor resistance of this coating to mechanical damage during shear or subsidence of the soil.

Waterproofing wood fence posts

In shaded areas, in places with high humidity, fence posts and boards will quickly lose their original appearance and be affected by a fungus without proper waterproofing. Consider how to process wooden fence posts so that they serve for more than one year and retain their attractive appearance. Poles require the use of various insulating means for the outer and the part that is in the ground.

Treatment of the underground part of the pillars

There are many methods of how and how to handle fence posts with your own hands:

1

. coating the pillars with birch tar (the most proven method);

2

. processing of wooden poles by working out in several layers;

3

. treatment of fence posts with bitumen or polymer mastic.

Mineral oil is an excellent water-repellent antiseptic, acid salts in working out kill any fungus on the surface of the wood.

You can prepare the part of the log that will be buried in the ground. A wooden pole is burned on a fire to create a charred layer several millimeters deep. Next, the surface is treated with tar or bitumen in two layers. Bituminous mastic is black, so only process the part of the post that will be in the ground with the composition.

Processing of the visible part of the column

The outer part of the wooden pole also requires protection with antiseptics and paints and varnishes from the negative effects of precipitation. If it is important for you to preserve the texture of wood, then you should pay attention to coatings such as varnish, stain, Belinka or Pinotex impregnations. If this is not important, then a simple, most inexpensive oil paint, as well as various wood paints, will do.

Video. Waterproofing metal fence posts

Rate the article: (already voted 3 visitors, overall rating: 5,00 )Wooden poles in suburban areas are still very popular. If we are talking about a capital monster fence, made of a metal profile with a claim “for centuries”, which should intimidate a potential intruder with its appearance, of course it is better to use concrete or metal poles-pipes. But when it is necessary to enclose a front garden with flowers, to protect the garden from the penetration of domestic animals, and in general, only to designate a decorative fence, it is better to use cheap wooden poles. But wooden poles, unfortunately, have a very low durability, since the tree rots very quickly when in contact with constantly wet ground. Even oak and larch, which in water, without contact with atmospheric oxygen, stand for centuries, being buried in the ground will not last even two decades. But there are fairly simple ways to protect wooden poles from decay.

First of all, consider the causes of decay. Wood rots in the constant presence of moisture and oxygen. Such conditions are created at the border of earth and air, in the place where the pillar sticks out of the ground. In this place, decay occurs most intensively. Above this place, the wood is well ventilated and does not rot so intensively. Below - on the contrary, oxygen is not enough for active decay and decay there also slows down. This means that we need to take some measures to protect the tree at the point where the wooden post leaves the ground.

The second point is the typical mistakes of summer residents when using wooden poles and supports. Firstly, in most cases they bury the pole on the wrong side. Wood raises its juices along the trunk due to osmosis. Osmosis is the upward movement of fluid through the finest capillaries. And if you bury a log in the same way as it grew (with a butt below), then it will continue to draw moisture from the ground into the trunk. If you bury it upside down, the suction of moisture along the trunk will decrease significantly.

Secondly, to protect the tree, its underground part is often smeared with molten bitumen, wrapped with roofing material. In this case, a kind of "glass" is formed. Moisture, having got into it once, can no longer leave it, and the tree constantly has its own supply of moisture.

Thirdly, completely unprepared raw wood is used for temporary use, cheap, “replace at any time”. But there is nothing more permanent than temporary buildings. Over time, they are overgrown with infrastructure, they get used to them, and sometimes it’s not all of a sudden to get close to a rotten pole, let alone replace it. And the props and pegs begin to go. The fence takes on a dilapidated appearance.

Meanwhile, it is enough to carry out simple preparatory activities that will take a little time and your fence will be like new for many, many years, even with wooden posts. These rules are quite simple.

1. Initially use only healthy wood, dried, with no signs of rot. If this is not edged lumber, but a log - a pod, be sure to sand it and let it weather a little. And it’s better in general - to dry out under a canopy for a year.

2. Soak the part that is planned for deepening, plus 30-50 cm above (remember that this is the apical part, not the butt), soak with a penetrating antiseptic. Better - by immersion for a day - two. Copper or iron vitriol has proven itself perfectly. A tree impregnated with a 5-7% solution of vitriol does not rot in the ground for 15-20 years.

3. So that the impregnation does not wash out, put on some kind of cap on the upper end of the column, nail a tin cover. Moisture is very intensively absorbed into the butt of the tree. And the cover not only protects the tree from moisture, but can also serve as a decorative decoration.

4. When installing the post, dig (drill) a hole 2-3 times wider than the diameter of the post. First, throw some large gravel at the bottom of the hole. Then, having installed a post, fill the hole with large gravel as well, and not with earth. Thus, you will ensure excellent drainage of the underground part of the column and its relative ventilation. It will be even better if you first insert a "glass" without a bottom into the hole made of non-woven material such as "Agrotex", "Geotextile", etc. It will not allow the drainage to become clogged with earth.

5. Be sure to paint the column itself. This will not only improve its appearance, but also protect it from moisture. But it is recommended to paint only well-dried wood.

6. If you want to really solve the issue with the columns completely, then you can use metal sleeves - pipe trimmings. They are buried in the ground so that they rise 10-15 cm above the ground. And wooden posts are inserted into them. So you can save a lot on columns, because. wood is much cheaper than metal, and one post will only take about 1/3 of the pipe you would have to use, make the posts all metal. Yes, and the wooden posts look prettier. So that the column does not fall into the sleeve, the diameter of the latter is taken somewhat smaller than the size of the column, and the column itself is hemmed to the required size.

As you can see, the activities are not at all complicated, but they will make your wooden posts practically “eternal”.

Konstantin Timoshenko

Wood remains the most common building material that owners of country houses and cottages use to build various fences on the site. The wattle fence between the recreation area and the beds near the cottage, a beautiful wooden fence around a country house or a low wooden picket fence around flower beds in the yard will look harmonious. But unprotected wood is subject to rapid deterioration due to constant interaction with rain, wind, snow, and the sun.

In shaded areas in the yards of cottages, in places with high humidity, boards quickly lose their original appearance and become moldy or affected by fungus. How to process fence posts and the plank fence of a country house itself so that they retain their attractive appearance for more than one year? There are many ways to treat wood, although fence posts, for example, require different protections for the outside and the one that goes into the ground.

Common mistakes when installing wooden poles

Initially, it is important to understand the reasons why the support posts for the fence become unusable and how they need to be processed. This happens, first of all, under the influence of moisture, which, by impregnating the wood, creates “good” conditions for the development of all kinds of bacteria. And if the top of the pillar has time to dry out under the sun and wind, then at the point of contact with the damp earth, the process becomes irreversible. The tree begins to rot, becomes covered with mold, insect pests start up there. The processes of decay in the lower part of the column are somewhat slower, but inevitable. There is no better way to prevent this process than to treat the fence posts with antiseptics and waterproof their lower part.

The typical mistakes of summer residents when installing wooden poles include the wrong choice and installation of a log, as well as non-compliance with the rules for processing the underground part.

When choosing pillars, you should pay attention to the general condition of the wood - the absence of signs of rot, blueing, pests. The moisture content of wood should not exceed 15%. Logs must be sanded and dried before treatment with antiseptics.

It is important to determine where the log has the top and where the bottom is, since the pole must always be dug up with the butt up. This prevents "sucking" of water through the capillaries.

In no case do not wrap the treated end of the tree with roofing material, since when moisture enters such a “glass”, it remains there forever, creating conditions for decay.

The treatment of wooden poles is necessary with preparations that have antiseptic, moisture-proof and fire-retardant properties.

Compositions for processing the underground part of the pillars

There are many folk methods on how and with what to process fence posts.

Here are a few of them:

- Coating with birch tar or spruce resin (the oldest and most proven method).

- Processing with used car oil (the cheapest way). The oil is applied in several layers in a heated state, thoroughly soaking all the ends and cracks. 90% of the mining composition is mineral oil - a good water-repellent antiseptic. The acid salts contained in the mining kill any fungus in the wood.

- Roasting and processing with bitumen. That part of the log that will be buried in the ground can be burned either on a fire or with a gas burner, creating a charred layer of several millimeters. The burnt part is treated with molten tar or bitumen.

The protective layer is applied in two stages, so that each layer of bituminous impregnation can harden, it is necessary to withstand the drying period of the first layer for about a day. Bituminous impregnation is correspondingly black, so only treat the part of the wooden fence post that will be hidden in the ground with it.

It is not recommended to apply bituminous impregnation on wooden poles during fog or rain.

The construction market also offers all kinds of synthetic waterproofing compounds - mastics, pastes, etc. For example, Biom-2 or Izhora bituminous mixtures, several layers of which, in combination with a fiberglass mesh and a protective film, create excellent waterproofing with high protective properties, designed for 10-15 years of operation. Moreover, a 15-kilogram bucket of such a mixture costs only 450 rubles.

Neomid 430 eco - preservative indelible antiseptic for external use, which provides maximum protection for wood during prolonged contact with soil and moisture. Protects against damage by wood-destroying and wood-coloring mold fungi, algae, mosses, as well as wood-boring insects for up to 35 years.

Installing unfinished poles is strongly discouraged.

Step-by-step instructions for installing and protecting support poles

Step one.

We determine where the butt of the log is and mark that this will be the top of the pillar. Before proceeding with the installation of fence posts, its lower part should be treated with a penetrating antiseptic to a height of 1.5 meters. Better by immersion for two days in a 5% solution of copper or iron sulphate. You can also apply a 5% solution of potassium bichromate in 5% sulfuric acid, the remaining solution will need to soak the soil around the dug-in post. This will provide antifungal protection for 15-20 years.

Step two.

After impregnation with an antiseptic, the buried part is treated with one of the types of waterproofing (bitumen, tar, mastic, mining, etc.).

Step three.

We are in the process of installing the pole. There are several different ways, some of which provide additional protection for the pole from interacting with wet soil.

Option one (cheapest). The processed end of the column is buried in the ground and carefully rammed. After a few years, it is imperative to check its base for the appearance of fungus or rot.

Option two. Prepare a hole a little over a meter deep and twice as wide as the diameter of the column. The bottom is covered with gravel, then a “glass” without a bottom is made of geotextile or other non-woven material around the perimeter, which will protect the gravel backfill from clogging with earth. The entire space is covered not with soil, but with gravel or rubble, carefully tamped and spilled with mining.

Option three (the most expensive, since the purchase of pipes is added to the costs). Using a sleeve made of a metal or asbestos-cement pipe into which a wooden pole is inserted. Since the sleeve rises 10 centimeters above ground level, the tree will not have direct contact with the ground, and therefore will be subject to decay processes.

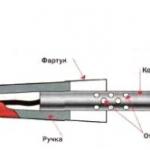

The process of installing a wooden pole into a sleeve requires care and time. So that the pillar does not fall inward, you should select a piece of pipe (100 cm) with a diameter less than the diameter of the pillar by about 10 centimeters. The log is laid on the goats and at a height of about 30-40 they make a circular cut, and then with the help of an ax remove the necessary layer. The resulting cylinder should enter the pipe freely.

First, this part of the column is impregnated with drying oil or mining, and allowed to dry for several days. Then, the tar is heated on a fire to a liquid state, the beveled end of the column is thickly coated with a hot mass with a brush, and a piece of pipe is planted. The gap between the tree and the pipe and the lower part of the post are also treated with tar. The resulting pole is buried so that the top of the pipe protrudes slightly above the ground.

Step four.

Impregnation of the visible part of the column with an antiseptic and applying the main coating (paint, varnish). To further protect the pole, experts recommend covering it with a tin cover.

Protective coatings for the visible part of the post

The upper part of the post, which is above ground level, also requires special protection with both antiseptics and protective paints and varnishes. To understand how to process fence posts, decide on the type of coverage. If it is important to preserve the texture of wood, then coatings such as Pinotex or Belinka, Biotex, AVIS timbercoat varnish have long established themselves on the market.

If it is planned to apply paint, then both a simple domestic-made oil paint based on zinc white and wood paints from the largest foreign manufacturers Tikkurila (Finland), Selena (Poland), Alpa (France), Akzo N.V. » (Netherlands), Belinka Belles (Slovenia).

Before applying a layer of paint, the tree is always primed.

The paintwork should be renewed every three to five years to keep the wood from rotting and being damaged by insects.